Академический Документы

Профессиональный Документы

Культура Документы

Carousel

Загружено:

Catalin AlexandruИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Carousel

Загружено:

Catalin AlexandruАвторское право:

Доступные форматы

C:\Documents and Settings\Administrator\Desktop\airport specs\Carousel Rev B.

doc

1

Geo. Robson & Co. (Conveyors) Ltd

Coleford Road, Sheffield, S9 5PA

Tel. +44 (0)114 2444221 Fax. +44 (0)114 2433066

Info@robson.co.uk www.robson.co.uk

Baggage Carousel

Geo. Robson & Co. Airport Baggage Mechanical Handling Solutions offer the

ultimate for speed, reliability, robustness and product life.

With a range of conveying solutions to suit the most challenging of sites and

surroundings. Robsons offer conveyors configured for Weighing, Sorting,

Security, X-Ray, Out of Gauge, Diverting Horizontally and Vertically. With

Merging capabilities, Incline and Decline plus Power Bends, Robsons take

the lead for the total solution package.

A Robson Carousel provides an endless surface which baggage can be displayed prior to

reclaim. A combination of straight and radius sections gives the Robson carousel the

flexibility to form different types of shapes such as L, J , U, T, I most shapes can be

accommodated depending on available space.

Rigidly constructed on to a 6mm mild steel sub-frame, choices of galvanised or powder

coated mild steel or x240 grit finish stainless steel casings are available.

With a nominal speed of 0.45 metres per second and having all fixings internal to the casing

resulting with no protruding items plus integral Kick Plates the Robson Carousel ensures the

safety of all uses, Baggage Handlers or passengers.

The conveying surface comprises of overlapping flexible rubber slats, supported on the

underside by steel carriers, this gives a user friendly surface that eliminates finger traps,

whist having a strong support able to withstand heavy luggage.

Available in two combinations the Robson Carousel offers a comprehensive product that

gives an unrivalled robust and reliable performance. Low maintenance, heavy-duty

components ensure the Robson Carousel gives an optimal performance under all demanding

operational duties.

Caterpillar Drive

A Caterpillar drive engages horizontally with the Bi Planer, chain via pairs of teeth forming the outer links. There

are a minimum of two teeth in engagement at any time. The tow chain is of the Bi-planer type allowing articulation

both the horizontal and vertical planes

Friction Drive

The Bi Planer chain is made up of universal links formed from Glass reinforced polymer.

A Friction Drive provides power to the chain links The Friction Drive Carousel offers the following advantages over

a conventional carousel

low noise level

low power requirement

low whole life cost

low maintenance

lower lead-time

attractive design

C:\Documents and Settings\Administrator\Desktop\airport specs\Carousel Rev B.doc

2

Geo. Robson & Co. (Conveyors) Ltd

Coleford Road, Sheffield, S9 5PA

Tel. +44 (0)114 2444221 Fax. +44 (0)114 2433066

Info@robson.co.uk www.robson.co.uk

Baggage Carousel

Caterpillar Drive

Friction Drive

Typical Carousel Layouts

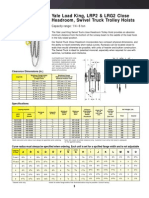

BAGGAGE CAROUSEL SPECIFICATION (Caterpillar Drive & Friction Drive)

Dimensions Unlimited

Widths Airside Baggage Hall1000mm Passenger Baggage Reclaim 890mm / 1150mm

Bend Diameter Min 1150mm Max Unlimited

Material Mild Steel or Stainless Steel

Finish Choice Galvanised or Powder Coated Mild Steel or x240 Grit Finish Stainless Steel

Speed 0.45 metres per second

Capacity Maximum Chain Pull 540 kgs.

