Академический Документы

Профессиональный Документы

Культура Документы

Six Sigma GreenBelt BlackBelt 2009

Загружено:

hpss77Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Six Sigma GreenBelt BlackBelt 2009

Загружено:

hpss77Авторское право:

Доступные форматы

NC STATE UNIVERSITY

What is Six Sigma, according to

Dr. Blanton Godfrey?

In a service or manufacturing environment, a

Six Sigma process is virtually defect-free: in

one million operations of a process, Six Sigma

allows only 3.4 defects. Most companies

operate at four Sigma, which allows 6,000

defects per million operations of a process.

Motorola developed Six Sigma in the 1980s to

reduce the number of defects in its products.

What is a Six Sigma Black Belt?

Black Belts are on-site implementers of Six

Sigma projects who are trained in statistical

methodology to reduce variation of products

and services to the Six Sigma level. They also

facilitate, lead and manage Six Sigma teams to

sustain significant bottom-line results.

What does the training involve?

The program consists of four 5-day sessions.

You will need to bring a project to work on

during the course of training. Upon completion,

you will have the skill set to lead and conduct

Six Sigma projects to achieve significant finan-

cial results throughout your organization.

What are the Six Sigma Black Belt

objectives?

d Reduction in total defects

d Increased capacity, output, and customer

satisfaction

d Better product and service reliability

d Financial results through process

improvement ($100,000 to $200,000

direct cost reduction per project)

What materials are included?

d Statistical software packages used for

Six Sigma projects. A PC laptop must

be brought to each session.

d Jurans Quality Handbook, fifth edition,

by Godfrey and Juran, co-editors

d The Black Belt Memory

Jogger: A Pocket Guide

for Six Sigma Success

Black Belt 2009

Program Dates:

(using MINITAB

software)

[Raleigh] March 2-6,

April 6-10, May 4-8,

and June 1-5

[Raleigh] September 21-25,

October 19-23, November 16-20,

and December 14-18

(using SAS JMP

software)

[Raleigh] June 15-19, July 13-17,

August 10-14, and September 14-18

(+2 with MINITAB

and JMP

)

[Raleigh] January 5-9 and February 9-13

For more updated class schedules

and information about training,

please go to

www.tx.ncsu.edu/sixsigma

www.ies.ncsu.edu/sixsigma

Contact the IES representative

nearest you.

Arden Chris McGraw 828.231.4038

Concord Gene Beneduce 704.369.9019

Dobson Dennis Atkins 336.755.5273

Durham Mitch Poteat 919.227.6790

Fayetteville Alex Reed 910.988.4494

Greensboro Barrett Walker 336.404.3415

Greensboro Ken Hoover 336.362.5170

Greenville Dick Oates 252.643.1086

Raleigh Doug Hummer 919.291.1268

Raleigh Marie Griffin 919.830.7206

Smithfield Kami Baggett 919.830.7292

Wilkesboro Gary Harris 336.469.1979

Williamston Rex Raiford 252.799.1621

Help your company

reduce defects,

improve productivity,

and increase profit

through improved

performance.

Be recognized as an

extraordinary problem

solverbecome a

Six Sigma Black Belt.

S903

For more information about Black Belt training contact

Alisa Hunt-Lowery at 919.515.6534 [alisa_lowery@ncsu.edu] or

Christy Guion at 919.830.7092 [christy_guion@ncsu.edu]

Dr. A. Blanton

Godfrey, Dean of the

NC State University

College of Textiles

and former CEO of

the Juran Institute.

Black Belt 2009

NC STATE UNIVERSITY

What is Six Sigma, according to

Dr. Blanton Godfrey?

In a service or manufacturing environment, a Six

Sigma process is virtually defect-free: in one mil-

lion operations of a process, Six Sigma allows

only 3.4 defects. Most companies operate at four

Sigma, which allows 6,000 defects per million

operations of a process. Motorola developed

Six Sigma in the 1980s to reduce the number of

defects in its own products.

What is a Six Sigma Green Belt?

As the problem-solvers assigned to Black Belt

projects, Green Belts play an important role

in a companys Six Sigma implementation

strategy. Green Belts learn to apply the right

tools at the right time to maximize efficiency in

measuring, analyzing, improving and control-

ling critical processes to increase cost savings.

Green Belts are project leaders on smaller

Six Sigma projects in addition to being team

members on black belt projects.

What does the training involve?

The training consists of two 4-day training

sessions that include a day for review and final

assessment. Each participant is encouraged to

bring a project to work on during the course of

Green Belt training.

