Академический Документы

Профессиональный Документы

Культура Документы

DAT Belt Conveyor

Загружено:

EDUARDO0 оценок0% нашли этот документ полезным (0 голосов)

495 просмотров8 страницThis document provides design data for a belt conveyor system including specifications for materials, operating conditions, capacity requirements, conveyor profile, drive and take-up arrangements, pulleys, idlers, belting, motors, and structural components. Key details include a maximum capacity of [quantity] tonnes per hour, a belt width of [quantity] mm, and a profile sketch showing the conveyor layout with [quantity] bends and the locations of the drive pulley and take-up assembly.

Исходное описание:

Авторское право

© © All Rights Reserved

Доступные форматы

XLS, PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документThis document provides design data for a belt conveyor system including specifications for materials, operating conditions, capacity requirements, conveyor profile, drive and take-up arrangements, pulleys, idlers, belting, motors, and structural components. Key details include a maximum capacity of [quantity] tonnes per hour, a belt width of [quantity] mm, and a profile sketch showing the conveyor layout with [quantity] bends and the locations of the drive pulley and take-up assembly.

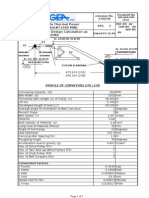

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате XLS, PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

495 просмотров8 страницDAT Belt Conveyor

Загружено:

EDUARDOThis document provides design data for a belt conveyor system including specifications for materials, operating conditions, capacity requirements, conveyor profile, drive and take-up arrangements, pulleys, idlers, belting, motors, and structural components. Key details include a maximum capacity of [quantity] tonnes per hour, a belt width of [quantity] mm, and a profile sketch showing the conveyor layout with [quantity] bends and the locations of the drive pulley and take-up assembly.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате XLS, PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 8

Rev: 0

1 Rev DESIGN DATA

2 MATERIAL

3 Description: Physical Characteristics:

4 Bulk Density ( kg/m

3

) Size Distribution Moisture Content

5 Material Temp ( C ) Max. Lump Size ( mm ) Angle of Repose ( )

6 Friction Factor for Skirts Vertical Fall ( m ) CEMA Class

7 LOCATION, SITE AND OPERATING CONDITIONS

8 Ambient temperature Min Max (C)

9 Electrical class.: CL Gr Div Relative humidity Min Max

10 Wind Pressure (kPa)

11 Operating schedule: ( hr/day ) Days/Year No. Starts per Hour No. Starts per Day

12 CAPACITY AND POWER REQUIREMENTS

13 Conveyor Capacity (tonnes/hr) Normal Design Peak Rate Freq of Peak

14 Belt Width ( mm ) Belt Speed ( m/s ) Max. Allow. Belt Speed ( m/s )

15 Belt Loading Percent ( % ) Max. Belt Load ( tonnes/hr ) Surcharge Angle ( )

16 Idler Troughing Angle ( ) Power, kW at Motor Shaft ( Design / Calculated )

17 CONVEYOR PROFILE

18

19

20

21

22

23

24

25

26

27

28

29

30

31 SKETCH IS AN EXAMPLE - ALTERNATE SKETCHES MAY BE SELECTED OR MODIFIED FROM ATTACHED PAGES

32

33 DRIVE ARRANGEMENT TAKE-UP ARRANGEMENT

34

35

36

37

38

39

38

39

40

41

ALTERNATE SKETCHES MAY BE SELECTED ALTERNATE SKETCHES MAY BE SELECTED

42 OR MODIFIED FROM ATTACHED PAGES OR MODIFIED FROM ATTACHED PAGES

DATE BY CHK'D APP'D

Equip. Name:

Client:

DATA SHEET

Project: BELT CONVEYOR

REVISION LOG

REV: DESCRIPTION

ADL Doc. No: ENG-DAT-000066

Plant/Area: Equip. No:

WO #:

x

x

x

Inlet

xx

1

x

0

5

Drive

Radius = x m

xxxx

xxxx

Take-up

2

3

4

Tail

Skirts ( x m)