Optional extra Flame retardant rubber slats to ISO 340

OUTLINE OF TOW

CHAIN GUIDE WHEEL

1000

3

5

0

>

6

5

0

OUTLINE OF SLAT AND

CARRIER

OUTLINE OF STD

SIDE CASING

OUTLINE OF TOE

GUARD

OUTLINE OF COMPOSITE

CHAIN

L

J

U

T

I

Вам также может понравиться

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsОт EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsРейтинг: 4.5 из 5 звезд4.5/5 (10)

- QDB 15 AirlawДокумент75 страницQDB 15 AirlawKueh Chew Chai78% (9)

- Qj340 ManualДокумент68 страницQj340 Manualluis50% (2)

- Bridge Bearings & Expansion JointsДокумент16 страницBridge Bearings & Expansion Jointsjacob_arun100% (3)

- Cabletorq Thickeners/Clarifiers: Gl&V/Dorr-Oliver100Ft - Dia.Type"S"CabletorqthickenerДокумент4 страницыCabletorq Thickeners/Clarifiers: Gl&V/Dorr-Oliver100Ft - Dia.Type"S"Cabletorqthickenerdgomez686Оценок пока нет

- Demag - Jib CranesДокумент22 страницыDemag - Jib CranesGogyОценок пока нет

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!От EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Рейтинг: 5 из 5 звезд5/5 (2)

- Sky-High Controversyand High-Flying Claims? The Sturgeon Case Law in Light of Judicialactivism, Euroscepticismand EurolegalismДокумент31 страницаSky-High Controversyand High-Flying Claims? The Sturgeon Case Law in Light of Judicialactivism, Euroscepticismand EurolegalismDelia HaraОценок пока нет

- Pilot Operating Handbook: Aeroplanes DarДокумент32 страницыPilot Operating Handbook: Aeroplanes Darkisari0% (1)

- Can I Ask You A QuestionДокумент3 страницыCan I Ask You A QuestionlaiaОценок пока нет

- O'Brien Met-Track Workstation Bridge CranesДокумент16 страницO'Brien Met-Track Workstation Bridge Cranesdf_campos3353Оценок пока нет

- Defensas Maritimas - Complete FlotationДокумент32 страницыDefensas Maritimas - Complete FlotationFelipe FernandesОценок пока нет

- Quick Facts Rodan Steel Deck ModulesДокумент2 страницыQuick Facts Rodan Steel Deck ModulesPT. OMETRACO ARYA SAMANTA0% (1)

- Surface Belt Structure: Cema C & D SeriesДокумент8 страницSurface Belt Structure: Cema C & D SeriesSari Ully SibaraniОценок пока нет

- 5566 Drag ConveyorsДокумент8 страниц5566 Drag ConveyorsEduardo SaucedoОценок пока нет

- Amphibious ExcavatorДокумент6 страницAmphibious ExcavatorjohariakОценок пока нет

- The Circle of Refractory Maintenance: Brokk and Bricking SolutionsДокумент36 страницThe Circle of Refractory Maintenance: Brokk and Bricking SolutionsViet Nam M-TechОценок пока нет

- The Circle of Refractory Maintenance: Brokk and Bricking SolutionsДокумент36 страницThe Circle of Refractory Maintenance: Brokk and Bricking SolutionsManh PhamОценок пока нет

- 5501 Super Capacity Bucket ElevatorsДокумент16 страниц5501 Super Capacity Bucket ElevatorsceshesolОценок пока нет

- All Hangfu ProductДокумент34 страницыAll Hangfu ProductClarkОценок пока нет

- ACP SuperCorДокумент16 страницACP SuperCorHaryo WidodoОценок пока нет

- Spiral Conveyors: "Save Space and Increase Throughput"Документ2 страницыSpiral Conveyors: "Save Space and Increase Throughput"adilsonsantosОценок пока нет

- Grove Rough-Terrain Cranes: Features and BenefitsДокумент20 страницGrove Rough-Terrain Cranes: Features and BenefitsFranck SPERZAGNI PUBОценок пока нет

- 5566 Drag ConveyorsДокумент8 страниц5566 Drag Conveyorsashok_chakreeОценок пока нет

- Boat Landing Systems-2Документ6 страницBoat Landing Systems-2Guilherme LealОценок пока нет

- Conveyor ComponentsДокумент26 страницConveyor Componentswmacadd100% (6)

- Digger: Ship UnloaderДокумент16 страницDigger: Ship UnloaderLeonardo CanditoОценок пока нет

- 2065 Robor Conveyor Tubes IdlersДокумент2 страницы2065 Robor Conveyor Tubes IdlersWilmarОценок пока нет

