Академический Документы

Профессиональный Документы

Культура Документы

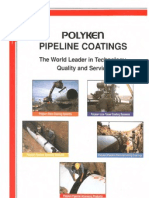

Polyken Utility Tape 900 910 908 911 920

Загружено:

Tracy EvansИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Polyken Utility Tape 900 910 908 911 920

Загружено:

Tracy EvansАвторское право:

Доступные форматы

P

o

l

y

k

e

n

P

i

p

e

l

i

n

e

C

o

a

t

i

n

g

s

Utility Tape

System Description

The Polyken utility tape coating systems have a rich tradition in the pipeline industry since their introduction in 1950.

Designed specifically for the gas utility, oil field, and plumbing industries, the polyethylene backing and butyl rubber

adhesive are highly conformable and remain flexible over a wide temperature range.

General utility tape

designed for small

diameter pipe

applications on elbows,

fittings, field joints, and

pipe sections. Highly

conformable hand

applied system for tight

uniform protection on a

wide variety of metal

substrates.

All purpose field applied

tape coating system for

use in the oil patch and

gas fields. Suited for hand

application on a variety of

steel structures common

to the oil field. Frequently

used for small makeshift

repair and temporary

corrosion protection

behind protection

diameter pipe gathering

systems.

General utility tape

coating system for

temporary makeshift

repair of primary coating

systems. Engineered for

either hand or machine

application,(only 911, not

908) the system is suited

for the in-ground

protection of joints,

elbows, and tees.

General utility tape

coating system to be

used where higher

mechanical protection is

required. Designed for

hand or machine

application, the

conformable polyethylene

backing delivers a tough,

uniform corrosion

protection system.

Polyken #900

Physical Properties

System Components

System Products

Product Advantages

Polyken # 910 Polyken # 911 # 908 Polyken # 920

D

S

-

U

t

i

l

i

t

y

T

a

p

e

-

R

E

V

6

-

F

e

b

1

0

Established and roven erlormance

Exceeds LT 1512A, LTOO77, and ML 77O8

Conlormable to irreqular shaes secilications

hand or machine alication

Comatible with most qeneric lant coatinq systems

/ 1O27 Frimer Layer

Percent solids: 30%

wt/qal. 7.8 lbs

Flash point: 40 F

Also available. low v0C and

/ero v0C rimer

Thickness:

Total Thickness

ASTM B 1OOO

Backing Thickness

Adhesive Thickness

Tensile Strength:

ASTM B 1OOO

Elongation

ASTM B 1OOO

Peel Adhesion to

Primed Pipe:

ASTM 17

Dielectric Strength:

ASTM B 14O

Water Vapor

Transmission Rate:

ASTM F 124O

100F, 100%RH

Holiday Detection

Voltage:

hACE RFO274

Temperature Range:

hormal inqround

service

# 900

12 mils

0.3 mm

8 mils

4 mils

5 lbs/in

44 h/1O mm

175%

13 kv

4.3 kv

# 908

8 mils

O.2O mm

5 mils

3 mils

12 lbs/in

21 h/1O mm

300%

7 kv

3.5 kv

# 910

10 mils

O.25 mm

6 mils

4 mils

18 lb/in

82 h/1O mm

25O%

8 kv

4.0 kv

# 911

9 mils

O.28 mm

6 mils

3 mils

25 lb/in

44 h/1O mm

100%

13 kv

3.8 kv

# 920

2O mils

0.51 mm

15 mils

5 mils

35 lb/in

G1 h/1O mm

25O%

16 kv

5.6 kv

Utility Coating

Roll width. 1, 2, 4, G inch

Roll length: 100 feet

Colors. Black, qray, yellow

1OO o//in 11 h/1O mm

0.05 g/100 in

2

/24 hr O.8 q/1OO cm

2

/24 hr

8O to 15OF 84 to GGC

D

S

-

U

t

i

l

i

t

y

T

a

p

e

-

R

E

V

6

-

F

e

b

1

0

Berry Plastics warrants that the product conforms to its chemical and physical description and is appropriate for the use stated on the technical data sheet when used in compliance with Berry Plastics

written instructions. Since many installation factors are beyond the control of Berry Plastics, the user shall determine the suitability of the products for the intended use and assume all risks and liabilities

in connection herewith. Berry Plastics liability is stated in the standard terms and conditions of sale. Berry Plastics makes no other warranty either expressed or implied. All information contained in

this technical data sheet is to be used as a guide and is subject to change without notice. This technical data sheet supersedes all previous data sheets on this product.

