Академический Документы

Профессиональный Документы

Культура Документы

RENOLIT H 443-HD 88 EP High Performance Grease for Bearings Operating at High Loads and Temperatures

Загружено:

Oscar Cabrera0 оценок0% нашли этот документ полезным (0 голосов)

195 просмотров2 страницыRENOLIT H 443-HD 88 is a lithium soap based, heat-resistant, water-repellent and easily pumpable grease with very effective additives increasing the pressure absorption capacity of the lubricating film. Its green colour helps to distinguish it from other lithium soap greases (multipurpose lubricants). Minimum shelf life is 36 months if the product is properly stored between 0degC and 40degC in its unopened original container in a dry place.

Исходное описание:

Оригинальное название

Calipsol H 443-HD 88

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документRENOLIT H 443-HD 88 is a lithium soap based, heat-resistant, water-repellent and easily pumpable grease with very effective additives increasing the pressure absorption capacity of the lubricating film. Its green colour helps to distinguish it from other lithium soap greases (multipurpose lubricants). Minimum shelf life is 36 months if the product is properly stored between 0degC and 40degC in its unopened original container in a dry place.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

195 просмотров2 страницыRENOLIT H 443-HD 88 EP High Performance Grease for Bearings Operating at High Loads and Temperatures

Загружено:

Oscar CabreraRENOLIT H 443-HD 88 is a lithium soap based, heat-resistant, water-repellent and easily pumpable grease with very effective additives increasing the pressure absorption capacity of the lubricating film. Its green colour helps to distinguish it from other lithium soap greases (multipurpose lubricants). Minimum shelf life is 36 months if the product is properly stored between 0degC and 40degC in its unopened original container in a dry place.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 2

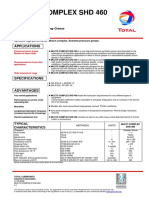

RENOLIT H 443-HD 88

EP High Performance Grease

PI 5-4665e, Page 1, PM 5, 06/09

Description

RENOLIT H 443-HD 88 is a lithium soap based,

heat-resistant, water-repellent and easily pumpable

grease with very effective additives increasing the

pressure absorption capacity of the lubricating film.

RENOLIT H 443-HD 88 contains additives to

improve corrosion protection, aging resistance and

adhesiveness. Its green colour helps to distinguish it

from other lithium soap greases (multipurpose

lubricants).

Application

RENOLIT H 443-HD 88 is used for lubricating plain

bearings and roller bearings operating under high

load, at high temperatures and in a humid

atmosphere. It is also suitable for lubricating roller

bearings operating at temperatures until +140C

under specific high strain, in particular strain

produced by shocks and vibrations e.g. in

unbalanced motors, vibrating screens, vibrators, soil

tampers and electrical machines.

RENOLIT H 443-HD 88 can be applied for

lubricating plain bearings if the grease is supplied by

Stauffer grease cups, lubricating nipples or

centralized greasing systems.

RENOLIT H 443-HD 88 features extreme

adhesiveness resulting in good suitability for high

loads produced by shocks in a wide speed range.

Advantages

Extremely adhesive

Water resistant

Good corrosion protection

Aging resistant

Highly loadable

Easily pumpable

Suitable for oscillating movements

Specifications/Approvals

RWE Rheinbraun

Flender

SKF

Shelf Life

The minimum shelf life is 36 months if the product is

properly stored between 0C and 40C in its

unopened original container in a dry place.

RENOLIT H 443-HD 88

EP High Performance Grease

PI 5-4665e, Page 2, PM 5, 06/09

Characteristics

Properties Unit Data Test method

Colour - green -

Thickener lithium-soap -

Dropping point C > 180 IP 396

Worked penetration (Pw 60) 0.1 mm 250 - 265 DIN ISO 2137

NLGI-grade - 3/2 DIN 51 818

Corrosion protection properties (Emcor-test)

standard

3% NaCl-solution

degree of corr.

