Академический Документы

Профессиональный Документы

Культура Документы

Archundia Tena Grande EngStru 2013

Загружено:

jrobert123321Исходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Archundia Tena Grande EngStru 2013

Загружено:

jrobert123321Авторское право:

Доступные форматы

(This is a sample cover image for this issue. The actual cover is not yet available at this time.

)

This article appeared in a journal published by Elsevier. The attached

copy is furnished to the author for internal non-commercial research

and education use, including for instruction at the authors institution

and sharing with colleagues.

Other uses, including reproduction and distribution, or selling or

licensing copies, or posting to personal, institutional or third party

websites are prohibited.

In most cases authors are permitted to post their version of the

article (e.g. in Word or Tex form) to their personal website or

institutional repository. Authors requiring further information

regarding Elseviers archiving and manuscript policies are

encouraged to visit:

http://www.elsevier.com/copyright

Author's personal copy

Behavior of reinforced concrete haunched beams subjected to cyclic

shear loading

Hans I. Archundia-Aranda

a,b

, Arturo Tena-Colunga

a,

, Alejandro Grande-Vega

a

a

Departamento de Materiales, Universidad Autnoma Metropolitana, Edicio P4, ltimo Piso, Av, San Pablo 180, Col. Reynosa Tamaulipas, 02200 Mxico, DF, Mexico

b

Divisin de Estudios de Posgrado, Facultad de Ingeniera, UNAM, Ciudad Universitaria, 04510 Mxico, DF, Mexico

a r t i c l e i n f o

Article history:

Received 18 November 2011

Revised 23 October 2012

Accepted 24 October 2012

Keywords:

Haunched beams

Tapered elements

Nonprismatic elements

Shear strength

Deformation capacity

Cyclic testing

a b s t r a c t

Final research results and interpretations of the testing of ten prototype simply-supported reinforced

concrete beams (eight haunched and two prismatic) designed to develop a shear failure under cyclic

loading are presented. Five beams (four haunched and one prismatic) were tested without shear rein-

forcement whereas the remaining ve (four haunched and one prismatic) were tested with a shear rein-

forcement satisfying the minimum required for prismatic beams by the concrete norms of Mexicos

Federal District Code (MFDC). These haunched beams are identical in geometry and reinforcement to a

set of haunched beams previously tested under static loading. These additional cyclic testing conrmed

the usefulness of a proposed equation to estimate the shear strength of reinforced concrete haunched

beams, taking into account parameters such as the haunch angle, the concrete compressive strength,

the shear reinforcement and the contribution of the inclined longitudinal reinforcement. From the

obtained results, it can be observed that haunched beams have a different cyclic shear behavior with

respect to prismatic beams, having higher deformation and energy dissipation capacities, among other

reasons, because non-prismatic beams favor an arching action in the haunched length as the main resist-

ing mechanism, that develops smoother cracking patterns.

2012 Elsevier Ltd. All rights reserved.

1. Introduction

Reinforced concrete haunched beams (RCHBs) are often used in

simply-supported or continuous bridges worldwide (Figs. 1 and 2)

and in midrise framed buildings in Latin American countries like

Mexico and Ecuador or in European countries like Germany. Rein-

forced concrete haunched beams (RCHBs) are often used because

they offer some structural and nonstructural advantages over pris-

matic elements, such as stiffness or moment capacity to self-

weight ratio, providing an smaller effective height at midspan for

supporting frames (bridges and buildings) which eases the place-

ment of different facilities (i.e., air conditioning, piping) along the

building. Nevertheless, in some countries RCHBs are unlikely a

common structural solution in buildings because their use involve

higher construction costs, as special formwork and qualied con-

struction workers are required. In particular, haunched beams have

been used in RC bridges and buildings in Mexico City from a long

time ago. Despite this fact, there are no specic recommendations

for haunched beams in reinforced concrete norms for Mexico [1]

(NTCC-04, 2004) and the United States [2] (ACI-318-11) that would

insure the ductile detailing of these elements.

Although the German code [3] (DIN 1045-1, 2001) and some

textbooks [48] have some brief recommendations for the shear

design of RCHBs, these guidelines do not include experimental

data. The experimental evidence available is reduced to monotonic

tests of prototypes failing in shear [914]. The analytical research

related to the shear design of RCHBs is also limited. Besides the

works in which the shear resistance of a haunched section is the

sum of the contribution of the concrete, plus the contribution of in-

clined and transverse steel reinforcements [45,7,914], few works

are available where a plastic truss model has been used to analyze

the haunched element [6,8,1517].

In order to insure the desirable ductile behavior of RCHBs

according to capacity-design rules, it is necessary rst to under-

stand how sudden failures under monotonic and cyclic loads occur,

for example, the shear failure. Once this goal is achieved, it can be

possible to study how to warrant a ductile exural failure. There-

fore, in this paper the experimental results of ten RCHBs designed

to develop shear failure and tested under cyclic loading are pre-

sented. This study complements a previous study of twin RCHB

but subjected to static loading [14]. The described study is summa-

rized in following sections.

0141-0296/$ - see front matter 2012 Elsevier Ltd. All rights reserved.

http://dx.doi.org/10.1016/j.engstruct.2012.10.037

Corresponding author. Tel.: +52 55 5318 9460; fax: +52 55 5318 9085.

E-mail addresses: archundia_aranda@yahoo.com.mx (H.I. Archundia-Aranda),

atc@correo.azc.uam.mx (A. Tena-Colunga), alexgrande_ein@yahoo.com.mx

(A. Grande-Vega).

Engineering Structures 49 (2013) 2742

Contents lists available at SciVerse ScienceDirect

Engineering Structures

j our nal homepage: www. el sevi er. com/ l ocat e/ engst r uct

Author's personal copy

2. Description of test beams

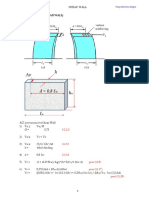

The geometry of prototypes RCHBs was dened according to a

survey conducted in existing bridges and buildings in Mexico City

(Figs. 2 and 3). The width (b) for all beams was 220 mm, the effec-

tive span (L) was 2800 mm, and the shear span (a) was 1083 mm.

The haunched length (L

h

) at both beam ends was one-third the

effective span (L

h

= L/3 933 mm). Five different linear tapering

geometries were obtained by keeping constant the overall depth

at each beam end (h

max

= 450 mm) and reducing the overall depth

at the central prismatic length to h

min

= 450 (prismatic control ele-

ment), 400, 350, 300 and 250 mm. Therefore, haunched angles

from the horizontal (a) were 0, 3.07, 6.12, 9.13 and 12.10

respectively.

The geometry of all prototypes satised the requirement L/h > 5

to be considered as slender beams by the Mexican code (L/

h

max

> 5). In addition, with the purpose of not magnifying the char-

acteristic arching mechanism observed experimentally and analyt-

ically in haunched beams [9,10,18], all prototypes were checked to

fulll the well-known a/d limiting ratio between slender beams

and short beams (a/d

max

> 2.5). The top and bottom reinforcement

cover was 40 mm.

The specied material properties for design were a compressive

strength f

0

c

24:5 MPaf

0

c

250 kg=cm

2

for the concrete, and a

yield tensile stress f

y

= 412 MPa (f

y

= 4200 kg/cm

2

) for all the steel

reinforcement. The measured properties for the steel reinforce-

ment from coupon tests are given in Table 1. The measured prop-

erties from compression tests of small cylindrical specimens at the

date of testing are identied in Table 2.

Two beams were constructed for each one of the ve different

geometries considered: (a) one beam without shear reinforcement,

only with four stirrups outside the shear span to hold the longitu-

dinal steel reinforcement and (b) one beam with minimum shear

reinforcement according to NTCC-04 for prismatic elements con-

sidering the effective depth at the support (d

max

). Therefore, ten

prototype haunched beams were tested.

