Академический Документы

Профессиональный Документы

Культура Документы

Hydrogen Recovery by PSA

Загружено:

Sharif M Mizanur RahmanАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Hydrogen Recovery by PSA

Загружено:

Sharif M Mizanur RahmanАвторское право:

Доступные форматы

Hydrogen Recovery

by Pressure

Swing Adsorption

3 Introduction

4 The process

5 The PSA sequence

6 Scope of work

7 The advantages

8 Contact

Contents.

2

The experience.

The use of the Pressure Swing Adsorption (PSA) process

has seen tremendous growth during the last decades

mainly due to its simplicity and low operating costs.

Major applications have been the recovery of high purity

hydrogen, methane and carbon dioxide as well as the

generation of nitrogen and oxygen. In addition, it has

gained significance for the bulk removal of carbon

dioxide from direct reduction top-gases.

Linde as the world leader in adsorption technology

has designed and supplied more than 500 PSA plants

including the worlds largest units and units with

highest availability.

Introduction.

3

The Linde hydrogen PSA units

The well proven Linde high performance PSA

units are designed for the recovery and purifi-

cation of pure hydrogen from different hydrogen

-rich streams, such as synthesis gases from

steam reforming process, partial oxidation or

gasification, as well as from various off-gases

in refineries or petrochemical processes, e.g.

ethylene off-gas, coke oven gas, methanol and

ammonia purge gas.

Capacities range from a few hundred Nm/h to

large scale plants with more than 400,000 Nm/h.

The hydrogen product meets every purity re-

quirement up to 99.9999 mol-% and is achieved

at highest recovery rates.

Main hydrogen consumers are refineries re-

quiring this valuable gas for example for their

cracking, dearomatization or desulphurization

processes.

As a second group of users in the petrochemical

industry has a demand for hydrogen for its

methanol and ammonia synthesis, MTBE pro-

cesses, etc.

Lindes PSA systems have proven to be success-

ful in cases where performance, flexibility, avail-

ability and reliability are the determining factors.

High quality and easy accessibility to all compo-

nents minimize and facilitate maintenance to

the maximum extent.

Qualitative ranking of adsorption forces

Separation by adsorption

The Pressure Swing Adsorption (PSA) techno logy

is based on a physical binding of gas molecules

to adsorbent material. The respective force act-

ing between the gas molecules and the adsorb-

ent material depends on the gas component,

type of adsorbent material, partial pressure of

the gas component and operating temperature.

A qualitative ranking of the adsorption forces is

shown in the figure below.

The separation effect is based on differences in

binding forces to the adsorbent material. Highly

volatile components with low polarity, such as

hydrogen, are practically non-adsorbable as

opposed to molecules as N

2

, CO, CO

2

, hydrocar-

bons and water vapour. Consequently, these

impurities can be adsorbed from a hydrogen-

containing stream and high purity hydrogen is

recovered.

Adsorption and regeneration

The PSA process works at basically constant

temperature and uses the effect of alternating

pressure and partial pressure to perform adsorp-

tion and desorption. Since heating or cooling is

not required, short cycles within the range of

minutes are achieved. The PSA process conse-

quently allows the economical removal of large

amounts of impurities.

The figure on page 5 illustrates the pressure

swing adsorption process. It shows the adsorp-

tion isotherms describing the relation between

partial pressure of a component and its equili-

brium loading on the adsorbent material for a

given temperature.

Adsorption is carried out at high pressure (and

hence high respective partial pressure) typically

in the range of 10 to 40 bar until the equilibrium

loading is reached. At this point in time, no

further adsorption capacity is available and the

adsorbent material must be regenerated. This

regeneration is done by lowering the pressure

to slightly above atmospheric pressure resulting

in a respective decrease in equilibrium loading.

As a result, the impurities on the adsorbent

material are desorbed and the adsorbent material

is regenerated. The amount of impurities re-

moved from a gas stream within one cycle

corresponds to the difference of adsorption to

desorption loading.

After termination of regeneration, pressure is

increased back to adsorption pressure level and

the process starts again from the beginning.

