Академический Документы

Профессиональный Документы

Культура Документы

US20130261330 Vynil Asetat

Загружено:

Debby Theresia Silaban0 оценок0% нашли этот документ полезным (0 голосов)

25 просмотров11 страницThe document describes a process for inhibiting impurity formation in the production of vinyl acetate. The process involves providing a reactor with an inlet section, outlet section, filler, and catalyst block section. The filler is disposed in the outlet section. The process introduces reactants into the inlet section where they contact the catalyst to form a crude vinyl acetate composition. This composition is then directed into the outlet section containing the filler.

Исходное описание:

patent

Оригинальное название

US20130261330 vynil asetat

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документThe document describes a process for inhibiting impurity formation in the production of vinyl acetate. The process involves providing a reactor with an inlet section, outlet section, filler, and catalyst block section. The filler is disposed in the outlet section. The process introduces reactants into the inlet section where they contact the catalyst to form a crude vinyl acetate composition. This composition is then directed into the outlet section containing the filler.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

25 просмотров11 страницUS20130261330 Vynil Asetat

Загружено:

Debby Theresia SilabanThe document describes a process for inhibiting impurity formation in the production of vinyl acetate. The process involves providing a reactor with an inlet section, outlet section, filler, and catalyst block section. The filler is disposed in the outlet section. The process introduces reactants into the inlet section where they contact the catalyst to form a crude vinyl acetate composition. This composition is then directed into the outlet section containing the filler.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 11

US 20130261330A1

( 19 ) United Sta tes

( 12) Pa tent Applica tion Publica tion ( 10) Pub. N o. : US 2013/0261330 A1

As la m et a l. ( 4 3) Pub. D a te: Oct. 3, 2013

( 5 4 ) PROCESSES FOR PROD UCIN G VIN YL Publica tion Cla s s i? ca tion

ACETATE COMPOSITION HAVIN G LOW

IMPURITY CON TEN T ( 5 1) Int- Cl

C07C 67/05 ( 2006. 01)

( 71) Applica nt: CELAN ESE IN TERN ATION AL B01J19 /00 ( 2006- 01)

CORPORATION , Ir v ing , TX ( US) ( 5 2) US. Cl.

CPC . C07C 67/05 ( 2013. 01) ; B01J19 /00 ( 2013. 01)

( 72) Inv entor s : N a v eed As la m, Pa s a dena , TX ( US) ; USPC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 60/24 1; 4 22/129

Jes s ica Fr eema n, Pa s a dena , TX ( US) ; ( 5 7) ABSTRACT

Ilia s S. Kots ia nis , Hous ton, TX ( US) ; . . . . .

The pr es ent 1nv ent1on, 1n one embodiment, is to a pr oces s f or

La ur en Moor e, Webs ter , TX ( US) ; . . . . . . . . .

, Y B t R LA S 1nh1b1t1ng impur ity f or ma tion a v inyl a ceta te f or ma tion r ea c

Qula ng a 0 a on Oug e ( U ) tion. The pr oces s compr is es the s tep of pr ov iding a r ea ctor

compr is ing a n inlet s ection, a n outlet s ection, a ? ller ( or

( 21) App1_ N O; 13/771, 5 69 ? ller s ) , a nd a ca ta lys t block s ection. The ? ller is dis pos ed in

the outlet s ection. The ca ta lys t block s ection ma y be in com

_ munica tion With a nd con? g ur ed between the inlet a nd outlet

( 22) Flledi Feb- 20, 2013 s ections . The pr oces s f ur ther compr is es the s teps of intr oduc

ing the r ea cta nts to the inlet s ection a nd conta cting the r ea c

Rela ted U s Applica tion D a ta ta nts 1n the ca ta lys t block s ect1on under conditions ef f ectiv e

to f or m a cr ude v inyl a ceta te compos ition. The pr oces s ma y

( 60) Pr ov is iona l a pplica tion N o. 61/ 617, 325 , ? led on Ma r . f ur ther compr is e the s tep of dir ecting the cr ude v inyl a ceta te

29 , 2012, pr ov is iona l a pplica tion N o. 61/614 , 9 4 7, compos ition into the outlet s ection, Which compr is es the

? led on Ma r . 23, 2012. ? ller .

15 8

164

C02

Pr oces s ing

160

102 14 2 Wa ter

14 0 Str ipping

02 I

1 2

104 6

Ethylene 126 138 \_ _ 15 4

128

110 \ VA

15 6

134 H I

ecyc e

100 // Inhibitor

Wa ter

106 166

132 Or g a nic 137 N

112 120

HOAc

130 14 4 Cr ude

124 Ta nk

108 118

Hea v y Ends

Pr oces s ing

Pa tent Applica tion Publica tion Oct. 3, 2013 Sheet 2 0f 2 US 2013/0261330 A1

2N

E

2m

3m / \ a m

mom 8 m

mom

N E

N . GE

US 2013/0261330 A1

PROCESSES FOR PROD UCIN G VIN YL

ACETATE COMPOSITION HAVIN G LOW

IMPURITY CON TEN T

CROSS REFEREN CE TO RELATED

APPLICATION S

[ 0001] The pr es ent a pplica tion cla ims pr ior ity to US. Pr o

v is iona l Pa tent Applica tion N o. 61/ 617, 325 , ? led Ma r . 29 ,

2012, a nd to US. Pr ov is iona l Pa tent Applica tion N o. 61/614 ,

9 4 7, ? led Ma r . 23, 2012, the entir e contents a nd dis clos ur e of

Which a r e her eby incor por a ted by r ef er ence.

FIELD OF THE IN VEN TION

[ 0002] This inv ention r ela tes to pr oces s es f or pr oducing

v inyl a ceta te a nd, in pa r ticula r , to impr ov ed pr oces s es f or

pr oducing v inyl a ceta te, Which r educe the a mount v inyl

a ceta te impur ities in the v inyl a ceta te pr oduct.

BACKGROUN D OF THE IN VEN TION

[ 0003] Vinyl a ceta te is a n impor ta nt monomer in the pr o

duction of polyv inyl a ceta te a nd polyv inyl a lcohol pr oducts .

Vinyl a ceta te is conv entiona lly pr epa r ed by conta cting a cetic

a cid a nd ethylene With molecula r oxyg en to f or m a cr ude

v inyl a ceta te compos ition. The r ea ction is typica lly con

ducted in the pr es ence of a s uita ble ca ta lys t, Which ma y

compr is e pa lla dium, a n a lk a li meta l a ceta te pr omoter , a nd,

optiona lly, a co- pr omoter , e. g . , g old or ca dmium, on a ca ta lys t

s uppor t. US. Pa t. N o. 6, 69 6, 5 9 6, f or exa mple, indica tes tha t

it is Well k noWn to ma nuf a ctur e v inyl a ceta te in a r ea ction in

the g a s pha s e With a cetic a cid a nd oxyg en or oxyg en conta in

ing g a s s es ov er ? xed- bed ca ta lys ts . US. Pa t. N o. 6, 04 0, 4 74 ,

a s a nother exa mple, des cr ibes the ma nuf a ctur e of a cetic a cid

a nd/ or v inyl a ceta te us ing tWo r ea ction zones Wher ein the ? r s t

r ea ction zone compr is es ethylene a nd/ or etha ne f or oxida tion

to a cetic a cid With the s econd r ea ction zone compr is ing a cetic

a cid a nd ethylene With the pr oduct s tr ea ms being s ubs e

q uently s epa r a ted ther eby pr oducing v inyl a ceta te. Als o, US.

Pa t. N o. 6, 4 76, 261 des cr ibes a n oxida tion pr oces s f or the

pr oduction of a lk enes a nd ca r boxylic a cids s uch a s ethylene

a nd a cetic a cid, Which a r e r ea cted to f or m v inyl a ceta te,

demons tr a ting tha t mor e tha n one r ea ction zone ca n be us ed to

f or m the v inyl a ceta te.

[ 0004 ] In a ddition, US. Pa t. N o. 6, 013, 8 34 dis clos es a pr o

ces s f or the pr oduction of v inyl a ceta te by r ea ction in the

v a por pha s e of ethylene, oxyg en a nd a cetic a cid a s r ea cta nts ,

compr is ing pa s s ing a t a temper a tur e s uf ? cient to initia te the

r ea ction, a f eed g a s compr is ing s a id r ea cta nts a nd continu

ous ly or inter mittently conta ining liq uid a cetic a cid a nd/or

non- v ola tile components , thr oug h a ? lter a nd dis tr ibution bed

of iner t ma ter ia l ha v ing thr oug hout its v olume s ubs ta ntia l

inter communica ting open s pa ces a mong the s olid por tions ,

a nd thence thr oug h a plur a lity of tubes ea ch conta ining a bed

of ca ta lys t f or the r ea ction, a nd Withdr a Wing a pr oduct g a s

compr is ing VA. The ? lter a nd dis tr ibution bed a cts to ? lter out

the liq uid a cetic a cid a nd/or non- v ola tile components a nd

dis tr ibute mor e ev enly the f eed g a s into the tubes .

[ 0005 ] This v inyl a ceta te r ea ction, hoWev er , lends its elf to

the pr oduction of s ev er a l unWa nted impur ities , including , f or

exa mple, non- v ola tile r es idues s uch a s polymer ized v inyl

a ceta te, polymer ized ethylene, a nd hea v y ends , s uch a s

a cetoxya cetic a cid. The f or ma tion of thes e impur ities is det

r imenta l in ma ny r es pects . For exa mple, the f or ma tion of

Oct. 3, 2013

thes e impur ities r educes v inyl a ceta te yield a nd ma y lea d to

f ouling of v inyl a ceta te pr oduction eq uipment, e. g . , pur i? ca

tion toWer s a nd v a por izer s .

[ 0006] Conv entiona lly, a hea v y ends toWer is utilized to

r emov e thes e impur ities . The hea v y ends toWer , hoWev er , is

expens iv e. Als o, the lev el of pur i? ca tion a chiev ed by the

hea v y ends toWer lea v es much to be des ir ed. Thus , the need

exis ts f or methods f or pr oducing a v inyl a ceta te compos ition

Wher ein the f or ma tion of impur ities is inhibited or Wher ein

the impur ity content is r educed.

[ 0007] The r ef er ences mentioned a bov e a r e her eby incor

por a ted by r ef er ence.

