Академический Документы

Профессиональный Документы

Культура Документы

Application Guide For Epoxy Grouts

Загружено:

amitkap00r0 оценок0% нашли этот документ полезным (0 голосов)

38 просмотров4 страницыc

Оригинальное название

Application Guide for Epoxy Grouts

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документc

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

38 просмотров4 страницыApplication Guide For Epoxy Grouts

Загружено:

amitkap00rc

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 4

PARCHEM CONCRETE REPAIR FLOORING JOINTING SYSTEMS WATERPROOFING

TECHNICAL DATA SHEET MARCH 2014

www.parchem.com.au 7 Lucca Road, Wyong NSW 2259 Phone 1300 737 787 ABN 80 069 961 968 1

Application Guide

Conbextra Epoxy Grouts

Installing Conbextra Epoxy Grouts

APPLICATION OF CONBEXTRA EPOXY GROUTS

INSTALLING CONBEXTRA GROUTS

The following information is provided as a guide to typical

grouting of machine bases. If any doubt exists on site

regarding the product or process being used it is important

that consultation with all parties involved takes place and

then proceed with an agreed plan.

PREPARATION OF THE FOUNDATION

The concrete foundation or plinth on to which we are

grouting our machine or similar will generally have been

cast weeks before the grouting is to take place. A minimum

28 days (4 weeks) curing should be allowed unless special

concrete mixes are being used.

Remove the laitance layer from the surface of the cured

concrete. This is a weak layer which could affect the bond

strength to the foundation. It is critical that the laitance

layer is removed without damaging the concrete below.

The end result should be a surface showing around 50%

clean aggregate with no dust or loose material evident.

Scabblers and Chipping guns are very effective methods of

preparation. When using the correct multi-point heads,

these machines produce a sufficiently low impact force

which will not disrupt the aggregate in the concrete but

easily removes the cement matrix. Small hand units are

available and larger units for larger areas.

Captive Blast machines are very effective for preparing

large areas. These machines are adjustable to meet most

concrete strength and depth of removal required.

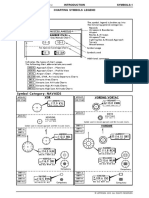

MACHINE / BASEPLATE INSTALLATION

The baseplate will first be positioned

and levelled to the required height

leaving a gap to be grouted.

Following are several leveling

methods commonly used on site.

Threaded bolt with 2 nuts - this is a

common way to level small

baseplates in non-critical applications.

The lower nut under the baseplate

can be adjusted up or down to suit

and the top not is tightened to sandwich the baseplate

into position. This method is NOT recommended as after

grouting, the weight of the machine is still resting mostly

on the lower nut and the threaded bolt; post-tensioning is

impossible (tightening the top not just squashes the

baseplate without tensioning it down)

Metal shim plates - a common process used to level large

equipment. The machine is lifted and thin metal shims are

placed under the baseplate on to the concrete foundation and

the machine lowered on to the shims however unless the

shims are removed after grouting, they will (like the bolt and

2 nuts) bear most of the weight; post tensioning is not possible

unless the shims are removed.

Levelling Screws (Bolts) - the best method. Threaded holes

are made through the baseplate; bolts are threaded into these

holes from the top and the tip of the bolt rests on metal pads

positioned on the foundation. The bolts are turned up or down

to achieve the correct level of the machine; the grout installed

and when hard enough the bolts can be backed out of the

threaded holes leaving only the grout to support the weight

of the machine. One of the things to make this process a

success is to isolate the thread of the leveling bolts from

adhering to the grout (especially resin grouts) - this can be

achieved with petrolatum tape or rubber tubing around the

bolt.

Typical levelling screw arrangement

ANCHOR BOLTS

It is common practice for anchor bolt / holding down bolts

to be grouted into preformed pockets as part of the grouting

process. Epoxy resin based grouts or specialist anchoring

products are best for this as they have greater bond

strength and tensile strength than typical cement based

grouts.

