Академический Документы

Профессиональный Документы

Культура Документы

Max Safe Working Pressure Pipes

Загружено:

jok19740 оценок0% нашли этот документ полезным (0 голосов)

99 просмотров1 страницаАвторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

99 просмотров1 страницаMax Safe Working Pressure Pipes

Загружено:

jok1974Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 1

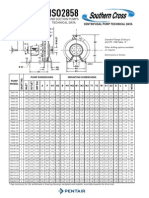

MAXIMUM SAFE WORKING PRESSURES

TUBELINE MEDIUM & HEAVY PRESSURE PIPE

Specification : AS 1074

Mass per

Metre Maximum

Nominal Outside Wall Black Recommended Maximum Safe Working Pressure

Size Quality Diameter Thickness Plain Ends Test Pressure at Metal Temperature

o

C

(DN) & Grooved Ambient Temp

- 45

o

C to 50

o

C

100 150 200 250 300 350 400

mm mm kg/m MPa P.S.I. MPa P.S.I. MPa P.S.I. MPa P.S.I. MPa P.S.I. MPa P.S.I. MPa P.S.I. MPa P.S.I. MPa P.S.I.

20 Medium 26.9 2.6 1.56 22.1 3210 14.7 2140 13.5 1960 12.2 1780 11.0 1600 9.75 1420 8.73 1270 8.05 1170 7.71 1120

Heavy 26.9 3.2 1.87 27.8 4040 18.5 2690 17.0 2460 15.4 2240 13.8 2010 12.3 1780 11.0 1590 10.1 1470 9.70 1410

25 Medium 33.7 3.2 2.41 21.7 3150 14.5 2100 13.2 1920 12.0 1740 10.8 1570 9.56 1390 8.56 1240 7.90 1150 7.56 1100

Heavy 33.7 4.0 2.94 27.8 4030 18.5 2690 16.9 2460 15.4 2230 13.8 2000 12.2 1780 11.0 1590 10.1 1470 9.68 1400

32 Medium 42.4 3.2 3.10 16.9 2450 11.3 1640 10.3 1500 9.37 1360 8.41 1220 7.46 1080 6.68 969 6.16 894 5.90 856

Heavy 42.4 4.0 3.80 21.5 3120 14.4 2080 13.1 1910 11.9 1730 10.7 1550 9.50 1380 8.50 1230 7.84 1140 7.51 1090

40 Medium 48.3 3.2 3.57 14.7 2140 9.81 1420 8.98 1300 8.15 1180 7.32 1060 6.49 942 5.81 843 5.36 778 5.13 745

Heavy 48.3 4.0 4.38 18.7 2710 12.5 1810 11.4 1660 10.4 1500 9.30 1350 8.24 1200 7.38 1070 6.80 988 6.52 946

50 Medium 60.3 3.6 5.03 13.2 1910 8.78 1270 8.04 1170 7.30 1060 6.55 951 5.81 843 5.20 755 4.80 696 4.59 667

Heavy 60.3 4.5 6.19 16.7 2420 11.1 1620 10.2 1480 9.25 1340 8.31 1210 7.37 1070 6.60 958 6.08 883 5.83 846

65 Medium 76.1 3.6 6.43 10.3 1500 6.88 998 6.30 914 5.72 829 5.13 745 4.55 661 4.07 591 3.76 545 3.60 522

Heavy 76.1 4.5 7.93 13.0 1890 8.70 1260 7.96 1160 7.22 1050 6.49 942 5.75 835 5.15 748 4.75 689 4.55 660

80 Medium 88.9 4.0 8.37 9.79 1420 6.53 948 5.98 867 5.42 787 4.87 707 4.32 627 3.87 561 3.57 518 3.42 496

Heavy 88.9 5.0 10.3 12.4 1800 8.25 1200 7.55 1100 6.85 995 6.15 893 5.46 792 4.89 709 4.50 654 4.31 626