Вам также может понравиться

- 18 Inch 9 5 MM Combo (MFL+CLP+IMU) (Ver Data Sheet Pàg. 8) PDFДокумент19 страниц18 Inch 9 5 MM Combo (MFL+CLP+IMU) (Ver Data Sheet Pàg. 8) PDFOscar Miguel Fuquen SanabriaОценок пока нет

- Dimensions, Sizes and Specification of JIS B2220 Standard Steel Flanges PDFДокумент8 страницDimensions, Sizes and Specification of JIS B2220 Standard Steel Flanges PDFMohamad RifkiОценок пока нет

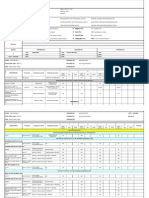

- Halliburton Multi Chem Batch Plant Project: Purchase Order/Contract NumberДокумент7 страницHalliburton Multi Chem Batch Plant Project: Purchase Order/Contract NumberTahseen Ahmed100% (1)

- Preliminary Inspection Report - RevДокумент12 страницPreliminary Inspection Report - RevGood GamerОценок пока нет

- Basics On Piping LayoutДокумент11 страницBasics On Piping Layoutpuru55980Оценок пока нет

- Anchor FlangeДокумент1 страницаAnchor FlangeHector MejiaОценок пока нет

- WPS Sa 517Документ2 страницыWPS Sa 517DHANANNJAI SINGH -Оценок пока нет

- Hottaping FURMANITEДокумент85 страницHottaping FURMANITEAriz Joelee ArthaОценок пока нет

- CVMCДокумент4 страницыCVMCAzhar HussainОценок пока нет

- Cs Installation of 11kv MV Switchgear Rev.00Документ1 страницаCs Installation of 11kv MV Switchgear Rev.00syed fazluddinОценок пока нет

- Wrapping MethodДокумент5 страницWrapping Methodnnuek67% (3)

- Visual Inspection Checklist PipingДокумент2 страницыVisual Inspection Checklist PipingshifaОценок пока нет

- Bondstrand Fiberglass Flanges Assembly Instructions - AmeronДокумент8 страницBondstrand Fiberglass Flanges Assembly Instructions - AmeronFabio SilvaОценок пока нет

- Supplier Document Requirement Listing (SDRL)Документ23 страницыSupplier Document Requirement Listing (SDRL)Nouredine KoufiОценок пока нет

- USB - Ole Gjerstad - SUT - Manifolds and Connections May 2014Документ76 страницUSB - Ole Gjerstad - SUT - Manifolds and Connections May 2014solicoco100% (1)

- Gasket BrochureДокумент8 страницGasket BrochureKumar JbsОценок пока нет

- LE B-255 H4R: ClassificationДокумент2 страницыLE B-255 H4R: ClassificationVivien EmeraldoОценок пока нет

- Sample Shutdown Schedule For Heat Exchanger Cleaning and InspectionДокумент3 страницыSample Shutdown Schedule For Heat Exchanger Cleaning and Inspectionman alamОценок пока нет

- LT26G PDFДокумент4 страницыLT26G PDFraul gonzalezОценок пока нет

- D Pi 175Документ2 страницыD Pi 175reza329329Оценок пока нет

- Egp ReportДокумент109 страницEgp ReportvyshnapramodОценок пока нет

- Guide For Test Pack Eng ResponsibiliesДокумент1 страницаGuide For Test Pack Eng ResponsibiliesDinesh RadhakrishnanОценок пока нет

- 20G Boiler Steel Pipe PDFДокумент5 страниц20G Boiler Steel Pipe PDFHeza FirdausОценок пока нет

- Rubber Gasket TypesДокумент92 страницыRubber Gasket Typessushant_moreyОценок пока нет

- Maintenance and User Manual: Borehole TV Camera Inspection System Setting Up InstructionsДокумент21 страницаMaintenance and User Manual: Borehole TV Camera Inspection System Setting Up InstructionsFranklin L SilvaОценок пока нет

- Upheaval & Lateral Buckling Calculations For Buried Pipelines - TR Engineering Consultancy LLCДокумент2 страницыUpheaval & Lateral Buckling Calculations For Buried Pipelines - TR Engineering Consultancy LLCRaakze MoviОценок пока нет

