Академический Документы

Профессиональный Документы

Культура Документы

Pref

Загружено:

AmirAmiriОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Pref

Загружено:

AmirAmiriАвторское право:

Доступные форматы

Preface

This third edition has been written to thoroughly update the coverage of injection molding in

the World of Plastics. There have been changes, including extensive additions, to over 50%

of the content of the second edition. Many examples are provided of processing different

plastics and relating the results to critical factors, which range from product design to meeting

performance requirements to reducing costs to zero-defect targets. Changes have not been

made that concern what is basic to injection molding. However, more basic information has

been added concerning present and future developments, resulting in the book being more

useful for a long time to come. Detailed explanations and interpretation of individual subjects

(more than 1500) are provided, using a total of 914 figures and 209 tables. Throughout the

book there is extensive information on problems and solutions as well as extensive cross-

referencing on its many different subjects.

This book represents the ENCYCLOPEDIA on IM, as is evident from its extensive and

detailed text that follows from its lengthy Table of CONTENTS and I NDEX with over

5200 entries. The worldwide industry encompasses many hundreds of useful plastic-related

computer programs. This book lists these programs (ranging from operational training to

product design to molding to marketing) and explains them briefly, but no program or series

of programs can provide the details obtained and the extent of information contained in this

single sourcebook.

In the manufacture of molded products there is always a challenge to utilize advanced

techniques, such as understanding the different plastic melt flow behaviors, operational moni-

toring and control systems, testing and quality control, and statistical analysis. However,

these techniques are only helpful if the basic operations of molding are understood and

characterized, to ensure the elimination or significant reduction of potential problems.

The book provides an understanding that is concise, practical, and comprehensive and that

goes from A to Z on the complete subject of injection molding. I t provides concise information

for either the technical or the nontechnical reader, interrelating and understanding basic

factors starting with the plastics melt flow behavior during processing. It should be useful

to the fabricator, moldmaker, designer, engineer, maintenance person, accountant, plant

manager, testing and quality control worker, cost estimator, sales and marketing person,

venture capitalist, buyer, vendor, educator/trainer, workshop leader, librarian/information

provider, lawyer, consultant, and others. People with different interests can focus on and

interrelate across subjects that they have limited or no familiarity with in the World of Plastics.

As explained throughout this book, this type of understanding is required in order to be

successful in the design, prototyping, and manufacture of the many different marketable

molded products worldwide.

xxi x

xxx Preface

The reader will have a useful reference for pertinent information readily available in the

table of contents and the index. As past book reviewers have commented, the information

contained in this book is of value to even the most experienced designers and engineers, and

provides a firm basis for the beginner. The intent is to provide a complete review of all aspects

of the injection molding process that goes from the practical to the theoretical, and from the

elementary to the advanced.

This book can provide people not familiar with injection molding an understanding of

how to fabricate products in order to obtain its benefits and advantages. It also provides

information on the most common and costly pitfalls or problems that can develop, resulting

in poor product performance or failures. Accompanying the problems are solutions. This

book will enhance the intuitive skills of those people who are already working in plastics. Its

emphasis is on providing a guide to understanding the worldwide technology and business of

injection-molded products.

From a pragmatic standpoint, every theoretical aspect that is presented has been expressed

so that it is comprehensive and useful. The theorist, for example, will gain insight into the

limitations of plastics relative to other materials such as steel and wood. After over a century

of worldwide production of all kinds of injection-molded products, they can be processed

successfully, yielding high quality, consistency, and profitability. As described in this book, one

can apply the correct performance factors based on an intelligent understanding of the subject.

This book has been prepared with the awareness that its usefulness will depend on its

simplicity and its ability to provide essential information. With the experience gained in

working in the injection molding industry worldwide and in preparing the first and second

editions as well as other books, we believe that we have succeeded in that purpose and have

provided a useful, practical reference work.

The injection molding industry consumes about 32 wt% of all plastics. The plastics industry

as a whole is ranked as the fourth largest industry in the United States. With plastics, to

a greater extent than other materials, opportunity for improvement will always exist, since

new and useful developments in materials and processing continually are on the horizon.