2

Conbextra Epoxy Grouts

It is important that the filling of the anchor pockets is done

as a separate process to the general grout application to

ensure the anchor pockets are filled without entrapping air.

If cement based grouts are being used for anchoring then

the anchor pocket must be pre-soaked with water for at

least 2 hours (preferably 24 hours) and the water vacuumed

out just prior to the grout being placed. The anchor holes

must also be undercut (tapered) or rough sided to provide

mechanical resistance to pulling out. This is also the case

when using polyester resin based anchoring systems which

have limited bond strength and are prone to shrinkage.

Depending on the particular application and engineering

requirements, there may be a requirement for the anchor

bolts to be isolated from the grout and even from part

length of the anchor material to allow for free stretch in the

bolt when tensioned at the end of the installation. This can

be achieved using foam pipe insulation or petrolatum

wrapping tape or similar. Refer to the relevant design

requirement on site.

FORMWORK

Epoxy resin based grouts are installed as fluid or flowable

consistencies. The grout should be flowed in a single pass

from one side of the baseplate to the other ideally across

the smaller dimension. The most common arrangement is a

header box on one side into which the grout will be poured,

lateral formwork against the baseplate to direct the flow

and maintain the head of pressure and the exit form which

allows the progress of the grout to be monitored. For large

pours it may be necessary to construct a moveable header

box which can be moved along the length of the pour or

have several header boxes and simultaneously pour the

grout in. NEVER attempt to pour grout from more than one

side unless the pour has been well planned with air relief

holes positioned in the baseplate.

Formwork materials it is important that once the installed

grout has set that any formwork can be easily removed

without damaging the grout. Good quality new form-ply

can generally used for based grouts however to minimise

the grout from sticking to the formwork a thin application of

a wax compound should be used. A suitable product for

this is wax floor paste which is rubbed on to the formwork

taking care not to contaminate the foundation or baseplate.

Liquid wax compounds should not be used as they may run

and contaminate the concrete.

When it does come time to remove the formwork use a

gentle tapping action to protect the fresh grout which may

still be relatively weak.

The following drawings are examples of formwork set ups

when installing flowable / fluid grouts. There may be

variations of these required on site depending on the actual

configuration and shape of the situation but the basic

principle remains, which is, to flow the grout via a header

box on one side, under the baseplate in one flow to the

opposite side.

Typical grout formwork set up

Typical lateral formwork arrangement

PRE-SOAKING THE SUBSTRATE

This only applies to cement based grouts do NOT pre-

soak when using resin based grouts.

MIXING

Correct mixing of the grout is critical to the success of the

total job. Sufficient man power and suitable equipment is

essential.

Temperature considerations - All grouts should be stored at

suitable temperatures typically above 10

o

C and below

30

o

C; ideal conditions are at 23

o

C. This not only protects the

shelf life of the product but also improves the mixing and

placement properties of the products.

Conbextra Epoxy Grouts are supplied in convenient size kits

of base component and hardener component. Full kits must

always be mixed as supplied - DO NOT attempt to mix part

kits. The mix ratio is critical to the performance of the cured

grout.

3

Conbextra Epoxy Grouts

Make sure the drum is secure before the mixing process

begins. With suitable equipment begin mixing the base

component first to help re-incorporate any settlement;

slowly add all the hardener component while continuing to

mix; at the lowest setting possible (setting 1 for the Protool

MXP 1602 E) once all the hardener is poured in continue to

mix for a further 3 minutes taking care to mix product from

around the sides and bottom of the containers. Scraping

down the mixer and sides of the container half way through

the mixing is a good idea. Ensure the paddle is fully

immersed in the grout whilst mixing. Do not pull the paddle

up and down whilst mixing. By following these two points

will help minimise the entrapment of air

Mixing should be monitored with a stopwatch / clock to

ensure sufficient mixing time is achieved.