To insure a shear failure along the haunches, the design was

made providing the exural capacity in the central prismatic

length and keeping continuous the longitudinal reinforcement

along the prototypes. As described in a previous paper [14], all

the specimens (monotonic and cyclic) were originally designed to

insure that they failed in shear while following general NTCC-04

guidelines for prismatic beams. The following considerations were

done:

(a) The nominal contribution of concrete to shear (V

c

) was

assessed according to NTCC-04 considering an effective

depth.

(b) The transverse steel reinforcement was placed at the maxi-

mum spacing allowed by NTCC-04, s

max

= d/2. The separation

used for the construction of the specimens was obtained

from adjusting the theoretical s

max

= 205 mm to s

max

= 185 -

mm, in order to have stirrups almost equally spaced at the

haunched length L

h

= 933 mm (Fig. 3), and

(c) additional shear reinforcement at the vertex zone was

placed to account for the abrupt change of direction of the

bottom longitudinal reinforcement (Fig. 4). For this purpose,

a recommendation originally proposed by Park and Paulay

Fig. 1. Urban bridge with RC haunched beams in downtown Seattle.

Fig. 2. Urban bridges with RC haunched beams in Buenavista District, Mexico City

(photo courtesy of Luis A. UrbinaCalifornias).

h

L 25 = 93.3 93.3 93.3 25

25 L= 280

330

25

h

m

a

x

=

4

5

= 0, 3.07, 6.12,

9.13 and 12.10

5

a = 108.3

V V

10

(

4

5

,

4

0

,

3

5

,

3

0

a

n

d

2

5

)

[cm]

=

v

a

r

i

a

b

l

e

+ +

V - - V

m

i

n

h

Fig. 3. Geometry and loading for the test specimens.

28 H.I. Archundia-Aranda et al. / Engineering Structures 49 (2013) 2742

Author's personal copy

[4] was adapted. According to Fig. 4, the additional vertical

(shear) force that can be transmitted at the vertex at yielding

is:

F

v

T

y

sina A

s

f

y

sina 1

where A

s

is the area of the longitudinal inclined steel reinforcement

and a is the angle of slope of haunch from horizontal. Therefore, the

separation of the additional shear reinforcement at the vertex re-

gion (s

cd

) can be computed as:

s

cd

A

v

f

y

d

min

F

v

2

where d

min

is the effective depth at the prismatic section of the

haunched beam and A

v

is the area of the transverse shear reinforce-

ment. The theoretical separation s

cd

was computed according to Eqs.

(1) and (2) and then adjusted to practical values in order to ease the

construction of the specimens. If the computed or adjusted s

cd

was

smaller than the maximum separation for the transverse steel rein-

forcement (s

max

= 185 mm), the transverse reinforcement at the ver-

tex zone was spaced at s

cd

; otherwise, the transverse reinforcement

at the vertex zone was spaced at s

max

.

The shear capacity at the haunched sections was later checked

with semi-empirical equations previously proposed by the authors

[14], as described later in this paper in the section comparison

with nominal shear strength.

The cryptogram for the identication of the prototypes is TAS-

Cai-Rj-c, where i is an index that indicates the considered

haunched angle: i = 0 = 0, i = 1 = 3.07, i = 2 = 6.12, i = 3 = 9.13,

and i = 4 = 12.10; j is an index that indicates the shear reinforced:

j = 0 indicates the absence of shear reinforced whereas j = 1

indicates the use of a minimum shear reinforced with the charac-

teristic already referred.

Following the described general design procedure, the provided

longitudinal reinforcement for all beams consisted of 3#8 bars at

the top and 4#8 bars at the bottom (#8 bars = bars one inch in

diameter). For all beams with shear reinforcement, the transverse

shear reinforcement consisted of seven closed stirrups (two legs)

made with #2.5 bars (#2.5 bars = bars 5/16 inch in diameter) along

the haunched length (7S#2.5@ 185 mm) and 2S#2.5@ 185 mm at

the prismatic length. The reinforcement at the vertex zone con-

sisted of 3S#2.5@ 185 mm for beams up to 3.07 (TASCa0-R1-c

and TASCa1-R1-c), 3S#2.5@ 140 mm for beam TASCa2-R1-c,

3S#2.5@ 75 mm for beam TASCa3-R1-c and 3S#2.5@ 45 mm for

beam TASCa4-R1-c. Typical arrangements are shown in Figs. 57.

3. Instrumentation and test displacement history

In order to assess the contribution of the steel reinforcement,

beams were internally instrumented with strain gages to measure

tensional and compressional strains in the longitudinal steel rein-

forcement along the haunched length, as well as to measure strains

of some stirrups in the same zone, as schematically depicted in

Figs. 8 and 9.

Beams were simply supported and tested under concentrated

cyclic loads (V) that were applied 100 mm from the vertex formed

by the intersection of tapered sections with the prismatic section

towards the centerline, as depicted in Fig. 3 and 10a. Loads and

reactions were applied through 25.4 100 220 mm steel plates

to avoid local bearing crushing failures. The load was measured

with load cells at each point of loading.

Table 1

Measured experimental properties for the steel reinforcement.

Bar number f

y

kg/cm

2

(MPa) e

y

f

sh

kg/cm

2

(MPa) e

sh

f

u

kg/cm

2

(MPa) e

u

8 4348 (426.5) 0.00237 4348 (426.5) 0.0086 7707 (756.1)

2.5 4592 (450.5) 0.00235 4592 (450.5) 0.0074 7436 (729.5)

Table 2

Measured experimental shear forces and characteristic displacements from cyclic tests.

Beam ID a () h

+

() f

0

c

kg=cm

2

MPa V

cr

t (kN) V

u

t (kN) V

collapse

t (kN) V

nHB

t (kN) V

nHB

/V

u

d

cr

(mm) d

u

(mm) d

collapse

(mm)

TASCa0-R0-c 0 51 454 (44.5) 8.78 (86.1) 12.61 (123.7) 12.06 (118.3) 9.94 (97.5) 0.788 6.06 12.10 18.10

TASCa1-R0-c 3.07 43 433 (42.5) 4.41 (43.3) 4.41 (43.3) 4.41 (43.3) 8.58 (84.2) 1.946 6.12 9.48 19.00

TASCa2-R0-c 6.12 41 354 (34.7) 5.97 (58.6) 6.08 (59.6) 4.21 (41.3) 6.69 (65.6) 1.100 6.14 8.88 24.30

TASCa3-R0-c 9.13 35 395 (38.7) 3.83 (37.6) 3.85 (37.8) 4.37 (42.9) 5.98 (58.7) 1.553 6.10 9.22 30.22

TASCa4-R0-c 12.10 33 361 (35.4) 1.61 (15.8) 2.76 (27.1) 3.41 (33.5) 4.67 (45.8) 1.692 3.08 18.14 60.46

TASCa0-R1-c 0 38 227 (22.3) 4.56 (44.7) 24.89 (244.2) 12.92 (126.1) 17.88 (175.4) 0.718 4.14 20.42 33.60

TASCa1-R1-c 3.07 40 245 (24.0) 8.18 (80.2) 20.75 (203.6) 11.38 (111.6) 16.05 (157.5) 0.733 8.04 24.10 36.46

TASCa2-R1-c 6.12 33

o

217 (21.3) 6.16 (60.4) 13.23 (129.8) 7.55 (74.1) 13.73 (134.7) 1.038 8.00 20.02 32.40

TASCa3-R1-c 9.13 36 284 (27.9) 2.92 (28.6) 13.70 (134.4) 9.77 (95.8) 12.43 (121.9) 0.907 4.06 29.28 40.56

TASCa4-R1-c 12.10 29 245 (24.0) 1.52 (14.9) 7.88 (77.3) 5.12 (50.2) 9.94 (97.5) 1.261 4.08 33.92 57.88

Fig. 4. Additional shear reinforcement at the vertex zone due to the abrupt change of direction of the bottom longitudinal reinforcement.

