Академический Документы

Профессиональный Документы

Культура Документы

Technical Delivery Conditions for Steel Fasteners

Загружено:

Dorota HO0 оценок0% нашли этот документ полезным (0 голосов)

122 просмотров5 страницThis document provides technical delivery conditions for steel intended for fasteners with enhanced requirements, as developed by the Deutscher Schraubenverband e.V. (DSV). It specifies restricted chemical compositions and mechanical properties for various steel types in greater detail than national and international standards. The document is reviewed annually and updated as needed. It includes tables listing 56 different steel types, their intended purposes, applicable standards, and chemical element restrictions to ensure suitable properties for fasteners. Additional requirements are outlined for rod, bar and wire dimensions, surfaces, and cold heading capabilities.

Исходное описание:

Оригинальное название

TL-DSV_2012-05_engl_Br-1

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документThis document provides technical delivery conditions for steel intended for fasteners with enhanced requirements, as developed by the Deutscher Schraubenverband e.V. (DSV). It specifies restricted chemical compositions and mechanical properties for various steel types in greater detail than national and international standards. The document is reviewed annually and updated as needed. It includes tables listing 56 different steel types, their intended purposes, applicable standards, and chemical element restrictions to ensure suitable properties for fasteners. Additional requirements are outlined for rod, bar and wire dimensions, surfaces, and cold heading capabilities.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

122 просмотров5 страницTechnical Delivery Conditions for Steel Fasteners

Загружено:

Dorota HOThis document provides technical delivery conditions for steel intended for fasteners with enhanced requirements, as developed by the Deutscher Schraubenverband e.V. (DSV). It specifies restricted chemical compositions and mechanical properties for various steel types in greater detail than national and international standards. The document is reviewed annually and updated as needed. It includes tables listing 56 different steel types, their intended purposes, applicable standards, and chemical element restrictions to ensure suitable properties for fasteners. Additional requirements are outlined for rod, bar and wire dimensions, surfaces, and cold heading capabilities.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 5

DEUTSCHER SCHRAUBENVERBAND e.V.

Technical delivery conditions for steel for

fasteners with enhanced requirements

revision 05/12

page 1/5

Scope and Field of Application

These delivery conditions have been developed by the members of the Deutscher

Schraubenverband e.V. (DSV). They shall lead to a decrease of the total number of types of

fastener steels used. For all steels listed in these delivery conditions enhanced requirements

compared to the actual national and international standards are specified. These delivery

conditions will be checked annually and, if necessary, updated by the corresponding working

group of the DSV.

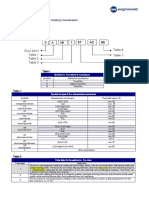

Ordering sample:

Steel DSV-TL (05/12) - 22 GKZ similar to steel DIN EN 10263-4 - 1.5535 GKZ

1 2 3 4 5 6 7

Purpose

Material

Steels not

intended for

heat

treatment

Case

harde-

ning

steels

Steels for

quenching

and

tempering

Steels for

high

tempe-

rature

applica-

tions

Steels for

low

tempe-

rature

applica-

tions

Stain-

less

steels

1 C10E X

2 C15E X X

11 C16E X

12 16MnCr5 X

13 C22 X

14 C22 + Mn X X

20 20MnB4 X X X

21 23MnB3 X X X

22 23MnB4 X X X

23 28B2 X

24 32CrB4 X

25 (35+38)B2 X X

26 36CrB4 X

27 30CrMoB1 X

31 (34+37)Cr4 X

32 34CrMo4 X

33 34CrNiMo6 X X

41 21CrMoV5-7 X

42 40CrMoV4-6 X

43 X21CrMoNiV12-1 X

44 X6NiCrTiMoVB25-15-2 X

51 X5CrNi18-10 X X

52 X3CrNiCu18-9-4 X X

53 X6CrNiTi18-10 X X

54 X5CrNiMo17-12-2 X X

55 X6CrNiMoTi17-12-2 X X

56 X3CrNiCuMo17-11-3-2 X X

DEUTSCHER SCHRAUBENVERBAND e.V.