Mixing equipment - When mixing one kit at a time the

Protool MXP 1602 E drill (product code: TT-6219141) or

equivalent is recommended with the Protool MXP 1602 E

mixing paddle (product code: TT614217) or equivalent. For

large pours a purpose made grout pump can be used such

as a diaphragm pump.

PLACEMENT

Baseplates should be grouted by forming up the area and

pouring or pumping the grout into place. When flowing a

grout under a baseplate it should be done in one

continuous pour action, from one side only, until the grout

emerges from under the baseplate on the opposite side.

This helps ensure any air is expelled and there should be

complete contact of the grout and the entire underside of

the baseplate. During this process it is acceptable to gently

rod the grout or use flexible strapping to help the flow

however using the correct consistency epoxy grout will

minimise the need for this. Vibrators should never be used.

Pumping grouts through injection ports in a baseplate is

possible providing it is well planned to ensure air pockets

are not created. Pumping grout under baseplates

horizontally is also acceptable; the hose should be inserted

to the farthest point under the baseplate and slowly

withdrawn as the grout is pumped in. This can also be a

useful procedure to complete a failed grout pour where the

initial grout pour has failed to reach to opposite side for

some reason.

CURING AND PROTECTION

The baseplate along with the grout should also be

protected as much as possible from extremes in weather

both hot and cold. Large volume pour of epoxy based

grouts can generate significant heat from exothermic

reaction insulation from sudden cold temperature should

be considered.

4

PARCHEM CONCRETE REPAIR FLOORING JOINTING SYSTEMS WATERPROOFING

TECHNICAL DATA SHEET MARCH 2014

www.parchem.com.au 7 Lucca Road, Wyong NSW 2259 Phone 1300 737 787 ABN 80 069 961 968

Conbextra Epoxy Grouts

ADDITIONAL INFORMATION

Parchem provides a wide range of complementary products

which include:

n concrete repair cementitious and epoxy

n grouts and anchors cementitious and epoxy

n waterproofing membranes liquid applied,

cementitious and bituminous sheet membranes

n waterstops pvc and swellable

n joint sealants building, civil and chemical resistant

n industrial flooring systems cementitious and

epoxy

n architectural coatings

n filler boards swellable cork, bituminous and

backing rod

n ancillary products

For further information on any of the above, please consult

with your local Parchem sales office.

IMPORTANT NOTICE

A Material Safety Data Sheet (MSDS) and Technical Data Sheet

(TDS) are available from the Parchem website or upon request

from the nearest Parchem sales office. Read the MSDS and

TDS carefully prior to use as application or performance data

may change from time to time. In emergency, contact any

Poisons Information Centre (phone 13 11 26 within Australia)

or a doctor for advice.

PRODUCT DISCLAIMER

This Application Guide summarises our best knowledge of the

product, including how to use and apply the product based on the

information available at the time. You should read this all literature

carefully and consider the information in the context of how the

product will be used, including in conjunction with any other product

and the type of surfaces to, and the manner in which, the product will

be applied. Our responsibility for products sold is subject to our

standard terms and conditions of sale. Parchem does not accept any

liability either directly or indirectly for any losses suffered in

connection with the use or application of the product whether or not

in accordance with any advice, specification, recommendation or

information given by it.

*Manufactured and sold under license from Fosroc International

Limited. Fosroc and the Fosroc logo are trade marks of Fosroc

International Limited, used under license. *Denotes a trade mark of

Fosroc International Limited.

