Академический Документы

Профессиональный Документы

Культура Документы

Corrosion Chemistry: DR Willard Pinnock CHEM 2601 (2013)

Загружено:

Claudia V-MathesonОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Corrosion Chemistry: DR Willard Pinnock CHEM 2601 (2013)

Загружено:

Claudia V-MathesonАвторское право:

Доступные форматы

11/4/2013

1

CORROSION CHEMISTRY

LECTURE 3

Dr Willard Pinnock

CHEM 2601 (2013)

Recap of Lecture 2 (I)

Our view of rusting is that it is an electrochemical process

and so the corrosion cell is essentially

a short-circuited cell (on the same piece of iron or steel)

with the difference in dissolved O

2

concentration (in the electrolyte)

near the metal, determining the anode and cathode.

The Nernst equation gives the potential difference

between anode and cathode of the concentration cell.

Corrosion occurs essentially at the anode through loss

of metal ions while the cathode behaves as an inert

electrode.

One can use indicators to visualize anode and cathode in

corrosion on a single piece of metal Evans Water Drop

Experiment is one such demonstration.

11/4/2013

2

Recap of Lecture 2 (II)

Corrosion can also be driven by the potential that arises

when two metals are in physical contact with both being

also in touch with an electrolyte.

Again the Nernst Equation helps us to estimate the

potential of such cells with the help of tabulated reduction

potentials.

The equation also applies when the solution is an

electrolyte other than water as long as the potentials

(E

0

) used are appropriate to the electrolyte in question

like seawater, or acid environments.

Application of the Nernst Equation to these two types of

cells are explored in Tutorial 1

Rate of Corrosion

The potentials give some idea of the driving force for the

corrosion process and helps to identify anode and cathode in

various situations, but does not say much about the rate of

corrosion.

When the corrosion is uniform over a reasonable-sized area, the

rate of corrosion is usually expressed as the amount of metal

lost in mass per unit area per unit time. (g cm

-2

s

-1

)

The rate of loss of metal can be directly related to the rate of

charge exchange between the metal and the oxidizing species in

solution, expressed as the corrosion current, i

corr

, .

Common units i

corr

, are C cm

-2

s

-1

or A cm

-2

(since an A = C s

-1

)

or sometimes A cm

-2

11/4/2013

3

Rate of Corrosion

Rate of corrosion = (i

corr

/nF) M

Fe

where n is the number of electrons transferred in each reaction,

F is the Faraday constant (96485 C mol

-1

)

M

Fe

is the molar mass of iron/ g mol

-1

Note that the equation is essentially the definition of the term

rate of corrosion broken down into an expression in terms of

the corrosion current.

If this rate of corrosion is divided by the density of the metal, a

very useful corrosion rate, in cm s

-1

, results.

This is sometimes called the penetration depth expressed in mils, mm,

or cm per year.

1 mil is a thousandth of an inch (= 0.254 cm)

So: Rate of corrosion/ density = penetration depth

Rate of Corrosion

Remember that the corrosion cell is essentially a short-

circuited cell, so the current will be limited only by factors

affecting the rate of charge exchange at the electrode-

solution interfaces.

The corrosion current will therefore be dependent on factors

such as: temperature, concentration and mobility of ions in

solution, but most importantly on the nature of the metal-

solution interfaces at anode and cathode.

In a cell that is used to store and deliver electrical power,

the influence of effects at the metal-solution interfaces are

deliberately reduced by the use of a salt bridge.

Here we want them to be as effective as possible so the

corrosion current, i

corr

, is kept small.

We will investigate these factors in some depth after we

explore the practical implications of the magnitude of i

corr

.

11/4/2013

4

Corrosion Rate Calculation

Sample Problem:

Plain carbon-steel, immersed in seawater, has a uniform corrosion

rate expressed as a penetration depth of 0.125 mm per year.

Assuming that the density of steel is 7.87 g cm

-3

, and that steel has

a molar mass of 55.8 g mol

-1

, find the mass (in grams) of iron lost in

corrosion per cm per year, and the corrosion current in A cm

-2

.