SUMMARY OF THE IN VEN TION

[ 0008 ] The pr es ent inv ention, in one embodiment, is to a

pr oces s f or inhibiting impur ity f or ma tion a v inyl a ceta te f or

ma tion r ea ction. The pr oces s compr is es the s tep of pr ov iding

a r ea ctor compr is ing a n inlet s ection, a n outlet s ection, a ? ller

( or ? ller s ) , a nd a ca ta lys t block s ection. The ? ller ma y be

dis pos ed in the outlet s ection. The ca ta lys t block s ection ma y

be in communica tion With a nd con? g ur ed betWeen the inlet

a nd outlet s ections . In one embodiment, the outlet s ection

compr is es a t lea s t one outlet line f or conv eying the cr ude

r ea ction mixtur e f r om the outlet cha mber . In thes e ca s es , the

? ller ma y be dis pos ed in the a t lea s t one outlet line. The

pr oces s f ur ther compr is es the s teps of intr oducing the r ea c

ta nts to the inlet s ection a nd conta cting the r ea cta nts in the

ca ta lys t block s ection under conditions ef f ectiv e to f or m a

cr ude v inyl a ceta te compos ition. The cr ude v inyl a ceta te

compos ition, a s f or med, ma y compr is e v inyl a ceta te ( mono

mer ) , r es idua l a cetic a cid, r es idua l oxyg en, Wa ter , a nd,

optiona lly, r es idua l ethylene ( monomer ) , a nd a n initia l

a mount of impur ities , e. g . , per oxides , non- v ola tile r es idues

( N VR ) , hea v y ends , lig ht ends a nd/or mixtur es ther eof . The

pr oces s ma y f ur ther compr is e the s tep of dir ecting the cr ude

v inyl a ceta te compos ition into the outlet s ection, Which com

pr is es the ? ller .

[ 0009 ] As a r es ult of us e of the ? ller in the outlet s ection, the

cr ude v inyl a ceta te compos ition tha t exits the outlet s ection

compr is es s ma ll a mounts , if a ny, impur ities , e. g . , les s tha n

2, 000 Wppm impur ities .

BRIEF D ESCRIPTION OF D RAWIN GS

[ 0010] The inv ention is des cr ibed in deta il beloW With r ef

er ence to the a ppended dr a Wing s , Wher ein lik e numer a ls des

ig na te s imila r pa r ts .

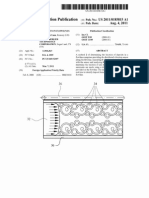

[ 0011] FIG. 1 is a s chema tic dia g r a m of a n exempla r y v inyl

a ceta te pr oduction pr oces s , Which includes r ea ction a nd s epa

r a tion a ccor ding to one embodiment of the pr es ent inv ention.

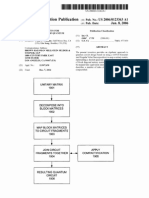

[ 0012] FIG. 2 is a s chema tic dia g r a m of a n exempla r y v inyl

a ceta te r ea ctor s hoWing a n inlet s ection, a ca ta lys t block

s ection, ? ller , a nd a n outlet s ection a ccor ding to one embodi

ment of the pr es ent inv ention.

[ 0013] FIG. 3 is a cr os s s ectiona l v ieW of a n outlet line

a ccor ding to one embodiment of the pr es ent inv ention.

D ETAILED D ESCRIPTION OF THE IN VEN TION

Intr oduction

[ 0014 ] Conv entiona l v inyl a ceta te pr oces s es s uf f er f r om

the pr oduction of unWa nted impur ities . Some of thes e impu

r ities include lig ht ends , non- v ola tile r es idues ( N VR ) , e. g . ,

polymer ized monomer s , hea v y ends , metha ne, etha ne, ca r

US 2013/0261330 A1

bon monoxide, iner ts , ca r bon dioxide, a nd ethyl a ceta te,

Which r educe yield a nd ha v e detr imenta l ef f ects on pr oduc

tion eq uipment. Exa mples of a f f ected pr oduction eq uipment

include pur i? ca tion toWer s a nd v a por iZ er s . As a r es ult, s ig

ni? ca nt r es our ces mus t be dev oted to r emov e thes e impur ities

f r om the cr ude v inyl a ceta te compos ition.

[ 0015 ] For exa mple, s ome unWa nted non- v ola tile r es idues

( N VR ) ma y be f or med v ia the polymer iza tion of monomer s

s uch a s ethylene a nd v inyl a ceta te. As a nother exa mple, oxy

g en a nd/ or per oxides tha t a r e pr es ent in a nd a r ound the r ea ctor

ma y pr omote the f or ma tion of undes ir a ble hea v y ends . Exem

pla r y hea v y ends include ethylene g lycol, ethylidene dia c

eta te, ethylene g lycol monoa ceta te, v inyl a cetoxy a ceta te,

ethylene g lycol dia ceta te, cis - dia cetoxy ethylene, tr a ns - dia c

etoxy ethylene, g lycolic a cid, a cetoxya cetic a cid, a nd mix

tur es ther eof .

[ 0016] Without being bound by theor y, it is believ ed tha t

polymer iZ a tion of monomer s ma y be induced by the pr es ence

of r a dica ls , e. g . , oxyg en r a dica ls . Typica lly, oxida tion of v inyl

a ceta te a nd/or ethylene is a cha in r ea ction. As s uch, the inter

r uption of the cha in r ea ction( s ) ma y s ig ni? ca ntly inhibit the

f or ma tion of detr imenta l impur ities . In a ddition, by limiting

conta ct betWeen the v inyl a ceta te monomer s , r es idua l ethyl

ene monomer s a nd/ or oxyg en/ oxyg en r a dica ls , the f or ma tion

of detr imenta l impur ities ma y be inhibited or elimina ted.

[ 0017] It ha s noW been dis cov er ed tha t cha in oxida tion

r ea ctions a nd/or monomer conta ct ma y be bene? cia lly inhib

ited by employing a ? ller in the s pa ces Wher e oxyg en a nd/or

oxyg en r a dica ls a nd monomer s a r e pr es ent With one a nother .

As a r es ult, f eWer impur ities a r e pr oduced, a nd the need f or

r emov a l of impur ities in the pur i? ca tion s ys tem is r educed or

elimina ted. Accor ding ly, pr oduction ef ? ciencies ma y be

impr ov ed. For exa mple, impur ity monitor ing a nd/ or r emov a l

eq uipment could be elimina ted.

[ 0018 ] Accor ding ly, the pr es ent inv ention r ela tes to the

inhibition of the f or ma tion of v inyl a ceta te impur ities a nd/or

to the r eduction of v inyl a ceta te impur ity content in a v inyl

a ceta te compos ition. In one embodiment, the r ea cta nts com

pr is e a r ea ction mixtur e of a cetic a cid, oxyg en, a nd ethylene.

The pr oces s compr is es the s tep of pr ov iding a r ea ctor com

pr is ing a n inlet s ection, a n outlet s ection, a ? ller or a plur a lity

of ? ller s , a nd a ca ta lys t block s ection. The inv entiv e pr oces s

f ur ther compr is es the s teps of intr oducing the r ea cta nts , e. g . ,

the r ea ction mixtur e, to the inlet s ection a nd conta cting the

r ea cta nts in the ca ta lys t block s ection under conditions ef f ec

tiv e to f or m the cr ude v inyl a ceta te compos ition a nd dir ecting

the cr ude v inyl a ceta te compos ition into the outlet s ection.

The ca ta lys t block s ection is in communica tion With a nd

con? g ur ed betWeen the inlet a nd outlet s ections . The ca ta lys t

block s ection compr is es a ca ta lys t tha t ca ta lyZ es a r ea ction of

the a cetic a cid, the oxyg en, a nd the ethylene to f or m a cr ude

v inyl a ceta te compos ition. The cr ude v inyl a ceta te compos i

tion compr is es , inter a lia , v inyl a ceta te monomer , r es idua l

ethylene monomer a nd/ or oxyg en, e. g . , r es idua l oxyg en a nd/

or oxyg en r a dica ls . In one embodiment, the ? ller is dis pos ed

in a t lea s t a por tion of the outlet s ection. By dis pos ing the ? ller

in the outlet s ection, conta ct betWeen 1) the ethylene a nd/or

v inyl a ceta te monomer s a nd/or 2) monomer s a nd the oxyg en

a nd/ or oxyg en r a dica ls is r educed a nd the potentia l cha in

r ea ction tha t ma y f or m impur ities is a dv a nta g eous ly inhibited

or elimina ted.

[ 0019 ] In one embodiment, the r es ulta nt cr ude v inyl a ceta te

compos ition exiting the outlet s ection of the r ea ctor com

pr is es v inyl a ceta te a nd optiona lly little, if a ny, impur ities ,

Oct. 3, 2013

e. g . , les s tha n 2, 000 Wppm impur ities , e. g . , les s tha n 1, 000

Wppm, les s tha n 5 00 Wppm, les s tha n 25 0 Wppm or les s tha n

100 Wppm. In ter ms of r a ng es , the cr ude v inyl a ceta te com

pos ition optiona lly compr is es f r om 0 Wppm to 2, 000 Wppm

impur ities , e. g . , f r om 100 Wppm to 1, 000 Wppm or f r om 25 0

Wppm to 1, 000 Wppm. In a nother embodiment, the inhibited

a mount of impur ities is les s tha n the a mount of impur ities tha t

Would be pr es ent ha d the ? ller not been employed, e. g . , a t

lea s t 10% les s tha n, a t lea s t 25 % les s tha n, or a t lea s t 4 0% les s

tha n. The cr ude v inyl a ceta te compos ition ma y f ur ther com

pr is e r es idua l a cetic a cid a nd Wa ter . Exempla r y Weig ht per

centa g e r a ng es f or thes e components , a nd other exempla r y

components , a r e s hoWn in Ta ble 1 beloW.

[ 0020] In one embodiment, the ? ller compr is es a n iner t

ma ter ia l, Which ma y be s elected f r om the g r oup cons is ting of

g la s s , Z eolites , s ilica , a nd Z ir conium oxide. In one embodi

ment, the ? ller ma y be s elected f r om the g r oup cons is ting of

a lumina , s ilica - a lumina , tita nia , Z ir conia , s ilica tes , a lumino

s ilica tes , tita na tes , s pinel, s ilicon ca r bide, ca r bon, a nd mix

tur es ther eof . The ? ller ma y be g a s per mea ble in or der to

a lloW the r ea cta nts to pa s s ther ethr oug h, a nd ma y include a

por ous netWor k f or this pur pos e. In one embodiment, the s iZ e

a nd s ha pe of the ? ller pa r ticles is s elected s uch tha t a pr ede

ter mined por os ity is a chiev ed. In one embodiment, the a v er

a g e por os ity r a ng es f r om 0. 2 to 0. 6, e. g . , f r om 0. 3 to 0. 5 . Other

por os ity r a ng es , hoWev er , a r e cons ider ed to be Within the

contempla tion of the inv ention. Por os ity is a mea s ur ement of

v oids , e. g . , empty s pa ces , pr es ent in the ? ller . As one

exa mple, por os ity ma y be a r a tio of the v olume of v oids a nd

the tota l v olume of the ? ller . In s ome embodiments , the s iZ e

a nd s ha pe of the ? ller pa r ticles ma y be s elected s o a s to a v oid

s ig ni? ca ntly a f f ecting the pr es s ur e dr op a cr os s the ? ller bed

or the r ea ctor bed.

[ 0021] In a nother a s pect, the ? ller compr is es pa r ticles , pel

lets or bea ds of a ? ller ma ter ia l a nd the por ous netWor k is

f or med by the v oids betWeen a dj a cent pa r ticles , pellets or

bea ds . In one embodiment, the ? ller pa r ticles a r e s pher ica l in

s ha pe. In a nother embodiment, the ? ller compr is es s ta inles s

s teel, e. g . , s teel Wool.