90 Medium 101.6 4.0 9.63 8.52 1240 5.68 825 5.20 755 4.72 685 4.24 615 3.76 546 3.37 489 3.10 450 2.97 431

Heavy 101.6 5.0 11.9 10.8 1560 7.17 1040 6.56 953 5.96 864 5.35 776 4.74 688 4.25 616 3.92 568 3.75 544

100 Medium 114.3 4.5 12.2 8.52 1240 5.68 825 5.20 755 4.72 685 4.24 615 3.76 546 3.37 489 3.10 450 2.97 431

Heavy 114.3 5.4 14.5 10.3 1500 6.87 997 6.29 913 5.71 828 5.13 744 4.54 660 4.07 591 3.75 545 3.59 522

125 Medium 139.7 5.0 16.6 7.72 1120 5.15 747 4.71 684 4.28 621 3.84 558 3.41 494 3.05 443 2.81 408 2.69 391

Heavy 139.7 5.4 17.9 8.36 1210 5.58 809 5.10 741 4.63 672 4.16 604 3.69 535 3.30 479 3.05 442 2.92 423

150 Medium 165.1 5.0 19.7 6.50 944 4.33 629 3.97 576 3.60 523 3.23 469 2.87 416 2.57 373 2.37 344 2.27 329

Heavy 165.1 5.4 21.3 7.04 1020 4.69 681 4.29 623 3.90 566 3.50 508 3.10 450 2.78 403 2.56 372 2.45 356

Notes !! 1) The above maximumrecommended test and working pressures are applicable only to the pipe , if and only if:- 2) The piping systemworking pressures can be limited by the type of couplings or the welding class used in the design of the pipeline.

- The applied loads are only frominternal pressure in straight pipe. The pipeline should be supported so that bending and 3) AS 3920.1 gives information on the hazard level of pressure piping and other pressure equipment and the QA required to

external loads are avoided. The pipeline must also be set up with suitable freedomof angular movement at joints and bends certify design, manufacture and installation.

and with provision to accommodate thermal expansion. 4) Pressures have been calculated in accordance with AS 4041 - 1998 and the draft revision ME/1/8/00-28.

- The maximumworking pressure is based on a design strength of 130 MPa at 50

o

C, and 90% of the nominal wall

p=2feMt

f

/ (D-t

f

) Where

p =

Safe working pressure.

thickness to allow for the minimumthickness tolerance of the relevant standard. f =Design strengths fromtable D2 of AS 4041 for AS 1074 product.

- AS 4041 limits the maximumpressure of this type of pipe (Class 2) to 10 MPa when carrying Very Harmful fluids (fluid type 2) e =0.85 Weld joint factor fromtable 3.12.2 of AS 4041 for AS 1074 ERW product.

and for Harmful gases (fluid type 3). This should be considered when designing pipelines. See the OneSteel (Tubemakers M =0.7 Class design factor fromAS 4041 table 3.12.3 for class 2.

piping systems) publication "Fluid type and classes for pressure piping systems" for information on fluid types. t f =0.9 x wall thickness, in mm.

- Use of this pipe is prohibited where the pipe contents are Lethal (AS 4041 fluid type 1). See the OneSteel (Tubemakers D =Outside diameter, in mm.

piping systems) publication "Fluid type and classes for pressure piping systems" for information on fluid types. 5) No allowance has been made for corrosion, threading, grooving or machining.

This publication has been prepared by OneSteel Market Mills, an operating business group of which OneSteel Trading Pty Ltd ABN 50 007 519 646 ia a part

Please note that any specifications or technical data referred to in this publication are subject to change and/or variation or improvement without notice and no warranty as to their suitability for any use is made.

To ensiure accuracy and adequacy or their purposes - are requested to check the information provided in this publication to satisfy themselves as to its appropriateness and not to rely on the information without first doing so.

Unless required by law, the company cannot accept any responsibility for any loss, damage or consequence resulting fromthe use of this publication. Current at March 2003. This brochure is not an offer to trade and shall not

formany part of the trading terms in any transaction. Copyright 2003. OneSteel Trading Pty Limited ABN 50 007 519 646. Issue 2, March 2003

Printed copies of this web page may not contain the latest information, check the OneSteel web site at www.onesteel.com for confirmation.