Examples of these developments are given in this book, providing guides to future trends in

the world of plastics.

The limited data presented on the properties of plastics are provided as comparative guides;

readers can obtain the latest information from material suppliers, industry software, and/or

sources mentioned in this books reference section. Our focus in the book is to present,

interpret, analyze, and interrelate the basic elements of injection molding for processing

plastic products. As explained in this book, there are over 17,000 plastic materials worldwide,

and selecting the right one requires specifying all product performance requirements, properly

setting up and controlling the injection molding process to be used, and intelligently preparing

a material specification purchase document and work order to produce the product.

The many properties of different plastics are important for different purposes. Some meet

high performance requirements such as long-time creep resistance, fatigue endurance, or

toughness. On the other hand, for some plastics, ready supply and low cost are the main ad-

vantages. As explained in this book, each of the different materials requires specific injection

molding operating procedures.

Patents or trademarks may cover some of the information presented. No authorization

to utilize these patents or trademarks is given or implied; they are discussed for informa-

tion purposes only. The use of general descriptive names, proprietary names, trade names,

commercial designations or the like does not in any way imply that they may be used as

common nouns. While the information presented is believed to be true and accurate, neither

the authors nor the publisher can accept any legal responsibility for any errors, omissions,

inaccuracies, or other factors.

Preface xxxi

In preparing this book and ensuring its completeness and the correctness of the subjects

reviewed, use was made of the authors worldwide personal, industrial, and teaching expe-

rience that totals over a century, as well as worldwide information from industry (personal

contacts, conferences, books, articles, etc.) and trade associations.

THE ROSATOS

Вам также может понравиться

- Guidelines: Injection Mold DesignДокумент4 страницыGuidelines: Injection Mold DesignAmirAmiriОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- 1320 HP Zr2440w MonitorДокумент2 страницы1320 HP Zr2440w MonitorAmirAmiriОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Moldeadora PDFДокумент12 страницMoldeadora PDFAmirAmiriОценок пока нет

- D 004663 PDFДокумент96 страницD 004663 PDFAmirAmiriОценок пока нет

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Engineering Plastics..Документ55 страницEngineering Plastics..AmirAmiriОценок пока нет

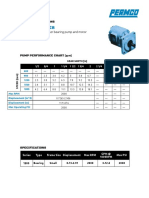

- Series: Small Displacement Roller Bearing Pump and MotorДокумент2 страницыSeries: Small Displacement Roller Bearing Pump and MotorAmirAmiriОценок пока нет

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Project Report FinalДокумент52 страницыProject Report FinalAmirAmiri0% (1)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Appendix Nve: RsionsДокумент7 страницAppendix Nve: RsionsAmirAmiriОценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Ground Spur Gears - Module 0.5: MaterialДокумент2 страницыGround Spur Gears - Module 0.5: MaterialAmirAmiriОценок пока нет

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Scoring Short Ipaq April04Документ9 страницScoring Short Ipaq April04AmirAmiriОценок пока нет

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Training Documents - SolidWorks ComposerДокумент2 страницыTraining Documents - SolidWorks ComposerAmirAmiri100% (1)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Injection Moulding: CD Catalogue Online CatalogueДокумент1 страницаInjection Moulding: CD Catalogue Online CatalogueAmirAmiriОценок пока нет

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- 522541Документ8 страниц522541AmirAmiriОценок пока нет

- Tool CRMДокумент36 страницTool CRMAmirAmiriОценок пока нет

- DV09PUB2 Study GuideДокумент5 страницDV09PUB2 Study GuideAmirAmiriОценок пока нет

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Harmonic Motion of A Maxwell Model: Trigonometric NotationДокумент4 страницыHarmonic Motion of A Maxwell Model: Trigonometric NotationAmirAmiriОценок пока нет

- 53.data Leakage Detection AbstractДокумент8 страниц53.data Leakage Detection AbstractJaya Chavan0% (1)

- Split Charge InstructionsДокумент4 страницыSplit Charge InstructionsAugusto ZanlungoОценок пока нет