Answer: 0.098 g cm

-2

year

-1

, i

corr

= 10.8 A cm

-2

Some idea of acceptable and unacceptable rates are

shown in the next slide.

Ranking of Corrosion Rates by NACE

Performance

Ranking

Corrosion

Rate in

mils*year

Corrosion Current Densities in A cm

-2

Aluminium Iron Lead

Outstanding 1 2.3 2.2 0.85

Excellent 1 - 5 2.3 12 2.2 11 0.8 4.3

Good 5 - 20 12 47 11 43 4.2 - 17

Fair 20 - 50 47 180 43 109 17 - 42

Poor 50 - 200 180 -470 109 430 42 - 170

Unacceptable 200 470 430 170

*1 mil = 0.0254 mm

Taken from Introduction to Corrosion Science by E. Mc Cafferty

(Springer)

11/4/2013

5

Measuring Corrosion Currents

It is really very useful to corrosion scientists to be able to measure

corrosion rates in various situations but it is difficult to measure

corrosion current directly .

This is because:

we cant readily separate cathode and anode electrically (since they are both on

the same piece of metal in most cases) and there is no net flow of charge to or

from the metal when the corrosion current flows.

This is true even when the electrodes are of two different metals in contact. If

they are separated in order to measure current, then the potential driving the

corrosion process is no longer operating.

We can measure the corrosion current indirectly however, by several

methods. The following are some of the most useful methods:

Weight loss method

Chemical analysis of corroding solutions

Thickness measurements

Electrical resistance measurements

Electrochemical polarization measurements

Measuring Corrosion Currents (I)

Weight Loss Method

Suitable when corrosion products are loose and do not adhere to

the metal.

Metal component is removed from the corroding environment and

cleaned (of corrosion products), dried and weighed at various

measured times.

In order to ensure accuracy, all the corrosion products (and only

corrosion products) should be removed from the component.

Weight loss per unit area of sample is plotted vs elapsed time and

the slope of that plot gives corrosion rate. From this the corrosion

current can be inferred.

The results of an experiment in which two types of steel were

exposed to the atmosphere (in an industrial environment) are

shown in the next slide.

11/4/2013

6

Measuring Corrosion Currents (II)

Note that the

corrosion rate

changes with time.

Note too that the

time scale of the

experiment is

several years, so it

is a demanding

experiment that

cannot be used to

give urgently

needed information.

Taken from:

Introduction to

Corrosion Science

by Mc Cafferty

Measuring Corrosion Currents (III)

Chemical Analysis of Solutions

Applicable when there is a constant volume of solution, or when the

investigator can isolate the corroding solution.

One must assume also that the time scale of measurements is

such that not much of the metal has precipitated as corrosion

product so the time scale is usually in hours or days.

Concentration of metal ions in the solution can be determined by

suitable means colorimetric or spectrophotometric for example.

Concentration vs elapsed time can be plotted as before and one

can determine corrosion rate and corrosion current from the slope,

with knowledge of the volume of solution involved.

11/4/2013

7

Measuring Corrosion Currents (IV)

Thickness Measurement Method

Suitable for measuring rates in situ in, for example, gas cylinders,

railroad hopper cars, storage tanks and pipelines.

X-ray or Ultra-sound can be used to measure thickness of walls.

Thickness of metal can be measured as a function of time and this

can be interpreted in terms of penetration depth which can then be

used with the density to infer corrosion currents.

Measuring Corrosion Currents (V)

Electrical Resistance Measurement Method

Suitable for use in wires or films whose resistance increases when

they are thinned by corrosion.

Resistance is given by R = l/A where is the resistivity of the

material.

If cross-sectional area A, decreases as a result of corrosion, resistance

increases and corrosion rates and currents may be inferred from the

density and dimensions of wire or film.

Comment on Methods so Far

Each of the methods described is useful in a very special situation,

and so they are not generally applicable to many practical corrosion

situations.