- Dimension ReportДокумент4 страницыDimension ReportKarthikeyan ShanmugavelОценок пока нет

- Piping Spec: CS150 TFS 1021: Engineering StandardДокумент4 страницыPiping Spec: CS150 TFS 1021: Engineering Standardbmanojkumar16Оценок пока нет

- Welder Sample Resume: Professional ExperienceДокумент1 страницаWelder Sample Resume: Professional ExperiencePhilip KrebsОценок пока нет

- Pressure Vessel Hydrotest Procedure - Google SearchДокумент3 страницыPressure Vessel Hydrotest Procedure - Google SearchAsad KhanОценок пока нет

- Tank Fabrication & ErectionДокумент72 страницыTank Fabrication & ErectionPramod GrОценок пока нет

- U BoltsДокумент14 страницU BoltsLuz DuarteОценок пока нет

- Tanhov Industrial Co.,Ltd: ITP (Inspection and Test Plan) FOR PRVДокумент2 страницыTanhov Industrial Co.,Ltd: ITP (Inspection and Test Plan) FOR PRVUmair AwanОценок пока нет

- Eadips Manual Engl PDFДокумент390 страницEadips Manual Engl PDFbkarabasevicОценок пока нет

- Pig Sig VДокумент8 страницPig Sig VAsemota OghoghoОценок пока нет

- Sa 980 P 11409 Ultrasonic Flowmeter Rev t02Документ3 страницыSa 980 P 11409 Ultrasonic Flowmeter Rev t02altipatlarОценок пока нет

- ITR-B (Piping) Witness Joint1Документ1 страницаITR-B (Piping) Witness Joint1Momo ItachiОценок пока нет

- 800D SeriesДокумент3 страницы800D Seriesvkeie0206Оценок пока нет

- Inspection and Test Plan: Rev Created by Checked by Approved by Date Issue StatusДокумент18 страницInspection and Test Plan: Rev Created by Checked by Approved by Date Issue StatusoberaiОценок пока нет

- Consultancy in Mechanical Integrity RBI, RCM, FFS, NDT & Vibration Analysis Services Training Based On API ASME and Other StandardsДокумент6 страницConsultancy in Mechanical Integrity RBI, RCM, FFS, NDT & Vibration Analysis Services Training Based On API ASME and Other StandardsShahbaz KhanОценок пока нет

- Understanding Article 2 ASME Sec V - Radiographic ExaminationДокумент46 страницUnderstanding Article 2 ASME Sec V - Radiographic Examinationrosli2503Оценок пока нет

- New SSIV InstallationДокумент12 страницNew SSIV InstallationDidiОценок пока нет

- Mantenimiento Valvulas LVFДокумент45 страницMantenimiento Valvulas LVFmelimonteОценок пока нет

- Technical Doc 1 - Technical Scope of Work Drs Eac181Документ25 страницTechnical Doc 1 - Technical Scope of Work Drs Eac181bhargavpansuria09Оценок пока нет

- Technical Manual - 2000 USG Horizontal Lined Acid TankДокумент20 страницTechnical Manual - 2000 USG Horizontal Lined Acid TankGade JyОценок пока нет

- VpCI-101 MSDS PDFДокумент5 страницVpCI-101 MSDS PDFJose Alberto Uribe Minier0% (1)

- OCS Prel WPS 007Документ2 страницыOCS Prel WPS 007vinothОценок пока нет

- Itp For Casing, Ducting, StackaaaaaaaaaaaДокумент4 страницыItp For Casing, Ducting, Stackaaaaaaaaaaaaymanmalah100% (1)

- 1-Manual Horizontal Stand CTS670 ST7H PDFДокумент121 страница1-Manual Horizontal Stand CTS670 ST7H PDFManikandaprabhu ManickamОценок пока нет

- Gauge - Pole - Cover - For - Floating - Roof - Tanks LR PDFДокумент2 страницыGauge - Pole - Cover - For - Floating - Roof - Tanks LR PDFArlen NurlanОценок пока нет

- Lamination Recipe-700mmДокумент1 страницаLamination Recipe-700mmSai PrasathОценок пока нет

- Utoc Preliminary Wps Shell Project 270807 PDFДокумент55 страницUtoc Preliminary Wps Shell Project 270807 PDFErick HoganОценок пока нет