SHAFT MOUNT

Indoor Outdoor Heated Unheated

Winterization Required Tropicalization Required

Source Doc: DS.131.0008M.CAL.R00 1 of 8

Rev: 0

Equip. Name:

Client:

DATA SHEET

Project: BELT CONVEYOR

ADL Doc. No: ENG-DAT-000066

Plant/Area: Equip. No:

WO #:

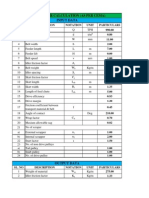

1 PULLEYS

2 DRIVE PULLEYS NON-DRIVE PULLEYS

3 Shell Thickness (mm):

4 End Disc Thick. (mm):

5 Hub Fitting to Shaft,

6 Keyway / Other

7 Lagging Thick. (mm)

8 Lagging Hardness

9 Durometer:

10 Shaft Material

11 Other

12 Herringbone Design

13 Depth/Width/Space (mm)

14 TABLE A: TYPICAL PULLEY & SHAFT ASSEMBLY

15 Number Location Description C D F L B b A d d1

16 1 Head

17 2 Bend

18 3 Take-Up

19 4 Bend

20 5 Tail

21

22

23 Description: F - Flat, C - Crown, S - Self Cleaning

24 PILLOW BLOCKS

25 Drive Pulleys Head Pulley Tail Pulley Take-Up Pulley Bend Pulleys

26 Manufacturer

27 Type

28 Size

29 Series No.

30 Seal Type

31 Housing Material

32 No. of Belts

33 Lubrication

34 L-10 Life Rating (hr)

35 Adjusting Screws

36 IDLERS

37 Impact Troughing Return Transition Training

38 Manufacturer

39 Type

40 Trade Name

41 CEMA Series

42 Shell Thickness (mm)

43 Roll Diameter (mm)

44 Bore Diameter (mm)

45 Shaft Diameter (mm)

46 Type of Seal

48 Lubrication

49 Bearing Type

50 L-10 Life Rating (hr)

51 Recommended Spacing (mm)

52 Number Required

53 Weight of Assembly (kg)

54

Source Doc: DS.131.0008M.CAL.R00 2 of 8

Rev: 0

Equip. Name:

Client:

DATA SHEET

Project: BELT CONVEYOR

ADL Doc. No: ENG-DAT-000066

Plant/Area: Equip. No:

WO #:

