Академический Документы

Профессиональный Документы

Культура Документы

Operation Impossible

Загружено:

Ramesh VictorАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Operation Impossible

Загружено:

Ramesh VictorАвторское право:

Доступные форматы

YOUR PROFITS CAN

GO UP

SCRAPS & YIELD

LOSSES CAN GO DOWN

YOUR OPERATIONS

COST CAN GO DOWN

START SEING RESULTS

WITHIN A WEEK

(one cycle of improvement)

SPECIALIST

At your

operational site,

working hands-on

with your staff to

start transforming

it within a week!

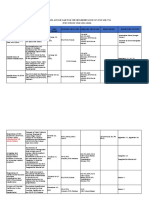

Typical Results Achieved Within a Week

HOW?

What is stopping your operations (manufacturing, projects,

production etc.) from giving results to its optimum level?

The missing piece has to be put in place.

Solutions for your operational performance are identified or

designed and put in place!

We address one to two performance problems at a time.

One cycle is five working days (one week)

PRAGMATIC

SOLUTIONS

EMPLOYEES GIVEN PRACTICAL SKILLS TO

ACHIEVE OPERATIONAL IMPROVEMENT AND

REPEAT IT AGAIN & AGAIN

Arrow Process

Why use graphics from PowerPointing.com?

MONITOR AND

AFFIRM

IMPROVEMENT

Diagnose to understand operational

focus area and plan improvement

Hands-On Diagnostics takes place

while team is given the skills to do so

Identify operational constraints

Activity planning and target results

Use Quick and Effective problem

solving methods and tools

Identify problem and use prolem

solving tools to immediately

address it

Act on implementation

immediately

Leave an impact in the plant

Plan for sustaining and

maintaining the culture

Deep Diving into operations:

Immediate actions to stop

operational problems/constraint

Constraint management activity

done and team learn skills to do so

Monitor implementation

and make changes if

necessary

Measure results, assess

and rectify risks and plan

for full implementation

PLAN &

IMPLEMENT

IMPROVEMENT

ACHIEVE

TARGETED

RESULTS

EXPLOIT THE

CONSTRAINT

DAY ONE

UNDERSTAND

THE PROBLEM

Typical 5-Days Operational

Improvement Activities

HANDS-ON

ALL FIVE

DAYS

Project Mentoring & Coaching by Consultants

We emphasises pragmatism and hands-on exposure of candidates to

use the tools learnt in real life projects. Effective deployment of tools

involves actual operational improvement. Project mentoring and

consulting sessions will involve:

Hand-holding teams in the methodology of tools

Giving thought provoking questions and inputs

Facilitating brain-storming on project improvement

where necessary

Helping in establishing right metrics

Monitoring progress

providing project management assistance and

resources

Sharing of experiences of consultants experience from

various factories around the world

Consulting Method: LEARN-DO-MENTORING

Mentor and coach on actual implementation

Amateurs work until

they get it right.

Professionals work

until they can't get it

wrong.

WE ARE REGISTERED SERVICE PROVIDERS

WITH PSMB AND MOST PROGRAMS

ARE HRDF CLAIMABLE AS SBL/SBL-KHAS

Operations Impossible is a Service Brand Name of

Advanced Manufacturing Consultancy Sdn. Bhd.

Servicing clients all over Asia since 2002

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5795)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1091)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Understanding NMR KeelerДокумент210 страницUnderstanding NMR KeelerДьего Фернандо100% (1)

- Final ThesisДокумент65 страницFinal ThesisDenielle PingolОценок пока нет

- Comparative and Superlative Predictions: Activity TypeДокумент2 страницыComparative and Superlative Predictions: Activity TypeFlamma HaОценок пока нет

- Application Checklist To The Master's Programs at TU Berlin: Deadline and Form of Application DocumentsДокумент2 страницыApplication Checklist To The Master's Programs at TU Berlin: Deadline and Form of Application DocumentsSrimoy SupkarОценок пока нет

- RPMS COT SheetsДокумент12 страницRPMS COT SheetsBerliese FriasОценок пока нет

- Proposed Action Plan For The Implementation of Jdvp-Shs TVLДокумент5 страницProposed Action Plan For The Implementation of Jdvp-Shs TVLKimberly Cler Suarez0% (1)

- Vanguard Observation-Reflection Form 1Документ4 страницыVanguard Observation-Reflection Form 1api-317362905Оценок пока нет

- APA Quick Reference Sheet For StudentsДокумент2 страницыAPA Quick Reference Sheet For StudentsHadeel KareemОценок пока нет

- Section I - Program Information: BA/BASW Application For Field Education Practicum/PlacementДокумент5 страницSection I - Program Information: BA/BASW Application For Field Education Practicum/PlacementAnanta ChaliseОценок пока нет

- Bachelorarbeit Dissertation QuelleДокумент5 страницBachelorarbeit Dissertation QuelleWhatShouldIWriteMyPaperOnCanada100% (1)

- GLOW & YMLP Gazette Issue 31: HTML Source Plain-Text Email DetailsДокумент5 страницGLOW & YMLP Gazette Issue 31: HTML Source Plain-Text Email DetailsJovche KrstitelcheОценок пока нет

- 4th Quarter Exam in Mathematics 9 Final 2022-2023Документ6 страниц4th Quarter Exam in Mathematics 9 Final 2022-2023liomer credoОценок пока нет

- TP 4 Past SimpleДокумент15 страницTP 4 Past SimpleAmira SirajaddinОценок пока нет

- FLIP Online TOEFL Assistant - ListeningДокумент73 страницыFLIP Online TOEFL Assistant - Listeningmy LucyОценок пока нет

- PFR 1Документ9 страницPFR 1Cesar Angelo SancioОценок пока нет

- Course OutlineДокумент5 страницCourse OutlineMagarsa BedasaОценок пока нет

- Panic Disorder Francesetti PDFДокумент11 страницPanic Disorder Francesetti PDFCésarRuizОценок пока нет

- AIM: Write A C Progran To Implement Bit Stuffing and DestuffingДокумент18 страницAIM: Write A C Progran To Implement Bit Stuffing and DestuffingKodipaka SaikrupaОценок пока нет

- Mathema PDFДокумент6 страницMathema PDFErland Garcia Ruiz Filho0% (4)

- Chapter 4Документ2 страницыChapter 4FatihGamzeGültekinОценок пока нет

- Sample Research PaperДокумент4 страницыSample Research PaperMarisol Guino50% (2)

- Course PlanningДокумент28 страницCourse PlanningKaren Kichelle Navarro EviaОценок пока нет

- IIRS AnswersДокумент12 страницIIRS Answers20at1a3145Оценок пока нет

- Brain Centered Training PDFДокумент6 страницBrain Centered Training PDFKhusnul YaqienОценок пока нет

- HM Complete Game Guide 0 11 1Документ252 страницыHM Complete Game Guide 0 11 1ČýbēŕBøţ¹³Оценок пока нет

- The Wheels On The Bus Lesson PlanДокумент3 страницыThe Wheels On The Bus Lesson PlanShellyОценок пока нет

- 9 Learning From Synthetic Data GДокумент5 страниц9 Learning From Synthetic Data GNeo ZroОценок пока нет

- ANSWERS1Документ1 страницаANSWERS1Charan KОценок пока нет

- Unit 21 - (Lomloe) 2023Документ7 страницUnit 21 - (Lomloe) 2023Nekane Cabrera GarcíaОценок пока нет

- B3-C302 Updated CommentsДокумент11 страницB3-C302 Updated CommentsBharath RamОценок пока нет