What are the Six Sigma Green Belt

objectives?

d Introduce the Six Sigma improvement

methodology

d Equip associates with tools to measure, ana-

lyze, improve, and control critical processes

to achieve cost savings objectives

You will learn to:

d Understand and describe the process flow

d Collect and analyze data

d Work efficiently in a team environment

d Communicate the basic Six Sigma

methodology to associates

d Use MINITAB

software to efficiently employ

process improvement tools

What are the topics in the

sessions?

d Cost of poor quality

d Measurement system analysis

d Value stream mapping

d Correlation and regression

d Failure mode effects analysis (FMEA)

d Process capability

d MINITAB

What materials are included?

d Six Sigma Memory Jogger II: A Pocket Guide

d MINITAB

software and workbooks with

data sets on CD

d MINITAB

Handbook, a $44.95 value

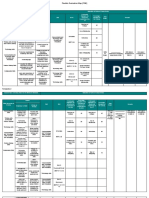

Green Belt 2009 Program Dates

(using MINITAB

software):

[Raleigh] February 23-26 and March 23-26;

August 3-6 and August 31-September 3

[Greensboro] May 18-21 and June 15-18

[Charlotte] November 16-19

and December 14-17

For more updated class schedules

and information about training,

please go to

www.tx.ncsu.edu/sixsigma

www.ies.ncsu.edu/sixsigma

Contact the IES representative

nearest you.

Arden Chris McGraw 828.231.4038

Concord Gene Beneduce 704.369.9019

Dobson Dennis Atkins 336.755.5273

Durham Mitch Poteat 919.227.6790

Fayetteville Alex Reed 910.988.4494

Greensboro Barrett Walker 336.404.3415

Greensboro Ken Hoover 336.362.5170

Greenville Dick Oates 252.643.1086

Raleigh Doug Hummer 919.291.1268

Raleigh Marie Griffin 919.830.7206

Smithfield Kami Baggett 919.830.7292

Wilkesboro Gary Harris 336.469.1979

Williamston Rex Raiford 252.799.1621

Help your company

reduce defects,

improve productivity,

and increase profit

through improved

performance.

Be recognized as an

extraordinary problem

solverbecome a

Six Sigma Green Belt.

Green Belt 2009

For more information about Black Belt training contact

Alisa Hunt-Lowery at 919.515.6534 [alisa_lowery@ncsu.edu] or

Christy Guion at 919.830.7092 [christy_guion@ncsu.edu]

Вам также может понравиться

- The Actual Diesel Engine CycleДокумент4 страницыThe Actual Diesel Engine Cyclehpss77Оценок пока нет

- LBM I Memory PDFДокумент23 страницыLBM I Memory PDFhpss77Оценок пока нет

- Gard AS - Case Study - Entry Into Enclosed SpaceДокумент2 страницыGard AS - Case Study - Entry Into Enclosed Spacehpss77Оценок пока нет

- Loss of Ship's Records When Changing Ownership or ManagementДокумент2 страницыLoss of Ship's Records When Changing Ownership or Managementhpss77Оценок пока нет

- Binary CodingДокумент13 страницBinary CodingsahildeoraОценок пока нет

- LBM I Memory PDFДокумент23 страницыLBM I Memory PDFhpss77Оценок пока нет

- (David Ehrenfeld) Swimming Lessons Keeping AfloatДокумент266 страниц(David Ehrenfeld) Swimming Lessons Keeping AfloatfuermiguelОценок пока нет

- 682 Verification of EEDIДокумент8 страниц682 Verification of EEDIhpss77Оценок пока нет

- SL 1996Документ14 страницSL 1996hpss77Оценок пока нет

- SL 1995Документ19 страницSL 1995hpss77100% (1)

- SL 1984Документ1 страницаSL 1984hpss77Оценок пока нет

- EthernetДокумент20 страницEthernethpss77Оценок пока нет

- SL 1999Документ23 страницыSL 1999hpss77Оценок пока нет

- SL 1998Документ20 страницSL 1998hpss77100% (1)

- Slide Type Fuel Valve Nozzles Extended TBOДокумент1 страницаSlide Type Fuel Valve Nozzles Extended TBOhpss77Оценок пока нет

- 808-Port State ControlДокумент4 страницы808-Port State Controlhpss77Оценок пока нет

- 2014fa CS61C L31 DG PipelineII 6upДокумент4 страницы2014fa CS61C L31 DG PipelineII 6uphpss77Оценок пока нет

- Man SL2009-511Документ4 страницыMan SL2009-511hpss77Оценок пока нет

- Control Air For ME Exh ValvesДокумент8 страницControl Air For ME Exh Valveshpss77Оценок пока нет

- Consultation Comments Table - Impact Assessment 8 December 2014Документ21 страницаConsultation Comments Table - Impact Assessment 8 December 2014hpss77Оценок пока нет

- 15 Propulsion and ResistanceДокумент31 страница15 Propulsion and Resistancehpss77Оценок пока нет

- Cylinder Lubrication Marine Engines ArticleДокумент10 страницCylinder Lubrication Marine Engines ArticleVijay Geddada100% (2)

- Hitachi Man-B&w Diesel Engine Service DataДокумент6 страницHitachi Man-B&w Diesel Engine Service Datar0% (1)