[ 0022] The pr oces s ma y f ur ther compr is e the s tep of pur i

f ying the cr ude v inyl a ceta te compos ition in a pur i? ca tion

s ys tem to pr oduce a pur i? ed v inyl a ceta te compos ition. An

exempla r y s epa r a tion Z one is des cr ibed beloW a nd in FIG. 1.

[ 0023] In one embodiment, the ? ller inhibits impur ity f or

ma tion by r educing conta ct betWeen the oxyg en a nd the eth

ylene, ea ch of Which ma y be pr es ent in the cr ude v inyl a ceta te

compos ition. In a nother embodiment, the ? ller inhibits impu

r ity f or ma tion a f ter the v inyl a ceta te r ea ction ha s ta k en pla ce

in the ca ta lys t block s ection. In this embodiment, the ? ller

r educes conta ct betWeen the oxyg en a nd the f or med v inyl

a ceta te ( a nd optiona lly r es idua l ethylene) to inhibit impur ity

f or ma tion. In one embodiment, the ? ller is dis pos ed in both

the inlet s ection a nd the outlet s ection. In thes e embodiments ,

impur ity inhibition is a chiev ed both lea ding up to the r ea ction

Z one, i. e. , the ca ta lys t block s ection, a nd a f ter the r ea ction ha s

ta k en pla ce. Thus , the pr oces s es of the pr es ent inv ention

bene? cia lly impr ov e v inyl a ceta te yield a nd r educe or elimi

na te the pr oblems ca us ed by the pr es ence of impur ity in the

pur i? ca tion eq uipment.

Acetoxyla tion of Ethylene

[ 0024 ] As s hoWn FIG. 1, in s ome embodiments , oxyg en

a nd ethylene a r e f ed to r ea ctor 100 v ia f eed lines 102 a nd 104 ,

r es pectiv ely. Acetic a cid ma y be f ed to v a por iZ er 106 v ia f eed

US 2013/0261330 A1

s tr ea m 108 . Va por ized a cetic a cid exits v a por izer 106 a nd is

dir ected to r ea ctor 100 v ia line 110. The v inyl a ceta te f or ma

tion r ea ction ta k es pla ce in r ea ctor 100. The cr ude v inyl

a ceta te s tr ea m exits r ea ctor 100 a s a n ef ? uent s tr ea m v ia line

112. FIG. 1 is f ur ther dis cus s ed below.

[ 0025 ] FIG. 2 s hoWs r ea ctor 200, Which compr is es inlet

s ection 202, outlet s ection 204 , a nd ca ta lys t block s ection

206. Ca ta lys t block s ection 206, Which ma y compr is e a ca ta

lys t bed, is con? g ur ed betWeen inlet s ection 202 a nd outlet

s ection 204 . Inlet s ection 202 is in communica tion With ca ta

lys t block s ection 206, Which, in tur n, is in communica tion

With outlet s ection 204 . As s uch, the r ea cta nts ma y be con

v eyed thr oug h inlet s ection 202 to ca ta lys t block s ection 206,

Wher e the v inyl a ceta te r ea ction occur s . The r ea ction yields a

cr ude v inyl a ceta te compos ition, Which is dir ected f r om ca ta

lys t block s ection 206 thr oug h outlet s ection 204 .

[ 0026] In one embodiment, inlet s ection 202 compr is es

inlet hous ing 208 , Which de? nes inlet cha mber 210. Inlet

cha mber 210 ma y be enclos ed by Wa lls of inlet s ection hous

ing 208 . In a ddition, inlet s ection 202 ma y a ls o compr is e a t

lea s t one inlet line 212 f or conv eying r ea cta nts f r om a n out

s ide s our ce to inlet cha mber 210. In one embodiment, the

a cetic a cid, oxyg en, a nd ethylene a r e combined to f or m a

r ea ction mixtur e a nd the r ea ction mixtur e is conv eyed to inlet

cha mber 210 v ia inlet line 212. In a nother embodiment ( not

s hoWn) , inlet s ection 202 compr is es a plur a lity of inlet lines .

As a n exa mple, ther e ma y be a s epa r a te inlet line f or ea ch

r ea cta nt. In one embodiment, the oxyg en a nd the ethylene a r e

combined pr ior to being intr oduced to inlet s ection 202. In

s uch a ca s e, a combined inlet line Would be f or med. As noted

a bov e, the outlet s ection compr is es ? ller 25 0. In s ome

embodiments , the ? ller is dis pos ed in the inlet s ection a s Well.

For exa mple the ? ller ma y be dis pos ed in a t lea s t a por tion of

inlet cha mber 210 a nd/or in one or mor e inlet lines 212 a nd/or

in the combined inlet line. In one embodiment, the ? ller 25 0

is dis pos ed in both inlet cha mber 210 a nd in a t lea s t one of

inlet lines 212.

[ 0027] In s ome embodiments , the one or mor e ? ller 25 0 a r e

dis pos ed in a t lea s t a por tion of inlet cha mber 210, e. g . , a t

lea s t 25 v ol. % of inlet cha mber 210, a t lea s t 5 0 v ol. %, a t lea s t

8 0 v ol. % or a t lea s t 9 5 v ol. % of inlet cha mber 210.

[ 0028 ] Outlet s ection 204 ma y compr is e outlet hous ing

214 , Which de? nes outlet cha mber 216. Outlet cha mber 216

ma y be enclos ed by Wa lls of outlet hous ing 214 . In a ddition,

outlet s ection 204 ma y a ls o compr is e a t lea s t one outlet line

218 f or conv eying the cr ude v inyl a ceta te compos ition f r om

outlet cha mber 216 f or f ur ther pr oces s ing or s tor a g e. In s ome

embodiments , the ? ller 25 0 is dis pos ed in a t lea s t a por tion of

outlet cha mber 216, e. g . , a t lea s t 25 v ol. % of outlet cha mber

216, a t lea s t 5 0 v ol. %, a t lea s t 8 0 v ol. % or a t lea s t 9 5 v ol. %

of outlet cha mber 216. In a nother embodiment, the one or

mor e ? ller 25 0 is dis pos ed in a t lea s t a por tion of a t lea s t one

of the outlet lines 212. In one embodiment, the one or mor e

? ller 25 0 is dis pos ed inboth outlet cha mber 216 a nd in a t lea s t

one of outlet lines 218 .

[ 0029 ] In one embodiment, the ? ller ma y be con? g ur ed

loos ely in either or both of the inlet a nd/or outlet s ection. In

a nother embodiment, a s s hoWn in FIG. 3, the ? ller 35 0 ma y be

dis pos ed in either or both the inlet line a nd/or outlet line,

optiona lly in the outlet line. For exa mple, the ? ller ma y be

loos ely pa ck ed into the inlet line a nd/or the outlet line. In

a nother embodiment, the ? ller ma y be a tta ched to a n inter ior

of the hous ing a nd/or to Wa ll 302 of a n inlet line a nd/or a n

outlet line. In a nother embodiment, the ? ller ma y be dis pos ed

Oct. 3, 2013

in either or both the inlet s ection a nd/or the outlet s ection a t a

loa ding f a ctor , B, a s de? ned beloW, r a ng ing f r om 0. 001 to 0. 8 ,

e. g . , f r om 0. 001 to 0. 5 , or f r om 0. 01 to 0. 5 . In ter ms of loWer

limits , the loa ding f a ctor ma y be a t lea s t 0. 001, e. g . , a t lea s t

0. 01 or a t lea s t 0. 05 . In ter ms of upper limits , the loa ding

f a ctor ma y be les s tha n 0. 8 , e. g . , les s tha n 0. 5 or les s tha n 0. 4 .

If the loa ding f a ctor is too la r g e, the pr es s ur e dr op a cr os s the

r es pectiv e hous ing or line ma y ha v e a tendency to a cceler a te

the ethylene/v inyl a ceta te oxida tion cha in r ea ctions undes ir

a bly ca us ing the f or ma tion of impur ities . For exa mple, With

out being bound by theor y, the concentr a tion of the polymer

pr ecur s or s ma y incr ea s e if the loa ding f a ctor is too hig h,

Which Would ma y pr omote polymer iza tion r a ther tha n inhibit

polymer iza tion. Conv er s ely, if the loa ding is too s ma ll, the

inhibiting ef f ect of the ? ller ma y be r educed.

[ 0030] In one embodiment, the loa ding f a ctor , B, is de? ned

by the f olloWing f or mula .

[ 0031] Wher ein PD is the pr es s ur e dr op per unit leng th

( Pa /m) under oper a ting conditions ; a nd

[ 0032] PS is the r a tio of ma s s ? oW ( k g / s ) to v olume ? oW

( m3/s ) , of a ll components under oper a ting conditions ,

multiplied by 9 . 8 1 ( m/ s ) .

[ 0033] The ? ller ma y g ener a lly compr is e a Wide v a r iety of

ma ter ia ls . In one embodiment, the ? ller compr is es ma ter ia ls

tha t a r e iner t or s ubs ta ntia lly iner t. As one exa mple, the ? ller

is r es is ta nt to r ea ctions With the r ea cta nts , e. g . , a cetic a cid,

ethylene, oxyg en, a nd Wa ter , a s Well a s to v inyl a ceta te its elf .

For exa mple, a luminum ma y r ea ct With the a cetic a cid. As a

r es ult, if a compos ition compr is ing a luminum is employed a s

the ? ller , the compos ition s hould compr is e loWer a mounts of

a luminum, e. g . , les s tha n 9 0 Wt % or les s tha n 8 0 Wt %.

Exempla r y ? ller ma ter ia ls include g la s s , zeolites , s ilica ,

s ta inles s s teel, a luminum ( in loWer a mounts ) , zir conium

oxide a nd mixtur es ther eof . The one or mor e ? ller ma y be

a tta ched or r eta ined in the r ea ctor a nd/ or inlet or outlet lines

us ing mecha nica l f a s tener s , a dhes iv es , Welding , a nd/or

s cr eening . Of cour s e, this lis ting is mer ely exempla r y a nd

other r eta ining mecha nis ms a r e Well Within the contempla

tion of the inv ention. In one embodiment, the ? ller is s ta inles s

s teel a nd the s ta inles s s teel ? ller is loos ely pa ck ed in the inlet

a nd outlet cha mber s . In a nother embodiment, the ? ller is

g la s s a nd the g la s s is a dhes iv ely bonded to the Wa ll of the inlet

a nd outlet lines . In one embodiment, the ? ller is pa ck ed into

the bed of the r ea ctor .

[ 0034 ] The s ha pe of the ? ller ma y v a r y Widely. In one

embodiment, the ? ller is s pher ica l in s ha pe. In a nother

embodiment, the ? ller is cubic or cylindr ica l in s ha pe. In one

embodiment, the ? ller compr is es s pher ica l pellets , optiona lly

s ta inles s s teel s pher ica l pellets or g la s s s pher es .

[ 0035 ] In a ddition to being unr ea ctiv e, the ? ller ma ter ia l

a ls o ma y be cha r a cter ized in ter ms of mecha nica l or phys ica l

pr oper ties , e. g . , tens ile s tr eng th or cr us h s tr eng th. Thus , ? ller

ha v ing hig h s tr eng th, e. g . , s ta inles s s teel, ma y be pa r ticula r ly

bene? cia l.