Hydrogen

Oxygen

Argon

Nitrogen

Carbon monoxide

Methane

Carbon dioxide

Ethane

Ethylene

Propane

Butane

Propylene

Ammonia

Hydrogen sulfide

Mercaptanes

BTX

Water

weak

strong

Pressure swing adsorption plant in Leuna, Germany

4

The process.

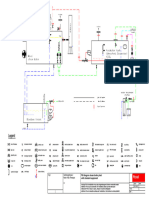

A PSA plant consists basically of the adsorber

vessels containing the adsorbent material, tail

gas drum(s), valve skid(s) with interconnecting

piping, control valves and instrumentation and

a control system for control of the unit.

The pressure swing adsorption process has four

basic process steps:

Adsorption

Depressurization

Regeneration

Repressurization

To provide continuous hydrogen supply, mini-

mum 4 adsorber vessels are required. The figure

on page 6 shows the combination of the sequen-

ces of four adsorber vessels as a pressure-time-

diagram.

Adsorption

Adsorption of impurities is carried out at high

pressure being determined by the pressure of

the feed gas. The feed gas flows through the

adsorber vessels in an upward direction. Impuri-

ties such as water, heavy hydrocarbons, light

hydrocarbons, CO

2

, CO and nitrogen are selec-

tively adsorbed on the surface of the adsorbent

material. Highly pure hydrogen exits the adsor-

ber vessel at top. After a defined time, the ad-

sorption phase of this vessel stops and regen-

eration starts. Another adsorber takes over the

task of adsorption to ensure continuous hydro-

gen supply.

Regeneration

The regeneration phase consists of basically

five consecutive steps:

Pressure equalization

Provide purge

Dump

Purging

Repressurization

The steps are combined so as to minimize hydro-

gen losses and consequently to maximize the

hydrogen recovery rate of the PSA system.

Pressure equalization (step E1)

Depressurization starts in the co-current direc-

tion from bottom to top. The hydrogen still stored

in the void space of the adsorbent material is

used to pressurize another adsorber having just

terminated its regeneration. Depending on the

total number of adsorbers and the process con-

ditions, one to four of these so-called pressure

equalization steps are performed. Each addi-

tional pressure equalization step minimizes

hydrogen losses and increases the hydrogen

recovery rate.

Provide purge (step PP)

This is the final depressurization step in co-

current direction providing pure hydrogen to

purge or regenerate another adsorber.

Dump (step D)

At a certain point of time, the remaining pres-

sure must be released in counter-current direc-

tion to prevent break-through of impurities at

the top of the adsorber. This is the first step of

the regeneration phase when desorbed impuri-

ties leave the adsorber at the bottom and flow

to the tail gas system of the PSA plant.

Adsorption loading

Desorption loading

D

i

f

f

e

r

e

n

t

i

a

l

l

o

a

d

i

n

g

Adsorption isotherms

P

D

Desorption pressure

P

A

Adsorption pressure

Partial pressure

0C

200C

50C

30C

Adsorption and regeneration by pressure swing

5

The PSA sequence.

Purging (regeneration)

Final desorption and regeneration is performed

at the lowest pressure of the PSA sequence.

Highly pure hydrogen obtained from an adsorber

in the provide purge step, is used to purge the

desorbed impurities into the tail gas system.

The residual loading on the adsorbent material is

reduced to a minimum to achieve high efficiency

of the PSA cycle.

Repressurization (steps R1/R0)

Before restarting adsorption, the regenerated

adsorber must be pressurized again. This is

accomplished in the pressure equalization step

by using pure hydrogen from adsorbers presently

under depressurization. Since final adsorption

pressure cannot be reached with pressure

equalization steps, repressurization to adsorp-

tion pressure is carried out with a split stream

from the hydrogen product line.

Having reached the required pressure level

again, this regenerated adsorber takes over the

task of adsorption from another vessel having

just terminated its adsorption phase.

The typical scope of supply

of Lindes PSA units includes:

Prefabricated valve skid

Adsorber vessels

Specially selected adsorbent material

Tail gas drum

Process control system

The scope can be altered to best suit clients

needs. Based on the customers requirements,

feed gas compressor or tail gas compressor

systems can be offered through Linde as a

integrated PSA solution.