Вам также может понравиться

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Question Bank of PWay Engineering For TMO TRACK MACHINEДокумент28 страницQuestion Bank of PWay Engineering For TMO TRACK MACHINEamitkap00rОценок пока нет

- Construction MaterialДокумент9 страницConstruction Materialamitkap00rОценок пока нет

- Management of Engineering Stores GeneralДокумент4 страницыManagement of Engineering Stores Generalamitkap00rОценок пока нет

- Importance of Bond in RCCДокумент23 страницыImportance of Bond in RCCamitkap00rОценок пока нет

- 2021 - 09 - 06 RBCE - CE-I-CT Change of Base Year of Consumer Price Index of Industrial Workers (Labour Index)Документ3 страницы2021 - 09 - 06 RBCE - CE-I-CT Change of Base Year of Consumer Price Index of Industrial Workers (Labour Index)amitkap00rОценок пока нет

- Hydraulics & HydrologyДокумент4 страницыHydraulics & Hydrologyamitkap00rОценок пока нет

- General KnowledgeДокумент36 страницGeneral Knowledgeamitkap00rОценок пока нет

- Strength of Materials, Structural Design & DrawingsДокумент24 страницыStrength of Materials, Structural Design & Drawingsamitkap00rОценок пока нет

- SURVEYINGДокумент29 страницSURVEYINGamitkap00rОценок пока нет

- Foundation & Construction EngineeringДокумент20 страницFoundation & Construction Engineeringamitkap00rОценок пока нет

- Reaffirmed 2002Документ14 страницReaffirmed 2002amitkap00rОценок пока нет

- Lowgradegypsum-Useinbuilding - ., - Industry-Codeofpractice 0 T ,' - VRM"RSДокумент7 страницLowgradegypsum-Useinbuilding - ., - Industry-Codeofpractice 0 T ,' - VRM"RSamitkap00rОценок пока нет

- IndexДокумент1 страницаIndexamitkap00rОценок пока нет

- Tax Information: Collecting CustomerДокумент2 страницыTax Information: Collecting Customeramitkap00rОценок пока нет

- 6508Документ6 страниц6508amitkap00rОценок пока нет

- Annexure Classification of ServicesДокумент20 страницAnnexure Classification of Servicesamitkap00rОценок пока нет

- t2 Lounges SydneyДокумент10 страницt2 Lounges Sydneyamitkap00rОценок пока нет

- Reaffirmed 2002Документ9 страницReaffirmed 2002amitkap00rОценок пока нет

- Reaffirmed 2005Документ12 страницReaffirmed 2005amitkap00rОценок пока нет

- Preparationandusbof Ltm-E-Pozzolana Mixtureconcrete Inbuildingsandroads-Code Ofpractice (Документ11 страницPreparationandusbof Ltm-E-Pozzolana Mixtureconcrete Inbuildingsandroads-Code Ofpractice (amitkap00rОценок пока нет

- 3564Документ13 страниц3564amitkap00rОценок пока нет

- Reaffirmed 2001Документ15 страницReaffirmed 2001amitkap00rОценок пока нет

- Indian Standard 58.x: Specification For Drawer .Loc&, I.: 5..:, Cupbcfard Locksand Box Locks 4 .-! IДокумент21 страницаIndian Standard 58.x: Specification For Drawer .Loc&, I.: 5..:, Cupbcfard Locksand Box Locks 4 .-! Iamitkap00rОценок пока нет

- Reaffirmed 2000Документ15 страницReaffirmed 2000amitkap00rОценок пока нет

- Reaffirmed 2001Документ18 страницReaffirmed 2001amitkap00rОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5795)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1091)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- pLINES Datasheet FP V2.22Документ2 страницыpLINES Datasheet FP V2.22TrinhDinhLoc0% (1)

- Institute of Technology & Engineering, Malegaon BK.: Lesson Teaching Plan (LTP)Документ3 страницыInstitute of Technology & Engineering, Malegaon BK.: Lesson Teaching Plan (LTP)Pramod DhaigudeОценок пока нет

- Project On RaymondДокумент36 страницProject On Raymonddinesh beharaОценок пока нет

- Uncoated SteelДокумент2 страницыUncoated SteelBui Chi TamОценок пока нет

- 825P A Rele E3000Документ4 страницы825P A Rele E3000asssasas100% (1)