- Aero Belt ConveyorДокумент8 страницAero Belt ConveyorsrinivasakumarОценок пока нет

- Azimuth Tunnel ThrustersДокумент10 страницAzimuth Tunnel ThrustersAnoop VAОценок пока нет

- Drag Chain Con Bototm Wear Liner MaterialДокумент4 страницыDrag Chain Con Bototm Wear Liner MaterialSandeep GuptaОценок пока нет

- Diamondback Brochure2013Документ10 страницDiamondback Brochure2013Amir Hooshang Ghadymi MahaniОценок пока нет

- Industrial Products BrochureДокумент16 страницIndustrial Products BrochureJames EllisОценок пока нет

- RT Features and Benefits EMEAДокумент20 страницRT Features and Benefits EMEAdavid diazОценок пока нет

- ACO Systems Ductile Iron Brochure SmallДокумент28 страницACO Systems Ductile Iron Brochure SmallilieoniciucОценок пока нет

- Operator Seat AIR 569 - KabseatingДокумент20 страницOperator Seat AIR 569 - KabseatingSolitario AntofaОценок пока нет

- Groundworks BrochureДокумент19 страницGroundworks BrochureMohammed HafizОценок пока нет

- BN Islander BrochureДокумент16 страницBN Islander BrochureMF84Оценок пока нет

- 2013 Catalogue BДокумент188 страниц2013 Catalogue BjmartinezmoОценок пока нет

- Introduction To Work Station Cranes (Gobel)Документ16 страницIntroduction To Work Station Cranes (Gobel)Yadi KusmayadiОценок пока нет

- Euro Weigh-BridgeДокумент12 страницEuro Weigh-BridgeCalvinyeohОценок пока нет

- Trio - Group Washers LogДокумент4 страницыTrio - Group Washers LogCemYurtseverОценок пока нет

- Dymax Work Tools: Rail Cleanup BucketsДокумент1 страницаDymax Work Tools: Rail Cleanup BucketsMax SashikhinОценок пока нет

- Bemo Rail General ManualДокумент19 страницBemo Rail General ManualTh NattapongОценок пока нет

- HWY - AIR Brochure (Web)Документ16 страницHWY - AIR Brochure (Web)MudduKrishna shettyОценок пока нет

- Groundworks BrochureДокумент19 страницGroundworks BrochureMagdy BakryОценок пока нет

- Guincho VolanteДокумент1 страницаGuincho VolanteGustavo GomesОценок пока нет

- Introduction To TrackДокумент81 страницаIntroduction To TrackiritmspceОценок пока нет

- B&D ManufacuringДокумент20 страницB&D ManufacuringRodolfoMarínОценок пока нет

- Notes MachineryДокумент2 страницыNotes MachineryIndrajeet GuptaОценок пока нет

- NL1002 eДокумент128 страницNL1002 eThiago FaúlaОценок пока нет

- Self Aligning RotatorsДокумент4 страницыSelf Aligning RotatorsOdprirodeОценок пока нет

- Conveyor Components Product Handbook PDFДокумент52 страницыConveyor Components Product Handbook PDFJean GrégoireОценок пока нет

- Sam McCoy MFG - Catalogue 2004 - 2Документ29 страницSam McCoy MFG - Catalogue 2004 - 2Sam McCoy ManufacturingОценок пока нет

- Bearing Pad - 2007Документ4 страницыBearing Pad - 2007Kumar JbsОценок пока нет

- Ryson BucketДокумент4 страницыRyson Bucketaani1984Оценок пока нет

- Icon Conveyors PDFДокумент4 страницыIcon Conveyors PDFActive watersaverОценок пока нет

- Catalogo CablesДокумент16 страницCatalogo CablesBorja MuñizОценок пока нет

- Yard Ramp: Loading Made EasyДокумент2 страницыYard Ramp: Loading Made EasyhdtОценок пока нет

- Yale Load King, LRP2 & LRG2 Close Headroom, Swivel Truck Trolley HoistsДокумент1 страницаYale Load King, LRP2 & LRG2 Close Headroom, Swivel Truck Trolley HoistsdmitosОценок пока нет