Pressure time diagram

Adsorption

P

r

e

s

s

u

r

e

Adsorber A

Adsorber B

Adsorber C

Adsorber D

Time

Regeneration

Regeneration

Regeneration

Adsorption

Adsorption

Adsorption

R0

E1

R1

R1

D

E1

D PP

Regeneration R1

PP

D

E1

R0

PP

R0

R0

R1

D

E1

PP

PSA valve skid

6

Scope of work.

The Linde high performance PSA units provide

remarkable advantages such as:

Lindes expertise in adsorption technology

Based on customers requirements, the Linde

PSA specialists will select the optimum PSA

system for the specific purification task in terms

of optimum ratio between plant performance

and investment cost.

Quality

The high switching cycles of PSA units require

special equipment distinguished by a high de-

gree of durability. Linde only applies qualified

components, which meet these demands per-

fectly and which are proven during many years

of experience.

Reliability

The use of selected and suitable components

implies the high reliability of Lindes PSA sys-

tems. Especially high performance switching

valves are used in Lindes PSA process.

Availability

The Linde PSA systems are characterized by an

outstanding availability of hydrogen supply.

With its special features such as operation with

reduced number of adsorbers, adsorber group

isolation and redundant control system, Lindes

PSA units achieve virtually 100% on-stream

performance and availability.

Flexibility

Excellent flexibility to match actual clients

needs are achieved with Lindes PSA systems

as they are capable of providing a high degree

of flexibility to cope with feed gas conditions

and varying hydrogen demand.

Modular design and prefabricated equipment

Lindes high performance PSA systems are pre-

fabricated to a maximum extent. The valve skids

containing switching and control valves, instru-

mentation and interconnecting piping are com-

pletely prefabricated, preassembled and tested

prior to delivery. This design philosophy reduces

time and costs for erection and commissioning

on site to and absolute minimum.

Easy maintenance

Maintenance is limited to easy and quick rou-

tine actions which can be carried out by the

operators on site. Highest attention is given to

a proper accessibility of all valves and instru-

ments inside the valve skid. Assistance from

Linde is hence normally not required but is

certainly available at any time convenient to

client.

Two pressure swing adsorption units in Canada

7

The advantages.

Engineering Division head office:

Linde AG

Engineering Division

Pullach, Germany

Phone: +49.(0)89.7445-0

Fax: +49.(0)89.7445-4908

info@linde-le.com

H

A

/

H

1

.

1

.

e

/

0

9

Lindes Engineering Division continuously develops extensive process engineering know-how in the planning,

project management and construction of turnkey industrial plants.

The range of products comprises:

Petrochemical plants

LNG and natural gas processing plants

Synthesis gas plants

Hydrogen plants

Gas processing plants

Adsorption plants

Air separation plants

Cryogenic plants

Biotechnological plants

Furnaces for petrochemical plants and reneries

Linde and its subsidiaries manufacture:

Packaged units, cold boxes

Coil-wound heat exchangers

Plate-n heat exchangers

Cryogenic standard tanks

Air heated vaporizers

Spiral-welded aluminium pipes

Engineering Division headquarters:

Linde AG

Engineering Division, Dr.-Carl-von-Linde-Str. 6-14, 82049 Pullach, Germany

Phone +49.89.7445-0, Fax +49.89.7445-4908, E-Mail: info@linde-le.com, www.linde.com

More than 3,800 plants worldwide document the leading position of the Engineering Division in international plant construction.

Engineering Division

Schalchen Plant

Tacherting, Germany

Phone +49.8621.85-0

Fax +49.8621.85-6620

plantcomponents@linde-le.com

Linde-KCA-Dresden GmbH

Dresden, Germany

Phone +49.351.250-30

Fax +49.351.250-4800

lkca.dresden@linde-kca.com

Selas-Linde GmbH

Pullach, Germany

Phone +49.89.7447-470

Fax +49.89.7447-4717

selas-linde@linde-le.com

Cryostar SAS

Hsingue, France

Phone +33.389.70-2727

Fax +33.389.70-2777

info@cryostar.com

Linde CryoPlants Ltd.