Also, in many situations of practical interest it can take years to obtain

reliable data.

Electrochemical methods (which we are about to discuss) offer the

advantages of: (i) being more generally applicable, and (ii) requiring

less time to obtain reliable data.

Вам также может понравиться

- Solutions Manual to accompany Engineering Materials ScienceОт EverandSolutions Manual to accompany Engineering Materials ScienceРейтинг: 4 из 5 звезд4/5 (1)

- 7 Forms of Corrosion IДокумент39 страниц7 Forms of Corrosion IJesus De la RosaОценок пока нет

- Corrosion and its Consequences for Reinforced Concrete StructuresОт EverandCorrosion and its Consequences for Reinforced Concrete StructuresОценок пока нет

- Love Show - Audrey BellДокумент440 страницLove Show - Audrey BellClaudia V-Matheson100% (4)

- Love Show - Audrey BellДокумент440 страницLove Show - Audrey BellClaudia V-Matheson100% (4)

- Characteristic Study of Aluminium Based Mmcs With Hybrid Mixture of Alumina and ZnoДокумент10 страницCharacteristic Study of Aluminium Based Mmcs With Hybrid Mixture of Alumina and ZnoHarshith S GowdaОценок пока нет

- 2nd ProjectДокумент72 страницы2nd ProjectrohanОценок пока нет

- MKM6144 Advanced Material: Faculty of Mechanical Engineering Universiti Malaysia PahangДокумент159 страницMKM6144 Advanced Material: Faculty of Mechanical Engineering Universiti Malaysia PahangHazim HamdanОценок пока нет

- Metal Corrosion and Its Prevention: Material ScienceДокумент49 страницMetal Corrosion and Its Prevention: Material Sciencedr nfОценок пока нет

- NosaДокумент9 страницNosaosaroboОценок пока нет

- Corrosion Behavior of Copper at Elevated Temperature: Int. J. Electrochem. Sci., 7 (2012) 7902 - 7914Документ13 страницCorrosion Behavior of Copper at Elevated Temperature: Int. J. Electrochem. Sci., 7 (2012) 7902 - 7914idanfriОценок пока нет

- Laboratory 2 - Gutierrez 1Документ3 страницыLaboratory 2 - Gutierrez 1John Michael MarianoОценок пока нет

- Galvanic, Concentration and Pitting CorrosionДокумент42 страницыGalvanic, Concentration and Pitting CorrosionLeeMayYanОценок пока нет

- Literature ReviewДокумент9 страницLiterature ReviewGayathri Devi RОценок пока нет

- Engineering Corrosion OH-4: University of Hafr Al BatinДокумент41 страницаEngineering Corrosion OH-4: University of Hafr Al BatinHussain Al-DawoodОценок пока нет

- Corrosion: Industrial Heat ExchangersДокумент5 страницCorrosion: Industrial Heat ExchangersnmahagedaraОценок пока нет

- Engineering Corrosion OH-4: University of Hafr Al BatinДокумент41 страницаEngineering Corrosion OH-4: University of Hafr Al BatinHussain Al-DawoodОценок пока нет

- Corrosion Studies (Metrohm)Документ15 страницCorrosion Studies (Metrohm)vinook6Оценок пока нет

- L12-Cathodic & Anodic ProtectionДокумент41 страницаL12-Cathodic & Anodic ProtectionAmir Khalid100% (1)

- Corrosion PresentationДокумент51 страницаCorrosion PresentationJawad AslamОценок пока нет

- W The Rate in Weight Gain or Loss (G/CM I Current DensityДокумент12 страницW The Rate in Weight Gain or Loss (G/CM I Current Densityهدوء السماءОценок пока нет

- Environment and CorrosionДокумент39 страницEnvironment and Corrosionabdullah anwarОценок пока нет