- Rope Winches and GearboxesДокумент20 страницRope Winches and Gearboxesiturcic9100% (1)

- High-Performance GM LS-Series Cylinder Head GuideОт EverandHigh-Performance GM LS-Series Cylinder Head GuideРейтинг: 4.5 из 5 звезд4.5/5 (2)

- Analiza Swot NikeДокумент7 страницAnaliza Swot NikeCatalin AlexandruОценок пока нет

- Analiza Swot NikeДокумент4 страницыAnaliza Swot NikeCatalin AlexandruОценок пока нет

- Hat ZZZZДокумент13 страницHat ZZZZCatalin AlexandruОценок пока нет

- Analiza Swot NikeДокумент11 страницAnaliza Swot NikeCatalin AlexandruОценок пока нет

- Aprovizionare Sau Prin Concentrarea Asupra Noilor: Canale de DistribuţieДокумент13 страницAprovizionare Sau Prin Concentrarea Asupra Noilor: Canale de DistribuţieCatalin AlexandruОценок пока нет

- Aprovizionare Sau Prin Concentrarea Asupra Noilor: Canale de DistribuţieДокумент13 страницAprovizionare Sau Prin Concentrarea Asupra Noilor: Canale de DistribuţieCatalin AlexandruОценок пока нет

- Y205-EN2-07+IndAutomGuide2014 - SensingДокумент146 страницY205-EN2-07+IndAutomGuide2014 - SensingCatalin AlexandruОценок пока нет

- MaterialData 126201122Документ3 страницыMaterialData 126201122Catalin AlexandruОценок пока нет

- Asdasd::,., PRR - F LRFДокумент3 страницыAsdasd::,., PRR - F LRFCatalin AlexandruОценок пока нет

- Ulllted States Patent (19) (11) Patent Number: 5,844,807: / / Total Height 46.28 208Документ29 страницUlllted States Patent (19) (11) Patent Number: 5,844,807: / / Total Height 46.28 208Catalin AlexandruОценок пока нет

- RC Conveyor / Slope Conveyor: Placing Concrete Across Flat Slabs or On SlopesДокумент2 страницыRC Conveyor / Slope Conveyor: Placing Concrete Across Flat Slabs or On SlopesCatalin AlexandruОценок пока нет

- Sept. 23, 1969 C. P. Nanney Etal 3,458,436: Filed July 7. 1967Документ18 страницSept. 23, 1969 C. P. Nanney Etal 3,458,436: Filed July 7. 1967Catalin AlexandruОценок пока нет

- MaterialData 1262011223354Документ3 страницыMaterialData 1262011223354Catalin AlexandruОценок пока нет

- MaterialData 1262011Документ3 страницыMaterialData 1262011Catalin AlexandruОценок пока нет

- MaterialData 12620112Документ3 страницыMaterialData 12620112Catalin AlexandruОценок пока нет

- 8crisplant Automsated Container Handling System 07Документ2 страницы8crisplant Automsated Container Handling System 07Catalin AlexandruОценок пока нет

- 11crisplant Baggage Lifting Table 07Документ2 страницы11crisplant Baggage Lifting Table 07Catalin AlexandruОценок пока нет

- MaterialData 126201Документ2 страницыMaterialData 126201Catalin AlexandruОценок пока нет

- 3crisplant Ps Crisbag 08Документ4 страницы3crisplant Ps Crisbag 08Catalin AlexandruОценок пока нет

- Daewoo 432X 523XДокумент4 страницыDaewoo 432X 523XCatalin AlexandruОценок пока нет

- United States: (12) Patent Application Publication (10) Pub. No.: US 2012/0145519 A1Документ17 страницUnited States: (12) Patent Application Publication (10) Pub. No.: US 2012/0145519 A1Catalin AlexandruОценок пока нет

- Daewoo Chassis CP 102s DTB 21s6, 21s7Документ57 страницDaewoo Chassis CP 102s DTB 21s6, 21s7Catalin AlexandruОценок пока нет

- Air RegulationsДокумент26 страницAir RegulationsJoy AndriyasОценок пока нет

- Civil Simulator Census2013Документ48 страницCivil Simulator Census2013kit0925Оценок пока нет