Aldershot, Great Britain

Phone +44.1.252.3313-51

Fax +44.1.252.3430-62

info@linde-lcl.com

Linde Impianti Italia S.p.A.

Rome, Italy

Phone +39.066.5613-1

Fax +39.066.5613-200

r.tikovsky@lindeimpianti.it

Linde Kryotechnik AG

Pfungen, Switzerland

Phone +41.52.3040-555

Fax +41.52.3040-550

info@linde-kryotechnik.ch

Cryo AB

Gteborg, Sweden

Phone +46.3164-6800

Fax +46.3164-2220

gunnar.lenneras@cryo.aga.com

Linde Process Plants, Inc.

Tulsa, OK, U.S.A.

Phone +1.918.4771-200

Fax +1.918.4771-100

sales@lppusa.com

Selas Fluid Processing Corp.

Blue Bell, PA, U.S.A.

Phone +1.610.834-0300

Fax +1.610.834-0473

john.mcdermott@selasfluid.com

Linde Engenharia do Brasil Ltda.

Rio de Janeiro, Brazil

Phone +55.21.3545-2255

Fax +55.21.3545-2257

jaime.basurto@linde.com

Linde Process Plants (Pty.) Ltd.

Johannesburg, South Africa

Phone +27.11.490-0513

Fax +27.11.490-0412

lindepp@global.co.za

Linde-KCA Russia Branch

Moscow, Russia

Phone +7.495.646-5242

Fax +7.795.646-5243

dirk.westphal@linde-kca.com

Linde Arabian Contracting Co. Ltd.

Riyadh, Kingdom of Saudi Arabia

Phone +966.1.419-1193

Fax +966.1.419-1384

linde-ksa@linde-le.com

Linde Engineering Middle East LLC

Abu Dhabi, United Arab Emirates

Phone +971.2.4477-631

Fax +971.2.4475-953

linde@emirates.net.ae

Linde Engineering India Pvt. Ltd.

Vadodara, Gujarat, India

Phone +91.265.3056-789

Fax +91.265.2335-213

sales@linde-le.com

Linde Engineerig Far East, Ltd.

Seoul, South Korea

Phone +82.2789-6697

Fax +82.2789-6698

hanyong.lee@linde.com

Linde Engineering Division

Bangkok, Thailand

Phone +66.2636-1998

Fax +66.2636-1999

anuwat.krongkrachang@linde.com

Linde Engineering Co. Ltd.

Dalian, P.R. of China

Phone +86.411.39538-800

Fax +86.411.39538-855

jochen.nippel@lindeleh.com

Linde Engineering Co. Ltd.

Hangzhou, P.R. of China

Phone +86.571.87858-222

Fax +86.571.87858-200

hangzhou.leh@lindeleh.com

Linde Engineering Division

Beijing Representative Office

Beijing, P.R. of China

Phone +86.10.6437-7014

Fax +86.10.6437-6718

linde@public.bta.net.cn

Linde AG Taiwan Branch

Engineering Division

Taipei, Taiwan

Phone +886.2.2786-3131

Fax +886.2.2652-5871

bernhard.puerzer@linde-le.com

Linde Australia Pty. Ltd.

Chatswood N.S.W., Australia

Phone +61.29411-4111

Fax +61.29411-1470

willy.dietrich@linde.com.au

Designing Processes - Constructing Plants.

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Kyokushin Karate Complete GuideДокумент129 страницKyokushin Karate Complete Guidemalarem67% (3)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Ge Strategies For Protein PurificationДокумент167 страницGe Strategies For Protein PurificationSharif M Mizanur RahmanОценок пока нет

- Turbine Operation Manual 600 MW DongfangДокумент223 страницыTurbine Operation Manual 600 MW Dongfangkumar_ranjan_373% (11)

- Chicken Grill RecipeДокумент1 страницаChicken Grill RecipeSharif M Mizanur RahmanОценок пока нет

- History of Science Fullversion PDFДокумент70 страницHistory of Science Fullversion PDFSharif M Mizanur RahmanОценок пока нет

- Respiration HandoutДокумент9 страницRespiration HandoutSharif M Mizanur RahmanОценок пока нет

