Академический Документы

Профессиональный Документы

Культура Документы

Tilting Disc

Загружено:

Giovanny Salazar Flores0 оценок0% нашли этот документ полезным (0 голосов)

14 просмотров8 страницThe Henry Pratt Company was the first to introduce many of the flow control products in use today. The first rubber seated butterfly valve, one of the first nuclear N-Stamp valves were developed by Pratt. Today, Pratt provides the following range of superior products to the water, wastewater and power generation industries.

Исходное описание:

Оригинальное название

49418 Tilting Disc

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документThe Henry Pratt Company was the first to introduce many of the flow control products in use today. The first rubber seated butterfly valve, one of the first nuclear N-Stamp valves were developed by Pratt. Today, Pratt provides the following range of superior products to the water, wastewater and power generation industries.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

14 просмотров8 страницTilting Disc

Загружено:

Giovanny Salazar FloresThe Henry Pratt Company was the first to introduce many of the flow control products in use today. The first rubber seated butterfly valve, one of the first nuclear N-Stamp valves were developed by Pratt. Today, Pratt provides the following range of superior products to the water, wastewater and power generation industries.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 8

Engineering Creative Solutions

for Fluid Systems Since 1901

Tilting Disc Check Valve

A Tradition of Excellence

With the development of the first rubber seated butterfly

valve more than 70 years ago, the Henry Pratt Company

became a trusted name in the flow control industry,

setting the standard for product quality and customer

service. Today Pratt provides the following range of

superior products to the water, wastewater and power

generation industries.

Butterfly Valves: from 3" to 162"

Rectangular Valves: 1' x 1' to 14' x 16'

Ball Valves

Rubber Seated: from 4" to 60"

Metal Seated: from 6" to 48"

Plug Valves: from 1/2" to 36", 3 ways

Hydraulic Control Systems

Valve Controls

Energy Dissipating Valves

and Fixed Energy Dissipaters

Cone Valves

Check Valves

A Commitment to Meeting

The Customers Needs

Henry Pratt valves represent a long-term commitment

to both the customer and to a tradition of product

excellence. This commitment is evident in the number

of innovations we have brought to the industries we

serve. In fact, the Henry Pratt Company was the first to

introduce many of the flow control products in use today,

including the first rubber seated butterfly valve, one of

the first nuclear N-Stamp valves, and the bonded seat

butterfly valve.

Innovative Products

For Unique Applications

Though many of the standard valves we produce are

used in water filtration and distribution applica tions, Pratt

has built a reputation on the ability to develop specialized

products that help customers to meet their individual

operational challenges.

Creative Engineering

for Fluid Systems

Pratts ability to provide practical solutions to complex

issues is demonstrated by the following case histories.

Earthquake Proof Valves

Pratt designed and manufactured hydraulically actuated

valves for a water storage application so that the valves

would automatically operate in the event of earthquakes.

This lead to the development of a valve that will withstand

acceleration forces of up to 6gs.

Custom Actuation/Isolation Valves

Pratt designed and manufactured valves that would

isolate a working chamber in the event of a nuclear

emergency during the decommissioning of armed

nuclear warheads. The valves were able to close in

a millisecond using specially designed Pratt electro-

pneumatic actuators.

Valves Designed for

Harsh Environments

Pratt designed and manufactured a 144" diameter

butterfly valve for the emergency cooling system at

a jet engine test facility. The valve was designed to supply

water to help dissipate the tremen dous heat generated by

the engines during testing.

Through experience, commitment and creative engineering, Pratt is uniquely

suited to provide superior products for our customers special needs.

For more information, contact our corporate headquarters in Aurora, Illinois.

Henry Pratt Company | 1

Table of Contents

Pratt / Tilted Disc Check Valve

Introduction ......................................................................................................................................................................................................... 2

Scope of Line ..................................................................................................................................................................................................... 2

Low Headloss Design Advantage .............................................................................................................................................................. 2

Design Details .................................................................................................................................................................................................... 3

Features and Benefits .................................................................................................................................................................................... 3

Dimensional Data ........................................................................................................................................................................................45

Suggested Specifications ............................................................................................................................................................................. 4

401 South Highland Avenue

Aurora, Illinois 60506-5563

www.henrypratt.com

phone: 630.844.4000

fax: 630.844.4160

2 | Henry Pratt Company

Introduction

The Henry Pratt Tilting Disc Check Valve is the most versatile and

reliable check valve Pratt has to offer. This valve offers signicant

energy and cost savings over the life of the valve due to its large ow

area and low head loss characteristics. Short disc travel from full open

to full close provides the ability to close very rapidly or very slowly to

avoid contributing to slamming and surges. The tilting disc check valve

is also offered with an upper hydraulic dashpot to aid in disc closure

in multiple pump systems even after a power failure. Henry Pratt

continues to expand our product offering to those customers who

require specialty valves for applications where opening and closing

times are critical to control ow reversal and reduce water hammer.

