Академический Документы

Профессиональный Документы

Культура Документы

Supply Chain Case)

Загружено:

Dexter KhanОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Supply Chain Case)

Загружено:

Dexter KhanАвторское право:

Доступные форматы

Forecasting drives the business tasks of planning, replenishment, purchasing, and allocation.

As forecasts become more accurate, businesses run more efficiently by buying the right

inventory at the right time. This ultimately lowers inventory levels, improves safety stock

requirements, improves customer service, and increases the companys profitability.

1. In our country, challenge to creating accurate forecasts is predicting demand for items

with a limited sales history. The accuracy of time series forecasts is diminished when

short or sparse historical data is fed into the forecasting model. The Demand

Forecasting approach to this challenge is to generate forecasts at multiple levels of

data aggregation.

2. Future forecasts should be based on past demand. Unfortunately, retailers cannot

record demand, but instead record sales. These two figures can differ when inventory

drops to zero and there is demand, but no sales. To deal with this situation, there

should be a module that recognizes when sales might be lower than actual demand,

and adjusts sales values up to a level to a predicted level of where demand might have

been. Another situation when a retailer might want to adjust sales before using them

as proxies for demand in forecasting is when past sales were unusually high due to an

external event that is not expected to repeat.

3. It is a great challenge forecasting in a country like Bangladesh. Because several kinds

of uncertain reasons like political unrest, natural disasters and many other uncertain

reasons can hamper the forecasts. So the planner should forecast keeping this

condition in mind.

4. It is a great challenge to forecast demand for new products and locations for which no

sales history exists. You can model a new products demand behavior based on that

of an existing similar product for which you do have a history. Forecasts can thus be

generated for the new product based on the history and demand behavior of the

existing one. Likewise, the sales histories of existing store locations can be used as the

forecast foundation for new locations in the chain. This is crucial information.

5. In some industries an initial "order" may not be a firm order; in this case the certainty

of the order estimated subjectively or using an objective criterion will be useful

information. A particular view of order information we have found useful for

predicting demand is order quantity grouped by lead-time.

6. To enhance forecast accuracy with pricing and promotion information, a prerequisite

is a well-maintained and managed database of price and promotions corresponding to

historical demand information. This requires a disciplined process to capture the

information in a timely manner. Even more challenging is collecting and maintaining

historical data of competitors' promotions and price changes. Such information is

especially crucial in industries where products are of the commodity type.

7. In many industries, a product can be expected to have a life of at most one year. As is

customary, it can inherit older history from its predecessor product, which can in turn

inherit history from its own predecessor and so on. This means that in order to get,

say, two to three years history, we need a well-organized product map over time. At

this point in time, we have found that many organizations do not have such product

map data stored in a usable manner.

8. For ease of product management, most, if not all, organizations use a product

hierarchy. With a sizable number of products in its portfolio, organizations now have

a different product hierarchy every month. This presents at least two challenges.

First, we need to find a way to obtain the history of every node in this changing

hierarchy. For nodes representing individual products, we can use inheritance as

described. For nodes at levels higher than the individual products, we need to

"reconstruct" its history every time the hierarchy is used, based on the current children

of the node. This results in a complex data preprocessing step. Second, the historical

forecast made in the past no longer corresponds to the newly constructed history or to

the most current product hierarchy. It is not clear how we can obtain running statistics

of historical forecast errors. Subsequently, forecast monitoring becomes difficult.

9. Promotions, non-regular holidays, and other causal events create another significant

challenge to accurate forecasting. Promotions such as advertised sales and free gifts

with purchase can have a significant impact on a products sales history, as can

irregularly occurring holidays. Promote attempts to identify the causes of deviations

from the established seasonal profile, quantify these effects, and use the results to

predict future sales when conditions in the selling environment will be similar.

Recommendation:

Alert management is a feature that provides user-defined and user-maintained exception

reporting. Through the process of alert management, you define measures that are checked

daily to see if any values fall outside of an acceptable range or do not match a given value.

When this happens, an alert is generated to let you know that a measure may need to be

examined and possibly amended in a workbook.

The Alert Manager is a dialog box that is displayed automatically when you log on to the

system. This dialog provides a list of all identified instances in which a given measures

values fall outside of the defined limits. You may pick an alert from this list and have the

system automatically build a workbook containing that alerts measure. In the workbook,

you can examine the actual measure values that triggered the alert and make decisions about

what needs to be done next.