- Lectures 1-9 History and Philosophy of Science and TechnologyДокумент59 страницLectures 1-9 History and Philosophy of Science and TechnologyZaky IbenОценок пока нет

- BlackHoles Thorne StarmusДокумент10 страницBlackHoles Thorne StarmusSharif M Mizanur RahmanОценок пока нет

- 03 Practical ApplicationДокумент1 страница03 Practical ApplicationSharif M Mizanur RahmanОценок пока нет

- Diabetic Cooking RecipesДокумент43 страницыDiabetic Cooking Recipesmoro4500Оценок пока нет

- Tanning KnowlegeДокумент5 страницTanning KnowlegeAnwar SuliantoОценок пока нет

- Kyokushin TerminologieДокумент13 страницKyokushin TerminologieSharif M Mizanur RahmanОценок пока нет

- FISHYДокумент1 страницаFISHYSharif M Mizanur RahmanОценок пока нет

- Meraj and ScienceДокумент93 страницыMeraj and ScienceSharif M Mizanur RahmanОценок пока нет

- FISHYFRIEEДокумент1 страницаFISHYFRIEESharif M Mizanur RahmanОценок пока нет

- s40550 016 0045 3Документ9 страницs40550 016 0045 3Kate MaryОценок пока нет

- Recipe For HealthДокумент1 страницаRecipe For HealthSharif M Mizanur RahmanОценок пока нет

- Ethanolfromcornstarch PDFДокумент44 страницыEthanolfromcornstarch PDFDerrick Scott FullerОценок пока нет

- PRON 25 WordsДокумент1 страницаPRON 25 WordsSharif M Mizanur RahmanОценок пока нет

- Development of An ASPEN PLUSДокумент36 страницDevelopment of An ASPEN PLUSkiny81Оценок пока нет

- Ranna Khaddo O Pusti by Siddika Kabir Part 2 (p190-p309)Документ60 страницRanna Khaddo O Pusti by Siddika Kabir Part 2 (p190-p309)Sharif M Mizanur RahmanОценок пока нет

- Fakruddin Recipe BiryaniДокумент1 страницаFakruddin Recipe BiryaniSharif M Mizanur RahmanОценок пока нет

- CARFAX Vehicle History Report For This 2007 TOYOTA COROLLAДокумент6 страницCARFAX Vehicle History Report For This 2007 TOYOTA COROLLASharif M Mizanur RahmanОценок пока нет

- Recipetehari PDFДокумент153 страницыRecipetehari PDFSharif M Mizanur RahmanОценок пока нет

- Ranna Khaddo O Pusti by Siddika Kabir Part 1 (p50-p189)Документ73 страницыRanna Khaddo O Pusti by Siddika Kabir Part 1 (p50-p189)Sharif M Mizanur RahmanОценок пока нет

- Diabetic Cooking RecipesДокумент43 страницыDiabetic Cooking Recipesmoro4500Оценок пока нет

- Isoa Hea OMPASS - 2016 - 2017 PDFДокумент13 страницIsoa Hea OMPASS - 2016 - 2017 PDFSharif M Mizanur RahmanОценок пока нет

- Ranna Khaddo O Pusti by Siddika Kabir Part 4 (p430-p524)Документ48 страницRanna Khaddo O Pusti by Siddika Kabir Part 4 (p430-p524)Sharif M Mizanur Rahman0% (1)

- Ranna Khaddo O Pusti by Siddika Kabir Part 3 (p310-p429)Документ60 страницRanna Khaddo O Pusti by Siddika Kabir Part 3 (p310-p429)Sharif M Mizanur RahmanОценок пока нет

- U.S. Meat Goat Operations: Veterinary ServicesДокумент4 страницыU.S. Meat Goat Operations: Veterinary ServicesSharif M Mizanur RahmanОценок пока нет

- Energy Guide Refrig - 2265225Документ2 страницыEnergy Guide Refrig - 2265225Sharif M Mizanur RahmanОценок пока нет

- DVM S Technical Bulletins - DVM S System Refrigerant Pump Down Guideline PDFДокумент2 страницыDVM S Technical Bulletins - DVM S System Refrigerant Pump Down Guideline PDFDavid AlmeidaОценок пока нет