- The Evolution of Civil Aircraft Design at Bombardier: An Historic PerspectiveДокумент15 страницThe Evolution of Civil Aircraft Design at Bombardier: An Historic PerspectiveJuan GutierrezОценок пока нет

- Crisis Pan AmДокумент8 страницCrisis Pan Amruben guillermo paniОценок пока нет

- ASN 085.12 - WorldTracer System Enhancement UpdatesДокумент3 страницыASN 085.12 - WorldTracer System Enhancement UpdatesBurcu Yıldız100% (2)

- English Practice READING BLOCK: This Text About Behavior On Airplanes Comes FromДокумент4 страницыEnglish Practice READING BLOCK: This Text About Behavior On Airplanes Comes Fromanward muhammed arcila ridiaОценок пока нет

- Personal Best B1 Unit 12 Vocab TestДокумент1 страницаPersonal Best B1 Unit 12 Vocab TestJavier EguiaОценок пока нет

- Military Heli Global Market ReportДокумент47 страницMilitary Heli Global Market ReportLuis Filipe Martins Barros100% (3)

- NTSB Molokai Helicopter Crash Preliminary ReportДокумент4 страницыNTSB Molokai Helicopter Crash Preliminary ReportHawaii News NowОценок пока нет

- Annex 18 - The Safe Transport of Dangerous Goods by Air: Supplement ToДокумент16 страницAnnex 18 - The Safe Transport of Dangerous Goods by Air: Supplement Tosama9ma912Оценок пока нет

- Distinction PPT - PPTX Auto Saved)Документ28 страницDistinction PPT - PPTX Auto Saved)Abhinash PoddarОценок пока нет

- EMBRAER 170/175/190/195 CTA Master Minimum Equipment List: Empresa Brasileira de Aeronáutica S.AДокумент185 страницEMBRAER 170/175/190/195 CTA Master Minimum Equipment List: Empresa Brasileira de Aeronáutica S.AperrymekОценок пока нет

- MARKET FORECAST 2014 - 2033: Bombardier Commercial AircraftДокумент43 страницыMARKET FORECAST 2014 - 2033: Bombardier Commercial AircraftMina MokhtarОценок пока нет

- R66 TCDS R00015LA - Rev5Документ5 страницR66 TCDS R00015LA - Rev5evanОценок пока нет

- Tenses Practice 2 KeyДокумент1 страницаTenses Practice 2 KeyJason Yoshia AndrianОценок пока нет

- Jet Airways IssuesДокумент6 страницJet Airways IssuesRam RaikwarОценок пока нет

- AS350 B2 - IntroДокумент25 страницAS350 B2 - IntroEX919Оценок пока нет

- ICAO 9734 Safety Oversight ManualДокумент52 страницыICAO 9734 Safety Oversight ManualNkemakolam Celestine ChukwuОценок пока нет

- Transportation Vocabulary Matching Exercise ESL Worksheets For Kids and New Learners 8629Документ2 страницыTransportation Vocabulary Matching Exercise ESL Worksheets For Kids and New Learners 8629ErwinОценок пока нет

- Air Brake CourseДокумент215 страницAir Brake Courserizaazari4530100% (3)

- BRS-Continuous Descent Approaches. SmartLynx VersionДокумент31 страницаBRS-Continuous Descent Approaches. SmartLynx VersionMiran MirОценок пока нет

- Eurocontrol European Aviation Overview 20230602Документ20 страницEurocontrol European Aviation Overview 20230602Neo PilОценок пока нет

- Soạn Đề Ilearn 7 Giữa KìДокумент6 страницSoạn Đề Ilearn 7 Giữa Kìgiasutaihue1Оценок пока нет

- HMPE1 Prelim'sДокумент118 страницHMPE1 Prelim'sGerlie Mae GomezОценок пока нет

- Fight Ticket PDFДокумент1 страницаFight Ticket PDFRaviteja ChintaОценок пока нет

- FAA A Historical Perspective, 1903-2008Документ200 страницFAA A Historical Perspective, 1903-2008Tavi Grig100% (1)