Tubeline AS1074 Medium & Heavy CHS March 2003

Pressure Ratings

Вам также может понравиться

- Basics of Dental Technology: A Step by Step ApproachОт EverandBasics of Dental Technology: A Step by Step ApproachРейтинг: 5 из 5 звезд5/5 (1)

- United States Census Figures Back to 1630От EverandUnited States Census Figures Back to 1630Оценок пока нет

- Weight Chart 14333 PE 100Документ1 страницаWeight Chart 14333 PE 100ALOKОценок пока нет

- Npat 2Документ2 страницыNpat 2aaaОценок пока нет

- API 5L Line Pipe ODДокумент2 страницыAPI 5L Line Pipe ODZainudinОценок пока нет

- Aluminum Solid Rivet Weight ChartsДокумент2 страницыAluminum Solid Rivet Weight ChartsRakesh ParaliyaОценок пока нет

- Spec25051 - Teck CableДокумент4 страницыSpec25051 - Teck Cablecrfg2003Оценок пока нет

- Tally Net-Log LbspieДокумент6 страницTally Net-Log LbspieLeonardo PieriniОценок пока нет

- Pipe Span ChartДокумент1 страницаPipe Span ChartcoyuncoОценок пока нет

- Profile Laminate-CornierДокумент7 страницProfile Laminate-CornierdarabafloОценок пока нет

- Pump Dimensions: End Suction Pumps Technical DataДокумент8 страницPump Dimensions: End Suction Pumps Technical DataKatibi VanhasОценок пока нет

- Wastewater Technical ManualДокумент32 страницыWastewater Technical ManualagonzalezcordovaОценок пока нет

- IS: 4984 Wall Thickness & Weight Chart of Pipes For Material Grade PE-63Документ1 страницаIS: 4984 Wall Thickness & Weight Chart of Pipes For Material Grade PE-63Deputy Executive Engineeer RWS & S Nrpm100% (2)

- Industrial Ventilation Design Guidebook OLD VERSIONДокумент343 страницыIndustrial Ventilation Design Guidebook OLD VERSIONwalter_micale_yahoo100% (11)

- IS: 4984 Wall Thickness & Weight Chart of Pipes For Material Grade PE-100Документ1 страницаIS: 4984 Wall Thickness & Weight Chart of Pipes For Material Grade PE-100Deputy Executive Engineeer RWS & S Nrpm100% (2)

- Tension Force Calculation Sheet For Steel Bolts PDFДокумент1 страницаTension Force Calculation Sheet For Steel Bolts PDFVỸ TRẦNОценок пока нет

- L I G H TДокумент4 страницыL I G H TPrem SharmaОценок пока нет

- JJJJДокумент4 страницыJJJJPrem SharmaОценок пока нет

- RBL Precision Ansi RollerДокумент8 страницRBL Precision Ansi RollerRingball_GusОценок пока нет

- Astm - ASTM D 2270 PDFДокумент7 страницAstm - ASTM D 2270 PDFthuandiemОценок пока нет

- B1 PowerSafe TS Range SummaryДокумент4 страницыB1 PowerSafe TS Range Summarylostris234Оценок пока нет

- LLPPДокумент4 страницыLLPPPrem SharmaОценок пока нет

- WashPipe Data SheetДокумент1 страницаWashPipe Data SheetAman Aayra Srivastava100% (4)

- L I G H TДокумент4 страницыL I G H TPrem SharmaОценок пока нет

- LlooДокумент4 страницыLlooPrem SharmaОценок пока нет

- For Uses in Water, Gas, Steam and Air Line Conforming To IS: 1239 (PT I) - 2004, Equivalent To BS - 1387 / 1985Документ4 страницыFor Uses in Water, Gas, Steam and Air Line Conforming To IS: 1239 (PT I) - 2004, Equivalent To BS - 1387 / 1985Prem SharmaОценок пока нет