H.I. Archundia-Aranda et al. / Engineering Structures 49 (2013) 2742 29

Author's personal copy

External instrumentation for cyclic loading was designed to

measure vertical deections at midspan (two micrometers, one

to measure deections of beams with respect to the reaction beam

and one to measure the deection of the reaction beam with re-

spect to the ground oor, to correct beam deections) and the ap-

plied loads with four load cells (Fig. 10a).

Cyclic tests were displacement-controlled in terms of the mea-

sured displacement at midspan d. According to previous results of

monotonic tests [14], in order to capture rst shear cracking and

failure states, midspan displacement increments of 3 mm were

set in the displacement history in beams without shear reinforce-

ment, whereas in beams with stirrups, displacement increments

of 4 mm were used. Positive loads (gravity direction) induce a

positive moment and vice versa. Two cycles at the same displace-

ment were set in the displacement history, as schematically de-

picted in Fig. 10b. This was done in order to evaluate key

structural parameters such as stiffness and strength degradation,

energy dissipation, and equivalent viscous damping. Tests were

stopped when beams lost the ability of supporting more load,

due to excessive damage (structural instability).

4. Experimental results

4.1. Hysteretic response

Hysteretic curves obtained for the test specimens without and

with shear reinforcement are depicted in Figs. 11 and 12 respec-

tively. The deection (d) at midspan was corrected by a xed co-

lineal measurement to take into account the exibility of the

strong beam where the hydraulic jacks reacted (Fig. 10a). The shear

force (V) corresponds to the haunched end where the failure

occurred.

Because prototypes were subjected to the same deection his-

tory, which means that deection history is not a variable [19], it

is feasible to describe a general behavior for the RCHBs: increasing

the haunched angle diminishes the shear capacity and the stiffness

of the beams (directly related with the fact that when the

haunched angle increases, the volume of concrete diminishes

[14]), but increases the number of cycles that can sustain and their

deformation capacity (primarily related to the capacity of RCHB to

redistribute cracking along the haunched length). All elements

exhibited a pinching at the origin which is characteristic of

25 93.3

SECTION 1

93.3

SECTION 1

330

93.3

3 # 2.5 @ 4.5

4 # 8

3 # 8

SECTION 2

25

[cm]

8 # 2.5 @ 18.5

Fig. 6. Reinforcement for beam TASCa4-R1-c.

4 # 8

3 # 8

SECTION 2

# 2.5

SECTION 1

4 # 8

22

35 45

[cm]

25

30

22

40

45

3 # 8

VARIABLE

4

4

4

4

VARIABLE

30

35

40

45

25

STIRRUPS

STIRRUPS

# 2.5

Fig. 7. Typical cross sections.

Fig. 8. Typical internal instrumentation for beams TASCai-R0-c.

25 93.3

SECTION 1 SECTION 1

93.3

2 # 2.5 @ 110

4 # 8

330

3 # 8

93.3

SECTION 2

25

[cm]

Fig. 5. Reinforcement for beam TASCa1-R0-c.

30 H.I. Archundia-Aranda et al. / Engineering Structures 49 (2013) 2742

Author's personal copy

elements failing in shear [20]. As the haunch angle a increases, the

pinching behavior is more pronounced (Figs. 11 and 12) due to the

sliding along shear cracks. In addition, it is evident a slight asym-

metry in the hysteresis due to: (1) the geometry and reinforcement

asymmetry of the prototypes with respect to a longitudinal axis

and (2) the self weight of the beams.

On the basis of experimental observations and in agreement

with the monotonic testing [14], three characteristic forces were

identied from the full hysteretic response: (1) the shear force that

caused the rst diagonal cracking (V

cr

), (2) the ultimate (maxi-

mum) shear force (V

u

) and (3) the shear that caused the collapse

of the beams (V

collapse

). All characteristic stages occurred under

(a)

-24

-20

-16

-12

-8

-4

0

4

8

12

16

20

24

0 1 2 3 4 5 6 7 8 9 10 11

(mm)

first cycles

second cycles

(b)

CYCLE NUMBER

Fig. 10. Experimental program: (a) testing setup (prototype TASCa4-R1-c) and (b) cyclic displacement history.

Fig. 11. Hysteretic curves for beams TASCai-R0-c (without shear reinforcement).

Fig. 9. Typical internal instrumentation for beams TASCai-R1-c.

H.I. Archundia-Aranda et al. / Engineering Structures 49 (2013) 2742 31

Author's personal copy

positive loads (Fig. 3). The characteristic shear forces already de-

scribed are summarized in Table 2. Finally, the displacements

associated to each characteristic stage are also summarized in

Table 2.

Fig. 12. Hysteretic curves for beams TASCai-R1-c (with shear reinforcement).

Fig. 13. Loaddisplacement envelope curves for beams TASCai-R0-c (without shear reinforcement).

32 H.I. Archundia-Aranda et al. / Engineering Structures 49 (2013) 2742

Author's personal copy

4.2. Peak response envelopes

Loaddisplacement envelopes for peak responses obtained for

the rst and second cycles of deformation (distinguished with dif-

ferent lines) are depicted in Fig. 13 for the test specimens without

shear reinforcement and in Fig. 14 for the test specimens with

shear reinforcement, where plots are in different scale to improve

visualization. Nominal shear strength (V

nHB

) capacities assessed as

described in the following section are also depicted.

In these curves it can be conrmed that as the haunched angle

increases: (a) the deformation capacity increases and, (b) the shear

strength is reduced. As it is explained with more detail in next sec-

tion, it is evident in Fig. 13 that the expected shear capacity in

beams without shear reinforcement (R0-c beams) was overesti-

mated, whereas in Fig. 14 it is observed that the prediction of the

shear capacity was much better for haunched beams with mini-

mum shear reinforcement.

It is worth noting in Fig. 13 that beam TASCa1-R0-c (3) pre-

sented an anomalous brittle failure at a smaller shear force than

TASCa2-R0-c (6), as in the monotonic tests it was always observed

that the shear strength was reduced as the haunched angle a in-

creased (Table 3). First diagonal cracking occurred in most beams

at a displacement around 6 mm (Table 2), except for beam TAS-

Ca4-R0-c (12), where rst cracking occurred at 3 mm.

It can also be observed from the loaddisplacement envelopes

depicted in Figs. 13 and 14 that the envelopes for rst and second

cycles start to differ after the major crack was formed at or near the

failure state, although this difference is smaller for beams TASCa1-

R0-c (3), TASCa4-R0-c (12) and TASCa4-R1-c (12). In other

words, stiffness and strength degradation due to cyclic loading

Fig. 14. Loaddisplacement envelope curves for beams TASCai-R1-c (with shear reinforcement).

Table 3

Evaluation of cyclic degradation from cyclic and monotonic test results.