Scope of Line:

Tilting Disc Check Valve

n Available in sizes 4 inches through 60 inches

n Various end congurations available

n Ductile iron body, disc and cover

n Bronze disc and body seat rings

Low Headloss

Design Advantage

The Tilting Disc Check Valve offers

signicant energy savings compared

to other types of conventional check

valves because of its larger ow area

and low head loss characteristics. The

valve achieves full opening when the

disc tilts in the ow of the media. The

tilting disc design through lifting and

stabilizing in the full-open position,

provides minimal ow resistance.

n Stainless steel hinge pin

n Other materials available upon request

n Rated working pressure 250 psi

10

9

8

7

6

5

4

1 P.S.I.

3

2

1

0

0 1 2 3 4 5 6 7 8 9 10 11 12

VELOCITY IN PIPE (F.P.S.)

NOTE: CURVES BASED ON 6 INCH VALVE SIZE FOR ILLUSTRATION PURPOSES ONLY.

PRESSURE LOSS COMPARISON

P

R

E

S

S

U

R

E

L

O

S

S

(

I

N

F

E

E

T

O

F

W

A

T

E

R

)

CUSHION SWING

CHECK VALVE

SILENT CHECK VALVE

TILTING DISC

CHECK VALVE

2 P.S.I.

3 P.S.I.

Henry Pratt Company | 3

Feature Benefit

Variable opening and closing speeds Short disc travel from full open to full close provides the ability to

close very rapidly or very slowly to avoid contributing to slamming

and surges.

Cushioned closure Action of the fluid on the disc is balanced due to pivot points that

allow for cushioned movement of the disc into the seat.

Long body laying length Permits smooth passage of water with minimum turbulence and

low potential for cavitation.

Low maintenance The stainless steel stub shafts do not come in contact with fluid

and can be lubricated either manually or automatically.

Non-slam characteristics The design of the seat and hydraulic dashpot cushions the closing

forces on the disc to allow for smooth operation. This prevents

slamming of the disc into the seat.

Low headloss Minimal effort to keep the disc open is achieved through the

balanced disc design thatprovides light weight lifting properties,

which translates to minimal flow resistance.

Less risk of reverse ow Rapid closing of the disc decreases the chance of reverse flow to

occur.

Design Details:

Tilting Disc Check Valve

DESCRIPTION MATERIAL

Body Ductile Iron ASTM A536 Gr. 65-45-12

Disc Ductile Iron ASTM A536 Gr. 65-45-12

Cover Ductile Iron ASTM A536 Gr. 65-45-12

Disc Seat Ring Stainless Steel ASTM A269 Type 304

Body Seat Ring Stainless Steel ASTM A269 Type 304

Hinge Pin Stainless Steel ASTM A276 Type 304

Bearing Bush Bronze B62

Other materials available on request.

4 | Henry Pratt Company

Diameter

Face-to-face

Length

Approximate

Weight

4" 11.5" 135 lbs.

6" 15" 160 lbs.

8" 19.5" 375 lbs.

10" 24.5" 330 lbs.

12" 24" 462 lbs.

14" 30" 771 lbs.

16" 30" 1062 lbs.

18" 33" 1200 lbs.

20" 32" 1652 lbs.

24" 38" 2368 lbs.

30" 52" 3525 lbs.

36" 59.5" 5177 lbs.

42" 60" 5727 lbs.

48" 65" 8745 lbs.

54" 70" 11345 lbs.

*May vary with pressure.

Dimensional Data

Suggested Specifications

General

The check valve shall be of the tilting disc type as

manufactured by Henry Pratt Company. The tilting disc

check valve shall consist of a circular disc with conical rim,

hinged about a fixed pivot above its center-line and offset

from the plane of the seat, sealing against a body seat

clamped between the two sections of the valve body.