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- PAM-1, PAM-2, and PAM-4: Multi-Voltage Relay ModulesДокумент2 страницыPAM-1, PAM-2, and PAM-4: Multi-Voltage Relay Modulestrinadh pillaОценок пока нет

- 2023-24 S.Y. B.sc. ElectronicsДокумент14 страниц2023-24 S.Y. B.sc. Electronicsanil sonawaneОценок пока нет

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Unit 4 5 MCQ PPT CombinedДокумент252 страницыUnit 4 5 MCQ PPT CombinedSyed ZubairОценок пока нет

- CIM For Enterprise Integration (IEC) 61968Документ53 страницыCIM For Enterprise Integration (IEC) 61968Igor SangulinОценок пока нет

- ClassiCool MSP - English - Summary - EOSДокумент16 страницClassiCool MSP - English - Summary - EOSMohammed KandeelОценок пока нет

- PCP - VersionДокумент33 страницыPCP - VersionKiran JoshiОценок пока нет

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Regional Development Plan PDFДокумент16 страницRegional Development Plan PDFAlexandra FricosuОценок пока нет

- Sample ResumeДокумент2 страницыSample ResumeJackkyОценок пока нет

- An Overview On Evolution of Mobile Wireless Communication Networks: 1G-6GДокумент4 страницыAn Overview On Evolution of Mobile Wireless Communication Networks: 1G-6GAsmaa AbduОценок пока нет

- Huawei SE1000 Series Enterprise SBC Data SheetДокумент4 страницыHuawei SE1000 Series Enterprise SBC Data Sheetarranguezjr5991Оценок пока нет

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- OnGuard 7.3 Data Sheet PDFДокумент2 страницыOnGuard 7.3 Data Sheet PDFdune_misterОценок пока нет

- 2021 Campus Selection Process & EligibilityДокумент1 страница2021 Campus Selection Process & EligibilityNishant KumarОценок пока нет

- 23 Construction Schedule Templates in Word & ExcelДокумент7 страниц23 Construction Schedule Templates in Word & ExcelnebiyuОценок пока нет

- LW SeriesДокумент8 страницLW SeriesAbraham AutomationОценок пока нет

- Practical Earthing Bonding Lightning and Surge ProtectionДокумент16 страницPractical Earthing Bonding Lightning and Surge ProtectionAHMED YOUSEFОценок пока нет

- Pumper March 2011 IssueДокумент108 страницPumper March 2011 IssuePumper MagazineОценок пока нет

- Project Management Plan Training Plan For Plus Portal Management System Dauran Mcneil University of The West IndiesДокумент25 страницProject Management Plan Training Plan For Plus Portal Management System Dauran Mcneil University of The West IndiesdauranОценок пока нет

- Agnes CVДокумент3 страницыAgnes CVMaziwa ProОценок пока нет

- Chapter Test Css g12Документ30 страницChapter Test Css g12flash driveОценок пока нет

- ASR9000xr Understanding SNMP and TroubleshootingДокумент56 страницASR9000xr Understanding SNMP and TroubleshootingDharmendraОценок пока нет

- BookExcerpt 02 09Документ1 страницаBookExcerpt 02 09Ademola OridateОценок пока нет

- Manual Generador MagravДокумент6 страницManual Generador MagravacuonautОценок пока нет

- 6-Speed Manual Gearbox 0B3 Front-Wheel DriveДокумент91 страница6-Speed Manual Gearbox 0B3 Front-Wheel DriveergdegОценок пока нет

- PostRoute ClockTran FixДокумент8 страницPostRoute ClockTran Fixsneha96669100% (1)

- Pcan-Usb Userman EngДокумент29 страницPcan-Usb Userman EngantidoteunrealОценок пока нет

- 441 1105 1 PBДокумент6 страниц441 1105 1 PBblackraidenОценок пока нет

- OopДокумент53 страницыOopsadani1989Оценок пока нет

- Vin PlusДокумент20 страницVin PlusNamrata ShettiОценок пока нет

- Well Control for Completions and InterventionsОт EverandWell Control for Completions and InterventionsРейтинг: 4 из 5 звезд4/5 (10)