Beam type a () Cyclic test results Monotonic test results Evaluation of the cyclic

degradation

Vuc

f

0

c

p

kg

p

cm

Vcolc

f

0

c

p

kg

p

cm

f

0

c

kg=cm

2

MPa

V

u-m

t (kN) V

col-m

t (kN)

Vum

f

0

c

p

kg

p

cm

Vcolm

f

0

c

p

kg

p

cm

Vuc

Vum

Vcolc

Vcolm

Vuc =

f

0

c

p

Vum=

f

0

c

p

Vcolc =

f

0

c

p

Vcolm=

f

0

c

p

Without shear

reinforcement

0 591.8 566.0 334 (32.8) 7.5 (73.6) 7.5 (73.6) 410.4 410.4 1.68 1.61 1.44 1.38

3.07 211.9 211.9 321 (31.5) 6.75 (66.2) 8.75 (85.8) 376.7 488.4 0.65 0.50 0.56 0.43

6.12 323.1 223.8 295 (28.9) 6.0 (58.9) 6.5 (63.8) 349.3 378.4 1.01 0.65 0.93 0.59

9.13 193.7 219.9 236 (23.2) 3.75 (36.8) 8.0 (78.5) 244.1 520.8 1.03 0.55 0.79 0.42

12.10 145.3 179.5 281 (27.6) 3.0 (29.4) 4.0 (39.2) 179.0 238.6 0.92 0.85 0.81 0.75

With shear

reinforcement

0 1652.0 857.5 315 (30.9) 25.0 (245.3) 25.5 (250.2) 1408.6 1436.8 1.00 0.51 1.17 0.60

3.07 1325.7 727.0 269 (26.4) 20.0 (196.2) 21.0 (206.0) 1219.4 1280.4 1.04 0.54 1.09 0.57

6.12 898.1 512.5 292 (28.6) 17.0 (166.8) 17.0 (166.8) 994.8 994.8 0.78 0.44 0.90 0.52

9.13 812.9 579.7 288 (28.3) 12.0 (117.7) 14.0 (137.3) 707.1 825.0 1.14 0.70 1.15 0.70

12.10 503.4 327.1 212 (20.8) 8.0 (78.5) 8.0 (78.5) 549.4 549.4 0.99 0.64 0.92 0.60

H.I. Archundia-Aranda et al. / Engineering Structures 49 (2013) 2742 33

Author's personal copy

have a negligible impact almost up to the ultimate load V

u

, as the

curves for the rst and second cycles are almost identical; how-

ever, strength and stiffness degradation become very important

after V

u

.

Loaddisplacement envelopes for peak responses obtained for

the rst cycles of deformation for the test specimens with shear

reinforcement (TASCai-R1-c) are compared in Fig. 15 with those

obtained for their counterpart twin beams previously tested under

monotonic loading (TASCai-R1) [14]. From the observation of this

gure one may conclude that for most beams, the developed shear

capacity (V

u

) for monotonic and cyclic (positive cycles) tests are

very similar, and that the differences in the global deformation

capacity are also small. In addition, measured experimental ulti-

mate and collapse shear forces for cyclic (V

u-c

and V

col-c

) and mono-

tonic (V

u-m

and V

col-m

) tests are compared in Table 3 by computing

a simple ratio between the strength for cyclic and monotonic loads

(

Vuc

Vum

and

V

colc

V

colm

). The previous observation is also supported with the

obtained

Vuc

Vum

ratios for test specimens with shear reinforcement, as

the only beam where a reduction of strength higher than 20% was

observed was the 6.12 haunched angle beam TASCa2-R1-c.

Excluding prismatic beams, the average ratio for the four studied

haunched angles was

Vuc

Vum

0:99. The importance of the degrading

effects of cyclic loads after major cracking occurred can be

observed in Fig. 15 and can be addressed with the obtained

V

colc

V

colm

ratios for test specimens with shear reinforcement. Much higher

strength degradation was observed for all specimens subjected to

cyclic loads. Excluding prismatic beams, the average ratio for the

four studied haunched angles was

V

colc

V

colm

0:58.

Perhaps a one to one comparison between cyclic and monotonic

tests might not be fair enough, as the concrete mechanic character-

istics (i.e., f

0

c

, Table 3) are different because: (a) concrete admix-

tures were not made at the same time, as specimens for

monotonic tests were casted several months before, (b) the age

of testing was different for each specimen and (c) environmental

variables (temperature, humidity, etc.) may affect the strength

and stiffness for the concrete. For these reasons, measured experi-

mental shear forces (at ultimate and at collapse) for cyclic and

monotonic tests were normalized with the square root of the

compressive strength of concrete (f

0

c

) at the age of testing for each

element, as also identied in Table 3. The reported

Vuc =

f

0

c

p

Vum=

f

0

c

p and

V

colc

=

f

0

c

p

V

colm

=

f

0

c

p ratios mostly conrmed previous observations for test

specimens with shear reinforcement: (a) the developed shear

capacity for monotonic and cyclic tests were very similar and (b)

much higher strength degradation was observed for specimens

subjected to cyclic loads with respect to those subjected to

monotonic loads. Excluding prismatic beams, the average ratios

for the four studied haunched angles were

Vuc =

f

0

c

p

Vum=

f

0

c

p 1:01 and

V

colc

=

f

0

c

p

V

colm

=

f

0

c

p 0:60.

4.3. Comparison with nominal shear strength

As explained in greater detail in Tena-Colunga et al. [14],

nominal shear strength capacities in the haunched length (V

nHB

)

have been traditionally assessed according to an empirical but

statics-based approach [3,4,7,912], in which the shear resistance

of a section is the sum of the contribution of the concrete, plus

the contribution of inclined and transverse steel reinforcements.

This methodology is the most widely used and accepted by

practicing engineers and that is the reason that still prevails in

most reinforced concrete regulations worldwide.

Nominal shear strength (V

nHB

) capacities were computed

according to what it is proposed in Tena-Colunga et al. [14] are also

reported in Table 2:

V

nHB

V

pc

V

isr

V

s

3

where V

pc

is the concrete shear strength of constant depth beam

having the same cross section as that considered for haunched

beam, V

isr

is the shear contribution of the inclined steel reinforce-

ment and V

s

is the contribution of the transverse steel reinforce-

ment. In the assessment of V

isr

, the positive sign should be used if

the moment increases in the same direction as the depth increases,

and the negative sign when the depth decreases while the moment

increases [7,914]; for the simply supported haunched beams un-

der study, a negative sign must be used. In Eq. (3), V

pc

and V

isr

terms

were obtained from the moment equilibrium equation at the sec-

tion of interest.

Individual shear contributions were assessed as follows:

V

pc

0:5

f

c

p

176q

w

V

n

d

cr

M

n

bd

cr

4

V

isr

M

cr

d

cr

tana 5

V

s

A

v

f

yv

d

cr

s tan45 a

6

d

cr

d

min

1 1:35tana 6

h

max

h

min

h

2

max

2l

h

h

max

!

r

" #

7

-28.5

-14.3

0.0

14.3

28.5

-280

-140

0

140

280

-60 -40 -20 0 20 40 60

V (t) V (kN)

(mm)

0

1

2

4

3

-28.5

-14.3

0.0

14.3

28.5

-280

-140

0

140

280

0 20 40 60

V (t) V

(kN)

(mm)

0

1

2

3

4

(a) Cyclic tests (TASCi-R1-c) (b) Monotonic tests (TASCi-R1)

Fig. 15. Comparison of loaddisplacement envelope curves for beams with shear reinforcement.

34 H.I. Archundia-Aranda et al. / Engineering Structures 49 (2013) 2742

Author's personal copy

where V

n

and M

n

are the nominal shear force and bending moment

at the critical haunched section (absolute values), q

w

is the ratio of

longitudinal reinforcement, b is the width of the beam, d

cr

is the

effective equivalent depth at the critical haunched section, M

cr

is

the developed bending moment at the critical section (taking into

account premature bond-slip failures of the inclined reinforcement

Fig. 16. Final damage patterns for beams TASCai-R0-c (without shear reinforcement).

Fig. 17. Cracking patterns in beam TASCa0-R1-c at dened damage states.

H.I. Archundia-Aranda et al. / Engineering Structures 49 (2013) 2742 35

Author's personal copy

in over-reinforced beams), a is the angle of slope of haunch from

horizontal, h

max

and h

min

are the maximum and minimum depth

of the haunched beam respectively, L

h

is the haunched length, r is

the concrete cover for the longitudinal reinforcement, A

v

is the area

of the transverse shear reinforcement, f

yv

is the yield stress of the

shear reinforcement and s is the separation of the transverse shear

reinforcement.