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Unit 2 Module 2 Combined-1Документ14 страницUnit 2 Module 2 Combined-1api-2930012170% (2)

- Damage To Bottom Ash Handling SysДокумент6 страницDamage To Bottom Ash Handling SyssanjeevchhabraОценок пока нет

- Promoting Services and Educating CustomersДокумент28 страницPromoting Services and Educating Customershassan mehmoodОценок пока нет

- 1000 Base - T Magnetics Modules P/N: Gst5009 LF Data Sheet: Bothhand USA Tel: 978-887-8050Документ2 страницы1000 Base - T Magnetics Modules P/N: Gst5009 LF Data Sheet: Bothhand USA Tel: 978-887-8050DennisSendoyaОценок пока нет

- Demand, Supply, and Market EquilibriumДокумент15 страницDemand, Supply, and Market EquilibriumAnonymous HBQ86kОценок пока нет

- 1Документ14 страниц1Cecille GuillermoОценок пока нет

- Unix SapДокумент4 страницыUnix SapsatyavaninaiduОценок пока нет

- Communication MethodДокумент30 страницCommunication MethodMisganaw GishenОценок пока нет

- Quality Assurance Plan-75FДокумент3 страницыQuality Assurance Plan-75Fmohamad chaudhariОценок пока нет

- YS1700 Drum Level ControlДокумент2 страницыYS1700 Drum Level ControlIdriss BarçaОценок пока нет

- GSM Based Prepaid Electricity System With Theft Detection Using Arduino For The Domestic UserДокумент13 страницGSM Based Prepaid Electricity System With Theft Detection Using Arduino For The Domestic UserSanatana RoutОценок пока нет

- EIL 6-51-0051-Rev 06 - 1.1kv-Xlpe - Dimension Cat - B Armour-BbpДокумент2 страницыEIL 6-51-0051-Rev 06 - 1.1kv-Xlpe - Dimension Cat - B Armour-BbpShubham BaderiyaОценок пока нет

- Award Presentation Speech PDFДокумент3 страницыAward Presentation Speech PDFNehal RaiОценок пока нет

- Prosocial Behaviour: Hans W. BierhoffДокумент20 страницProsocial Behaviour: Hans W. BierhoffSahil Mushaf100% (1)

- James KlotzДокумент2 страницыJames KlotzMargaret ElwellОценок пока нет

- Zimbabwe - Youth and Tourism Enhancement Project - National Tourism Masterplan - EOIДокумент1 страницаZimbabwe - Youth and Tourism Enhancement Project - National Tourism Masterplan - EOIcarlton.mamire.gtОценок пока нет

- Manual de Utilizare HUMAX DIGI TV RDSДокумент116 страницManual de Utilizare HUMAX DIGI TV RDSenamicul50Оценок пока нет

- The Abcs of Edi: A Comprehensive Guide For 3Pl Warehouses: White PaperДокумент12 страницThe Abcs of Edi: A Comprehensive Guide For 3Pl Warehouses: White PaperIgor SangulinОценок пока нет

- LNWH Alcohol GUIDELINE SUMMARY 2018Документ1 страницаLNWH Alcohol GUIDELINE SUMMARY 2018Ai Hwa LimОценок пока нет

- IPMI Intelligent Chassis Management Bus Bridge Specification v1.0Документ83 страницыIPMI Intelligent Chassis Management Bus Bridge Specification v1.0alexchuahОценок пока нет

- Tushnet - An Essay On RightsДокумент43 страницыTushnet - An Essay On RightslarisamannОценок пока нет

- Study of Employees Performance Appraisal System in Hindustan Unilever LimitedДокумент9 страницStudy of Employees Performance Appraisal System in Hindustan Unilever LimitedSimranjitОценок пока нет

- Robert Egby - DecreesДокумент9 страницRobert Egby - DecreesmuzickaueОценок пока нет

- Preboard Practice PDFДокумент25 страницPreboard Practice PDFGracielle NebresОценок пока нет

- Protected PCM USB Memory Sticks For Pa3X.Документ1 страницаProtected PCM USB Memory Sticks For Pa3X.mariuspantera100% (2)

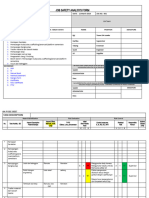

- JSA FormДокумент4 страницыJSA Formfinjho839Оценок пока нет

- D2E133AM4701 Operating Instruction UsДокумент9 страницD2E133AM4701 Operating Instruction UsMohamed AlkharashyОценок пока нет

- Jail Versus Substance Abuse TreatmentДокумент5 страницJail Versus Substance Abuse Treatmentapi-240257564Оценок пока нет

- 2015 Grade 4 English HL Test MemoДокумент5 страниц2015 Grade 4 English HL Test MemorosinaОценок пока нет

- Internship (1) FinalДокумент12 страницInternship (1) FinalManak Jain50% (2)