- Indian Standard IsДокумент4 страницыIndian Standard IsPrem SharmaОценок пока нет

- For Uses in Water, Gas, Steam and Air Line Conforming To IS: 1239 (PT I) - 2004, Equivalent To BS - 1387 / 1985Документ4 страницыFor Uses in Water, Gas, Steam and Air Line Conforming To IS: 1239 (PT I) - 2004, Equivalent To BS - 1387 / 1985Prem SharmaОценок пока нет

- Hollow Bar ChartДокумент1 страницаHollow Bar Charthornet121Оценок пока нет

- MS-Maneurop Catalogue PDFДокумент8 страницMS-Maneurop Catalogue PDFMacSparesОценок пока нет

- Gi Pipe Size Is 1239Документ4 страницыGi Pipe Size Is 1239sshnvlОценок пока нет

- L I G H TДокумент4 страницыL I G H TPrem SharmaОценок пока нет

- Measurements, Sizes, Shafts, KeywaysДокумент91 страницаMeasurements, Sizes, Shafts, KeywaysVenkat DoraОценок пока нет

- GgooДокумент4 страницыGgooPrem SharmaОценок пока нет

- A 9Документ4 страницыA 9Prem SharmaОценок пока нет

- For Uses in Water, Gas, Steam and Air Line Conforming To IS: 1239 (PT I) - 2004, Equivalent To BS - 1387 / 1985Документ4 страницыFor Uses in Water, Gas, Steam and Air Line Conforming To IS: 1239 (PT I) - 2004, Equivalent To BS - 1387 / 1985Prem SharmaОценок пока нет

- L I G H TДокумент4 страницыL I G H TPrem SharmaОценок пока нет

- PVC Cables FinolexДокумент8 страницPVC Cables FinolexMaria DenetОценок пока нет

- Triaxial Testing of SoilДокумент9 страницTriaxial Testing of SoilladheedhanasrinОценок пока нет

- L I G H TДокумент4 страницыL I G H TPrem SharmaОценок пока нет

- For Uses in Water, Gas, Steam and Air Line Conforming To IS: 1239 (PT I) - 2004, Equivalent To BS - 1387 / 1985Документ4 страницыFor Uses in Water, Gas, Steam and Air Line Conforming To IS: 1239 (PT I) - 2004, Equivalent To BS - 1387 / 1985Prem SharmaОценок пока нет

- L I G H TДокумент4 страницыL I G H TPrem SharmaОценок пока нет

- Thickness Chart Is 4984 PE 63Документ1 страницаThickness Chart Is 4984 PE 63JОценок пока нет

- For Uses in Water, Gas, Steam and Air Line Conforming To IS: 1239 (PT I) - 2004, Equivalent To BS - 1387 / 1985Документ4 страницыFor Uses in Water, Gas, Steam and Air Line Conforming To IS: 1239 (PT I) - 2004, Equivalent To BS - 1387 / 1985Prem SharmaОценок пока нет

- Astm D2270-04Документ6 страницAstm D2270-04Alvaro VelardeОценок пока нет

- L I G H TДокумент4 страницыL I G H TPrem SharmaОценок пока нет

- Anchor Bolt FactsДокумент9 страницAnchor Bolt FactsRanaОценок пока нет

- Astm 2270 Indice de Viscosidad PDFДокумент6 страницAstm 2270 Indice de Viscosidad PDFgjusecheoОценок пока нет

- L I G H TДокумент4 страницыL I G H TPrem SharmaОценок пока нет

- Heat TreatmentДокумент5 страницHeat TreatmentAnonymous XzGgqTОценок пока нет

- L I G H TДокумент4 страницыL I G H TPrem SharmaОценок пока нет

- Principal Particulars For A General Cargo Ship: Waterlines (Half Breadths)Документ13 страницPrincipal Particulars For A General Cargo Ship: Waterlines (Half Breadths)ManojОценок пока нет