It is worth noting that for consistency with prismatic sections,

V

pc

(Eq. (4)) was derived in terms of the equation proposed by

the ACI 318 code [2], whereas V

isr

(Eq. (5)) is the contribution of

the inclined steel reinforcement as already proposed in the litera-

ture [7,914]. The contribution of the transverse steel reinforce-

ment V

s

(Eq. (6)) was derived considering the angle of inclination

of the principal shear crack with respect to an horizontal axis (h),

which was proposed as h = 45-a based upon experimental evi-

dence, practical considerations and for consistency with the design

already established for prismatic sections [14]. The rst term of d

cr

(Eq. (7)) was obtained from a linear regression of experimental

data [14], whereas the limiting value provided in the second term

of Eq. (7) was derived analytically to insure that d

cr

would keep a

physical meaning, avoiding that it could be numerically greater

than the maximum effective depth [14].

Based upon previous experimental data [14], for simply sup-

ported beams without shear reinforcement, the assessment of

the developed moment at the critical section (M

cr

) could be done

as follows:

M

cr

0:15M

n

1 2:5tana 8

and for simply supported beams with shear reinforcement:

M

cr

0:5M

n

1 1:6tana 9

Then, shear capacities V

nHB

were computed considering the mea-

sured properties for the concrete and steel reinforcement. The mea-

sured compressive strength for the concrete (f

0

c

) is reported in Table

2. The measured yield stresses were f

y

= 426.5 MPa (f

y

= 4348 kg/

cm

2

) for the longitudinal reinforcement and f

y

= 450.5 MPa (f

y

=

4592 kg/cm

2

) for the shear reinforcement (Table 1).

From the reported values in Table 2 it is evident that the

expected shear capacity in beams without shear reinforcement

(R0-c beams) was overestimated. This can be explained by the fact

that the absence of stirrups favored a more pronounced concrete

degradation that was increased by load reversals [21]. As observed

in monotonic testing [14] for the haunched beams with shear rein-

forcement, the shear capacity prediction was good principally in

Fig. 18. Cracking patterns in beam TASCa1-R1-c at dened damage states.

36 H.I. Archundia-Aranda et al. / Engineering Structures 49 (2013) 2742

Author's personal copy

haunched beams up to haunched angles of nine degrees for the

beams with minimum shear reinforcement. The average ratio for

all ve beams with transverse shear reinforcement was V

nHB

/

V

u

= 0.94 with and standard deviation of 0.218. However, if only

the four haunched beams are considered, the average ratio in-

creases to V

nHB

/V

u

= 0.995 and the standard deviation decreases

to 0.208. Beam TASCa2-R1-c (a = 6.12) was tested at early age

(32 days old) in comparison with the rest of the beams (200

250 days old, because the testing lab in the university was closed

as it was going to be upgraded). In addition, this element had the

lowest concrete strength (Table 2). These facts favored an excessive

exural cracking along the element which could explain the devel-

oped strength.

4.4. Deformation capacity

It can be observed from the loaddisplacement envelopes for

peak responses depicted in Figs. 13 and 14 and the data provided

in Table 2 that curves for beams with (R1-c) and without (R0-c)

shear reinforcement are similar until V

cr

, but after the rst crack-

ing, the strength and deformation of R0-c and R1-c specimens start

to differ because of the contribution of the steel shear reinforce-

ment. It is also evident from Fig. 13 that RCHB have some deforma-

tion capacity even without shear reinforcement, situation different

from prismatic beams, where once the diagonal cracking occurred,

prismatic beams lose all capacity to sustain the load through defor-

mation. This increment is primarily related to the capacity of RCHB

to redistribute cracking along the haunched length, as discussed in

more detail in the following section.

4.5. Cracking patterns

As mentioned earlier, haunched beams exhibited a greater

deformation and energy dissipation capacity. This increment is pri-

marily related to the capacity of RCHB to redistribute cracking

along the haunched length (Fig. 16b) compared to prismatic beams

(Fig. 16a), even for beams without shear reinforcement. The better

cracking distribution (i.e., Fig. 16b) allowed that the ultimate shear

strength V

u

did not suddenly happened after the appearance of the

rst important diagonal crack, as it happened for prismatic beams

in both monotonic and cyclic tests (Fig. 16a). The observed behav-

ior for RCHB is less brittle than for prismatic beams, as the shear

failure for RCHB is noticeably less sudden than the one presented

in prismatic beams. These observations are in full agreement with

the results obtained for the twin beams during monotonic tests

[14].

Typical cracking patterns for beams with shear reinforcement

are shown in Figs. 1721. For the RCHBs (Figs. 1821), the cracking

patterns at ultimate and collapse stages clearly show a full diago-

nal crack distribution along the shear span (haunched length). This

crack pattern supports the well identied arching mechanism in

monotonic tests [914] and analytical studies. This arching mech-

anism was pronounced by the presence, in each haunch, of inclined

compression struts in both loading directions. In agreement with

monotonic tests [14], these struts tend to form between the point

Fig. 19. Cracking patterns in beam TASCa2-R1-c at dened damage states.

H.I. Archundia-Aranda et al. / Engineering Structures 49 (2013) 2742 37

Author's personal copy

of application of the load and the midpoint of the haunched length.

As expected, deformation demands were higher in the struts of

RCHB with shear reinforcement, where the force developed by

the strut considerably deformed the initial geometry of the beam

(Figs. 18c, 19c, 20c and 21c). Therefore, it can be concluded that

the greatest deformation capacity observed in RCHBs in compari-

son with the prismatic elements is associated to the ability of

RCHBs to redistribute cracks. As a general rule, increasing the

haunched angle increases the allowed damage (Figs. 1721) and

increases the pinching (Fig. 12) due to the sliding along the cracks.

Moreover, the characteristic brittle and sudden shear failure of

prismatic elements (Fig. 17) is reduced in RCHBs due to this behav-

ior (Figs. 1821).

As summary, the cracking patterns identied in the tested

RCHBs under cyclic loading conrmed the arch mechanism previ-

ously reported for RCHBs with shear reinforcement [10,14] and

without shear reinforcement [13,14]. This arch mechanism was

pronounced by the presence, in each haunch, of inclined compres-

sion struts. The struts tend to form between the point of applica-

tion of the load and the midpoint of the haunched length. As

expected, deformation demands were higher in the struts of RCHBs

with shear reinforcement, where the force developed by the strut

considerably deformed the initial geometry of the beam. For all

RCHBs, the shear cracking was distributed, and more than one

important diagonal crack always appeared with or without shear

reinforcement.

Finally, it was conrmed that as observed in monotonic tests

[14], there is a trend where the angle of inclination of the principal

shear crack with respect to a horizontal axis (h

+

, Table 2) seem to

decrease as the haunch angle a increases.

4.6. Longitudinal reinforcement

In agreement with previous monotonic tests [14], readings of

the strain gages in the inclined longitudinal steel reinforcement

in tension showed that the deformations associated to the failure

of the specimens without shear reinforcement were much smaller

than the yield strain of the steel reinforcement obtained from

coupon tests (about 12%). These values were obtained usually

between V

u

and V

collapse

(Table 2) and a displacement around

1213 mm, before readings were lost when the opening of a major

crack damaged the strain gage. The longitudinal steel reinforce-

ment at the top had similar readings than the ones obtained for

the inclined reinforcement; however, as they were not damaged

because of the presence of a major crack, they kept giving readings

up to displacements near d

collapse

. For example, for beam TASCa4-

R0-c, at d = 55.6 mm, the peak strain reading was about 56% the

yield strain of the steel reinforcement.

The applied shear force (V) was then related to the measured

strain of the top and bottom longitudinal steel reinforcement for

all specimens as described in detail in Grande-Vega [22]. As ex-

pected, higher strains developed at the steel reinforcement from

beam ends towards the points of application of the concentrated

loads, as the bending moment increases in this direction. Yielding

of the steel reinforcement (e P0.00213) was measured at strain

gages located at the vertex and at the tapered section nearby the

vertex and at midspan. It was also evident that the development

of crack patterns affected the readings of the strain gages, as one

can relate the developed crack patterns (Fig. 20) with the curves

obtained from the measured strains (not shown, Grande Vega

[22]).