Technical delivery conditions for steel for fasteners with enhanced requirements

revision 05/12

page 2/5

Currently valid standards for chosen steels

Standard Title Material

1 2 11 12 13 14 20 21 22 23 24 25 26 27 31 32 33 41 42 43 44 51 52 53 54 55 56

1 EN 10263 1

Steels for cold heading and cold extrusion

General

2 EN 10083 1 Quenched and temp. steels General

3 EN 10263 2

Unalloyed steel not intended for heat

treatment

X X

4 EN 10084 Case hardening steels X X X X

5 EN 10263 3 Case hardening steels X X X X X

6 EN 10083 2

Quenched and temp. steels unalloyed

quality steels

X X

7 EN 10083 3 Quenched and temp. steels boron steels X X X

8 EN 10263 4 Quenched and tempered steels X

X

1

)

X X X X X X X X

9 EN 10269

Steel and nickel alloys for fasteners for use at

elevated and / or low temperatures

X

2

)

X

2

)

X

2

)

X X X X X X X X X X

10 DIN 267 13

Parts for bolted connections with specific

mechanical properties

X X X X X X X X X

11 EN 1515-1 Flanges and their joints bolting X X X X X X X X

12 ISO 3506

Corrosion and acid resistant stainless steel

fasteners

X X X X X

13 EN 10088 Stainless steels X X X X X X

14 EN 10263 5 Stainless steels X X X X X

1)

Intended for EN 10263-4

2)

Intended for EN 10269

DEUTSCHER SCHRAUBENVERBAND e.V.

Technical delivery conditions for steel for

fasteners with enhanced requirements

Revision 05/12

page 3/5

Restricted chemical analysis of steels specified in EN 10263 and EN 10269

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

DSV Material

Analysis

Identification

C Si Mn P S Cr Mo Ni V Ti Al Cu B N

No.

% % % % % % % % % % % % ppm %

1

1.1122

C10E

0,08

0,12

-

0,10

0,30

0,60

-

0,025

-

0,025

0,02

-

-

0,25

2

1.1132

C15E

0,13

0,17

-

0,10

0,35

0,60

-

0,015

-

0,015

0,02

-

-

0,25

11

1.1148

C16E

0,14

0,18

-

0,15

0,70

0,90

-

0,015

-

0,015

-

0,25

12

1.7131

16MnCr5

0,15

0,19

-

0,15

1,10

1,30

-

0,015

-

0,015

0,95

1,10

-

0,25

13

1.1152

C22

0,20

0,24

-

0,15

0,40

0,60

-

0,015

-

0,015

-

0,25

14

(1.1152)

C22 + Mn

0,20

0,24

-

0,15

0,80

1,00

-

0,015

-

0,015

-

0,25

20

1.5525

20MnB4

0,18

0,23

-

0,15

0,90

1,10

-

0,015

-

0,015

-

0,10

-

0,10

-

0,06

0,02

0,06

-

0,25

8

50

b)

-

0,008

21

1.5507

23MnB3

0,21

0,25

-

0,15

0,80

1,00

-

0,015

-

0,015

0,25

0,35

C)

-

0,06

0,02

0,06

-

0,25

8

50

b)

22

1.5535

23MnB4

0,21

0,25

-

0,15

1,00

1,20

-

0,015

-

0,015

0,20

0,30

-

0,06

0,02

0,06

-

0,25

8

50

b)

23

1.5510

28B2

0,25

0,29

-

0,15

0,70

0,90

-

0,02

a)

-

0,015

0,15

0,30

-

0,06

0,02

0,06

-

0,25

8

50

b)

24

1.7076

32CrB4

0,30

0,34

-

0,15

0,70

0,90

-

0,02

a)

-

0,015

1,05

1,20

-

0,06

0,02

0,06

-

0,25

8

50

b)

25

1.5511

(35+38)B2

0,35

0,39

-

0,15

0,70

0,90

-

0,02

a)

-

0,015

0,15

0,30

-

0,06

0,02

0,06

-

0,25

8

50

b)

26

1.7077

36CrB4

0,34

0,38

-

0,15

0,70

0,90

-

0,02

a)

-

0,015

1,05

1,20

-

0,06

0,02

0,06

-

0,25

8

50

b)

27

---

30CrMoB1

0,28

0,32

-

0,15

0,80

1,10

-

0,015*

-

0,015

0,15

0,30

0,08

0,15

-

0,06

0,02

0,06

-

0,25

8

50

b)