- HRSG HydrotestДокумент7 страницHRSG Hydrotestshubham raj bhawsarОценок пока нет

- DOD-ITP - INS-008-ITP FOR Installation and Testing of Fiber Optic Cable - Rev.0Документ2 страницыDOD-ITP - INS-008-ITP FOR Installation and Testing of Fiber Optic Cable - Rev.0Bharathi100% (1)

- CV PIPING and STRUCTURE PREPARATORДокумент2 страницыCV PIPING and STRUCTURE PREPARATORSali NdjiddaОценок пока нет

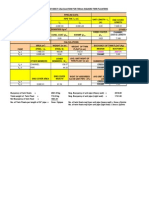

- Calculation Sheet For 700mm SQ Metal FloatersДокумент3 страницыCalculation Sheet For 700mm SQ Metal FloatersAdagharaОценок пока нет

- Resume For Mechanical Engineer With EPC CompanyДокумент3 страницыResume For Mechanical Engineer With EPC CompanyShivaji DhonnarОценок пока нет

- Therminol vp1Документ10 страницTherminol vp1karthik1amarОценок пока нет

- Polyken 1600 High TempДокумент2 страницыPolyken 1600 High TempKyaw Kyaw AungОценок пока нет

- Hose Technic DataДокумент28 страницHose Technic Dataerol_ay98Оценок пока нет

- AspenIcarusV8 0 RefДокумент990 страницAspenIcarusV8 0 RefTracy EvansОценок пока нет

- Allowable Steam Turbine LoadsДокумент5 страницAllowable Steam Turbine LoadsSami SyedОценок пока нет

- Bolt Torque EquationsДокумент3 страницыBolt Torque Equationsree2jОценок пока нет

- Summary of Differences PSL 1 & PSL 2: Era EnergyДокумент1 страницаSummary of Differences PSL 1 & PSL 2: Era EnergyTracy EvansОценок пока нет

- Brochures Polyken PlainДокумент6 страницBrochures Polyken PlainBayu ImbangsonoОценок пока нет

- Polyken Cold Applied Field Joint Installation GuideДокумент6 страницPolyken Cold Applied Field Joint Installation GuideTracy EvansОценок пока нет

- FLNG 1500 Kris MartinickДокумент100 страницFLNG 1500 Kris MartinickTracy Evans100% (1)

- Geothermal Pipe Line DesignДокумент15 страницGeothermal Pipe Line DesignjohnjuantamadОценок пока нет

- DOE Mechanical Science Volume 2 of 2 DOE-HDBK-10182-93Документ130 страницDOE Mechanical Science Volume 2 of 2 DOE-HDBK-10182-93Titer100% (1)

- Chemical and Metallurgical ThermodynamicsДокумент111 страницChemical and Metallurgical ThermodynamicsGatesolutions Metallurgy100% (7)

- Chapter 07Документ39 страницChapter 07kevinmathew27Оценок пока нет

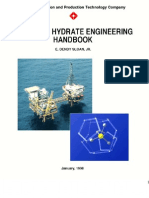

- Hydrate HandbookДокумент255 страницHydrate Handbookmarclangford100% (3)

- Piping Workbook PIDesignДокумент73 страницыPiping Workbook PIDesignUrsula MoeringsОценок пока нет

- Installation Manual enДокумент10 страницInstallation Manual enTracy EvansОценок пока нет

- Chapter 07Документ39 страницChapter 07kevinmathew27Оценок пока нет

- Surge AnalysisДокумент30 страницSurge AnalysisRadhakrishna MadabhushiОценок пока нет

- Design Storage Tanks For Sulphuric AcidДокумент2 страницыDesign Storage Tanks For Sulphuric AcidTracy Evans100% (2)

- Ring Joint Catalog 1Документ20 страницRing Joint Catalog 1guttykОценок пока нет

- PVV Ball Valve CatalogДокумент6 страницPVV Ball Valve CatalogGovundan GuruОценок пока нет

- F45 CDD 01Документ54 страницыF45 CDD 01paimpillyОценок пока нет

- Project Standards and Specifications Piping and Instrument Diagram Rev01Документ50 страницProject Standards and Specifications Piping and Instrument Diagram Rev01Tracy EvansОценок пока нет

- Getting You To Test Day: An 8-Week Prep Plan For The TOEFL TestДокумент2 страницыGetting You To Test Day: An 8-Week Prep Plan For The TOEFL Testsmith90Оценок пока нет