- Electrochemical Impedance Study On Galvanized Steel Corrosion Under Cyclic Wet-Dry Conditions - in Uence of Time of WetnessДокумент13 страницElectrochemical Impedance Study On Galvanized Steel Corrosion Under Cyclic Wet-Dry Conditions - in Uence of Time of WetnessVanessa Rios NolayaОценок пока нет

- Influence of Liquid Sodium On Mechanical Properties of Steels, Refractory Alloys and CeramicsДокумент39 страницInfluence of Liquid Sodium On Mechanical Properties of Steels, Refractory Alloys and Ceramicsmahmoud EissaОценок пока нет

- Tribocorrosion: Material Degradation Due To The Combined Effect of Corrosion andДокумент1 страницаTribocorrosion: Material Degradation Due To The Combined Effect of Corrosion andreddyОценок пока нет

- Experiment No. 8 DoneДокумент25 страницExperiment No. 8 DoneshahОценок пока нет

- Unit Iii NotesДокумент29 страницUnit Iii NotesSadhasivam CОценок пока нет

- Electroplating IIДокумент53 страницыElectroplating IIGarima UppadhyayОценок пока нет

- Corrosion Monitoring in Petroleum Refineries: K.R. Soni, Saga Global ConsultantsДокумент40 страницCorrosion Monitoring in Petroleum Refineries: K.R. Soni, Saga Global Consultantsokoro matthewОценок пока нет

- A Method To Determine The Corrosion Potential of Rock Bolts On Coal MinesДокумент36 страницA Method To Determine The Corrosion Potential of Rock Bolts On Coal MinesJulio LópezОценок пока нет

- Admin,+10 Comparison+of+Potentiodynamic+Polarization+and+Weight+Loss+Measurement+Techniques+in+the+Study+of+Corrosion+Behavior+of+Документ7 страницAdmin,+10 Comparison+of+Potentiodynamic+Polarization+and+Weight+Loss+Measurement+Techniques+in+the+Study+of+Corrosion+Behavior+of+Putra Temas ToyebОценок пока нет

- Chapter 2-Metal CorrosionДокумент75 страницChapter 2-Metal Corrosionshenouda403Оценок пока нет

- 21SPTE313 - Lecture 10Документ40 страниц21SPTE313 - Lecture 10Mohamed SolimanОценок пока нет

- Final Presentation - Corrected (1) .PPTX RaviДокумент15 страницFinal Presentation - Corrected (1) .PPTX RavisudamОценок пока нет

- 2-Corrosion Rate MeasurementДокумент32 страницы2-Corrosion Rate Measurement이선엽100% (1)

- Cavitation Erosion Resistance of Two Steels With The Same Percentage of Chromium and Nickel But Different Carbon ContentДокумент7 страницCavitation Erosion Resistance of Two Steels With The Same Percentage of Chromium and Nickel But Different Carbon Contentaloliveira7811Оценок пока нет

- Department of Chemical Engineering: Material Science and TechnologyДокумент67 страницDepartment of Chemical Engineering: Material Science and Technologytenguria samriddhОценок пока нет

- CorrosionДокумент65 страницCorrosionSurendra Kamal100% (9)

- Aqeuous CorrosionДокумент11 страницAqeuous Corrosionthankz4venomОценок пока нет

- Evironmental Degradation of Materials: Rushikesh KulkarniДокумент30 страницEvironmental Degradation of Materials: Rushikesh KulkarniSanketDesai100% (1)

- Corrosion: Food Process Equipment Design Module-2Документ20 страницCorrosion: Food Process Equipment Design Module-2ssfoodtechОценок пока нет

- Durability Assessment of Concrete StructuresДокумент68 страницDurability Assessment of Concrete StructuresDeRudy100% (1)

- US Army Corp Piping - c-4Документ20 страницUS Army Corp Piping - c-4minhphuongphamОценок пока нет

- Assessment of Corrosion Rate in Prestressed Concrete With Acoustic EmissionДокумент13 страницAssessment of Corrosion Rate in Prestressed Concrete With Acoustic Emissionjesé m.Оценок пока нет