Vinyl Aceta te Compos ition

[ 0036] The s peci? c compos ition of the cr ude v inyl a ceta te

compos ition ma y v a r y Widely depending , f or exa mple, on the

r ea ction conditions a nd ca ta lys t employed. Some exempla r y

compos itions f or the cr ude v inyl a ceta te compos ition a r e

pr es ented in Ta ble 1 . Thes e compos itions a r e ba s ed on a cr ude

US 2013/0261330 A1

v inyl a ceta te compos ition pr epa r ed in a r ea ctor compr is ing

? ller dis pos ed in the inlet s ection a nd/or in the outlet s ection.

TABLE 1

Cr ude Vinyl Aceta te Compos itions

Component Conc. ( Wt. %) Conc. ( Wt. %) Conc. ( Wt. %)

Vinyl Aceta te 1 to 75 1 to 5 0 2 to 35

Acetic Acid 1 to 8 0 1 to 5 0 5 to 25

Impur ities 0 to 2, 000 100 to 1, 000 25 0 to 1, 000

WPPIH WPPIH WPPIH

Ethylene 10 to 9 0 10 to 5 0 20 to 4 0

Etha ne 1 to 4 0 1 to 20 5 to 15

Wa ter 1 to 20 1 to 10 2 to 8

Ca r bon D ioxide 1 to 75 1 to 5 0 2 to 35

[ 0037] As s hoWn in Ta ble 1, a s a r es ult of the ? ller being

dis pos ed in the outlet s ection of the r ea ctor , the cr ude v inyl

a ceta te compos ition tha t is f or med compr is es a ma j or a mount

of v inyl a ceta te a nd, bene? cia lly, a loW a mount of impur ities ,

if a ny. Beca us e of thes e loW a mounts of r es ulta nt impur ities ,

the need f or a dditiona l s epa r a tion pr oces s es a nd units to

r emov e s a me is minimiZ ed or elimina ted. In one embodiment,

a ma j or a mount r ef er s to a n a mount g r ea ter tha n 5 0 Wt %,

e. g . , g r ea ter tha n 60 Wt % or g r ea ter tha n 70 Wt %. Weig ht

per centa g e r a ng es f or other components tha t ma y be pr es ent

in the cr ude v inyl a ceta te a r e pr es ented in Ta ble 1.

[ 0038 ] The r ea ctor s utiliZ ed in conv entiona l v inyl a ceta te

pr oduction pr oces s es ha v e not utiliZ ed ? ller in the outlet

s ections to inhibit impur ity f or ma tion. As s uch, the cr ude

v inyl a ceta te compos itions , a s f or med, conta in s ig ni? ca ntly

hig her a mounts of impur ities . Thus , s ur pr is ing ly a nd unex

pectedly, the f or med v inyl a ceta te compos itions of the pr es ent

inv ention bene? cia lly compr is e loWer a mounts of impur ities

tha n conv entiona l s ys tems . In s ome embodiments , f or

exa mple, the r ea ction s ys tem of the inv ention f or ms a t lea s t

10% les s impur ities tha n a n a na log ous s ys tem, r un under the

s a me conditions , but Without us ing a ny ? ller , e. g . , a t lea s t 25

Wt. % les s impur ities or a t lea s t 25 Wt. % impur ities .

Vinyl Aceta te For ma tion

[ 0039 ] The f ea tur es of the pr es ent inv ention ma y be a pplied

to a ny s uita ble v inyl a ceta te pr oduction pr oces s . As noted

a bov e, the f or ma tion of v inyl a ceta te ma y be ca r r ied out by

r ea cting a cetic a cid a nd ethylene in the pr es ence of oxyg en. In

other embodiments , the inv entiv e us e of the ? ller ma y a pply

to pr oduction of other monomer s s uch a s , f or exa mple, a cr ylic

a cid, v inyl es ter s , or dia cetoxyethylene. This r ea ction ma y

ta k e pla ce heter o g eneous ly With the r ea cta nts being pr es ent in

the g a s pha s e. The r ea ctor ma y be con? g ur ed s uch tha t the

r ea ctor is ca pa ble of r emov ing hea t f r om the r ea ction. Suit

a ble r ea ctor types include, but a r e not limited to, a ? xed bed

r ea ctor a nd a ? uidized bed r ea ctor . In one embodiment, the

mola r r a tio of ethylene to a cetic a cid in the r ea ction r a ng es

f r om 1: 1 to 10: 1, e. g . , f r om 1: 1 to 5 : 1; or f r om 2: 1 to 3: 1. In

one embodiment, the mola r r a tio of ethylene to oxyg en in the

r ea ction r a ng es f r om 1: 1 to 20: 1, e. g . , f r om 1. 5 : 1 to 10: 1; or

f r om 2: 1 to 5 : 1. In a nother embodiment, the mola r r a tio of

a cetic a cid to oxyg en in the r ea ction r a ng es f r om 1: 1 to 10: 1,

e. g . , f r om 1: 1 to 5 : 1; or f r om 1: 1 to 3: 1.

[ 004 0] The r a W ma ter ia ls , e. g . , a cetic a cid, us ed in connec

tion With the pr oces s of this inv ention ma y be der iv ed f r om

a ny s uita ble s our ce including na tur a l g a s , petr oleum, coa l,

bioma s s , a nd s o f or th. For pur pos es of the pr es ent inv ention,

Oct. 3, 2013

a cetic a cid ma y be pr oduced us ing a metha nol f eed v ia metha

nol ca r bonyla tion a s des cr ibed in Us . Pa t. N os . 7, 208 , 624 ;

7, 115 , 772; 7, 005 , 5 4 1; 6, 65 7, 078 ; 6, 627, 770; 6, 14 3, 9 30;

5 , 5 9 9 , 9 76; 5 , 14 4 , 068 ; 5 , 026, 9 08 ; 5 , 001, 25 9 ; a nd 4 , 9 9 4 , 608 ,

the entir e dis clos ur es of Which a r e incor por a ted her ein by

r ef er ence. Optiona lly, the pr oduction of etha nol ma y be inte

g r a ted With s uch metha nol ca r bonyla tion pr oces s es .

[ 004 1] As petr oleum a nd na tur a l g a s pr ices ? uctua te

becoming either mor e or les s expens iv e, methods f or pr oduc

ing a cetic a cid a nd inter media tes s uch a s metha nol a nd ca r

bon monoxide f r om a lter na te ca r bon s our ces ha v e dr a Wn

incr ea s ing inter es t. In pa r ticula r , When petr oleum is r ela tiv ely

expens iv e, it ma y become a dv a nta g eous to pr oduce a cetic

a cid f r om s ynthes is g a s ( s yng a s ) tha t is der iv ed f r om mor e

a v a ila ble ca r bon s our ces . U. S. Pa t. N o. 6, 232, 35 2, the

entir ety of Which is incor por a ted her ein by r ef er ence, f or

exa mple, tea ches a method of r etr o? tting a metha nol pla nt f or

the ma nuf a ctur e of a cetic a cid. By r etr o? tting a metha nol

pla nt, the la r g e ca pita l cos ts a s s ocia ted With CO g ener a tion

f or a neW a cetic a cid pla nt a r e s ig ni? ca ntly r educed or la r g ely

elimina ted. All or pa r t of the s yng a s is div er ted f r om the

metha nol s ynthes is loop a nd s upplied to a s epa r a tor unit to

r ecov er CO, Which is then us ed to pr oduce a cetic a cid. In a

s imila r ma nner , hydr og en f or the hydr og ena tion s tep ma y be

s upplied f r om s yng a s .

[ 004 2] In s ome embodiments , s ome or a ll of the r a W ma te

r ia ls ma y be der iv ed pa r tia lly or entir ely f r om s yng a s . For

exa mple, the a cetic a cid ma y be f or med f r om metha nol a nd

ca r bon monoxide, both of Which ma y be der iv ed f r om s yng a s .

The s yng a s ma y be f or med by pa r tia l oxida tion r ef or ming or

s tea m r ef or ming , a nd the ca r bon monoxide ma y be s epa r a ted

f r om s yng a s . Simila r ly, hydr og en tha t is us ed in the s tep of

hydr og ena ting the a cetic a cid to f or m the cr ude etha nol pr od

uct ma y be s epa r a ted f r om s yng a s . The s yng a s , in tur n, ma y

be der iv ed f r om v a r iety of ca r bon s our ces . The ca r bon s our ce,

f or exa mple, ma y be s elected f r om the g r oup cons is ting of

na tur a l g a s , oil, petr oleum, coa l, bioma s s , a nd combina tions

ther eof . Syng a s or hydr og en ma y a ls o be obta ined f r om bio

der iv ed metha ne g a s , s uch a s bio- der iv ed metha ne g a s pr o

duced by la nd? lls or a g r icultur a l Wa s te.

[ 004 3] In a nother embodiment, in a ddition to the a cetic a cid

f or med v ia metha nol ca r bonyla tion, s ome a dditiona l a cetic

a cid ma y be f or med f r om the f er menta tion of bioma s s a nd

ma y be us ed in the hydr og ena tion s tep. The f er menta tion

pr oces s ma y utiliZ e a n a cetog enic pr oces s or a homoa cetog e

nic micr oor g a nis m to f er ment s ug a r s to a cetic a cid pr oducing

little, if a ny, ca r bon dioxide a s a by- pr oduct. The ca r bon

ef ? ciency f or the f er menta tion pr oces s ma y be g r ea ter tha n

70%, g r ea ter tha n 8 0% or g r ea ter tha n 9 0% a s compa r ed to

conv entiona l yea s t pr oces s ing , Which typica lly ha s a ca r bon

ef ? ciency of a bout 67%. Optiona lly, the micr oor g a nis m

employed in the f er menta tion pr oces s is of a g enus s elected

f r om the g r oup cons is ting of Clos lr idium, La cloba cillus ,

Moor ella , T her moa na er oba cler , Pr opioniba cler ium, Pr opi

onis per a , Ana er obios pir illum, a nd Ba cler iodes , a nd in pa r

ticula r , s pecies s elected f r om the g r oup cons is ting of

Clos lr idium f or micoa celicum, Clos lr idium bulyr icum,

Moor ella lher moa celica , T her moa na er oba cler k iv ui, La cto

ba cillus delbr uk ii, Pr opioniba cler ium a cidipr opionici, Pr o

pionis per a a r bor is , Ana er obios pir illum s uccinicpr oducens ,

Ba cler iodes a mylophilus a nd Ba cler iodes r uminicola .

Optiona lly in this pr oces s , a ll or a por tion of the unf er mented

r es idue f r om the bioma s s , e. g . , lig na ns , ma y be g a s i? ed to

f or m hydr og en tha t ma y be us ed in the hydr og ena tion s tep of

US 2013/0261330 Al

the pr es ent inv ention. Exempla r y f er menta tion pr oces s es f or

f or ming a cetic a cid a r e dis clos ed in Us . Pa t. N os . 6, 5 09 , 18 0;

6, 9 27, 04 8 ; 7, 074 , 603; 7, 5 07, 5 62; 7, 35 1, 5 5 9 ; 7, 601, 8 65 ;

7, 68 2, 8 12; a nd 7, 8 8 8 , 08 2, the entir eties of Which a r e incor

por a ted her ein by r ef er ence. See a ls o U. S. Pub. N os . 2008 /

019 39 8 9 a nd 2009 /028 135 4 , the entir eties of Which a r e incor

por a ted her ein by r ef er ence.