0 - 0

2 - 2

DIN 51 802

Four-ball method, welding load N 2600 DIN 51 350-4

Water resistance Eval.-stage 1 90 DIN 51 807-1

Base oil viscosity at 40 C mm/s 130 DIN 51 562-1

Temperature range C -30 up to +140 -

Вам также может понравиться

- Renolit H 443-HD 88Документ2 страницыRenolit H 443-HD 88miguelfpintoОценок пока нет

- STEDESA Fisa Tehnica RENOLIT LX-PEP-2 (TDS) (GB) PDFДокумент3 страницыSTEDESA Fisa Tehnica RENOLIT LX-PEP-2 (TDS) (GB) PDFCorina StanculescuОценок пока нет

- Shell Gadus S5 T460:: Shell Stamina Grease HDSДокумент2 страницыShell Gadus S5 T460:: Shell Stamina Grease HDSPablo Soler SalazarОценок пока нет

- Molykote AerossoisДокумент6 страницMolykote AerossoisMarcos Tati CunhaОценок пока нет

- Описания RENOLIT DURAPLEX EP 2Документ3 страницыОписания RENOLIT DURAPLEX EP 2ahmed.kab.ak01011954Оценок пока нет

- Chevron Sri Grease NL Gi 2Документ2 страницыChevron Sri Grease NL Gi 2msharathsОценок пока нет

- Henan Dongsen Lubrication Technology Co., LTD: Multipurpose Calcium GreaseДокумент1 страницаHenan Dongsen Lubrication Technology Co., LTD: Multipurpose Calcium Greasesunhell1611Оценок пока нет

- Velloils High Temperature & Speciality Grease Velloplex GreaseДокумент6 страницVelloils High Temperature & Speciality Grease Velloplex GreaseBhusarapu SrinivasОценок пока нет

- Eni Grease LCX 2-220 PDFДокумент2 страницыEni Grease LCX 2-220 PDFranjanguptОценок пока нет

- Fuchs Oil SpecificationДокумент1 страницаFuchs Oil SpecificationmohammedОценок пока нет

- Mobilgrease XHP 460Документ3 страницыMobilgrease XHP 460Jaime Miloz Masle JaksicОценок пока нет

- Shell Gadus S5 T460 1 5 TDSДокумент2 страницыShell Gadus S5 T460 1 5 TDSSuresh RajanОценок пока нет

- 501 Renolit MPДокумент1 страница501 Renolit MPjafaristsОценок пока нет

- PDSDetail PageДокумент2 страницыPDSDetail PageDiego BeltraminiОценок пока нет

- High Performance Multi-Purpose GreaseДокумент2 страницыHigh Performance Multi-Purpose GreaseAhsan IjazОценок пока нет

- .Au ProductsAndServices Pages LubricantProДокумент3 страницы.Au ProductsAndServices Pages LubricantProabid azizОценок пока нет

- Alvania r3Документ2 страницыAlvania r3Senthil Kumar Ganesan75% (4)

- Bentone HD Grease: Package Sizes: 450g Cartridge Product Codes: BENHDGR00045 Issue: December 2012Документ1 страницаBentone HD Grease: Package Sizes: 450g Cartridge Product Codes: BENHDGR00045 Issue: December 2012Fikreslasie LemaОценок пока нет

- Molykote 7348Документ2 страницыMolykote 7348Luz Angela GuerreroОценок пока нет

- Alvania WR 2Документ2 страницыAlvania WR 2Kafeel AhmedОценок пока нет

- High Temp Grease for BearingsДокумент1 страницаHigh Temp Grease for BearingsranjanguptОценок пока нет

- GPCDOC GTDS Shell Gadus S5 T100 2 (En) TDSДокумент3 страницыGPCDOC GTDS Shell Gadus S5 T100 2 (En) TDSAlОценок пока нет

- Mobil - Glygoyle - 460Документ3 страницыMobil - Glygoyle - 460the anhОценок пока нет

- PDSDetail PageДокумент3 страницыPDSDetail PageOSPEN NOAH SITHOLEОценок пока нет

- SP Eng 7014 Extended Temperature Aviation GreaseДокумент2 страницыSP Eng 7014 Extended Temperature Aviation GreaseundraazolbayarОценок пока нет

- Gadus S2 U460LДокумент3 страницыGadus S2 U460LAxel Mahya AvichenaОценок пока нет

- Product Information: High-Temperature Grease For Food Processing TechnologyДокумент2 страницыProduct Information: High-Temperature Grease For Food Processing TechnologyFelipe OsorioОценок пока нет

- High Performance Lubricants Molykote: G-2001 High Speed Bearing GreaseДокумент2 страницыHigh Performance Lubricants Molykote: G-2001 High Speed Bearing GreaseRildo CarvalhoОценок пока нет

- ROCOL Maintenance BrochureДокумент48 страницROCOL Maintenance Brochurejeancon100% (1)

- TDS Sinopec HP-R Grease enДокумент2 страницыTDS Sinopec HP-R Grease ennghiaОценок пока нет

- Product Data Sheet: Optimol OptipitДокумент2 страницыProduct Data Sheet: Optimol OptipitFBОценок пока нет