- Corrosion of Heat ExchangerДокумент5 страницCorrosion of Heat ExchangerAhmed Ibrahim Ahmed EissaОценок пока нет

- Cathodic Protection 1Документ36 страницCathodic Protection 1rampokalaОценок пока нет

- Design of A Bike Chain Sprocket ProjectДокумент38 страницDesign of A Bike Chain Sprocket Projectvishnukumar muruganОценок пока нет

- Section IV: Testing For Corrosion Types: J. R. Scully, EditorДокумент7 страницSection IV: Testing For Corrosion Types: J. R. Scully, Editordraindrop8606Оценок пока нет

- Icmerepi 357Документ5 страницIcmerepi 357Renalyn TorioОценок пока нет

- Fundamental Study On The Effectiveness of Sacrificial Point Anode For Corrosion Prevention of Steel Bars in Chloride Contaminated ConcreteДокумент11 страницFundamental Study On The Effectiveness of Sacrificial Point Anode For Corrosion Prevention of Steel Bars in Chloride Contaminated ConcreteRahmita Sari RafdinalОценок пока нет

- Review Questions For Corrosion Engineering Viva-VoiceДокумент5 страницReview Questions For Corrosion Engineering Viva-VoiceJustin VarunОценок пока нет

- Corrosion Cooling SystemsДокумент12 страницCorrosion Cooling SystemsQuốc Anh KhổngОценок пока нет

- Preferential Weld Corrosion of X65 Pipeline Steel in Flowing Brines Containing Carbon DioxideДокумент32 страницыPreferential Weld Corrosion of X65 Pipeline Steel in Flowing Brines Containing Carbon DioxideSantosh Iim LucknowОценок пока нет

- 09 - Chapter 1 PDFДокумент59 страниц09 - Chapter 1 PDFchantayya bОценок пока нет

- Cathodic Protection With Localised Galvanic Anodes in Slender Carbonated Concrete ElementsДокумент17 страницCathodic Protection With Localised Galvanic Anodes in Slender Carbonated Concrete ElementsTarek ChikerОценок пока нет

- Corrosion 2 PDFДокумент46 страницCorrosion 2 PDFEenadu paperОценок пока нет

- Corrosive Damage in Metals and Its PreventionДокумент36 страницCorrosive Damage in Metals and Its Preventionsamurai7_7783% (6)

- Corrosion Prevention and ControlДокумент22 страницыCorrosion Prevention and ControlMobile LegendsОценок пока нет

- Corrosion Potential AssessmentДокумент17 страницCorrosion Potential AssessmentKunwar Apoorv Singh PariharОценок пока нет

- Ductile Brittle TransitionДокумент7 страницDuctile Brittle Transitionssnathan794508Оценок пока нет

- Encyclopaedia Britannica, 11th Edition, Volume 6, Slice 8 "Conduction, Electric"От EverandEncyclopaedia Britannica, 11th Edition, Volume 6, Slice 8 "Conduction, Electric"Оценок пока нет

- CHEM2601 Aquatic Tutorial 2013Документ2 страницыCHEM2601 Aquatic Tutorial 2013Claudia V-MathesonОценок пока нет

- Instrument: UV/Vis Spectrophotometer: Brand: Thermo Scientific Type: Helios Omega SpectrophotometerДокумент6 страницInstrument: UV/Vis Spectrophotometer: Brand: Thermo Scientific Type: Helios Omega SpectrophotometerClaudia V-MathesonОценок пока нет

- HCM634G - Winding 07: Technical Data SheetДокумент7 страницHCM634G - Winding 07: Technical Data SheetAtanasio PerezОценок пока нет

- E BallДокумент22 страницыE BallKanishk YenugulaОценок пока нет

- Traction Control of Electric Vehicle Based On The Estimation of Road Surface ConditionДокумент8 страницTraction Control of Electric Vehicle Based On The Estimation of Road Surface ConditionMahta SafrullahОценок пока нет

- General Information 1:1Документ10 страницGeneral Information 1:1Wahyu Setyo PОценок пока нет