31

1.7033 / 1.7034

(34+37)Cr4

0,34

0,37

-

0,15

0,70

0,90

-

0,02

a)

-

0,015

1,05

1,20

-

0,02

-

0,25

32

1.7220

34CrMo4

0,34

0,37

-

0,15

0,70

0,90

-

0,015

-

0,015

1,05

1,20

0,20

0,30

-

0,02

-

0,25

33

1.6582

34CrNiMo6

0,34

0,38

-

0,15

0,50

0,70

-

0,02

a)

-

0,015

1,55

1,70

0,15

0,30

1,40

1,70

-

0,02

-

0,25

41

1.7709

21CrMoV5-7

0,21

0,25

0,15

0,35

0,60

0,80

-

0,025

-

0,015

1,35

1,50

0,65

0,80

0,25

0,35

-

0,03

42

1.7711

40CrMoV4-7

0,40

0,44

0,15

0,35

0,60

0,80

-

0,025

-

0,015

1,05

1,20

0,60

0,75

0,25

0,35

-

0,015

43

1.4923

X21CrMoV12-1

0,20

0,24

0,10

0,50

0,60

0,80

-

0,025

-

0,015

11,0

12,5

0,80

1,20

0,30

0,80

0,25

0,35

44

1.4980

X6NiCrTiMoVB25-15-2

0,04

0,08

-

1,0

1,0

2,0

-

0,025

-

0,015

13,5

16,0

1,0

1,5

24,0

27,0

0,10

0,50

1,9

2,3

-

0,35

30

100

51

A2 1.4301

X5CrNi18-10

-

0,07

-

1,0

-

2,0

-

0,045

-

0,030

17,0

19,0

8,0

11,0

-

0,11

52

A2 1.4567

X3CrNiCu18-9-4

-

0,04

-

1,0

-

2,0

-

0,045

-

0,030

17,0

19,0

8,0

10,0

3,0

4,0

-

0,11

53

A3 1.4541

X6CrNiTi18-10

-

0,08

-

1,0

-

2,0

-

0,045

-

0,030

17,0

19,0

9,0

12,0

5xC

0,80

54

A4 1.4401

X5CrNiMo17-12-2

-

0,07

-

1,0

-

2,0

-

0,045

-

0,030

16,5

18,5

2,0

2,5

10,5

13,5

-

0,11

55

A5 1.4571

X6CrNiMoTi17-12-2

-

0,08

-

1,0

-

2,0

-

0,045

-

0,030

16,5

18,5

2,0

2,5

10,5

13,5

5xC

0,80

56

A4 1.4578

X3CrNiCuMo17-11-3-2

-

0,04

-

1,0

-

2,0

-

0,045

-

0,015

16,5

17,5

2,0

2,5

10,0

11,0

3,0

3,5

-

0,11

a)

In case of steels with DSV No. 23, 24, 25, 26, 31 or 33 a content of P 0,015% may be specified if

necessary

b)

The content of boron may reach 0,005% provided that the not effective boron is controlled by additives of

titanium and/or aluminium.

c)

Exceptions possible

DEUTSCHER SCHRAUBENVERBAND e.V.

Technical delivery conditions for steel for

fasteners with enhanced requirements

Revision 05/12

page 4/5

Additional properties of steel rods, bars and wires

1. Diameter and concentricity Wire rod Bar

Further treatment calibrated to be drawn --

Specified in DIN EN 10108 DIN EN 10017 DIN EN 10060

Acceptable deviation of the diameter

B A -- --

Acceptable out-of-roundness of the

cross section related to the permissible

deviation of the diameter

80 % 80 % 80 % 80 %

2. Surface Discontinuities

The surface properties of the wire shall meet the requirements of grade E as specified in EN

10221 and shall be free of discontinuities, which would cause the wire to burst if cold headed or

heat treated. This is to be proofed by cold heading tests. A cold heading relation of 4:1 (h

0

/d

0

= 2)

shall be used for annealed wires and a relation of 3:1 (h

0

/d

0

= 1,5) for unannealed wires.