Valve Construction

The body shall be two-piece, consisting of an entrance

and a discharge section bolted together at an angle with

the pipeline. An O-ring seal in a groove between the body

flanges shall be in place to prevent leakage between

the flanges when bolted together. The valve shall be

complete with ANSI class flanges to mate with adjacent

equipment.

A body seat shall be clamped in place in a slot between

the two body sections. The body seat shall have a

conical finish to mate with the disc seat. There shall

be an inspection port provided in both the entrance

and discharge sections to provide visual access both

upstream and downstream of the disc. An indicator shall

be provided to show disc position for the full range of

travel. Bosses shall be cast in both the entrance and

discharge sections to allow for a top mounted oil dashpot

for controlled opening and closing.

All valve castings shall be ductile iron ASTM A536 Grade

65-45-12. The disc and body seat ring shall be stainless

steel ASTM A269 Type 304. The hinge-pin shall be

stainless steel ASTM A276 Type 304. The bearing sleeve

shall be Bronze B62.

Testing

Seat and leakage testing shall be in strict accordance with

AWWA Standard C-508 latest edition for Swing Check

Valves. Rated working pressure of the check valve line is

250 psi.

Coating

Coating shall be a NSF61 approved epoxy.

Henry Pratt reserves the right to change parts and components to

improve product performance.

Henry Pratt Company | 5

Dimensional Data:

Tilting Disc Check Valve

4" 36" Tilted Disc Check Valve

4" 36" Tilted Disc Check Valve

with Dashpot

These dimensions are correct at time of publication and are not to be construed as certified drawings. Certified drawings

available upon request.

Size ANSI B16.1 CL.125

d L D C h n T A H

4 11 9 7 8 1516 13 10

6 15 11 9 316 8 1 16 13

8 19 13 11 316 8 1 19 16

10 24 16 14 1 12 1316 23 18

12 24 19 17 1 12 1 26 21

14 30 21 18 1 12 1 29 23

16 30 23 21 1 16 1716 32 26

18 33 25 22 1 16 1916 36 30

20 32 27 25 1 20 11116 39 32

24 38 32 29 1 20 1316 46 37

30 52 38 36 1 28 234 54 47

36 59 46 42 1 32 234 64 51

Size ANSI B16.1 CL.125

d L D C h n T A H J K

4 11 9 7 8 1516 13 10 12 19

6 15 11 9 8 1 16 13 12 23

8 19 13 11 316 8 1 19 16 17 29

10 24 16 14 1 12 1316 23 18 17 31

12 24 19 17 1 12 1 26 21 21 33

14 30 23 20 1 20 2 29 23 21 36

16 30 25 22 1 20 2 32 26 24 43

18 33 28 24 1 24 2 36 30 24 45

20 32 30 27 1 24 2 39 32 28 53

24 38 36 32 1 24 2 46 37 28 56

30 52 43 39 2 28 3 54 47 36 66

36 59 50 46 2 32 3 64 51 36 78

2011 Henry Pratt Company | Printed in the U.S.A. | CHECK-0611

PRATT PRODUCT GUIDE

Model

2FII

Monoflange

MKII

Plug

Valve

Triton

XR70

Indicating Butterfly Valve

UL & FM approved

Tilting Disc

Check Valve

Triton

XL

N-Stamp Nuclear

Butterfly Valve

Cone

Valve

Rectangular PIVA Post Indicating Valve Assembly

UL & FM approved

Sleeve

Valve

Rubber Seated

Ball Valve

Triton

HP250

Check

Valve

Groundhog

Valve

Control

Systems

Compact Controllable

Energy Dissipater

Metal Seated

Ball Valve

Henry Pratt Company

401 South Highland Avenue

Aurora, Illinois 60506-5563

United States

630-844-4000

Fax 630-844-4160

www.henrypratt.com

ISO 9001: 2000 Certified

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (120)

- Chapter 1 - Water Supply System For BuildingsДокумент33 страницыChapter 1 - Water Supply System For BuildingsThế VinhОценок пока нет

- Guidance-On-The-Design-Construction-And-Testing-Of-Standard-Rail Tank-Cars-For-The-Transport-Of-Chemicals-In-BulkДокумент15 страницGuidance-On-The-Design-Construction-And-Testing-Of-Standard-Rail Tank-Cars-For-The-Transport-Of-Chemicals-In-BulkarisandiyusufОценок пока нет

- RCABC Roof Curb Pentrations and OpeningsДокумент13 страницRCABC Roof Curb Pentrations and OpeningsdomcristiniОценок пока нет