- Practical FileДокумент108 страницPractical FileRakesh KumarОценок пока нет

- Mars Climate Orbiter ReportДокумент27 страницMars Climate Orbiter Reportbiguelo100% (1)

- Literature Review 1Документ7 страницLiterature Review 1api-609504422Оценок пока нет

- Building The Gws Slow Stick PlaneДокумент21 страницаBuilding The Gws Slow Stick PlaneNUFA88Оценок пока нет

- Lesson Plan For C.O. 2Документ1 страницаLesson Plan For C.O. 2Jubilee BundaОценок пока нет

- Understanding The Self Lecture Lesson 1 Revised PDFДокумент41 страницаUnderstanding The Self Lecture Lesson 1 Revised PDFKylie CuadraОценок пока нет

- 3838-Article Text-7786-1-10-20230403Документ8 страниц3838-Article Text-7786-1-10-20230403Ramona Elena SpiridonОценок пока нет

- 2013 - To and Fro. Modernism and Vernacular ArchitectureДокумент246 страниц2013 - To and Fro. Modernism and Vernacular ArchitecturesusanaОценок пока нет

- AVT 2217 Module 5 Aiport Lighting SystemДокумент15 страницAVT 2217 Module 5 Aiport Lighting SystemJane PazОценок пока нет

- Removal Processes and Machine Tools: Indian Institute of Technology DelhiДокумент28 страницRemoval Processes and Machine Tools: Indian Institute of Technology DelhiEthan HuntОценок пока нет

- Criteria For Use in Evaluation of Testing Laboratories and Organizations For Examination and Inspection of Steel, Stainless Steel, and Related AlloysДокумент5 страницCriteria For Use in Evaluation of Testing Laboratories and Organizations For Examination and Inspection of Steel, Stainless Steel, and Related AlloysProduction DepartmentОценок пока нет

- Collimation of Binoculars With A LampДокумент33 страницыCollimation of Binoculars With A LampchristianОценок пока нет

- AWS Lecture NotesДокумент4 страницыAWS Lecture NotesAsad Bin Ala Qatari0% (1)

- Creativity MCQДокумент17 страницCreativity MCQAmanVatsОценок пока нет

- Existing VendorsДокумент1 страницаExisting VendorsSuperintending EngineerОценок пока нет

- Socio Economic Conditions of Migrant LabourДокумент7 страницSocio Economic Conditions of Migrant LabourDR SEKHARОценок пока нет

- RWB 60-856 Inst - Op. Mantto.Документ52 страницыRWB 60-856 Inst - Op. Mantto.Daniel Dennis Escobar Subirana100% (1)

- Probability of Event Intersections: Vietnamese-German UniversityДокумент17 страницProbability of Event Intersections: Vietnamese-German UniversityĐặng ThưОценок пока нет

- Remembering Thanu Padmanabhan - The HinduДокумент3 страницыRemembering Thanu Padmanabhan - The HinduIucaa libraryОценок пока нет

- Define-Phase Yellow BeltДокумент52 страницыDefine-Phase Yellow BeltBhadri NarayananОценок пока нет

- MgF2 SolGelДокумент8 страницMgF2 SolGelumut bayОценок пока нет

- Legend 1028KДокумент2 страницыLegend 1028KAndres Fdo Mora DОценок пока нет

- Giamarie Marbella - SP Essay Rough DraftДокумент11 страницGiamarie Marbella - SP Essay Rough Draftapi-667933283Оценок пока нет

- 31 The Emergence of Social GerontologyДокумент9 страниц31 The Emergence of Social GerontologygiacomobarnigeoОценок пока нет

- Exercise Workbook For Student 31: SAP B1 On Cloud - BASICДокумент40 страницExercise Workbook For Student 31: SAP B1 On Cloud - BASICDan Andrei BongoОценок пока нет

- Abu Khader Group ProposalДокумент5 страницAbu Khader Group ProposalChristine AghabiОценок пока нет

- Vocabulary Placement TestДокумент3 страницыVocabulary Placement TestMonica Vergara MejiaОценок пока нет

- Research Title Approval FormДокумент2 страницыResearch Title Approval FormJames EdlynОценок пока нет

- Ped Pressure Equipment Certification PDFДокумент8 страницPed Pressure Equipment Certification PDFProkopОценок пока нет