- Shohel Brothers: GMBH Neckar GermanyДокумент15 страницShohel Brothers: GMBH Neckar Germanyhasan shoaibОценок пока нет

- Handout For Training-TurbineДокумент30 страницHandout For Training-TurbineDibyajyoti NandaОценок пока нет

- Transient Thermal VibrationДокумент18 страницTransient Thermal VibrationJarot PrakosoОценок пока нет

- Steam Jet RefrigerationДокумент3 страницыSteam Jet RefrigerationSUMITОценок пока нет

- CSRAT-Y Air Cooled Chiller - R134aДокумент36 страницCSRAT-Y Air Cooled Chiller - R134aLeed ENОценок пока нет

- Goodman ss-gsz16Документ36 страницGoodman ss-gsz16nam nguyenОценок пока нет

- 9 Cooling SystemДокумент11 страниц9 Cooling SystemMehar Tariq GoheerОценок пока нет

- Thermal Fluid Heaters: 75,000 TO 40 MM BTU/HRДокумент16 страницThermal Fluid Heaters: 75,000 TO 40 MM BTU/HRRexx MexxОценок пока нет

- P&I Diagram Steam Boiler Plant With Standard EquipmentДокумент1 страницаP&I Diagram Steam Boiler Plant With Standard Equipmentrachman hardianОценок пока нет

- SSS Clutch ProjectДокумент4 страницыSSS Clutch ProjectMoustafa HelmyОценок пока нет

- Steam Blow PDFДокумент3 страницыSteam Blow PDFLIUJIFENGОценок пока нет

- Pfaudler Mixing SystemsДокумент6 страницPfaudler Mixing SystemstpchoОценок пока нет

- Pipe 100 Up (Dated - Docx Version 1Документ13 страницPipe 100 Up (Dated - Docx Version 1AjayBravoОценок пока нет

- Air Conditioning SystemsДокумент3 страницыAir Conditioning SystemsArman Ul NasarОценок пока нет

- Nibe GV HR110 Pliant 30 09 2013 enДокумент4 страницыNibe GV HR110 Pliant 30 09 2013 envaliОценок пока нет

- RBD PltuДокумент48 страницRBD Pltusugeng wahyudiОценок пока нет

- 1554 enДокумент1 страница1554 enBruno Alberto de SouzaОценок пока нет

- Ship Machineries: by Group 2Документ54 страницыShip Machineries: by Group 2Wilfred Joseph T. Casas100% (1)

- Ice Plant Visit Report 2019 PDF ThermalДокумент10 страницIce Plant Visit Report 2019 PDF ThermalMonuj BorahОценок пока нет

- Types and Applications of Overcurrent Relay 1Документ10 страницTypes and Applications of Overcurrent Relay 1Alfredo RamirezОценок пока нет

- Parts Diag. Syntia Class-Dgt Ita-Ing (Sup037dr) Rev.01Документ6 страницParts Diag. Syntia Class-Dgt Ita-Ing (Sup037dr) Rev.01sasizzo78Оценок пока нет

- 1A2. Circulating Fluidized Bed Combustion Technology (CFBC)Документ1 страница1A2. Circulating Fluidized Bed Combustion Technology (CFBC)kumarmm1234Оценок пока нет

- Instruction Manual FCGДокумент38 страницInstruction Manual FCGDennisОценок пока нет

- Technical Specifications For Solar PV System ComponentsДокумент5 страницTechnical Specifications For Solar PV System ComponentsNazeeh Abdulrhman AlbokaryОценок пока нет

- Huafengdongli 495 4100 Series Operationmanual PDFДокумент73 страницыHuafengdongli 495 4100 Series Operationmanual PDFSergio Ricardo IbañezОценок пока нет

- 100 KWP Solar Power Plant Technical Proposal PDFДокумент24 страницы100 KWP Solar Power Plant Technical Proposal PDFRabindra SinghОценок пока нет

- Annotated Bibliography-Solar EnergyДокумент6 страницAnnotated Bibliography-Solar Energyapi-355597172Оценок пока нет

- P&ID Symbols and Notation - LucidchartДокумент12 страницP&ID Symbols and Notation - Lucidchartajo zinzoОценок пока нет