- Aerocore PropertiesДокумент2 страницыAerocore PropertieskflimОценок пока нет

- 101 Pond Tips and Tricks (Pond Armor)Документ25 страниц101 Pond Tips and Tricks (Pond Armor)Tom MattauschОценок пока нет

- 5 Axis Generic PostДокумент68 страниц5 Axis Generic Postwidya90% (10)

- Jeppesen Charts LegendsДокумент34 страницыJeppesen Charts LegendsFatih OguzОценок пока нет

- Load Calculation JowharДокумент6 страницLoad Calculation JowharKhalid Abdirashid AbubakarОценок пока нет

- Microsoft PowerPoint - ASEP - NSCP 2015 Chapter6 - WOODДокумент75 страницMicrosoft PowerPoint - ASEP - NSCP 2015 Chapter6 - WOODRay Ramilo67% (9)

- MP-20x Datasheet 1Документ2 страницыMP-20x Datasheet 1Francisco MoragaОценок пока нет

- BME Joining ProcessesДокумент11 страницBME Joining ProcessesalysonmicheaalaОценок пока нет

- BioStrength ServiceExcite Loader Manual - 8.0Документ10 страницBioStrength ServiceExcite Loader Manual - 8.0powerliftermiloОценок пока нет

- Certification - Speech Testing - Assistant PartnersДокумент2 страницыCertification - Speech Testing - Assistant PartnersRodrigo Freire BragaОценок пока нет

- Sigmazinc 109 HS: Description Principal CharacteristicsДокумент4 страницыSigmazinc 109 HS: Description Principal CharacteristicsАлексейОценок пока нет

- Reference Jica-Chodai Scouring Manual in ThailandДокумент175 страницReference Jica-Chodai Scouring Manual in ThailandSeptinurriandianiОценок пока нет

- List of Accredited Service Center - ProtechДокумент1 страницаList of Accredited Service Center - ProtechLarryMatiasОценок пока нет

- CFRD 05 - BayardoДокумент23 страницыCFRD 05 - BayardodiegofernandodiazsepОценок пока нет

- ASSEMBLY AND PARTS ALBUM - Kipor Power Systems - KDE6700TA PDFДокумент2 страницыASSEMBLY AND PARTS ALBUM - Kipor Power Systems - KDE6700TA PDFracsoОценок пока нет

- Certificate of Analysis: CertificationДокумент2 страницыCertificate of Analysis: CertificationGunawan Alim CahyoОценок пока нет

- Penawaran Fility-70 Lebar 9 - ArmayaДокумент2 страницыPenawaran Fility-70 Lebar 9 - ArmayaSketchUp panduanОценок пока нет

- The Radio ClubДокумент7 страницThe Radio ClubDom CasualОценок пока нет

- Fpcroute User GuideДокумент34 страницыFpcroute User GuideJosé EireneОценок пока нет

- H 012200 Barame Sho Man 2Документ2 страницыH 012200 Barame Sho Man 2Obande OrinyaОценок пока нет

- QUEST M3s Coffee Roaster-110V (Semi-Direct Fire Semi-Hot Air)Документ7 страницQUEST M3s Coffee Roaster-110V (Semi-Direct Fire Semi-Hot Air)portfoliographyОценок пока нет

- Difference Between Dictionary Managed Tablespace (DMT) and Locally Managed Tablespace (LMT)Документ2 страницыDifference Between Dictionary Managed Tablespace (DMT) and Locally Managed Tablespace (LMT)Rose MaОценок пока нет

- Klauke - Bi-Metal Lugs & ConnectorsДокумент6 страницKlauke - Bi-Metal Lugs & ConnectorsBiplab PaulОценок пока нет

- Ampeg BA115HPTДокумент3 страницыAmpeg BA115HPTFederico BrunoОценок пока нет

- Dominion EnergyShareДокумент2 страницыDominion EnergyShareMichelle HuynhОценок пока нет