- Arteche CT Tripping Relays Catalog PDFДокумент28 страницArteche CT Tripping Relays Catalog PDFtamky SubstationОценок пока нет

- Xilinx XC 3000Документ21 страницаXilinx XC 3000shabbir470100% (1)

- EIN 01 Questions 20 November 10Документ22 страницыEIN 01 Questions 20 November 10Aleihs AyadneОценок пока нет

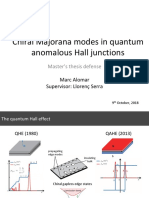

- Chiral Majorana ModesДокумент21 страницаChiral Majorana ModesMarcAlomarPayerasОценок пока нет

- 85TO3GHДокумент6 страниц85TO3GHVictor BondarenkoОценок пока нет

- PSU CalculatorДокумент10 страницPSU CalculatorVíctor RojasОценок пока нет

- Topic: Photoelectric Effect: Noble International SchoolДокумент22 страницыTopic: Photoelectric Effect: Noble International SchoolAnmol SinghalОценок пока нет

- LM 723Документ17 страницLM 723Maty AgaccioОценок пока нет

- Major Inventions in Control SystemsДокумент4 страницыMajor Inventions in Control SystemsAli AkhterОценок пока нет

- HP Viridia 26 24 SeriesДокумент2 страницыHP Viridia 26 24 SeriesYasuda ReiОценок пока нет

- ZCAR-1600A Six Phase Protective Relay Tester IntroductionДокумент4 страницыZCAR-1600A Six Phase Protective Relay Tester IntroductionMagidiel AraujoОценок пока нет

- Advantech Pac SolutionsДокумент40 страницAdvantech Pac SolutionsAfandie Van WhyОценок пока нет

- Bloch. Nuclear Induction Experiment 1946 PDFДокумент16 страницBloch. Nuclear Induction Experiment 1946 PDFEdward Ventura BarrientosОценок пока нет

- Understanding Langmuir Probe Current-Voltage 1Документ4 страницыUnderstanding Langmuir Probe Current-Voltage 1Denis_LОценок пока нет

- CS321 Computer ArchitectureДокумент160 страницCS321 Computer ArchitectureAnurag kumarОценок пока нет

- DP9127V DPДокумент11 страницDP9127V DPGustavo AlonsoОценок пока нет

- EXP8 Frequencyresponse StudentsДокумент4 страницыEXP8 Frequencyresponse StudentslucasОценок пока нет

- Canon Speedlite Transmitter ST-E2Документ19 страницCanon Speedlite Transmitter ST-E2Dorin CalugaruОценок пока нет

- "Final Year Ece Projects in Chennai, Bangalore, Vijayawada, Kakinada." GoodДокумент18 страниц"Final Year Ece Projects in Chennai, Bangalore, Vijayawada, Kakinada." Goodwondi BETОценок пока нет

- Application of Trans-Guard™ EXT and OS FusesДокумент14 страницApplication of Trans-Guard™ EXT and OS FusesroquceОценок пока нет

- Huawei ManualДокумент42 страницыHuawei ManualAntonio MenoyoОценок пока нет

- FPGA Interview Questions, FPGA Interview Questions & Answers, FPGAДокумент9 страницFPGA Interview Questions, FPGA Interview Questions & Answers, FPGArajeshpandaОценок пока нет

- Agni College of Technology Department of Ece Notice Board DetailsДокумент1 страницаAgni College of Technology Department of Ece Notice Board DetailsDevill DavajОценок пока нет

- Drillstring VibrationsДокумент4 страницыDrillstring VibrationsLoganBohannonОценок пока нет

- Exz110 enДокумент242 страницыExz110 enMiguel SanchezОценок пока нет

- MODEL NO.: N156B3-L0B: TFT LCD Preliminary SpecificationДокумент29 страницMODEL NO.: N156B3-L0B: TFT LCD Preliminary SpecificationJCP99Оценок пока нет