- Principal Particulars For A General Cargo Ship: Waterlines (Half Breadths)Документ13 страницPrincipal Particulars For A General Cargo Ship: Waterlines (Half Breadths)ManojОценок пока нет

- Principal Particulars For A General Cargo Ship: Waterlines (Half Breadths)Документ13 страницPrincipal Particulars For A General Cargo Ship: Waterlines (Half Breadths)ManojОценок пока нет

- L I G H TДокумент4 страницыL I G H TPrem SharmaОценок пока нет

- Stainless Steel Pipe Dimensions and Weight ChartДокумент5 страницStainless Steel Pipe Dimensions and Weight ChartArun Chopra33% (3)

- L I G H TДокумент4 страницыL I G H TPrem SharmaОценок пока нет

- British Commercial Computer Digest: Pergamon Computer Data SeriesОт EverandBritish Commercial Computer Digest: Pergamon Computer Data SeriesОценок пока нет

- The G.I. Collector's Guide: U.S. Army Service Forces Catalog, European Theater of Operations: Volume 2От EverandThe G.I. Collector's Guide: U.S. Army Service Forces Catalog, European Theater of Operations: Volume 2Оценок пока нет

- TESTINGДокумент7 страницTESTINGSoner Kulte100% (1)

- Valves Quality Control PlanДокумент1 страницаValves Quality Control Planjok1974Оценок пока нет

- Inspection & Test Plans 1 of 50Документ49 страницInspection & Test Plans 1 of 50jok1974Оценок пока нет

- Paint Inspection:: Daily Coating Inspection ReportДокумент1 страницаPaint Inspection:: Daily Coating Inspection ReportEhsan KhanОценок пока нет

- AWS D10.4,10.6,10.7,10.8,10.10,10.11,10.12,10.13 Committee Recommended Practices For WeldingДокумент148 страницAWS D10.4,10.6,10.7,10.8,10.10,10.11,10.12,10.13 Committee Recommended Practices For Weldinglram7083% (6)

- Preventingdelayedcracks in Ship WeldsДокумент20 страницPreventingdelayedcracks in Ship WeldsWahyu Nur ArifiantoОценок пока нет

- Arc BlowДокумент3 страницыArc BlowApostolie IulianОценок пока нет

- BS en 20898-1-1992Документ26 страницBS en 20898-1-1992consultach100% (4)

- Arc Welding of Nonferrous MetalsДокумент83 страницыArc Welding of Nonferrous Metalsapply19842371Оценок пока нет

- Q&A-15 How Polarity Affects Electrode Performance in Arc WeldingДокумент1 страницаQ&A-15 How Polarity Affects Electrode Performance in Arc Weldingnineapril82Оценок пока нет

- The Shielding Gas Handbook - AGAДокумент79 страницThe Shielding Gas Handbook - AGAjok1974100% (1)

- FillermetalsДокумент2 страницыFillermetalsjok1974Оценок пока нет

- Jazz Theory Resources - Volume1& 2Документ498 страницJazz Theory Resources - Volume1& 2zmenendez1100% (3)

- PantechSteel CatalogueДокумент36 страницPantechSteel Cataloguejok1974Оценок пока нет

- Weld Duplex Ss SteelДокумент12 страницWeld Duplex Ss SteelSan JaОценок пока нет

- Roughness Parameters Poster 10037103 07 2008Документ1 страницаRoughness Parameters Poster 10037103 07 2008jok1974Оценок пока нет

- PQR Template (Asme)Документ2 страницыPQR Template (Asme)jok1974Оценок пока нет

- The Shielding Gas Handbook - AGAДокумент79 страницThe Shielding Gas Handbook - AGAjok1974100% (1)

- Maintenance and Repair Welding On Board (UNITOR)Документ1 страницаMaintenance and Repair Welding On Board (UNITOR)jok1974100% (1)

- 01 Vacuum ComponentsДокумент84 страницы01 Vacuum ComponentsNick LaveryОценок пока нет

- Sheet Metal Gauge Calibre PDFДокумент1 страницаSheet Metal Gauge Calibre PDFHectorОценок пока нет