- ACS Heat - Loss - Calculator Dryer 3050D X 21000L Thermal Analysis ReportДокумент7 страницACS Heat - Loss - Calculator Dryer 3050D X 21000L Thermal Analysis Reportdwi sutiknoОценок пока нет

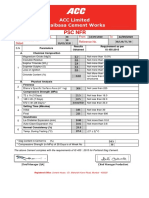

- Acc PSC - NFR - 38 - 2020Документ1 страницаAcc PSC - NFR - 38 - 2020kartick adhikaryОценок пока нет

- SR - No Description Unit Qty Unit Price Total PriceДокумент4 страницыSR - No Description Unit Qty Unit Price Total Priceatwik EnterprisesОценок пока нет

- Plumbing GlossaryДокумент45 страницPlumbing GlossarydonvantuongОценок пока нет

- M Tech I Sem II Mid TDДокумент4 страницыM Tech I Sem II Mid TDMir Mustafa AliОценок пока нет

- MPI 8 Page BrochureДокумент8 страницMPI 8 Page BrochuresidneidecarvalhoОценок пока нет

- Char Waste As Road Material: A Case StudyДокумент34 страницыChar Waste As Road Material: A Case StudyUmer FarooqОценок пока нет

- 1.toraflex Rubber Joints IomДокумент8 страниц1.toraflex Rubber Joints IomjacksonliОценок пока нет

- 03-Physic F5 2018-ElectricityДокумент32 страницы03-Physic F5 2018-ElectricitySreedrannОценок пока нет

- 0843 SigmatexДокумент2 страницы0843 SigmatexAhmed SakrОценок пока нет

- IS 2185-3 (1984) - Concrete Masonry Units, Part 3 - Autoclaved Cellular Aerated Concrete BlocksДокумент21 страницаIS 2185-3 (1984) - Concrete Masonry Units, Part 3 - Autoclaved Cellular Aerated Concrete Blocksmanish_shashikantОценок пока нет

- Ice Amice SyllabusДокумент57 страницIce Amice SyllabusBIJAY KRISHNA DAS100% (1)

- Daya Dukung - Pondasi DangkalДокумент34 страницыDaya Dukung - Pondasi DangkalRaditya PurnamahadiОценок пока нет

- Hvac Report 20140604Документ198 страницHvac Report 20140604Muhammad Yusuf FirdausОценок пока нет

- A1 Fence Specs For WebsiteДокумент22 страницыA1 Fence Specs For WebsitetajlandОценок пока нет

- Grape County Resort NasikДокумент1 страницаGrape County Resort Nasikaugupta2001Оценок пока нет

- On Base PlateДокумент20 страницOn Base PlateHemant SonawadekarОценок пока нет

- Hot BoltingДокумент6 страницHot BoltingNickath Banu100% (1)

- UMAT Theory - Nader Abedrabbo, PH.DДокумент2 страницыUMAT Theory - Nader Abedrabbo, PH.DSebastiao SilvaОценок пока нет

- Exergy AnalysisДокумент58 страницExergy Analysismohammed yaseenОценок пока нет

- Rate Analysis-NormsДокумент7 страницRate Analysis-NormsGajendra Joshi0% (1)

- Tunnelling and Underground Space Technology: L.X. Xie, W.B. Lu, Q.B. Zhang, Q.H. Jiang, M. Chen, J. ZhaoДокумент15 страницTunnelling and Underground Space Technology: L.X. Xie, W.B. Lu, Q.B. Zhang, Q.H. Jiang, M. Chen, J. ZhaoKatty MonsalveОценок пока нет

- Fittings & Flanges For Pipe Series 2410 and 3410 Using The TaperTaper Adhesive-Bonded Joint FP657-10 0898Документ40 страницFittings & Flanges For Pipe Series 2410 and 3410 Using The TaperTaper Adhesive-Bonded Joint FP657-10 0898nidhinОценок пока нет

- Sabiana FC CRCДокумент23 страницыSabiana FC CRCIgor SpasovicОценок пока нет

- Retrowrap Materials Performance FactsДокумент2 страницыRetrowrap Materials Performance FactsMОценок пока нет

- Direct Tensile Test of ConcreteДокумент7 страницDirect Tensile Test of ConcreteBunkun15100% (1)

- Avalon Astoria Service Manual PDFДокумент106 страницAvalon Astoria Service Manual PDFexchangenriОценок пока нет