[ 004 4 ] Exa mples of bioma s s include, but a r e not limited to,

a g r icultur a l Wa s tes , f or es t pr oducts , g r a s s es , a nd other cellu

los ic ma ter ia l, timber ha r v es ting r es idues , s of tWood chips ,

ha r dWood chips , tr ee br a nches , tr ee s tumps , lea v es , ba r k ,

s a Wdus t, of f - s pec pa per pulp, com, com s tov er , Whea t s tr a W,

r ice s tr a W, s ug a r ca ne ba g a s s e, s Witchg r a s s , mis ca nthus , a ni

ma l ma nur e, municipa l g a r ba g e, municipa l s eWa g e, commer

cia l Wa s te, g r a pe pumice, a lmond s hells , peca n s hells , coco

nut s hells , cof f ee g r ounds , g r a s s pellets , ha y pellets , Wood

pellets , ca r dboa r d, pa per , pla s tic, a nd cloth. See, e. g . , U. S.

Pa t. N o. 7, 8 8 4 , 25 3, the entir ety of Which is incor por a ted

her ein by r ef er ence. Another bioma s s s our ce is bla ck liq uor ,

a thick , da r k liq uid tha t is a bypr oduct of the Kr a f t pr oces s f or

tr a ns f or ming Wood into pulp, Which is then dr ied to ma k e

pa per . Bla ck liq uor is a n a q ueous s olution of lig nin r es idues ,

hemicellulos e, a nd inor g a nic chemica ls .

[ 004 5 ] Us . Pa t. N o. RE 35 , 377, a ls o incor por a ted her ein

by r ef er ence, pr ov ides a method f or the pr oduction of metha

nol by conv er s ion of ca r bona ceous ma ter ia ls s uch a s oil, coa l,

na tur a l g a s a nd bioma s s ma ter ia ls . The pr oces s includes

hydr og a s i? ca tion of s olid a nd/or liq uid ca r bona ceous ma te

r ia ls to obta in a pr oces s g a s Which is s tea m pyr oliZ ed With

a dditiona l na tur a l g a s to f or m s yng a s . The s yng a s is conv er ted

to metha nol Which ma y be ca r bonyla ted to a cetic a cid. The

method lik eWis e pr oduces hydr og en Which ma y be us ed in

connection With this inv ention a s noted a bov e. U. S. Pa t. N o.

5 , 8 21, 111, Which dis clos es a pr oces s f or conv er ting Wa s te

bioma s s thr oug h g a s i? ca tion into s yng a s , a nd Us . Pa t. N o.

6, 68 5 , 75 4 , Which dis clos es a method f or the pr oduction of a

hydr og en- conta ining g a s compos ition, s uch a s s yng a s includ

ing hydr og en a nd ca r bon monoxide, a r e incor por a ted her ein

by r ef er ence in their entir eties .

[ 004 6] The a cetic a cid f ed to the r ea ction ma y a ls o com

pr is e other ca r boxylic a cids a nd a nhydr ides , a s Well a s a ceta l

dehyde a nd a cetone. In one embodiment, a s uita ble a cetic

a cid f eed s tr ea m compr is es one or mor e of the compounds

s elected f r om the g r oup cons is ting of a cetic a cid, a cetic a nhy

dr ide, a ceta ldehyde, ethyl a ceta te, a nd mixtur es ther eof .

Thes e other compounds ma y a ls o be hydr og ena ted in the

pr oces s es of the pr es ent inv ention. In s ome embodiments , the

pr es ence of ca r boxylic a cids , s uch a s pr opa noic a cid or its

a nhydr ide, ma y be bene? cia l in pr oducing pr opa nol. Wa ter

ma y a ls o be pr es ent in the a cetic a cid f eed.

[ 004 7] Alter na tiv ely, a cetic a cid in v a por f or m ma y be

ta k en dir ectly a s cr ude pr oduct f r om the ? a s h v es s el of a

metha nol ca r bonyla tion unit of the cla s s des cr ibed in Us .

Pa t. N o. 6, 65 7, 078 , the entir ety of Which is incor por a ted

her ein by r ef er ence. The cr ude v a por pr oduct, f or exa mple,

ma y be f ed dir ectly to the etha nol s ynthes is r ea ction Z ones of

the pr es ent inv ention Without the need f or condens ing the

a cetic a cid a nd lig ht ends or r emov ing Wa ter , s a v ing ov er a ll

pr oces s ing cos ts .

[ 004 8 ] Althoug h ca r bonyla tion ma y be a n optiona l a cetic

a cid pr oduction method, other s uita ble methods ma y be

employed. In one embodiment tha t employs ca r bonyla tion,

the ca r bonyla tion s ys tem optiona lly compr is es a r ea ction

Z one, Which includes a r ea ctor , a ? a s her a nd optiona lly a

Oct. 3, 2013

r ea ctor r ecov er y unit. In one embodiment, ca r bon monoxide

is r ea cted With metha nol in a s uita ble r ea ctor , e. g . , a continu

ous s tir r ed ta nk r ea ctor ( CSTR ) or a bubble column r ea ctor .

In one embodiment, the ca r bonyla tion pr oces s is a loW Wa ter ,

ca ta lyZ ed, e. g . , r hodium- ca ta lyzed, ca r bonyla tion of metha

nol to a cetic a cid, a s exempli? ed in Us . Pa t. N o. 5 , 001, 25 9 ,

Which is her eby incor por a ted by r ef er ence.

[ 004 9 ] The ethylene s imila r ly ma y be pr oduced by a ny

s uita ble method. In one embodiment, the ethylene is f or med

v ia the hydr og ena tion of a cetic a cid f olloWed by the dehydr a

tion of the a cetic a cid to f or m ethylene. As a nother a lter na tiv e,

the a cetic a cid a nd the ethylene ma y be pr oduced v ia oxida

tion of a n a lk a ne, e. g . , etha ne, a s dis cus s ed in Us . Pa t. N o.

6, 4 76, 261, the dis clos ur e of Which is her eby incor por a ted by

r ef er ence. The oxyg en us ed in the f or ma tion of v inyl a ceta te

in the method of the pr es ent inv ention ma y f ur ther compr is e

other iner t g a s es s uch a s nitr og en. As one exa mple, the oxy

g en us ed in the v inyl a ceta te r ea ction is pr ov ided by a n a ir

s tr ea m.

[ 005 0] In one embodiment, a dditiona l ethylene ma y be f ed

to the r ea ctor . This a dditiona l ethylene, a s Well a s the r ea cta nt

ethylene mentioned a bov e, ma y be s ubs ta ntia lly pur e. In one

embodiment, the ethylene ma y be a dmixed, f or exa mple, With

one or mor e of nitr og en, metha ne, ca r bon dioxide, ca r bon

monoxide, hydr og en, a nd loW lev els of C3/C4 a lk enes /a l

k a nes . Additiona l oxyg en ma y be f ed to the r ea ctor . The

a dditiona l oxyg en, if us ed, ma y be a ir or a g a s r icher or poor er

in molecula r oxyg en tha n a ir . One s uita ble a dditiona l molecu

la r oxyg en- conta ining g a s ma y be, oxyg en diluted With a

s uita ble diluent, f or exa mple nitr og en or ca r bon dioxide. In

one embodiment, the a dditiona l molecula r oxyg en- conta in

ing g a s is oxyg en. In one embodiment, a t lea s t s ome of the

oxyg en is f ed to the r ea ctor independently f r om the ethylene

a nd a cetic a cid.

[ 005 1] The v inyl a ceta te r ea ction ma y s uita bly be ca r r ied

out a t a temper a tur e in the r a ng e of f r om 1000 C. to 300 C. ,

e. g . , f r om 14 00 C. to 220 C. or f r om 15 0 C. to 200 C. In

a nother embodiment, the r ea ction ma y be ca r r ied out pr es s ur e

in the r a ng e of f r om 0. 1 MPa to 10 MPa , e. g . , f r om 0. 1 MPa

to 2. 5 MPa or f r om 1 MPa to 2. 5 MPa .

[ 005 2] In one embodiment, the r ea ction is conducted ov er a

ca ta lys t. Suita ble ca ta lys ts include ca ta lys ts compr is ing a ? r s t

meta l a nd optiona lly one or mor e of a s econd meta l, a thir d

meta l, or a dditiona l meta ls . The ca ta lys t optiona lly compr is es

a ca ta lys t s uppor t. The ? r s t a nd optiona l s econd a nd thir d

meta ls ma y be s elected f r om pa lla dium, g old, bor on, a lk a li

meta ls , a nd Gr oup IB or VIIIB tr a ns ition meta ls . Some meta l

combina tions include pa lla dium/ g old a nd pa lla dium/bor on.

[ 005 3] The ? r s t meta l optiona lly is pr es ent in a n a mount

f r om 0. 1 to 10 Wt. %, e. g . , f r om 0. 2 to 5 Wt. %, or f r om 0. 2 to

2. 5 Wt. %. The a dditiona l meta ls , if pr es ent, ma y be pr es ent in

a mounts r a ng ing f r om 0. 1 to 10 Wt. %, e. g . , f r om 0. 2 to 5 Wt.

%, or f r om 0. 2 to 2. 5 Wt. %. In other embodiments , the

ca ta lys t ma y compr is e meta lloids , e. g . , bor on, in a mounts

r a ng ing f r om 0. 01 Wt. % to 1 Wt. %, e. g . , f r om 0. 01 Wt. % to

0. 2 Wt. %. For ca ta lys ts compr is ing tWo or mor e meta ls , the

tWo or mor e meta ls ma y be a lloyed With one a nother . Alter

na tiv ely, the tWo or mor e meta ls ma y compr is e a non- a lloyed

meta l s olution or mixtur e. Als o, meta l r a tios ma y v a r y

depending on the meta ls us ed in the ca ta lys t. If pa lla dium a nd

g old a r e utiliZ ed, the r a tio ma y r a ng e f r om 0. 5 : 1 to 20: 1, e. g . ,

f r om : 1. 8 : 1 to 10: 1. In s ome exempla r y embodiments Wher e

US 2013/0261330 A1

a ? r s t a nd s econd meta l a r e us ed, the mole r a tio of the ? r s t

meta l to the s econd meta l is f r om 5 : 1 to 1: 1, e. g . , f r om 3: 1 to

1: 1, or f r om 2: 1 to 1: 1.

[ 005 4 ] In a ddition to one or mor e meta ls , the exempla r y

ca ta lys ts f ur ther compr is e a s uppor t or a modi? ed s uppor t,

mea ning a s uppor t tha t includes a s uppor t ma ter ia l a nd a

s uppor t modi? er , Which a dj us ts the a cidity of the s uppor t

ma ter ia l. The tota l Weig ht of the s uppor t or modi? ed s uppor t,

ba s ed on the tota l Weig ht of the ca ta lys t, ma y be f r om 75 Wt.