- 4stroke B&WДокумент7 страниц4stroke B&Whpss77Оценок пока нет

- Pointers and MemoryДокумент31 страницаPointers and MemorySivasai KumarОценок пока нет

- An Introduction To Vibration Aspects of Two-Stroke Diesel Engines I, N ShipsДокумент11 страницAn Introduction To Vibration Aspects of Two-Stroke Diesel Engines I, N Shipshpss77100% (1)

- Battery MaintainenceДокумент4 страницыBattery Maintainencehpss77Оценок пока нет

- 50 Success ClassicsДокумент2 страницы50 Success Classicssobinj@gmail.comОценок пока нет

- Interest Calculation On DepositsДокумент3 страницыInterest Calculation On Depositshpss77Оценок пока нет

- ApkДокумент2 страницыApkhpss77Оценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Research Plan Project Summary For 1a - Comp 3Документ3 страницыResearch Plan Project Summary For 1a - Comp 3api-564040637Оценок пока нет

- Green DAOДокумент26 страницGreen DAOArslan AliОценок пока нет

- Contour CraftingДокумент43 страницыContour CraftingTEMY PETERОценок пока нет

- MT7-TL10C900B326 Software Upgrade GuidelineДокумент8 страницMT7-TL10C900B326 Software Upgrade Guidelinehilal288Оценок пока нет

- Summative Test in EPP6 ICT 2Документ2 страницыSummative Test in EPP6 ICT 2Lennex Marie Sario0% (1)

- Diagrama de Caja de Fusibles Ford f150 Año 1992Документ3 страницыDiagrama de Caja de Fusibles Ford f150 Año 1992Oscar Gutiérrez100% (2)

- Finaln DocumentДокумент52 страницыFinaln DocumentTemesgenОценок пока нет

- A Project Report On Facial Recognition Based Attendance SystemДокумент52 страницыA Project Report On Facial Recognition Based Attendance SystemJAY DESAIОценок пока нет

- S.O.L.I.D First Five Object-Oriented Design OODДокумент2 страницыS.O.L.I.D First Five Object-Oriented Design OODnacОценок пока нет

- SEM600 1988 Resonant Mode ConverterTopologiesДокумент14 страницSEM600 1988 Resonant Mode ConverterTopologiesjuanОценок пока нет

- Aberdeen Research Report Big Data AnalyticsДокумент11 страницAberdeen Research Report Big Data AnalyticsRosie3k90% (1)

- Catalog SanzДокумент55 страницCatalog SanzGotlem BordОценок пока нет

- E - NetworkAttachedStorage PDFДокумент65 страницE - NetworkAttachedStorage PDFNorisham Abd RahmanОценок пока нет

- NFW-22-E06-GP-C-017-A, Asphalting For Tank Foundation ProcedureДокумент6 страницNFW-22-E06-GP-C-017-A, Asphalting For Tank Foundation ProcedureTim JalurОценок пока нет

- Srs Latest VersionДокумент11 страницSrs Latest VersionVikram VarmaОценок пока нет

- Christine Jocson - EFAA1 - FEM - TemplateДокумент3 страницыChristine Jocson - EFAA1 - FEM - TemplateRomano Jocson100% (1)

- Scott GroverДокумент3 страницыScott GroverJoe StephensОценок пока нет

- FenilModi PDFДокумент7 страницFenilModi PDFSavan JaviaОценок пока нет

- Snake Robotics: by Rohit Raichura SowmyaДокумент22 страницыSnake Robotics: by Rohit Raichura SowmyaRohit RaichuraОценок пока нет

- SRS FormatДокумент3 страницыSRS FormatMayank Saraswat50% (4)

- A Project Report On: RF Id Access Control SystemДокумент16 страницA Project Report On: RF Id Access Control Systemharshraj086Оценок пока нет

- Experience: DEVOPS ENGINEER, Wipro Technologies (Pune)Документ2 страницыExperience: DEVOPS ENGINEER, Wipro Technologies (Pune)Rishabh PareekОценок пока нет

- Siddartha ResumeДокумент3 страницыSiddartha ResumeSasi KalaОценок пока нет

- Speed Controllers - FANSДокумент5 страницSpeed Controllers - FANSEmanuel LucaОценок пока нет

- ISTE Computational Thinking InfographicДокумент1 страницаISTE Computational Thinking InfographicRoberto Gutiérrez CamarenaОценок пока нет

- CS2253 Computer Organization and Architecture QBANK2Документ4 страницыCS2253 Computer Organization and Architecture QBANK2John LeonsОценок пока нет

- Samsung Galaxy J2 Pro (2018) ManualДокумент127 страницSamsung Galaxy J2 Pro (2018) ManualBruno CoutoОценок пока нет

- Social NetworkingДокумент34 страницыSocial NetworkingNandini TarwayОценок пока нет

- 05 JavascriptДокумент16 страниц05 JavascriptRaj KumarОценок пока нет

- Auto CAD Civil 3DДокумент2 страницыAuto CAD Civil 3DCadd CentreОценок пока нет