3. Surface carbon condition

Four point decarburization measurement method, proceeding

from the point of deepest decarburization

range of decarburization

maximum value average value

10 mm 0.1 mm 0.075 mm

10 mm 1.00 % d 0.75 % d

For case hardened steels and quenched and tempered steels (including boron steels and steels

for high temperature applications, excluding C10 and austenitic steels) a carburization or total

decarburization is not acceptable, a partial decarburization up to the limits specified above. In

case of dispute the evaluation of decarburization depth shall be done by checking the hardness

HV0,3 according to DIN EN ISO 6507-1. In EN 10263-1:02-2002 the decarburization depth is

defined, as the distance between the surface and the nearest point on the hardness-curve, which

represents the 80% hardness of the not decarburized area.

According to DIN EN ISO 6507-1 the minimum distance between the surface and the hardness-

impression are 2.5-times the impression-diagonal; however the measuring points should be as

close as possible to the surface. In case the distance defined above is to short, the geometric

impression and the ratio of the length of the two diagonals shall be checked in order to avoid

measuring mistakes. The result is not valid if the difference of the length of the two diagonals,

related to the shorter diagonal, exceeds 5 %.

4. Inclusions Other steels Austenitic steels

Total-sumparameter

according to DIN 50 602

K3 20 K4 = 0

DEUTSCHER SCHRAUBENVERBAND e.V.

Technical delivery conditions for steel for

fasteners with enhanced requirements

Revision 05/12

page 5/5

Additional properties of steel rods, bars and wires

5. Grain size

Steels not intended for

heat treatment and case

hardened steels

Quenched and

tempered steels

Austenitic

steels

Grain size according to

DIN 50601, ISO 643

5 and finer 5 and finer not specified

6. Maximum amount of trace elements not specified in standards*

(Agreement between VDEh and VDA)

Cr Mo Ni V Ti Nb Al N Cu B As Sn Pb** O**

% % % % % % % % % ppm % % % %

-

0,30

-

0,08

-

0,30

-

0,05

-

0,01

-

0,03

-

0,060

-

0,015

-

0,25

-

8

-

0,04

-

0,02

-

0,04

-

0,004

* Does not apply for austenitic steels.

** Pb and O values for guidance only.

Former revision

01/99, 4/00, 8/00, 12/00, 11/03, 03/06

Updates

In comparison to revision 03/06, following changes have been made.

All pages updated to the latest revision 05/12.

On page 1 the ordering example was changed into Steel DSV-TL (05/12) - 22 GKZ

similar to steel DIN EN 10263-4 - 1.5535 GKZ and updated onto the latest revision of TL.

On page 2 DSV No. 20 has been added; for DSV No. 20-22 footnotes

1) and 2)

were added.

On page 3 the DSV No. 20 has been added.

On page 3 the material (19 +23)MnB4-1.5523 (DSV No. 22) has been deleted and has

been replaced by material 23MnB4-1.5535.

On page 3 the max. Al-content of all boron steels were reduced from 0.08% to 0.06%.

On page 3 the chromium content of DSV No. 021 has been defined as 0.25-0.35 and

footnote

C)

has been added.

On page 4 the references to the withdrawn standards DIN 59115, DIN 59110 and DIN

59130 were replaced by the references to the current standards DIN EN 10108,

DIN EN 10017 and DIN EN 10060.

On page 4 the standard EN 10263-1:2001 has been changed into EN 10263-1:02-2002.

The note on page 5 has been deleted.

Вам также может понравиться

- LIBRO3Документ43 страницыLIBRO3Camilo LacoutureОценок пока нет

- Maleable Cast IronsДокумент0 страницMaleable Cast IronsGilang Miky Pratama AlwianОценок пока нет

- 2370 Ed1 ENДокумент5 страниц2370 Ed1 ENanhthoОценок пока нет

- Material Definitions & TermsДокумент3 страницыMaterial Definitions & TermsDr_M_SolimanОценок пока нет

- En 10088 Steel NumberДокумент3 страницыEn 10088 Steel Numberrvieira659Оценок пока нет

- Steel Grades and Standards ChartДокумент2 страницыSteel Grades and Standards Chartewva12Оценок пока нет

- An Investigation On The Weldability of Grey Cast Iron Using Nickel Filler MetalДокумент5 страницAn Investigation On The Weldability of Grey Cast Iron Using Nickel Filler MetalKhin Aung ShweОценок пока нет