1 BELTING

2 STEEL CORD FABRIC BELT TENSION ( kN )

3 Manufacturer Normal Maximum

4 Type / Trade Name Working / Rated

5 Carcass Material Tight Side

6 Number of Plies Slack Side

7 Rope Diameter (mm) Primary Pulley Effective

8 Cover Grade RMA Secondary Drive Effec.

9 Cover Thickness - Inter. Bet'n Drive Pulleys

10 Top / Bottom (mm) Take-Up

11 Belt Safety Factor Tail Belt - Tight Side

12 Belt Thickness (mm) Tail Belt - Slack Side

13 Belt Weight (kg/m) Tail Pulley Effective

14 Total Lgth ex.Splice (m)

15 Type of Splice

16 Splice Length (m)

17 Belt Rating (kN/m)

18 Ultimate Strength (kN/m)

19 Service Factor

20 TAKE-UP ACCESSORIES

21 Type: Belt Cleaners

22 Primary Secondary V-Plow

23 Control: Manufacturers

24 Force (kg) Travel (m) Location Type

25 MOTOR Tramp Iron Magnet

26 Manufacturer Manufacturers

27 Type Size ( kW ) RPM Size Rating

28 Frame Enclosure S.F. Metal Detector

29 Insulation Starter Type Manufacturer Model No

30 Rating Control Safety Switches

31 COUPLING Manufacturer Model No. No. Req'd

32 High Speed Low Speed Emergency Pull Cord

33 Manufacturer / / Beltside Travel

34 Type / Size / / Plugged Chute

35 Basic Rating / S.F. / / Low Speed Differential

36 Max / Min Bore Dia(mm) / / Limit

37 Number Required DRIVE BASE

38 HOLDBACK Manufacturer

39 Manufacturer FLUID COUPLING

40 Location Size Manufacturer

41 Torque Rating (kNm) Max. RPM Type Size Rating

42 S.F. Recommended Filling Angle Slip

43 BRAKE Max Trans. Torque (kNm)

44 Manufacturer Output Shaft Coupling Type

45 Location Size Material: Casing Runner

46 Torque Capacity (kNm) Type Impeller

48 Dutycycle S.F.

49 SPEED REDUCER

50 Manufacturer

51 Type Size Efficiency

52 Rating: Mech. / Thermal (kW) /

53 S.F. RPM: Input / Output /

54 Lubrication

Unpowered Gravity Horizontal Screw

Motorized Winch Hydraulic

Manual Automatic

Source Doc: DS.131.0008M.CAL.R00 3 of 8

Rev: 0

Equip. Name:

Client:

DATA SHEET

Project: BELT CONVEYOR

ADL Doc. No: ENG-DAT-000066

Plant/Area: Equip. No:

WO #:

1 V-BELT DRIVE SHEAVES

2 Manufacturer Manufacturer

3 Belt Section Type Belt Rating (kW/Belt) Speed Ratio No. of Grooves

4 S.F. No. Belts Req'd Outside Dia. Driver / Driven (mm) /

5 Centre Distance (mm) Belt Length (mm) Bore Dia. Driver / Driven (mm) /

6 Belt Speed (m/s) Hub Type: Driver / Driven /

7 CHAIN DRIVE SPROCKETS

8 Manufacturer Manufacturer

9 Chain Type / ANSI No.: / Outside Dia. Driver / Driven (mm) /

10 Ultimate Strength ( kN ) No. of Strands Bore Dia. Driver / Driven (mm) /

11 Pitch (mm) Hub Type: Driver / Driven /

12 No. of Teeth: Driver / Driven /

13 Speed Ratio

14 STRUCTURAL COMPONENTS MISCELLANEOUS STRUCTURAL STEEL

15 Material Thickness Weight Conveyor Location: Gallery:

16 (mm) (kg)

17 Feed Chute Conveyor Support:

18 Feed Chute Liner

19 Feed Chute Guard Walkway:

20 Head Chute Flooring Type: Platform Width (mm):

21 Discharge Chute Load / Metre Length (max. operating)

22 Disch.Chute Liner Conveyor (kg) Gallery (kg)

23 Skirtboards STRUCTURAL DIMENSIONS

24 Skirtboard Liner Stringers (m) Material

25 Dust Take-Off Legs (m) Material

26 Truss (m) Material

27 Truss Span (m)

28 NOTES

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

48

49

50

51

52

53

Open Closed

Tube Building

Conventional Tables

Other (Specify)

Single Double Not Required

Source Doc: DS.131.0008M.CAL.R00 4 of 8

PARALLEL SHAFT

RIGHT ANGLE

SHAFT MOUNT

DUAL PARALLEL

EXTERNAL BACK

DUAL RIGHT ANGLE

BASE MOUNT

RIGHT ANGLE

BASE MOUNT

SHAFT MOUNT

xxx

Shuttle

Head

Horizontal

1 2

xxx

Pebble Bin

Skirts ( xx m)

xxx

xx

Take-up

Tail

Horizontal

Skirt length say 3

Take-up Drive

2

1

Horizontal

Skirt length say 3 m

Take-up

Drive

4 1

2 2

3

5

2

1

Horizontal

Drive

xxx

xxx

5

4

3

Take-up

Skirts ( xx m)

Tail

Vibrating Screens

Skirts ( xx m)