- LGHP2 Datasheet eДокумент1 страницаLGHP2 Datasheet enata siagianОценок пока нет

- BECHEM High Performance Chain Oils 2015 GBДокумент7 страницBECHEM High Performance Chain Oils 2015 GBduy tanОценок пока нет

- Tds Total Multis Complex SHD 460 O8k 201412 enДокумент1 страницаTds Total Multis Complex SHD 460 O8k 201412 enM.TayyabОценок пока нет

- Tds Total Multis Complex SHD 460 O8k 201412 enДокумент1 страницаTds Total Multis Complex SHD 460 O8k 201412 enM.TayyabОценок пока нет

- Chevron SRI NLGI-2 GreaseДокумент2 страницыChevron SRI NLGI-2 Greaseisai4ZОценок пока нет

- Energrease LS-EPДокумент2 страницыEnergrease LS-EPDavid LieОценок пока нет

- Bechem Ceritol Psa 12 H PDSДокумент1 страницаBechem Ceritol Psa 12 H PDSVirender KumarОценок пока нет

- Molykote Lubrication Petro IndustriesДокумент6 страницMolykote Lubrication Petro IndustriesDicky PratamaОценок пока нет

- Plant Maintenance Lubricants 026224Документ4 страницыPlant Maintenance Lubricants 026224Koohestani Afshin100% (1)

- High Temperature-Grease-pds-EngДокумент3 страницыHigh Temperature-Grease-pds-Engdavide comuzziОценок пока нет

- Industrial PDFДокумент8 страницIndustrial PDFalireza naseriОценок пока нет

- Chevron Starplex EP-2 MSDSДокумент2 страницыChevron Starplex EP-2 MSDSCrystal RojasОценок пока нет

- Spesifikasi - Shell AlbidaДокумент2 страницыSpesifikasi - Shell AlbidanursetoОценок пока нет

- Mobilgrease XHP 222 Pds PDFДокумент3 страницыMobilgrease XHP 222 Pds PDFStefan Cel MareОценок пока нет

- Talusia-Hr-70 TDS v210316Документ2 страницыTalusia-Hr-70 TDS v210316Wassim LounissiОценок пока нет

- Molykote Brochure For Chemicals Petrochemicals IndustriesДокумент6 страницMolykote Brochure For Chemicals Petrochemicals IndustriesProject Sales CorpОценок пока нет

- Superior Wear Protection Open Gear LubricantДокумент2 страницыSuperior Wear Protection Open Gear LubricantArdi Sepdiniyoko01Оценок пока нет

- History of Rocol and Sapphire Bearing GreasesДокумент11 страницHistory of Rocol and Sapphire Bearing GreasesMehul PatelОценок пока нет

- GADUS S3 T220 2Документ2 страницыGADUS S3 T220 2danielr.hanna93Оценок пока нет

- Dux CUT SW 130Документ2 страницыDux CUT SW 130R.d. PoshiyaОценок пока нет

- SKF Food Compatible Bearing Grease LGFP 2: SKF Product Data SheetДокумент1 страницаSKF Food Compatible Bearing Grease LGFP 2: SKF Product Data SheetTan Minh Tam TruongОценок пока нет

- Ser 1Документ1 страницаSer 1rita132Оценок пока нет

- Velvex Industrial Oil - Nandan Petrochem LTDДокумент27 страницVelvex Industrial Oil - Nandan Petrochem LTDNandan Petrochem Ltd0% (1)

- Liquid Grease For Commercial Vehicles: Lithium Base Saponified High-Pressure Liquid Grease On The Basis of Synthetic OilДокумент1 страницаLiquid Grease For Commercial Vehicles: Lithium Base Saponified High-Pressure Liquid Grease On The Basis of Synthetic OilAnas EidОценок пока нет

- Sri Grease Eng NewДокумент3 страницыSri Grease Eng NewalishahsavarОценок пока нет

- Q8 Oils Plant Maintenance BrochureДокумент4 страницыQ8 Oils Plant Maintenance BrochureDannyTaitОценок пока нет

- Renolin CLPДокумент6 страницRenolin CLPjacl88Оценок пока нет

- Fuchs Usa-Sugar BrochureДокумент4 страницыFuchs Usa-Sugar BrochureOscar CabreraОценок пока нет

- BC Techguide 33334 en 0811 LoДокумент120 страницBC Techguide 33334 en 0811 LoMaize Lyn SangriaОценок пока нет