4.7. Shear reinforcement

The contribution of the shear reinforcement of R1-c specimens

was quantied with the measured deformations in the stirrups as

reported in detail elsewhere [22]. For illustration purposes, the ap-

plied shear force (V) versus measured strains in the stirrups curves

for the haunched element TASCa3-R1-c is depicted in Fig. 22. It is

worth noting that stirrup E03-I had wrong readings, perhaps be-

Fig. 20. Cracking patterns in beam TASCa3-R1-c at dened damage states.

38 H.I. Archundia-Aranda et al. / Engineering Structures 49 (2013) 2742

Author's personal copy

cause it was deciently glued it to the steel and then got lose dur-

ing the testing. It can be observed that all stirrups were working

primarily in tension, although most of them did not yield

(e < 0.00235) but stirrups nearby the vertex (or point of application

of the loads). In fact, higher strains are developed at the stirrups

from the beam ends towards the vertex. The most demanded stir-

rups were those that were located between the vertex and the

midsection of the haunched length (that is, stirrups E04-I, E05-I,

E06-I, E07-I at the left hand side and stirrups E04-D, E05-D, E06-

D, and E07-D at the right hand side). This is consistent with the

concentration of the damage in that zone because of the compres-

sion concrete struts and the location of the principal shear crack

(Fig. 20). It is worth noting that, as expected, stirrups at the sup-

ports (E01-I and E01-D) were not very demanded. Based upon

the analysis of the cyclic testing sequences, it was found that mea-

sured strains in the shear reinforcement (Fig. 22) were also affected

by the development (sequence) of the crack patterns (Fig. 20).

4.8. Stiffness degradation

Peak to peak secant stiffness (K) was computed for each com-

plete cycle (Fig. 23) and normalized with respect to the initial elas-

tic stiffness (K

0

), which was computed from the rst cycle readings

at small displacement amplitude. Elastic and normalized stiffness-

es are summarized in Table 4 whereas the evolution of the stiffness

degradation is depicted in Fig. 24. The effective secant stiffness for

the rst cycles of deformation was in general similar but slightly

higher than for the second cycles of response for all beams [19]

(not shown), and since the displacement amplitude of the cycles

was xed, this very small stiffness degradation must arise from

strength degradation. As expected, stiffness and strength degrada-

tion were more pronounced after the ultimate damage state (V

u

and d

u

, Table 2) was reached.

Indeed, as previously mentioned, stiffness and strength degra-

dation due to cyclic loading have a negligible impact almost up

to the ultimate load V

u

, as the curves for the rst and second cycles

are almost identical, but strength and stiffness degradation become

very important after V

u

(Figs. 13 and 14). In fact, before reaching V

u

,

a lack of stiffness and strength degradation due to previous cycles

of smaller amplitude and due to cycles of the same amplitude was

observed. However, near to and after V

u

, important stiffness and

strength degradation were observed due to: (a) previous cycles

of smaller amplitude and (b) cycles of the same amplitude.

From the results reported in Table 4 and the curves depicted in

Fig. 24 it is evident, and obvious, that the absence of stirrups in-

creases the stiffness degradation rate. It is specied in most rein-

forced concrete building codes [2,3], the Mexican code [1]

included, that a cracked beam shall to remain at 50% of their initial

Fig. 21. Cracking patterns in beam TASCa4-R1-c at dened damage states.

H.I. Archundia-Aranda et al. / Engineering Structures 49 (2013) 2742 39

Author's personal copy

stiffness properties at the moment to develop their exural capac-

ity. As can be observed from Table 4, RCHBs would be able to fulll

this requirement, because even under a brittle failure (shear

failure) the beams kept 60% of their original stiffness at the ulti-

mate stage.

4.9. Energy dissipation

Even though the haunch diminishes the concrete volume re-

spect to a prismatic element, the experimental evidence shown

that RCHBs dissipate, at least, energy equal to the prismatic ele-

ments (Table 5). To further highlight this fact, the accumulated en-

ergy density U

o

[23] was assessed, this is, the accumulated

E

-

0

8

-

I

E

-

0

7

-

I

E

-

0

6

-

I

E

-

0

5

-

I

E

-

0

4

-

I

E

-

0

3

-

I

E

-

0

2

-

I

E

-

0

1

-

I

E

-

0

1

-

D

E

-

0

2

-

D

E

-

0

3

-

D

E

-

0

4

-

D

E

-

0

5

-

D

E

-

0

6

-

D

E

-

0

7

-

D

E

-

0

8

-

D

Fig. 22. Measured strain versus shear curves for the strain gages of the transverse reinforcement of haunched beam TASCa3-R1-c.

Fig. 23. Peak-to-peak secant stiffness K.

Table 4

Peak to peak stiffness.

Beam ID K

o

(ton/mm) K

cr

/K

o

K

u

/K

o

K

collapse

/K

o

Beam ID K

o

(ton/mm) K

cr

/K

o

K

u

/K

o

K

collapse

/K

o

TASCa0-R0-c 1.46 0.92 0.60 0.42 TASCa0-R1-c 1.22 1.0 0.86 0.27

TASCa1-R0-c 0.72 0.85 0.61 0.31 TASCa1-R1-c 1.01 0.97 0.77 0.29

TASCa2-R0-c 0.95 0.98 0.58 0.20 TASCa2-R1-c 0.73 0.90 0.75 0.31

TASCa3-R0-c 0.64 0.92 0.55 0.25 TASCa3-R1-c 0.63 1.0 0.66 0.37

TASCa4-R0-c 0.57 0.98 0.28 0.06 TASCa4-R1-c 0.35 1.0 0.67 0.32

40 H.I. Archundia-Aranda et al. / Engineering Structures 49 (2013) 2742

Author's personal copy

hysteretic energy at failure (E

H

) was normalized with respect to the

half-volume of each beam (V

beam

/2), to point out the haunched ef-

fect (geometric effect). Therefore, U

o

was calculated as:

U

0

R

ncycles

0

@E

H

V

beam

2

10

The resulting accumulated energy densities are depicted in Fig. 25. It

can be conrmed that the accumulated energy density tend to in-

crease as the haunch angle a increases, as a direct consequence that

the number of cycles also tend to increase as the haunch angle a

increases.

5. Concluding remarks

This paper presented the results and interpretations about the

testing of prototype reinforced concrete haunched beams (RCHBs)

with and without shear reinforcement designed to develop a shear

failure under cyclic loading. The haunched length at both beam

ends of the considered RCHB was one-third the effective span of

the beam, whereas the haunched angle (a) varied from 3 to 12.

It was conrmed from cyclic tests what it was observed in

monotonic tests [14]: RCHB develop an arch mechanism which

allows the damage to be distributed in terms of several ssures

along the haunched length before the main diagonal cracks

develops, then causing smoother cracking patterns and a failure

mechanism that is less fragile than the typical sudden shear failure

observed in prismatic beams. The presence of a haunch modies

important structural properties such as ultimate strength and

deformation capacity, stiffness and energy dissipation. RCHB have

indeed more deformation capacity in shear than prismatic beams

and dissipate more energy or at least energy equal to those dissi-

pated by prismatic beams. On the other hand, the stiffness and

strength of RCHB is smaller with respect to those of prismatic

beams of the same depth.

From strain gages measurements it was conrmed that for sim-

ply-supported haunched beams, the presence of stirrups contrib-

utes indirectly to develop a higher negative vertical force by the

inclined longitudinal steel reinforcement, then, lessen in some ex-

Fig. 24. Peak to peak stiffness (computed from the rst cycles at a given displacement amplitude): (a) beams without shear reinforcement and (b) beams with shear

reinforcement.

Table 5

Accumulated hysteretic energy.