Vibrating Screens

2

Take-up

1

Driv

Skirt length say 3 m

3

5

0

0

Take-up

Drive

Skirt length say 3 m

2

3

4

5

1

3

5

0

0

xx m

xx m

Skirts ( xx m)

xxx m

Gravity

Take-up

Drive

Tail

Primary Crusher

1

2

3

4

5

x

x

x

Take-up

Drive

1

2

3

4

Skirt length = xxx m

Radius =

xxxx

xxx

5

Skirt length say x m

Take-up

Drive

Radius =

x

x

x

x

x

x

x

x

x

xxxx

xxxx

5

1

2

3

4

Take-up

Tail

xxxx

Skirts ( x m)

xxxx

xxxx

Radius = xxx m

x

0

x

x

x

7

6

Head

3

2

Drive

xx

0

4

1

5

x

x

x

Inlet

xx

1

x

0

5

Drive

Radius = x m

xxxx

xxxx

Take-up

2

3

4

Tail

Skirts ( x m)

Вам также может понравиться

- CONVEYOR CALCULATION SHEET DraftДокумент37 страницCONVEYOR CALCULATION SHEET Drafttvpham12350% (6)

- Belt Conveyor Capacity - CalculatorДокумент6 страницBelt Conveyor Capacity - CalculatorRolando Daclan67% (3)

- Travelling Tripper CalculationДокумент5 страницTravelling Tripper CalculationHarshGupta100% (2)

- Piccini Scout 5500 AutohormigoneraДокумент131 страницаPiccini Scout 5500 AutohormigoneraRonald Mosquera100% (1)

- Drag and Flight Conveyors Design CalculationДокумент3 страницыDrag and Flight Conveyors Design Calculationsudip giri100% (1)

- Chute Dia CalculationДокумент5 страницChute Dia CalculationManoj Thakur100% (1)

- Rotary Compressor API 619Документ26 страницRotary Compressor API 619EDUARDO25% (4)

- Apron FeederДокумент7 страницApron FeederEDUARDO0% (1)

- Belt Conveyor CalcsДокумент3 страницыBelt Conveyor Calcsjnmanivannan100% (4)

- Project: Vijayawada Thermal Power Station, Stage-IV Unit#7 (500 MW) Subject: Conveyor Design Calculation As Per 5th Edition of CEMAДокумент7 страницProject: Vijayawada Thermal Power Station, Stage-IV Unit#7 (500 MW) Subject: Conveyor Design Calculation As Per 5th Edition of CEMASara Lopez100% (8)

- Conveyor Design CalcДокумент6 страницConveyor Design CalcGregory Nick Toledo VelizОценок пока нет

- BELT CONVEYOR - Discharge TrajectoryДокумент3 страницыBELT CONVEYOR - Discharge TrajectorySergio Diaz DuarteОценок пока нет

- CONVEYOR CALCULATION SHEET DraftДокумент24 страницыCONVEYOR CALCULATION SHEET DraftRaghava0% (1)

- Manual Detail Calculation of Conveyor KCДокумент32 страницыManual Detail Calculation of Conveyor KCSergio Diaz100% (1)

- Belt Feeder Calculation CEMAДокумент7 страницBelt Feeder Calculation CEMANAITIK100% (4)

- Conveyor Design-DraftДокумент42 страницыConveyor Design-Draftmkchy1295% (21)

- Diagrama C13 LeeДокумент26 страницDiagrama C13 LeeTDVOMОценок пока нет

- Tad572ve enДокумент2 страницыTad572ve enPakito-sanОценок пока нет

- Screw ConveyorДокумент5 страницScrew ConveyorEDUARDO100% (3)

- Conveyor Belt Weigh ScaleДокумент2 страницыConveyor Belt Weigh ScaleEDUARDOОценок пока нет

- Conveyor Tension and Trajectory CalculationДокумент8 страницConveyor Tension and Trajectory CalculationGregory Nick Toledo Veliz50% (2)

- Belt Conveyor CalcsДокумент3 страницыBelt Conveyor Calcspandu_chemengОценок пока нет

- Conveyor CalculationДокумент32 страницыConveyor CalculationsutanuprojectsОценок пока нет

- Rubber Belt Conveyor Calculations (ISO 5048: 1989 E) : BC 2304 NDДокумент8 страницRubber Belt Conveyor Calculations (ISO 5048: 1989 E) : BC 2304 NDmah moudОценок пока нет