% to 9 9 . 9 Wt. %, e. g . , f r om 78 Wt. % to 9 7 Wt. %, or f r om 8 0

Wt. % to 9 5 Wt. %. In s ome embodiments tha t us e a modi? ed

s uppor t, the s uppor t modi? er is pr es ent in a n a mount f r om 0. 1

Wt. % to 5 0 Wt. %, e. g . , f r om 0. 2 Wt. % to 25 Wt. %, f r om 0. 5

Wt. % to 15 Wt. %, f r om 1 Wt. % to 8 Wt. %, f r om 1 Wt. % to

5 Wt. %, or f r om 2 Wt. % to 4 Wt. %, ba s ed on the tota l Weig ht

of the ca ta lys t.

[ 005 5 ] Suita ble s uppor t ma ter ia ls ma y include s ilica , a lu

mina , s ilica - a lumina , tita nia , tica no- s ilica tes , Z ir conia , Z ir

cono- s ilica te, niobia , s ilica tes , a lumino- s ilica tes , tita na tes ,

ca r bon, meta ls , a nd g la s s es . Pos s ible s uppor ts include Z ir co

nia , Z ir cono- s ilica tes , a nd tita no- s ilica tes . Suita ble s uppor t

modi? er s ma y include ba r ium, ma g nes ium, cer ium, pota s

s ium, ca lcium, niobium, ta nta lum, tita nium, yttr ium, s tr on

tium, Z ir conium, v a na dium, molybdenum, a nd r ubidium.

Pos s ible s uppor t modi? er s include niobium, tita nium, ma g

nes ium, a nd Z ir conium. In s ome embodiments , the ? ller ma y

compr is e ma ter ia ls tha t a r e typica lly employed a s s uppor t

ma ter ia ls , Which include thos e ma ter ia ls lis ted a bov e.

[ 005 6] Speci? c exa mples of s uita ble ca ta lys ts include, f or

exa mple, thos e des cr ibed in GB 1 5 5 9 5 4 01 ; EP 0 330 8 5 3; EP

0 672 4 5 63; US. Pa t. N os . 5 , 18 5 , 308 ; 5 , 69 1, 267; 6, 114 , 5 71;

6, 8 5 2, 8 77; a nd 6, 603, 038 . The dis clos ur es of a ll of the a bov e

mentioned r ef er ences a r e her eby incor por a ted by r ef er ence.

[ 005 7] GB 1 5 5 9 5 4 0 des cr ibes s uita ble ca ta lys ts tha t ca n

be employed in the pr epa r a tion of v inyl a ceta te by the r ea c

tion of ethylene, a cetic a cid a nd oxyg en. The ca ta lys ts a r e

compr is ed of : ( 1) a ca ta lys t s uppor t ha v ing a pa r ticle dia meter

of f r om 3 to 7 mm a nd a por e v olume of f r om a bout 0. 2 to 1. 5

ml per g r a m, a 10% by Weig ht Wa ter s us pens ion of the ca ta lys t

s uppor t ha v ing a pH f r om a bout 3. 0 to 9 . 0, ( 2) a pa lla dium

g old a lloy dis tr ibuted in a s ur f a ce la yer of the ca ta lys t s uppor t,

the s ur f a ce la yer extending les s tha n 0. 5 mm f r om the s ur f a ce

of the s uppor t, the pa lla dium in the a lloy being pr es ent in a n

a mount of f r om a bout 1. 5 to 5 . 0 g r a ms per liter of ca ta lys t, a nd

the g old being pr es ent in a n a mount of f r om a bout 0. 5 to 2. 25

g r a ms per liter of ca ta lys t, a nd ( 3) f r om 5 to 60 g r a ms per liter

of ca ta lys t of a lk a li meta l a ceta te.

[ 005 8 ] US. Pa t. N o. 5 , 18 5 , 308 des cr ibes a s hell impr eg

na ted ca ta lys t a ctiv e f or the pr oduction of v inyl a ceta te f r om

ethylene, a cetic a cid, a nd a n oxyg en- conta ining g a s , the ca ta

lys t cons is ting es s entia lly of ( 1) a ca ta lys t s uppor t ha v ing a

pa r ticle dia meter f r om a bout 3 to a bout 7 mm a nd a por e

v olume of 0. 2 to 1. 5 ml per g r a m, ( 2) pa lla dium a nd g old

dis tr ibuted in the outer mos t 1 . 0 mm thick la yer of the ca ta lys t

s uppor t pa r ticles , a nd ( 3) f r om a bout 3. 5 to a bout 9 . 5 % by

Weig ht of pota s s ium a ceta te Wher ein the g old to pa lla dium

Weig ht r a tio in s a id ca ta lys t is in the r a ng e 0. 6 to 1. 25 .

[ 005 9 ] US. Pa t. N o. 5 , 69 1, 267 des cr ibes a tWo s tep g old

a ddition method f or a ca ta lys t us ed in the g a s pha s e f or ma tion

of v inyl a ceta te f r om the r ea ction of ethylene, oxyg en, a nd

a cetic a cid. The ca ta lys t is f or med by ( 1) impr eg na ting a

ca ta lys t ca r r ier With a q ueous s olutions of a Wa ter - s oluble

pa lla dium s a lt a nd a ? r s t a mount of a Wa ter - s oluble g old

compound s uch a s s odium- pa lla dium chlor ide a nd a ur ic chlo

Oct. 3, 2013

r ide, ( 2) ? xing the pr ecious meta ls on the ca r r ier by pr ecipi

ta ting the Wa ter - ins oluble pa lla dium a nd g old compounds by

tr ea tment of the impr eg na ted ca r r ier s With a r ea ctiv e ba s ic

s olution s uch a s a q ueous s odium hydr oxide Which r ea cts With

the pa lla dium a nd g old compounds to f or m hydr oxides of

pa lla dium a nd g old on the ca r r ier s ur f a ce, ( 3) Wa s hing With

Wa ter to r emov e the chlor ide ion ( or other a nion) , a nd ( 4 )

r educing a ll the pr ecious meta l hydr oxides to f r ee pa lla dium

a nd g old, Wher ein the impr ov ement compr is es ( 5 ) impr eg na t

ing the ca r r ier With a s econd a mount of a Wa ter - s oluble g old

compound s ubs eq uent to ? xing a ? r s t a mount of Wa ter

s oluble g old a g ent, a nd ( 6) ? xing the s econd a mount of a

Wa ter - s oluble g old compound.

[ 0060] US. Pa t. N o. 6, 114 , 5 71 des cr ibes a ca ta lys t f or

f or ming v inyl a ceta te in the g a s pha s e f r om ethylene, a cetic

a cid, a nd oxyg en or oxyg en- conta ining g a s es Wher ein the

ca ta lys t is compr is ed of pa lla dium, g old, bor on, a nd a lk a li

meta l compounds on a s uppor t. The ca ta lys t is pr epa r ed by a )

impr eg na ting the s uppor t With s oluble pa lla dium a nd g old

compounds ; b) conv er ting the s oluble pa lla dium a nd g old

compounds on the s uppor t into ins oluble compounds by

mea ns of a n a lk a line s olution; c) r educing the ins oluble pa l

la dium a nd g old compounds on the s uppor t by mea ns of a

r educing a g ent in the liq uid pha s e; d) Wa s hing a nd s ubs e

q uently dr ying the s uppor t; e) impr eg na ting the s uppor t With

a s oluble a lk a li meta l compound; a nd f ) ? na lly dr ying the

s uppor t a t a ma ximum of 15 000 C. , Wher ein bor on or bor on

compounds a r e a pplied to the ca ta lys t pr ior to the ? na l dr ying .

[ 0061] US. Pa t. N o. 6, 603, 038 des cr ibes a method f or pr o

ducing ca ta lys ts conta ining meta l na nopa r ticles on a por ous

s uppor t, es pecia lly f or g a s pha s e oxida tion of ethylene a nd

a cetic a cid to f or m v inyl a ceta te. The inv ention r ela tes to a

method f or pr oducing a ca ta lys t conta ining one or s ev er a l

meta ls f r om the g r oup of meta ls compr is ing the s ub- g r oups Ib

a nd VIIIb of the per iodic ta ble on por ous s uppor t pa r ticles ,

cha r a cter ized by a ? r s t s tep in Which one or s ev er a l pr ecur s or s

f r om the g r oup of compounds of meta ls f r om s ub- g r oups Ib

a nd VIIIb of the per iodic ta ble is or a r e a pplied to a por ous

s uppor t, a nd a s econd s tep in Which the por ous , optiona lly

na nopor ous s uppor t to Which a t lea s t one pr ecur s or ha s been

a pplied is tr ea ted With a t lea s t one r eduction a g ent, to obta in

the meta l na nopa r ticles pr oduced in s itu in the por es of s a id

s uppor t.

[ 0062] EP 0 672 4 5 3 des cr ibes pa lla dium- conta ining ca ta

lys ts a nd their pr epa r a tion f or ? uid bed v inyl a ceta te pr o

ces s es .

[ 0063] An a dv a nta g e of us ing a pa lla dium- conta ining ca ta

lys t is tha t a ny ca r bon monoxide pr oduced in a pr ior r ea ction

Z one Will be cons umed in the pr es ence of oxyg en a nd the

pa lla dium- conta ining ca ta lys t in the s econd r ea ction Z one. An

exa mple of a pr ior r ea ction Z one is a r ea ction Z one f or pr e

pa r ing the r ea cta nts . This elimina tes the need f or a s epa r a te

ca r bon monoxide r emov a l r ea ctor .

[ 0064 ] The v inyl a ceta te r ea ction ma y be cha r a cter ized in

ter ms of conv er s ions ba s ed on the r ea cta nts . In one embodi

ment, a cetic a cid conv er s ions r a ng e f r om 1% to 100%, e. g . ,

f r om 5 % to 5 0% or f r om 10% to 4 5 %. Oxyg en conv er s ions

ma y r a ng e f r om 1% to 100%, e. g . , f r om 20% to 100% or f r om

20% to 5 0%. Ethylene conv er s ions ma y r a ng e f r om 1% to

9 0%, e. g . , f r om 5 % to 100% or f r om 10% to 5 0%. In one

embodiment, v inyl a ceta te s electiv ity, ba s ed on ethylene ma y

r a ng e f r om 20% to 100%, e. g . , f r om 5 0% to 9 5 % or f r om 75 %

to 9 0%.

US 2013/0261330 A1

[ 0065 ] In the v inyl a ceta te r ea ction, the ca ta lys t ma y ha v e a

pr oductiv ity ( mea s ur ed in s pa ce time yield, STY) r a ng ing

f r om 10 g /hr - liter to 5 , 000 g /hr - liter , e. g . , f r om 100 g /hr - liter

to 2, 000 g /hr - liter or f r om 200 g /hr - liter to 1, 000 g /hr - liter ,

Wher e g /hr - liter mea ns g r a ms of v inyl a ceta te per hour per

liter of ca ta lys t. In ter ms of upper limits , the s pa ce time yield

ma ybe les s tha n 20, 000 g /hr - liter , e. g . , les s tha n 10, 000 g /hr

liter or les s tha n 5 , 000 g /hr - liter .