- Nisshin Cold-Rolled Special Steel GuideДокумент28 страницNisshin Cold-Rolled Special Steel GuideekopujiantoeОценок пока нет

- Chinese To DinДокумент7 страницChinese To DinDamla KaymakçıОценок пока нет

- 304 DDQ SpecificationДокумент1 страница304 DDQ Specificationdac_angelovОценок пока нет

- Sa 351Документ6 страницSa 351Anil0% (1)

- Ford-WSS-M1A365-A11A23 - (2017-09) - (Steel-CR-HR-Low Carbon) 9pgДокумент9 страницFord-WSS-M1A365-A11A23 - (2017-09) - (Steel-CR-HR-Low Carbon) 9pgdpfloresОценок пока нет

- En 10139Документ2 страницыEn 10139releone11Оценок пока нет

- En 10164-2005 PDFДокумент15 страницEn 10164-2005 PDFUmut HızırОценок пока нет

- Aluminium - Specifications, Properties, Classifications and Classes, Supplier Data by AalcoДокумент2 страницыAluminium - Specifications, Properties, Classifications and Classes, Supplier Data by Aalcowongtathong1987Оценок пока нет

- LCM ValvesДокумент40 страницLCM ValvesAlexa Harper100% (1)

- ISO 15510 - Part 1Документ5 страницISO 15510 - Part 1Zdenko MahacekОценок пока нет

- Sa 426Документ6 страницSa 426Widya widyaОценок пока нет

- BS en 10215-1995 (1999)Документ16 страницBS en 10215-1995 (1999)Federico De Martini0% (1)

- 18 Ni CR Mo 5Документ2 страницы18 Ni CR Mo 5lavius_mОценок пока нет

- Astm E10 2001 PDFДокумент9 страницAstm E10 2001 PDFSofiaJabadanEspulgarОценок пока нет

- Automotive Gray Iron Castings: Standard Specification ForДокумент5 страницAutomotive Gray Iron Castings: Standard Specification ForJosé Ramón GutierrezОценок пока нет

- EN 760 (Flux-SAW)Документ2 страницыEN 760 (Flux-SAW)HoangОценок пока нет

- Astm e 2218 - 02Документ15 страницAstm e 2218 - 02Jaime Rafael Patron PrioloОценок пока нет

- Voestalpine Heavy Plate TTD DUROSTAT E 10042015Документ16 страницVoestalpine Heavy Plate TTD DUROSTAT E 10042015Ella Byla SaraОценок пока нет

- ASTM A802!A802M - 95 (Reapproved 2010) - STD Practice For Steel Castings Surface Acceptance STD & Visual ExaminationДокумент3 страницыASTM A802!A802M - 95 (Reapproved 2010) - STD Practice For Steel Castings Surface Acceptance STD & Visual ExaminationJoe ScopeliteОценок пока нет

- Steel grade 1.2312 propertiesДокумент4 страницыSteel grade 1.2312 propertiesFrancisco CarrascoОценок пока нет

- A319Документ2 страницыA319malika_000% (1)

- En Iso 377: Steel and Steel Products - Location and Preparation of Samples and Test Pieces For Mechanical TestingДокумент29 страницEn Iso 377: Steel and Steel Products - Location and Preparation of Samples and Test Pieces For Mechanical TestingKarol WalczykОценок пока нет

- ISO 1302 DIN 4768 Comparison of Surface Roughness Values Stainless Steel T PDFДокумент2 страницыISO 1302 DIN 4768 Comparison of Surface Roughness Values Stainless Steel T PDFWega Wahyu100% (2)

- ISO - TC 17 - SC 11 - Steel CastingsДокумент2 страницыISO - TC 17 - SC 11 - Steel CastingsNilesh MistryОценок пока нет

- Geomet 500 PDFДокумент2 страницыGeomet 500 PDFKaran Chadha100% (1)

- En 10029 PDFДокумент1 страницаEn 10029 PDFJan AmersfОценок пока нет

- Temper Embrittlement - J and X FactorДокумент2 страницыTemper Embrittlement - J and X Factorgovimano100% (2)

- MINEX Metallurgical CoДокумент41 страницаMINEX Metallurgical CoPriyank SamagraОценок пока нет