- BELT FEEDER Preliminary Dimension IngДокумент29 страницBELT FEEDER Preliminary Dimension Ingshani5573100% (1)

- Conveyor CalculationДокумент56 страницConveyor CalculationsigisyahОценок пока нет

- Conveyor CalculationДокумент40 страницConveyor CalculationAnonymous 5XvUbWynnОценок пока нет

- Conveyor CalculationДокумент46 страницConveyor CalculationBuditama Chandranegara100% (1)

- Belt Conveyors With Shaft SizingДокумент5 страницBelt Conveyors With Shaft SizingRakhi Mor100% (2)

- Conveyor 02Документ4 страницыConveyor 02kmats2Оценок пока нет

- CEMA8 5pgДокумент5 страницCEMA8 5pgkmats100% (2)

- Belt Conveyor: Designer's ChoiceДокумент4 страницыBelt Conveyor: Designer's ChoiceAmeu CostaОценок пока нет

- Conveyor CalculationsДокумент3 страницыConveyor Calculationsmishra_1982Оценок пока нет

- Belt Conveyor PowerДокумент10 страницBelt Conveyor PowerRyukiОценок пока нет

- Design (Metric) 6.25Документ8 страницDesign (Metric) 6.25Salih Has100% (2)

- 10 Drag Conveyor Section VIIДокумент11 страниц10 Drag Conveyor Section VIIBUDAPESОценок пока нет

- Apron Feeder Application Datasheet enДокумент1 страницаApron Feeder Application Datasheet enVaijayanti JoshiОценок пока нет

- BELT CONVEYOR - Discharge TrajectoryДокумент1 страницаBELT CONVEYOR - Discharge TrajectoryEslam FaroukОценок пока нет

- M 275 ContentДокумент40 страницM 275 ContentAnonymous DQ4wYUmОценок пока нет

- Design Aspects of A Motorised Travelling TripperДокумент5 страницDesign Aspects of A Motorised Travelling Trippercar5lyle100% (1)

- Belt Conveyor Capacity CalculatorДокумент5 страницBelt Conveyor Capacity CalculatorramsaiОценок пока нет

- 3 Date 2 1 0 R e V I S I o N Checked by Checked by Approve DbyДокумент2 страницы3 Date 2 1 0 R e V I S I o N Checked by Checked by Approve DbyidilfitriОценок пока нет

- Conveyor Chains TsubakiДокумент184 страницыConveyor Chains Tsubakitepu msosaОценок пока нет

- 3100 CV 0001Документ11 страниц3100 CV 0001tranceinttОценок пока нет

- Memoria de Calculo Faja 30 CV 001 Rev 00Документ24 страницыMemoria de Calculo Faja 30 CV 001 Rev 00Enrique100% (1)

- Screw ConveyorДокумент4 страницыScrew ConveyorRaji SuriОценок пока нет

- Conveyor Design DraftДокумент25 страницConveyor Design DraftDxFxОценок пока нет

- Mechanical Conveyors: 29 Materials HandlingДокумент2 страницыMechanical Conveyors: 29 Materials HandlingSMNCI Cadet EngineersОценок пока нет

- Apron Feeder PDFДокумент3 страницыApron Feeder PDFabdulloh_99100% (1)

- The Evolution of The Pipe ConveyorДокумент9 страницThe Evolution of The Pipe ConveyorJohnjun ChenОценок пока нет

- Apron Weigh FeederДокумент4 страницыApron Weigh FeederRaji SuriОценок пока нет

- Screw Conveyor DesignДокумент8 страницScrew Conveyor DesignRamsai ChigurupatiОценок пока нет

- Conveyor Design DraftДокумент47 страницConveyor Design DraftSandi Apriandi100% (1)

- Bucket ConveyorДокумент20 страницBucket ConveyorHoras Nies100% (1)

- Screw Conveyor CalculationДокумент1 страницаScrew Conveyor CalculationRavindra RautОценок пока нет

- Coupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsОт EverandCoupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsОценок пока нет