Beam ID Half volume (m

3

) Cracking Ultimate Collapse

E

H

t-mm (kN-mm) Cycle number E

H

t-mm (kN-mm) Cycle number E

H

t-mm (kN-mm) Cycle number

TASCa0-R0-c 0.144 26.53 (260.3) 3 144.55 (1418.0) 7 455.59 (4469.3) 11.5

TASCa1-R0-c

a

0.133 8.99 (88.2) 3 36.78 (360.8) 5 189.15 (1855.6) 11

TASCa2-R0-c 0.123 8.66 (85.0) 3 55.37 (543.2) 5 413.88 (4060.2) 15

TASCa3-R0-c 0.113 4.94 (48.5) 3 30.69 (301.1) 5 564.20 (5534.8) 20

TASCa4-R0-c 0.102 0.39 (3.8) 1 116.21 (1140.0) 11 2291.85 (22483.0) 36.5

TASCa0-R1-c 0.144 7.88 (77.3) 1 338.87 (3324.3) 9 1345.47 (13199.1) 15

TASCa1-R1-c 0.133 33.74 (331.0) 3 499.63 (4901.4) 11 1612.12 (15814.9) 17

TASCa2-R1-c

a

0.123 20.64 (202.5) 3 198.94 (1951.6) 9 904.19 (8870.1) 16

TASCa3-R1-c 0.113 4.53 (44.4) 1 491.53 (4821.9) 13 1418.89 (13919.3) 20

TASCa4-R1-c 0.102 2.34 (23.0) 1 425.13 (4170.5) 15 1739.62 (17062.7) 28

a

These elements had a premature failure.

Fig. 25. Accumulated energy density: (a) beams without shear reinforcement and (b) beams with shear reinforcement.

H.I. Archundia-Aranda et al. / Engineering Structures 49 (2013) 2742 41

Author's personal copy

tent the positive effect of the same stirrups to resist higher shear

forces.

It was also found from cyclic tests that stiffness and strength

degradation have a negligible impact almost up to the ultimate

load V

u

, but they become very important after V

u

. In fact, before

reaching V

u

, a lack of stiffness and strength degradation due to pre-

vious cycles of smaller amplitude and cycles of the same amplitude

was observed. However, near to and after V

u

, important stiffness

and strength degradation were observed due to: (a) previous cycles

of smaller amplitude and (b) cycles of the same amplitude.

The results obtained from the cyclic testing also conrmed the

usefulness of an empirical equation previously proposed [14] to as-

sess the shear strength of reinforced concrete haunched beams,

taking into account parameters such as the haunch angle, the con-

crete compressive strength, the shear reinforcement and the con-

tribution of the inclined longitudinal reinforcement. Therefore,

until more evidence would be available, it is advisable to estimate

the shear strength of simply supported RCHBs with that equation

for haunched beams with a haunch angle a up to nine degrees.

This study constitutes a step forward towards the understand-

ing of the behavior of RCHB under shear which may allow develop-

ing, in the near future, coherent guidelines to prevent brittle shear

failures. However, additional analytical and experimental research

is still needed to try to achieve this goal, mainly: (a) development

of truss (strut-and-tie) and compression eld analytical models, (b)

additional testing must be conducted in RCHB where the maxi-

mum shear force and bending moment occurs at the same section

(continuity condition) for cyclic loading, as this condition is closer

to the one that RCHB in framed buildings must face under lateral

loading.

Steps are currently being taken in this direction, as they are in-

deed needed before starting experimental programs devoted to in-

sure the ductile behavior of RCHB designed to develop exural

failure under cyclic loading.

Acknowledgments

Financial support of Conacyt, Secretara General de Obras del

Gobierno del Distrito Federal and Universidad Autnoma Metro-

politana are gratefully acknowledged. The construction of test

specimens was possible because of the enthusiastic collaboration

of several students: Jos Ramn guila, Jos Manuel Alonso, Misael

Bahena, Marco Antonio Castillo, Csar Carpio, Arturo de la Cruz,

Eleuterio Flores, Antonio Gascn, Eder Gudio, Efran Joaqun Die-

go, Alejandro Herrera, Gerardo Ibarra, Mara Fernanda Juan, Sergio

Lpez, Daniel Miranda, Miguel ngel Mendoza, Elas Josu Morn,

Roberto Moreno, Pablo Pineda, Carlos Ramrez, Rosaura Ramrez,

Marco Antonio Rico, Martn Santos, Alejandra Salcedo, Salvador

Vargas and Francisco Javier Vidal. MSc. Artemio Jurez-Angeles

Vctor H. Salinas-Vallejo and technicians Leopoldo Quiroz, Juan

Mateos, Jos Luis Caballero and Rubn Barreda assisted us in the

prototype testing.

References

[1] NTCC-2004. Normas Tcnicas Complementarias para Diseo y Construccin de

Estructuras de Concreto Gaceta Ocial del Distrito Federal. Mxico, October;

2004 [in Spanish].

[2] ACI-318-11. Building code requirements for structural concrete (ACI-318-11)

and commentary (ACI 318R-11). American Concrete Institute, Farmington

Hills, Michigan, USA; 2011.

[3] DIN 1045-1. Concrete, reinforcement and prestressed concrete structures, part

1: design. Deutsches Institut fr Normung e.V.; 2001.

[4] Park R, Paulay T. Estructuras de concreto reforzado, ninth printing of the rst

edition. Limusa, Mxico; 1997. p. 27984, 6912 [in Spanish].

[5] MacGregor JG. Reinforced concrete: mechanics and design. 3rd

ed. USA: Prentice Hall; 1997.

[6] Muttoni A, Shwartz J, Thrlimann B. Design of concrete structures with stress

elds. Germany: Birkhuser; 1997.

[7] Nilson AH. Diseo de estructuras de concreto. 12th ed. Santaf de Bogot,

Colombia: Mc Graw Hill; 1999. p. 1323 (in Spanish).

[8] Nilsen MP. Limit analysis and concrete plasticity. 2nd ed. Boca Raton,

Florida: CRC Press; 1999. p. 435.

[9] Mrsch E. Teora y prctica del hormign armado. Tomo II, rst edition Gili,

Argentina; 1952 [translated to Spanish from German].

[10] Debaiky SY, El-Niema EI. Behavior and strength of reinforced concrete

haunched beams in shear. ACI J 1982;79(3):18494.

[11] Stefanou GD. Shear resistance for reinforced concrete beams with non-

prismatic sections. Eng Fract Mech 1983;18(3):64367.

[12] El-Niema EI. Investigation of concrete haunched beams under shear. ASCE

Struct J 1988;114(4):91730.

[13] MacLeod IA, Houmsi A. Shear strength of haunched beams without shear

reinforcement. ACI Struct J 1994;91(1):7989.

[14] Tena-Colunga A, Archundia-Aranda HI, Gonzlez-Cuevas OM. Behavior of

reinforced concrete haunched beams subjected to static shear loading. Eng

Struct 2008;30(2):47892. http://dx.doi.org/10.1016/j.engstruct.2007.04.017.

[15] Marti P. Basic tools of reinforced concrete beam design. ACI J

1985;82(1):4656.

[16] Dilger WH, Langorh P. Shear design of haunched concrete box girders of the

Confederation Bridge. Can J Civil Eng 1997;24(6):898907.

[17] Muttoni A. Exercice 6: Dimensionnement dune poutre hauteur variable.

Structures en bton I, Ecole Polytechnique Fdrale de Lausanne, ENAC, IS-

BETON, Switzerland; 2008 [in French].

[18] El-Mezaini N, Balkaya C, itipitioglu E. Analysis of frames with nonprismatic

members. ASCE J Struct Eng 1991;117(6):157392.

[19] Hwang T, Scribner CF. R/C members cyclic response during various loadings.

ASCE J Struct Eng 1984;110(3):47789.