Sepa r a tion

[ 0066] Retur ning to FIG. 1, the v inyl a ceta te pr oduction

s ys tem includes a s epa r a tion Z one to r ecov er a nd/ or pur if y the

v inyl a ceta te f or med in r ea ctor 100. Rea ctor e? : luent s tr ea m

112 is dir ected to the s epa r a tion Z one. In one embodiment the

s epa r a tion Z one pr ov ides a t lea s t one der iv a tiv e of r ea ctor

e? : luent 112. In a nother embodiment, the der iv a tiv e s tr ea m( s )

of the r ea ctor e? : luent ma y be a ny s tr ea m tha t is yielded v ia the

units of the s epa r a tion Z one. In one embodiment, the der iv a

tiv e s tr ea ms a r e doWns tr ea m of the r ea ctor . Unr ea cted a cetic

a cid in v a por f or m ma y be cooled a nd condens ed. The

r ema inder of the cr ude v inyl a ceta te compos ition in line 118 ,

Which is a der iv a tiv e of the r ea ctor e? iuent, is dir ected to

pr e- dehydr a tion column ( PD C ) 120. In one embodiment,

the s ca v eng er is a dded to line 118 v ia s ca v eng er f eed line

114 1) . PD C 120 s epa r a tes the contents of line 118 into a

r es idue compr is ing v inyl a ceta te a nd a dis tilla te compr is ing

v inyl a ceta te, Wa ter , a cetic a cid, ca r bon monoxide, ca r bon

dioxide, lig ht ends , hea v y ends , a nd ethyl a ceta te. The v inyl

a ceta te- conta ining r es idue is dir ected to cr ude ta nk 122 v ia

line 124 . Fr om cr ude ta nk 122, the v inyl a ceta te- conta ining

r es idue ma y be s tor ed a nd/or dir ected to f ur ther pr oces s ing .

[ 0067] The PD C dis tilla te is optiona lly cooled, condens ed,

a nd dir ected to a n ov er hea d pha s e s epa r a tion unit, e. g . ,

deca nter 126, v ia line 128 , Which is a der iv a tiv e of the r ea ctor

e? iuent. In s ome embodiments , the s ca v eng er is a dded to line

128 v ia s ca v eng er f eed line 114 0. In one embodiment, the

a ddition of the s ca v eng er occur s in the PD C or doWns tr ea m

ther eof . Conditions a r e des ir a bly ma inta ined in the pr oces s

s uch tha t v a por contents of line 128 , once cooled, condens ed,

a nd dir ected to deca nter 126, Will s epa r a te into a lig ht pha s e

a nd a hea v y pha s e. Sca v eng er f eed line 114 0 s hoWs a ddition

of the s ca v eng er a f ter the cooling , hoWev er , a ddition pr ior to

cooling is ea s ily Within the contempla tion of the inv ention.

Gener a lly, line 128 is cooled to a temper a tur e s u? icient to

condens e a nd s epa r a te the condens a ble components , e. g . ,

v inyl a ceta te, Wa ter , a cetic a cid, a nd other ca r bonyl compo

nents , into a n a q ueous pha s e a nd a n or g a nic pha s e. The

or g a nic pha s e exits deca nter 126 v ia line 130. A por tion of the

or g a nic pha s e ma y be r e? uxed ba ck to PD C 120, a s s hoWn by

s tr ea m 132, Which is a der iv a tiv e of the r ea ctor ef ? uent. In one

embodiment, the s ca v eng er is a dded to line 132 v ia s ca v eng er

f eed line 114 d. The a q ueous pha s e exits deca nter 126 a nd is

dir ected v ia line 134 to f ur ther s epa r a tion pr oces s ing . As a n

exa mple, line 134 ma y be dir ected to deca nter 14 6 of a n

a Z eotr ope column 136. Lines 130 a nd 134 optiona lly ma y be

combined, a s s hoWn, a nd dir ected to deca nter 14 6 of a Z eo

tr ope column 136.

[ 0068 ] Str ea m 128 ma y include ca r bon monoxide, ca r bon

dioxide, ethylene, etha ne a nd other noncondens a ble g a s es ,

Which ma y be dir ected v ia s tr ea m 138 f r om deca nter 126 to

s cr ubber 14 0. Scr ubber 14 0 r emov es , inter a lia , ca r bon mon

oxide, ca r bon dioxide, a nd hydr oca r bons s uch a s ethylene

a nd etha ne f r om s tr ea m 128 . The s epa r a ted noncondens a ble

components ma y be conv eyed to f ur ther pr oces s ing , e. g . ,

Oct. 3, 2013

ca r bon dioxide r emov a l, a s s hoWn by s tr ea m 14 2. In a nother

embodiment, a t lea s t a por tion of s tr ea m 14 2 is r ecycled ba d

to the r ea ctor ef ? uent or to hea t excha ng e eq uipment doWn

s tr ea m of r ea ctor 100, a s s hoWn by s tr ea m 14 2' . The r es idue

exiting s cr ubber 14 0 compr is es v inyl a ceta te, Wa ter , a nd a ce

tic a cid. The r es idue is yielded f r om s cr ubber 14 0 v ia line 14 4

a nd ma y be combined With the v inyl a ceta te f r om line 124

pr ior to being dir ected to cr ude ta nk 122.

[ 0069 ] Fr om cr ude ta nk 122, the v inyl a ceta te is dir ected to

a Z eotr ope column 136 v ia line 137, Which is a der iv a tiv e of

the r ea ctor e? iuent. In one embodiment, the s ca v eng er is

a dded to line 137 v ia s ca v eng er f eed line 114 e. In a nother

embodiment the a ddition of the s ca v eng er occur s in a Z eotr ope

column 136 or doWns tr ea m ther eof . AZ eotr ope column 136

s epa r a tes line 137, Which compr is es v inyl a ceta te, a cetic a cid,

a nd Wa ter , into a dis tilla te s tr ea m in line 14 8 a nd a r es idue

s tr ea m 14 9 . D eca nter 14 6 a t the top of a Z eotr ope column 136

r eceiv es line 134 , Which compr is es the a q ueous a nd or g a nic

pha s es f r om deca nter 126. In a ddition, deca nter 14 6 r eceiv es

the dis tilla te f r om a Z eotr ope column 136. AZ eotr ope column

136 s epa r a tes line 137, Which compr is es v inyl a ceta te, a cetic

a cid, a nd Wa ter . The r es idue f r om a Z eotr ope column 136

compr is es a cetic a cid a nd Wa ter . This s tr ea m ma y be r ecycled

ba ck to v a por iZ er 106 v ia line 14 9 , or ma y be conv eyed

dir ectly to r ea ctor 100 ( not s hoWn) . The dis tilla te f r om a Z eo

tr ope column 136 compr is es v inyl a ceta te a nd Wa ter a nd is

dir ected to deca nter 14 6, e. g . , a r e? ux deca nter , v ia line 14 8 .

D eca nter 14 6 s epa r a tes a t lea s t a por tion of s tr ea ms 134 a nd

14 8 into a q ueous a nd or g a nic pha s es . The or g a nic pha s e,

Which compr is es v inyl a ceta te, exits deca nter 14 6 v ia line

15 2, Which is a der iv a tiv e of the r ea ctor e? iuent, a nd is

dir ected to f ur ther pr oces s ing . In one embodiment, the s ca v

eng er is a dded to line 15 2 v ia s ca v eng er f eed line 114 ] . As one

exa mple, line 15 2 is dir ected to dehydr a tion column 15 4 . The

a q ueous pha s e exits deca nter 14 6 v ia line 15 0. Line 15 0 ( or a

por tion ther eof ) ma y be r e? uxed ba ck to a Z eotr ope column

136.

[ 0070] D ehydr a tion column 15 4 r emov es a dditiona l Wa ter

f r om the contents of line 15 2, thus yielding pur i? ed v inyl

a ceta te v ia line 15 6. The Wa ter - conta ining dis tilla te of dehy

dr a tion column 15 4 ma y be dir ected to ov er hea d ta nk 15 8 v ia

line 160. Fr om ov er hea d ta nk 15 8 , line 162, Which conta ins a n

a mount of v inyl a ceta te, ma y be r etur ned to dehydr a tion

column 15 4 . Line 164 , Which compr is es Wa ter a nd impur ities

ma y be dir ected to f ur ther pr oces s ing , e. g . , Wa ter s tr ipping .

The r es idue of dehydr a tion column 15 4 exits v ia line 166. The

r es idue compr is es v a r ious r es idua ls , Which ma y be r ecycled

or other Wis e dis pos ed.

EXAMPLES

[ 0071] While the inv ention ha s been des cr ibed in deta il,

modi? ca tions Within the s pir it a nd s cope of the inv ention Will

be r ea dily a ppa r ent to thos e of s k ill in the a r t. In v ieW of the

f or eg oing dis cus s ion, r elev a nt k noWledg e in the a r t a nd r ef

er ences dis cus s ed a bov e in connection With the Ba ck g r ound

a nd D eta iled D es cr iption, the dis clos ur es of Which a r e a ll

incor por a ted her ein by r ef er ence. In a ddition, it s hould be

under s tood tha t a s pects of the inv ention a nd por tions of v a r i

ous embodiments a nd v a r ious f ea tur es r ecitedbeloW a nd/or in

the a ppended cla ims ma y be combined or inter cha ng ed either

in Whole or in pa r t. In the f or eg oing des cr iptions of the v a r i

ous embodiments , thos e embodiments Which r ef er to a nother

embodiment ma y be a ppr opr ia tely combined With other

embodiments a s Will be a ppr ecia ted by one of s k ill in the a r t.

US 2013/0261330 A1

Fur ther mor e, thos e of or dina r y s k ill in the a r t Will a ppr ecia te

tha t the f or eg oing des cr iption is by Wa y of exa mple only, a nd

is not intended to limit the inv ention.

We cla im:

1. A pr oces s f or inhibiting impur ity f or ma tion in a v inyl

a ceta te r ea ction, the pr oces s compr is ing :

( a ) pr ov iding a r ea ctor compr is ing a n inlet s ection, a n

outlet s ection, a ? ller in the outlet s ection, a nd a ca ta lys t

block s ection in communica tion With a nd con? g ur ed

betWeen the inlet a nd outlet s ections ;

( b) intr oducing r ea cta nts compr is ing a cetic a cid, oxyg en,

a nd ethylene to the inlet s ection;

( c) conta cting the r ea cta nts in the ca ta lys t block s ection

under conditions ef f ectiv e to f or m a cr ude v inyl a ceta te

compos ition; a nd

( d) dir ecting the cr ude v inyl a ceta te compos ition into the

outlet s ection.

2. The pr oces s of cla im 1, Wher ein the cr ude v inyl a ceta te

compos ition exiting the outlet s ection compr is es les s tha n

2, 000 Wppm impur ities .

3. The pr oces s of cla im 1, Wher ein the outlet s ection com

pr is es a hous ing de? ning a n outlet cha mber a nd the ? ller is

dis pos ed Within the outlet cha mber .