- C45 STD PDFДокумент2 страницыC45 STD PDFJeetu GosaiОценок пока нет

- Supraform S315-700 MC / EN10149-2 S315-700 MC: Hot Rolled High Strength Low Alloy Structural Steel CoilДокумент2 страницыSupraform S315-700 MC / EN10149-2 S315-700 MC: Hot Rolled High Strength Low Alloy Structural Steel CoilHugo RodriguezОценок пока нет

- Iso 683-2-2016 2Документ7 страницIso 683-2-2016 2Saju ShajuОценок пока нет

- Iso 683 1 2012Документ13 страницIso 683 1 2012Haluk TOKGÖZОценок пока нет

- Duplex Stainless Steel 329 Round Bars ManufacturerДокумент2 страницыDuplex Stainless Steel 329 Round Bars Manufacturertien100% (1)

- RJR PMMTДокумент16 страницRJR PMMTArun PrasadОценок пока нет

- 701 Steel InclusionRating DIN-50602Документ1 страница701 Steel InclusionRating DIN-50602ksathisОценок пока нет

- 26-ELKEM Poster-Graphite Structures in Cast IronsДокумент1 страница26-ELKEM Poster-Graphite Structures in Cast IronsHOSSIENОценок пока нет

- ISO 3755 Cast-Carbon-Steel-General-Engineering-PurposesДокумент9 страницISO 3755 Cast-Carbon-Steel-General-Engineering-PurposesLe Van TamОценок пока нет

- Metric Dowel PinsДокумент1 страницаMetric Dowel PinsAbhijeet MitraОценок пока нет

- Material Data Sheet en Aw 6082 Almgsi1Документ1 страницаMaterial Data Sheet en Aw 6082 Almgsi1pankajrs.mechengineer4502Оценок пока нет

- Iso 7452 2013 en PDFДокумент8 страницIso 7452 2013 en PDFfahmi aballiОценок пока нет

- Equivalent Grades of Gray IronДокумент2 страницыEquivalent Grades of Gray Ironsujay13780100% (1)

- IBR 73-80 Steel CastingsДокумент5 страницIBR 73-80 Steel CastingsRajivharolikarОценок пока нет

- SP1Документ25 страницSP1mugu12Оценок пока нет

- Disc Springs To Din 2093: Outside Dia. D I II III IV OMДокумент1 страницаDisc Springs To Din 2093: Outside Dia. D I II III IV OMstrijelavremenaОценок пока нет

- Din en 10132-4Документ14 страницDin en 10132-4Guilherme MendesОценок пока нет

- Continuously Hot-Rolled Low Carbon Steel Sheet and Strip For Cold FormingДокумент12 страницContinuously Hot-Rolled Low Carbon Steel Sheet and Strip For Cold FormingudayОценок пока нет

- Material Identification NumbersДокумент2 страницыMaterial Identification Numbersrajatapc12007Оценок пока нет

- As 2197-1978 Method For The Micrographic Assessment of The Non-Metallic Inclusion Content in Wrought SteelДокумент6 страницAs 2197-1978 Method For The Micrographic Assessment of The Non-Metallic Inclusion Content in Wrought SteelSAI Global - APAC0% (1)

- MIL-SPEC ARMOR STEEL PLATEДокумент39 страницMIL-SPEC ARMOR STEEL PLATEgman5900Оценок пока нет

- Dsc-Disc Springs To DIN 2093 UsДокумент6 страницDsc-Disc Springs To DIN 2093 UsYoe NoesОценок пока нет

- Outokumpu Supra Range DatasheetДокумент12 страницOutokumpu Supra Range DatasheetMichelОценок пока нет

- Forging PDFДокумент18 страницForging PDFhrh_pogcОценок пока нет

- Stress DeviceДокумент7 страницStress DeviceDorota HOОценок пока нет

- Ottawa RulesДокумент7 страницOttawa RulesDorota HOОценок пока нет

- Maisonneuve Fracture - Fajny Opis WięzozrostuДокумент6 страницMaisonneuve Fracture - Fajny Opis WięzozrostuDorota HOОценок пока нет

- Brochure Ef SchoolДокумент2 страницыBrochure Ef SchoolperulapiaОценок пока нет

- Foundation Practice Exam Questions 5Документ11 страницFoundation Practice Exam Questions 5Dr CoolzОценок пока нет