- Screw ConveyorДокумент5 страницScrew ConveyorsutanuprojectsОценок пока нет

- Screw ConveyorДокумент6 страницScrew ConveyorJobsonReisОценок пока нет

- Actuador PCVДокумент12 страницActuador PCVmggz_15Оценок пока нет

- Konveyör Hesabı 7.24Документ9 страницKonveyör Hesabı 7.24Salih HasОценок пока нет

- Datasheet Phe OnwjДокумент1 страницаDatasheet Phe OnwjMamank Ira Sudrajat100% (1)

- Rig 104 InventoryДокумент16 страницRig 104 InventorypetricamafteiОценок пока нет

- PRDS InstallationДокумент10 страницPRDS InstallationSankar GaneshОценок пока нет

- Design (Imperial) 7.23Документ9 страницDesign (Imperial) 7.23ozgurturunc4Оценок пока нет

- Dry CobbingДокумент1 страницаDry CobbingEDUARDOОценок пока нет

- 830 CB 120 M07 - Rev0Документ1 страница830 CB 120 M07 - Rev0EDUARDOОценок пока нет

- 820 CB 120G WM25 - Rev0Документ1 страница820 CB 120G WM25 - Rev0EDUARDOОценок пока нет

- Durban Classic Cover + Caposide in One Side (Shougang Project)Документ4 страницыDurban Classic Cover + Caposide in One Side (Shougang Project)EDUARDOОценок пока нет

- 820 CB 120G WM26 - Rev0Документ1 страница820 CB 120G WM26 - Rev0EDUARDOОценок пока нет

- Mine Operation Expansion Project and Benefit PlantДокумент10 страницMine Operation Expansion Project and Benefit PlantEDUARDOОценок пока нет

- 5720 D E DWG 0201 - RevAДокумент4 страницы5720 D E DWG 0201 - RevAEDUARDOОценок пока нет

- Mine Operation Expansion Project and Benefit Plant: A D For Quotation MNS MNS MNS MNS 02.06.2014Документ14 страницMine Operation Expansion Project and Benefit Plant: A D For Quotation MNS MNS MNS MNS 02.06.2014EDUARDOОценок пока нет

- Mine Operation Expansion Project and Benefit PlantДокумент10 страницMine Operation Expansion Project and Benefit PlantEDUARDOОценок пока нет

- Mine Operation Expansion Project and Benefit Plant: A D For Quotation MNS MNS MNS MNS 02.09.2014Документ14 страницMine Operation Expansion Project and Benefit Plant: A D For Quotation MNS MNS MNS MNS 02.09.2014EDUARDOОценок пока нет

- Steam BoilerДокумент10 страницSteam BoilerEDUARDOОценок пока нет

- Mine Operation Expansion Project and Benefit Plant: A D For Quotation MNS MNS MNS MNS 02.06.2014Документ14 страницMine Operation Expansion Project and Benefit Plant: A D For Quotation MNS MNS MNS MNS 02.06.2014EDUARDOОценок пока нет

- Mine Operation Expansion Project and Benefit Plant: A D For Quotation MNS MNS MNS MNS 02.06.2014Документ12 страницMine Operation Expansion Project and Benefit Plant: A D For Quotation MNS MNS MNS MNS 02.06.2014EDUARDOОценок пока нет

- Data Sheet: DescriptionДокумент6 страницData Sheet: DescriptionEDUARDOОценок пока нет

- Schedule Levels - Major Projects: Core Scheduling Papers: #6Документ5 страницSchedule Levels - Major Projects: Core Scheduling Papers: #6EDUARDOОценок пока нет

- 5921 D E DWG 0205 - RevAДокумент6 страниц5921 D E DWG 0205 - RevAEDUARDOОценок пока нет

- Data Sheet: Description and Site ConditionsДокумент2 страницыData Sheet: Description and Site ConditionsEDUARDOОценок пока нет

- Sewagw Treatment FilterДокумент1 страницаSewagw Treatment FilterEDUARDOОценок пока нет

- Reciprocating CompressorДокумент6 страницReciprocating CompressorEDUARDOОценок пока нет