4 . The pr oces s of cla im 3, Wher ein the outlet s ection com

pr is es a t lea s t one outlet line f or dir ecting the cr ude v inyl

a ceta te compos ition f r om the outlet cha mber a nd the ? ller is

dis pos ed in the a t lea s t one outlet line.

5 . The pr oces s of cla im 4 , Wher ein the ? ller is a tta ched to a t

lea s t one of a n inter ior of the hous ing or a Wa ll of the outlet

line.

6. The pr oces s of cla im 1, Wher ein the oxyg en a nd the

ethylene a r e combined pr ior to s tep ( b) in a combined inlet

line.

7. The pr oces s of cla im 1, Wher ein the ? ller is pr ov ided a t

a loa ding f a ctor r a ng ing f r om 0. 001 to 0. 8 .

8 . The pr oces s of cla im 1, Wher ein the pr es s ur e in the outlet

s ection r a ng es f r om 0. 1 MPa to 10 MPa .

Oct. 3, 2013

9 . The pr oces s of cla im 1, Wher ein the ? ller is s elected f r om

the g r oup cons is ting of g la s s , Z eolites , s ilica , Z ir conium

oxide, a nd mixtur es ther eof .

10. The pr oces s of cla im 1, Wher ein the ? ller compr is es

s ta inles s s teel.

11. A pr oces s f or pr oducing a v inyl a ceta te compos ition,

the pr oces s compr is ing :

( a ) pr ov iding a r ea ctor compr is ing a n inlet s ection, a n

outlet s ection, a ? ller in either or both of the inlet s ection

a nd the outlet s ection, a nd a ca ta lys t block s ection in

communica tion With a nd con? g ur ed betWeen the inlet

a nd outlet s ections ;

( b) intr oducing r ea cta nts compr is ing a cetic a cid, oxyg en,

a nd ethylene to the inlet s ection;

( c) conta cting the r ea cta nts in the ca ta lys t block s ection

under conditions ef f ectiv e to f or m a cr ude v inyl a ceta te

compos ition; a nd

( d) dir ecting the cr ude v inyl a ceta te compos ition into the

outlet s ection.

12. A r ea ctor f or f or ming v inyl a ceta te compr is ing :

a n inlet s ection f or r eceiv ing r ea cta nts ,

a n outlet s ection f or exiting a cr ude v inyl a ceta te compo

s ition;

a ca ta lys t block s ection in communica tion With a nd con

? g ur ed betWeen the inlet a nd outlet s ections f or ca ta

lyZ ing a r ea ction to f or m a cr ude v inyl a ceta te compo

s ition; a nd

a ? ller dis pos ed in a t lea s t a por tion of the outlet s ection to

f or m a ? lled outlet s ection.

13. The r ea ctor of cla im 12, Wher ein the outlet s ection

compr is es a hous ing de? ning a n outlet cha mber a nd the ? ller

is dis pos ed Within the outlet cha mber .

14 . The r ea ctor of cla im 12, Wher ein the outlet s ection

compr is es a t lea s t one outlet line f or dir ecting the cr ude v inyl

a ceta te compos ition f r om the outlet cha mber a nd the ? ller is

dis pos ed in the a t lea s t one outlet line.

* * * * *

Вам также может понравиться

- United States:) FflisiДокумент7 страницUnited States:) FflisiSarmiento FerОценок пока нет

- Us 20110139628Документ9 страницUs 20110139628Rahma Ama NuryantyОценок пока нет

- United States: (12) Patent Application Publication (10) Pub. No.: US 2002/0173605 A1Документ23 страницыUnited States: (12) Patent Application Publication (10) Pub. No.: US 2002/0173605 A1Muaathe IbrahimОценок пока нет

- US20130131400 Etil AsetatДокумент43 страницыUS20130131400 Etil AsetatDebby Theresia SilabanОценок пока нет

- Us 20120097550Документ11 страницUs 20120097550ddsfathОценок пока нет

- Ulllted States Patent (10) Patent N0.: US 7,893,674 B2Документ11 страницUlllted States Patent (10) Patent N0.: US 7,893,674 B2EliasA.TiongkiaoОценок пока нет

- Gel Strength (lbfl100 FT') : (12) United States Patent (10) Patent N0.2 US 6,955,220 B2Документ9 страницGel Strength (lbfl100 FT') : (12) United States Patent (10) Patent N0.2 US 6,955,220 B2b4rfОценок пока нет

- United States: (12) Patent Application Publication (10) Pub. No.: US 2012/0145519 A1Документ17 страницUnited States: (12) Patent Application Publication (10) Pub. No.: US 2012/0145519 A1Catalin AlexandruОценок пока нет

- Raise ClimberДокумент14 страницRaise ClimberAngeline WolfОценок пока нет

- 106 Yms @eiei: (19) United StatesДокумент15 страниц106 Yms @eiei: (19) United Statesacela3248Оценок пока нет

- US Patent 2011/0024635 CSLILN HALIDE SCINTILLATORДокумент17 страницUS Patent 2011/0024635 CSLILN HALIDE SCINTILLATORBill HigginsОценок пока нет

- Transformation of Animal Cells PDFДокумент8 страницTransformation of Animal Cells PDFJavier BecerraОценок пока нет

- Demolition - Best Practice Guidelines For Demolition in New ZealandДокумент67 страницDemolition - Best Practice Guidelines For Demolition in New ZealandAntares OrionОценок пока нет

- Bioprinting Three-Dimensional Structure Onto Microscale Tissue Analog DevicesДокумент20 страницBioprinting Three-Dimensional Structure Onto Microscale Tissue Analog DeviceswerfqwetfgОценок пока нет

- Patent - Paul BabcockДокумент25 страницPatent - Paul BabcockHappyJoeОценок пока нет

- Falha de Mola Por ContatoДокумент5 страницFalha de Mola Por ContatoFelipe UngaroОценок пока нет

- Us 3995792Документ5 страницUs 3995792werwer44345Оценок пока нет

- Trivich 1982 TR FinalДокумент118 страницTrivich 1982 TR FinalAlberto Mittiga0% (1)

- Ulllted States Patent (19) (11) Patent Number: 6,005,480: Banzhof Et Al. (45) Date of Patent: Dec. 21, 1999Документ13 страницUlllted States Patent (19) (11) Patent Number: 6,005,480: Banzhof Et Al. (45) Date of Patent: Dec. 21, 1999kthuang1Оценок пока нет

- Study of Accelerating Torque Requirements of A Reciprocating CompДокумент7 страницStudy of Accelerating Torque Requirements of A Reciprocating CompannaОценок пока нет

- Us 20040075824Документ18 страницUs 20040075824presuraОценок пока нет

- A Blockage Correction For Automotive Testing PDFДокумент19 страницA Blockage Correction For Automotive Testing PDFAntonio RodriguesОценок пока нет

- United States Patent (10) Patent N0.: US 6,827,075 B1Документ7 страницUnited States Patent (10) Patent N0.: US 6,827,075 B1Cristhian GraefОценок пока нет

- Ulllted States Patent (10) Patent N0.: US 8,362,408 B2Документ11 страницUlllted States Patent (10) Patent N0.: US 8,362,408 B2werwer44345Оценок пока нет

- United States: (12) Patent Application Publication (10) Pub. No.: US 2013/0251466 A1Документ6 страницUnited States: (12) Patent Application Publication (10) Pub. No.: US 2013/0251466 A1gowdas2011Оценок пока нет

- Ionic Liquids and Their Use AsДокумент10 страницIonic Liquids and Their Use AsTazien RashidОценок пока нет

- Simulating The Performance of Pulsation DampenersДокумент8 страницSimulating The Performance of Pulsation DampenersFrancesca CoattiОценок пока нет

- Alt-O. : Indlvlduelly /@Документ7 страницAlt-O. : Indlvlduelly /@drivinerОценок пока нет

- United States: (12) Patent Application Publication (10) Pub. No.: US 2006/0123363 A1Документ20 страницUnited States: (12) Patent Application Publication (10) Pub. No.: US 2006/0123363 A1coso1234Оценок пока нет

- Ubc 1997-0612Документ106 страницUbc 1997-0612Rollan F. KomajiОценок пока нет

- Us 3977329Документ4 страницыUs 3977329gtr56Оценок пока нет

- United States: (12) Patent Application Publication (10) Pub. No.: US 2011/0289351 A1Документ19 страницUnited States: (12) Patent Application Publication (10) Pub. No.: US 2011/0289351 A1SaideepNarasimhanОценок пока нет

- US Patent No. 8499869Документ11 страницUS Patent No. 8499869mlpraterОценок пока нет

- United States Patent 1191 1111 4,030,523: Cram Et A1. (45) 7 June 21, 1977Документ5 страницUnited States Patent 1191 1111 4,030,523: Cram Et A1. (45) 7 June 21, 1977Brunno VasquesОценок пока нет

- Us 20130079618Документ30 страницUs 20130079618Fercalo AndreiОценок пока нет

- Basic Electronics Lab ManualДокумент100 страницBasic Electronics Lab Manualalkeshkhatri87% (15)

- United States: (12) Patent Application Publication (10) Pub. No.: US 2011/0163259 A1Документ10 страницUnited States: (12) Patent Application Publication (10) Pub. No.: US 2011/0163259 A1remi1988Оценок пока нет

- Us 20140085181Документ16 страницUs 20140085181industrie_technosОценок пока нет

- Safety Procedures For Water and SanitationДокумент26 страницSafety Procedures For Water and Sanitationmolateam2Оценок пока нет

- United States Patent (10) Patent N0.: US 8,091,836 B2Документ8 страницUnited States Patent (10) Patent N0.: US 8,091,836 B2werwer44345Оценок пока нет

- Nomoto KalmanДокумент8 страницNomoto Kalmancostagomez99Оценок пока нет

- United States Patent: + T VCC CB (15 (16 H0 JVY/I - J:RДокумент16 страницUnited States Patent: + T VCC CB (15 (16 H0 JVY/I - J:RefremofeОценок пока нет

- Methods Direct Controlled Induction Motor Current: New Hybrid For Torque Drive For ReducedДокумент6 страницMethods Direct Controlled Induction Motor Current: New Hybrid For Torque Drive For ReducedKoukou AmkoukouОценок пока нет

- (12 Ulllted States Patent (10) Patent N0.: US 6,176,184 B1Документ13 страниц(12 Ulllted States Patent (10) Patent N0.: US 6,176,184 B1danceОценок пока нет

- A Stabilization of Frequency Oscillations in A Parallel AC DC Interconnected Power System Via An HVDC LinkДокумент8 страницA Stabilization of Frequency Oscillations in A Parallel AC DC Interconnected Power System Via An HVDC LinkDavid Jose Poma GuillenОценок пока нет

- Ferrous Pipeline Corrosion Processes (1 of 4) 01-88Документ88 страницFerrous Pipeline Corrosion Processes (1 of 4) 01-88Wigand JuniorОценок пока нет

- The Adoption of A Fully CatalyticДокумент10 страницThe Adoption of A Fully CatalyticKhairi Maulida AzhariОценок пока нет