- Wastewater Pumps - Eng'g ManualДокумент87 страницWastewater Pumps - Eng'g ManualIsmael Llamelo PerezОценок пока нет

- Gantt Chart: Enter Your Project Details HereДокумент8 страницGantt Chart: Enter Your Project Details HereOscar CabreraОценок пока нет

- Petrotac EP Premium Pds 9.09Документ2 страницыPetrotac EP Premium Pds 9.09Oscar CabreraОценок пока нет

- SAP Sample Questions ReviewДокумент18 страницSAP Sample Questions ReviewYasir Yamin SadiОценок пока нет

- Apostila de AseДокумент20 страницApostila de AseOdair Pereira Dos SantosОценок пока нет

- Role of Economic InstitutionsДокумент4 страницыRole of Economic InstitutionsElaine KingОценок пока нет

- Quantiacs Reading ListДокумент7 страницQuantiacs Reading Listdesikudi9000Оценок пока нет

- 3GPP LTE Positioning Protocol (LPP)Документ115 страниц3GPP LTE Positioning Protocol (LPP)dgonzalezmartinОценок пока нет

- Microsoft Excel - Application Note - Crunching FFTsДокумент5 страницMicrosoft Excel - Application Note - Crunching FFTsvoltus88Оценок пока нет

- VIK Traders Se Desculpa Com Clientes Por Dificuldades No SaqueДокумент2 страницыVIK Traders Se Desculpa Com Clientes Por Dificuldades No SaqueMetropolesОценок пока нет

- Political OrganizationДокумент12 страницPolitical Organizationrizalyn alegre0% (1)

- QC Story TRAINING SLIDEДокумент47 страницQC Story TRAINING SLIDEDIPAK VINAYAK SHIRBHATE83% (6)

- Postgresql Management and Automation With ClustercontrolДокумент42 страницыPostgresql Management and Automation With ClustercontrolYiannisZormpas50% (2)

- Process States and Memory Management LabДокумент8 страницProcess States and Memory Management LabJámesОценок пока нет

- Key Sentence Patterns - Ielts WritingДокумент5 страницKey Sentence Patterns - Ielts Writingranga priyasadОценок пока нет

- Complete Note Books of Leonardo Da VinciДокумент510 страницComplete Note Books of Leonardo Da VinciDanish MerajОценок пока нет

- Soft Uni SolutionsДокумент8 страницSoft Uni Solutionsnrobastos1451Оценок пока нет

- Plant SimulationДокумент3 страницыPlant SimulationGrant Schorsch KalilОценок пока нет

- Lecturio The 40 Day Study Schedule USMLE Step 1Документ20 страницLecturio The 40 Day Study Schedule USMLE Step 1Kimberly Kanemitsu50% (2)

- Java Programming EbookДокумент110 страницJava Programming EbookShaina Mae M. UngsonОценок пока нет

- Scherrer Equation - WikipediaДокумент7 страницScherrer Equation - WikipediaSilviu-Laurentiu BadeaОценок пока нет

- Aliceportman Com Septile SeriesДокумент5 страницAliceportman Com Septile SeriestratakОценок пока нет

- The Sharing EconomyДокумент2 страницыThe Sharing EconomyHiprasoОценок пока нет

- SGC Roles and FunctionsДокумент25 страницSGC Roles and FunctionsDivine Grace SamortinОценок пока нет

- Week 9 Lesson Plan - Types of WritingДокумент3 страницыWeek 9 Lesson Plan - Types of Writingapi-29831576Оценок пока нет

- E Role of Natural Resources in Economic Development PDFДокумент31 страницаE Role of Natural Resources in Economic Development PDFLisaMarieGaranОценок пока нет

- The Master-Slave DialecticДокумент16 страницThe Master-Slave DialecticGoran StanićОценок пока нет

- Sword FactsheetДокумент2 страницыSword Factsheetskywalk189Оценок пока нет

- Tilak Highschool Exam Activity Sheet for English SubjectДокумент8 страницTilak Highschool Exam Activity Sheet for English SubjectJay Bhatia0% (1)

- Cluster Sampling: ProcedureДокумент12 страницCluster Sampling: ProcedureAahil RazaОценок пока нет

- Inami, Problem Other MindsДокумент19 страницInami, Problem Other MindsfortyrrОценок пока нет

- Automatic Payment Program SAP Easy Access GuideДокумент19 страницAutomatic Payment Program SAP Easy Access GuidePrakash PalanisamyОценок пока нет

- Elements of A Web PlanДокумент2 страницыElements of A Web Plannadiaanwarmalik2296Оценок пока нет