- 04 - Motion in Two DimensionДокумент3 страницы04 - Motion in Two DimensionMathan KalyanasundaramОценок пока нет

- EI 6702-Logic and Distributed Control SystemДокумент2 страницыEI 6702-Logic and Distributed Control SystemMnskSaro50% (2)

- 2755 22 (G78A) Milwaukee PBДокумент2 страницы2755 22 (G78A) Milwaukee PBZeckОценок пока нет

- Ups Installation and Maintenance ManualДокумент141 страницаUps Installation and Maintenance ManualMuntasir100% (1)

- Agilent GSMДокумент74 страницыAgilent GSMShashank PrajapatiОценок пока нет

- 1724 Albany, Ferndale, MI - Updated, Spacious BungalowДокумент8 страниц1724 Albany, Ferndale, MI - Updated, Spacious BungalowTodd Waller Real EstateОценок пока нет

- UOP046-85 Wax Content in Petroleum OilsДокумент6 страницUOP046-85 Wax Content in Petroleum OilsZiauddeen Noor100% (1)

- Ignition Characteristics of Cracked JP-7 FuelДокумент4 страницыIgnition Characteristics of Cracked JP-7 Fuelfahrul3xОценок пока нет

- As 2773.2-1999 Ultrasonic Cleaners For Health Care Facilities BenchtopДокумент8 страницAs 2773.2-1999 Ultrasonic Cleaners For Health Care Facilities BenchtopSAI Global - APAC0% (1)

- AGAR ID 200 Series Brochure LowRes Electronic and WebДокумент2 страницыAGAR ID 200 Series Brochure LowRes Electronic and WebYareli de la CruzОценок пока нет

- Dynamometer - 1Документ3 страницыDynamometer - 1Vishal BhattОценок пока нет

- Using The IVM With Linux On PowerДокумент40 страницUsing The IVM With Linux On Powersurajit_choudhuryОценок пока нет

- Loop Back DSP Audio AppДокумент12 страницLoop Back DSP Audio AppGytis BernotasОценок пока нет

- IES 2012 Exam Civil Engineering Paper II Solved With Answer KeyДокумент21 страницаIES 2012 Exam Civil Engineering Paper II Solved With Answer KeyPratik Nayak0% (2)

- DLC3 Yaris 2016Документ3 страницыDLC3 Yaris 2016kurnia wanОценок пока нет

- The Writer Is A Young Boy Who Is Taken To The Railway Station To See Soldiers Departing For The Second World WarДокумент2 страницыThe Writer Is A Young Boy Who Is Taken To The Railway Station To See Soldiers Departing For The Second World WarFariha RahmanОценок пока нет

- Fuel Pressure Regulator - Remove and InstallДокумент3 страницыFuel Pressure Regulator - Remove and InstallGerardo VelazquezОценок пока нет

- FC100 ServiceManual MG90L102Документ209 страницFC100 ServiceManual MG90L102Said BoubkerОценок пока нет

- 1000100en Image LD DidacticДокумент12 страниц1000100en Image LD DidacticUditha MuthumalaОценок пока нет

- GNB Absoltye IIPДокумент18 страницGNB Absoltye IIPFederico Tellez QОценок пока нет

- Re 29037Документ12 страницRe 29037BorisОценок пока нет

- Checklist for Training Cleaning StaffДокумент1 страницаChecklist for Training Cleaning StaffharrydrivesucrazyОценок пока нет

- Type 3025 Sizes P462, P460-200 and P900 Diaphragm Actuator: Bulletin 61.1:3025Документ8 страницType 3025 Sizes P462, P460-200 and P900 Diaphragm Actuator: Bulletin 61.1:3025Datt NguyenОценок пока нет

- STG SiemensДокумент2 страницыSTG SiemensjoncperezОценок пока нет

- MiPs View ManualДокумент53 страницыMiPs View ManualClOudyo VirgílioОценок пока нет

- Anna University International Admissions GuideДокумент4 страницыAnna University International Admissions GuideAmir AzeezОценок пока нет

- Design and Safety Handbook 3001.5Документ51 страницаDesign and Safety Handbook 3001.5phankhoa83Оценок пока нет

- Prestige Bella VistaДокумент27 страницPrestige Bella VistaArun RajagopalОценок пока нет