[20] Brown RH, Jirsa JO. Reinforced concrete beams under load reversals. ACI J

1971;68(5):38090.

[21] Gosain NK, Brown RH, Jirsa JO. Shear requirements for load reversals on RC

members. ASCE J Struct Eng 1977;103(7):146176.

[22] Grande-Vega A. Mecanismos de resistencia y deformacin a cortante de trabes

acarteladas de concreto reforzado sujetas a cargas cclicas. MSc. Thesis,

Posgrado en Ingeniera Estructural, Divisin de Ciencias Bsicas e Ingeniera.

Universidad Autnoma Metropolitana Azcapotzalco, July 2009 [in Spanish].

[23] Popov EP. Engineering mechanics of solids. 2nd ed. USA: Prentice Hall; 1999.

42 H.I. Archundia-Aranda et al. / Engineering Structures 49 (2013) 2742

Вам также может понравиться

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5795)

- Bridge Seismic Design Csi Sap 2000Документ97 страницBridge Seismic Design Csi Sap 2000jrobert123321100% (5)

- Seismic Design - NIST - TN.1863-1Документ299 страницSeismic Design - NIST - TN.1863-1jrobert123321Оценок пока нет

- Bearingd Expansion JointsДокумент152 страницыBearingd Expansion Jointsjrobert123321Оценок пока нет

- JL-98-November-December Restraint Moments in Precast Prestressed Concrete Continuous BridgesДокумент18 страницJL-98-November-December Restraint Moments in Precast Prestressed Concrete Continuous Bridgesjrobert123321Оценок пока нет

- Ce 434-534 Masonry Class NotesДокумент135 страницCe 434-534 Masonry Class Notesjrobert123321Оценок пока нет

- 0 1405 9 PDFДокумент85 страниц0 1405 9 PDFjrobert123321Оценок пока нет

- GSCBS 1TechstreetTOC PDFДокумент4 страницыGSCBS 1TechstreetTOC PDFjrobert123321Оценок пока нет

- ss4-3 Ajmal PDFДокумент37 страницss4-3 Ajmal PDFjrobert123321Оценок пока нет

- 98 0006 PDFДокумент69 страниц98 0006 PDFjrobert123321Оценок пока нет

- 1302 1 PDFДокумент118 страниц1302 1 PDFjrobert123321Оценок пока нет

- Performance of Concrete Segmental and Cable-Stayed Bridges in Europe PDFДокумент107 страницPerformance of Concrete Segmental and Cable-Stayed Bridges in Europe PDFjrobert123321100% (1)

- NCHRP RPT 700 PDFДокумент104 страницыNCHRP RPT 700 PDFjrobert123321Оценок пока нет

- Pre-Feasibility Study Champlain Bridge Replacement PDFДокумент86 страницPre-Feasibility Study Champlain Bridge Replacement PDFjrobert123321Оценок пока нет

- 98 0001 PDFДокумент69 страниц98 0001 PDFjrobert123321Оценок пока нет

- 98 0003 PDFДокумент144 страницы98 0003 PDFjrobert123321Оценок пока нет

- 97 0016 PDFДокумент228 страниц97 0016 PDFjrobert123321Оценок пока нет

- 97 0013 PDFДокумент216 страниц97 0013 PDFjrobert123321Оценок пока нет

- 97 0002 PDFДокумент202 страницы97 0002 PDFjrobert123321Оценок пока нет

- (K.I. Majid) Non-Linear Structures Matrix Methods PDFДокумент179 страниц(K.I. Majid) Non-Linear Structures Matrix Methods PDFjrobert123321Оценок пока нет

- Computational Methods in Reinforced ConcreteДокумент211 страницComputational Methods in Reinforced ConcreteAndrei Cioroianu100% (1)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Steel Structures MCQДокумент60 страницSteel Structures MCQmidhun ChakravarthiОценок пока нет

- Class-2 - Truss Analysis - MOJ - DR Nazrul - 1Документ12 страницClass-2 - Truss Analysis - MOJ - DR Nazrul - 1Ann Nazmun SakibОценок пока нет

- Question About The Relationship Between Elastic Modulus and CreepДокумент3 страницыQuestion About The Relationship Between Elastic Modulus and CreepFrancesca TeocoliОценок пока нет

- Bucking of Thin Concrete DomesДокумент14 страницBucking of Thin Concrete DomesSack DavidОценок пока нет

- Lab 1 ASE 324 UtexasДокумент17 страницLab 1 ASE 324 UtexasBhagwan Jane100% (1)

- ShearWall SNI2847 2013Документ6 страницShearWall SNI2847 2013Tony WangОценок пока нет

- Mec411 Assignment LatestДокумент27 страницMec411 Assignment LatestLuqman Hakim Bin Abdul HarisОценок пока нет

- Assignement 1Документ1 страницаAssignement 1habtamugshОценок пока нет

- 1 s2.0 S0142112316303723 MainДокумент12 страниц1 s2.0 S0142112316303723 MainClaudio JuniorОценок пока нет

- Useful Algorithms and Formulas For RC deДокумент12 страницUseful Algorithms and Formulas For RC deMarco PlebaniОценок пока нет

- Sample Soil TestДокумент8 страницSample Soil TestAlexander Osmeña II50% (2)

- RILEM TC 162-TDF - Test and Design Methods For Steel Fibre Reinforced Concrete - S-E DESIGN METHODДокумент7 страницRILEM TC 162-TDF - Test and Design Methods For Steel Fibre Reinforced Concrete - S-E DESIGN METHODMihai GheorghiuОценок пока нет

- 13 Phu My Cable Stayed BridgeДокумент18 страниц13 Phu My Cable Stayed BridgeLengendary PhubrОценок пока нет

- Final Exam OutlineДокумент2 страницыFinal Exam OutlineBilal BatroukhОценок пока нет

- Effect of Shear Box Size On Shear Strength of SoilДокумент20 страницEffect of Shear Box Size On Shear Strength of Soillokesh loharОценок пока нет

- Dgcs Volume 2aДокумент126 страницDgcs Volume 2aJan-Simon Noveras75% (4)

- Behavior DS MM247LC (Bae2001)Документ6 страницBehavior DS MM247LC (Bae2001)Alex CostaОценок пока нет

- Chapter 2Документ40 страницChapter 2IntanLeeyanaОценок пока нет

- Model Exit Exam For Mechanical Engineering Graduate StudentsBlackДокумент26 страницModel Exit Exam For Mechanical Engineering Graduate StudentsBlackbereketОценок пока нет

- MC Barra de 5 OctavosДокумент53 страницыMC Barra de 5 OctavosJulio SjjОценок пока нет

- Torsional and Bending StressesДокумент6 страницTorsional and Bending StressesSajjadОценок пока нет

- Nonlinear Structural Analysis ANSYSДокумент94 страницыNonlinear Structural Analysis ANSYSSer InfinitoОценок пока нет

- Handbook For Marine Geotechnical Engineering Version 2Документ256 страницHandbook For Marine Geotechnical Engineering Version 2José Ignacio RamírezОценок пока нет

- Lecture 03-Design of Doubly Reinforced Beam in FlexureДокумент11 страницLecture 03-Design of Doubly Reinforced Beam in FlexureOmer MehsudОценок пока нет

- How To Calculate Slab Steel Quantity From Drawing Excel SheetДокумент15 страницHow To Calculate Slab Steel Quantity From Drawing Excel SheetJeany NoquilloОценок пока нет

- How Do I Locate The Neutral Axis in A Beam?: Answer Follow Request MoreДокумент7 страницHow Do I Locate The Neutral Axis in A Beam?: Answer Follow Request MoreDuke StonerОценок пока нет

- Basics of Strength of MaterialДокумент45 страницBasics of Strength of MaterialGaurav ChopraОценок пока нет

- Dummy Leg JacobsДокумент1 страницаDummy Leg Jacobsananyo_sengupta0% (1)