- Data Sheet: Description Unit Design DataДокумент1 страницаData Sheet: Description Unit Design DataEDUARDOОценок пока нет

- Plate ExchangerДокумент2 страницыPlate ExchangerEDUARDOОценок пока нет

- Mechanical Data Sheet Pressure Vessel: GeneralДокумент2 страницыMechanical Data Sheet Pressure Vessel: GeneralEDUARDOОценок пока нет

- MixerДокумент2 страницыMixerEDUARDOОценок пока нет

- Service Manual: Auto WasherДокумент47 страницService Manual: Auto WasherJuan Carlos Gonzalez ArangoОценок пока нет

- ClutchesДокумент17 страницClutchesRanjit RajendranОценок пока нет

- Km186f-c Diesel Engine PartsДокумент10 страницKm186f-c Diesel Engine PartsibnuОценок пока нет

- 37, 41, 42MT SSL Solenoids PDFДокумент4 страницы37, 41, 42MT SSL Solenoids PDFjuanОценок пока нет

- Bearing Power PointДокумент57 страницBearing Power Pointkesai100% (1)

- Crdi-Common Rail Direct Injection SystemДокумент20 страницCrdi-Common Rail Direct Injection SystemRollinG SuccesS100% (1)

- Cooline CDL SeriesДокумент20 страницCooline CDL SeriesRafik MeksenОценок пока нет

- Starling EngineДокумент7 страницStarling EngineLuis ParadaОценок пока нет

- Nissan Pathfider 2005 ManualДокумент84 страницыNissan Pathfider 2005 ManualDragos StefanОценок пока нет

- Sample Instruction Manual PDFДокумент25 страницSample Instruction Manual PDFKonigsОценок пока нет

- Inward RegisterДокумент8 страницInward RegisterOmkarОценок пока нет

- 06 Technical PDFДокумент24 страницы06 Technical PDFberth q llОценок пока нет

- Design & Fabrication of Groundnut Sheller MachineДокумент5 страницDesign & Fabrication of Groundnut Sheller MachineAnonymous kw8Yrp0R5rОценок пока нет

- Typical I/O SchduleДокумент3 страницыTypical I/O SchduleMohammad Faizul ZainudinОценок пока нет

- Termo King2.44-3.95Документ112 страницTermo King2.44-3.95Yuriy9v8u7p100% (4)

- Kinematic Structures and Machining Possibilities of Some CNC Machine ToolsДокумент9 страницKinematic Structures and Machining Possibilities of Some CNC Machine ToolsmusthakmechОценок пока нет

- Me423 PDFДокумент2 страницыMe423 PDFmaherkamelОценок пока нет

- 50 T Rig SpecДокумент6 страниц50 T Rig SpecgauravОценок пока нет

- Parts Manual CA150DДокумент253 страницыParts Manual CA150DJosé JuárezОценок пока нет

- Precision Ball Screw GuidesДокумент132 страницыPrecision Ball Screw GuideszokijОценок пока нет

- of Eddy Current Braking System NNNNДокумент17 страницof Eddy Current Braking System NNNNKaramjeet Singh MalhotraОценок пока нет

- Fast Moving Volvo PartsДокумент2 страницыFast Moving Volvo Partsali4299Оценок пока нет

- Engine Cooling SystemsДокумент5 страницEngine Cooling SystemsAdnan ParkerОценок пока нет

- 3408 Injector Sleeve InstallДокумент3 страницы3408 Injector Sleeve InstallbejoythomasОценок пока нет

- Parts Catalog: 1BJU0-100E1 September 2002Документ52 страницыParts Catalog: 1BJU0-100E1 September 2002maximchacaОценок пока нет

- Differential (Mechanical Device) - Wikipedia, The Free EncyclopediaДокумент8 страницDifferential (Mechanical Device) - Wikipedia, The Free EncyclopediavarunshastryОценок пока нет

- Ata 49 ApuДокумент77 страницAta 49 ApuSohaib Aslam Chaudhary100% (1)