- Contech ChemicalsДокумент8 страницContech ChemicalskiОценок пока нет

- ModernlongДокумент11 страницModernlongAttila EngiОценок пока нет

- Esr 1227Документ26 страницEsr 1227murdicksОценок пока нет

- BFP By-Pass Tie-A/B/C: Description Quantity Capacity 1 Item NoДокумент4 страницыBFP By-Pass Tie-A/B/C: Description Quantity Capacity 1 Item NoLouie Raymond Abbas FernandezОценок пока нет

- I Beam Price ListДокумент52 страницыI Beam Price ListRenalyn Andrade100% (8)

- European Steel and Alloy Grades: 50crmov13-15 (1.2355)Документ2 страницыEuropean Steel and Alloy Grades: 50crmov13-15 (1.2355)farshid KarpasandОценок пока нет

- Ultra High Performance Fiber Reinforced Concrete Hydration and MicrostructureДокумент3 страницыUltra High Performance Fiber Reinforced Concrete Hydration and MicrostructureShaker QaidiОценок пока нет

- MRTS29Документ10 страницMRTS29thecarlosgarciaОценок пока нет

- PEM Self Clinching Nuts CL SeriesДокумент12 страницPEM Self Clinching Nuts CL SeriesAce Industrial SuppliesОценок пока нет

- Piping Inspector QuestionsДокумент7 страницPiping Inspector Questionsnike_y2k100% (1)

- TDS-US-ParaWeb M, Nov15Документ1 страницаTDS-US-ParaWeb M, Nov15Ammarah AzmatОценок пока нет

- Tfo - 100723-01Документ2 страницыTfo - 100723-01Rahaf BashatОценок пока нет

- EM4 Exercise1 JcguiteringДокумент6 страницEM4 Exercise1 JcguiteringJefril Guitering IIОценок пока нет

- Final BodyДокумент63 страницыFinal BodyAbubakar MusaОценок пока нет

- Timber: Heavy Duty Wood Screw & Rafter/Truss To Top Plate ConnectionДокумент3 страницыTimber: Heavy Duty Wood Screw & Rafter/Truss To Top Plate ConnectionDan McGeeОценок пока нет

- Flange Table-3 PDFДокумент1 страницаFlange Table-3 PDFReşat DEMİRОценок пока нет

- PreamblesДокумент12 страницPreamblesMohamad Noor AffenddyОценок пока нет

- Form Work 3 - RemovedДокумент31 страницаForm Work 3 - Removedपूजा दासОценок пока нет

- FabricationДокумент7 страницFabricationg-ipgp23271000Оценок пока нет

- E 90 48Документ4 страницыE 90 48Agus Qupink Luph AriaОценок пока нет

- Review of Resistance Spot Welding of SteelДокумент31 страницаReview of Resistance Spot Welding of SteelLívia RodriguesОценок пока нет

- Indian Standard: Specification FOR 62 Percent Alumina Bricks and Blocks For Blast FurnaceДокумент7 страницIndian Standard: Specification FOR 62 Percent Alumina Bricks and Blocks For Blast Furnacear TaОценок пока нет

- Sika Hydrotite CJ-Type 2012-01-1Документ5 страницSika Hydrotite CJ-Type 2012-01-1pandavision76Оценок пока нет

- Concrete Storage StructuresДокумент51 страницаConcrete Storage Structuresruytguerra100% (1)

- VIVA VOCE Questions FinalДокумент5 страницVIVA VOCE Questions FinalS.m. Chandrashekar100% (2)

- Local Stress CheckДокумент7 страницLocal Stress Checkprabhakaran.cОценок пока нет

- Nu Bolt Techdata A4 PDFДокумент2 страницыNu Bolt Techdata A4 PDFMatthew ButlerОценок пока нет

- Concrete Basics - Portland Cement Association (PCA)Документ3 страницыConcrete Basics - Portland Cement Association (PCA)farhanshakeelОценок пока нет