Академический Документы

Профессиональный Документы

Культура Документы

TS BP SIM Solver Selection

Загружено:

Nurul HudaОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

TS BP SIM Solver Selection

Загружено:

Nurul HudaАвторское право:

Доступные форматы

Solver Selection

SolidWorks Simulation 2012 SP4

November 1, 2012

Revision 3.0

3

D

S

.

C

O

M

D

a

s

s

a

u

l

t

S

y

s

t

m

e

s

|

C

o

n

f

i

d

e

n

t

i

a

l

I

n

f

o

r

m

a

t

i

o

n

|

0

1

/

0

2

/

2

0

1

2

r

e

f

.

:

D

o

c

u

m

e

n

t

_

R

e

f

e

r

e

n

c

e

|

2

Table of Contents

1. Solver Options in SolidWorks Simulation.............................................................................................. 4

2. Tips and Facts to Consider for making the best choice ........................................................................ 4

3. Appendix: Usage of multiple CPUs and cores, and influence on solution time .................................... 6

a) Static Study performance comparison when using 1 through 12 cores ........................................... 6

b) Quad core versus single core comparison for Static, Frequency, Buckling, Thermal, and Nonlinear

Studies ....................................................................................................................................................... 7

c) Drop Test Studies .............................................................................................................................. 7

d) Fatigue Studies .................................................................................................................................. 8

e) Optimization Studies ......................................................................................................................... 8

f) Linear Dynamic Studies ..................................................................................................................... 8

g) Pressure Vessel Design Studies ......................................................................................................... 8

h) Notes ................................................................................................................................................. 8

3

Revision History

Rev # Date Description

1.0 June 2010 Document created.

2.0 Aug 2011 Document modified.

2.1 June 2012 Document modified with new template.

3.0 November 2012 Document updated for SolidWorks 2012, including benchmarks in appendix.

Note

All SolidPractices are written as guidelines. You are recommended to use these documents only

after properly understanding customer situation. Distribution of this document is limited to DS

SolidWorks employees and VARs.

4

1. Solver Options in SolidWorks Simulation

In general, there are three Solver options in SolidWorks Simulation which are listed below in

bullet points. The selection for a particular study can be changed by accessing the study

properties (Right Click on the study name in the Study Tree and select Properties).

Automatic: The most general option and lets the program automatically select the most

appropriate of the two solvers (Direct Sparse or FFEPlus).

Direct Sparse: Versatile, robust, and stable in handling a variety of analysis features by

directly solving the matrices (using matrix inversion) used for the numerical FEA

1

solution.

FFEPlus: Uses an iterative method of solving which does not require matrix inversion

and therefore allows larger models to be solved faster and with more efficient memory

management than Direct Sparse. However, the FFEPlus solver can be more susceptible to

difficulty in solver convergence and stability.

Please note that the program may not actually launch the user-selected solver if that solver

doesn't support one or more of the analysis options and/or features of the analysis. Typically this

is seen when FFEPlus has been selected, but Direct Sparse is launched instead since FFEPlus

does not support certain combinations of study features. Some examples where this may occur

are: using local bonded contact

2

in a mixed mesh

3

frequency analysis, having selected base

excitation

4

defined in a linear dynamic study, and in a frequency analysis where loading (such as

gravity or external forces) is applied.

2. Tips and Facts to Consider for making the best choice

The most general recommendation is to use Direct Sparse if the system has multiple

CPUs and enough RAM to solve the analysis (in linear static studies, about 1 GB of

RAM is required by the solver for an analysis with 200,000 DOF

5

)

Direct Sparse and FFEPlus are both equally efficient and fast for smaller problems

(25,000 DOF or less)

1

FEA refers to Finite Element Analysis the numerical method Simulation uses for solving real world problems.

2

Local bonded contact refers to a bonded contact set defined between explicit entities, for instance having a

contact set defined between two faces to keep them connected. This is different than having a global component

bonded contact where a component contact has been applied to the entire assembly.

3

Mixed mesh implies that of the four types of elements available in SolidWorks Simulation (solid, shell, beam,

truss), there are two or more types present in a given study. For instance, a study with both solids and shells would

be considered mixed mesh.

4

Selected base excitation is a type of external load in linear dynamic analysis.

5

DOF means Degree of Freedom. In Simulation, this concept is used in terms of number of DOF based on the

analysis type, number of nodes from the created mesh, and how the nodes are restrained. For a structural analysis

(such as a static study), solid and truss elements have three DOF per node (translation in three orthogonal

directions), while shells and beams have six (three translation plus three rotational directions). Thermal studies are

unique in that each node will have just one DOF regardless of element type (scalar value of temperature). In the

context of what appears in the solver status details, DOF is the number of unknowns (variables) being solved.

5

For medium sized problems (between 100,000 and 300,000 DOF), the amount of RAM

Direct Sparse requires to solve begins to grow rapidly and significantly with an

increasing number of DOF

Consider FFEPlus for large problems (more than 300,000 DOF), especially if using a 32

bit machine in order to prevent the solver from having to use the systems Page File

6

The FFEPlus solver will need only about 1 GB of RAM to solve a linear static study with

2,000,000 DOF

If Direct Sparse doesnt have enough RAM available during the solving process, it may

show an Out of core message and the solver progress will slow down significantly due

to use of the Page File

Direct Sparse can be faster and more accurate for problems involving one or more of the

following: incompatible bonded contact, connectors, no penetration contact, contact with

friction, models with multiple materials with dissimilar stiffness

In general, Direct Sparse is more efficient than FFEPlus at taking advantage of multiple

processors/cores (see Appendix for details)

Consider FFEPlus for a frequency study where the model is not adequately restrained

(has rigid body modes

7

)

Direct Sparse must be used in frequency studies if any kind of loading is included

Direct Sparse is generally preferred for nonlinear studies, though it may be necessary to

use FFEPlus if the model is too large for the computer to handle Direct Sparse

It is possible to change which solver is selected by default for a new study by changing

the Default solver selection under Simulation Options Default Options

6

The Page File is an area of the computers hard drive reserved for writing and reading temporary data which cannot

be stored in the RAM virtual space, usually due to a lack of available RAM.

7

Rigid body Mode refers to a type of motion in a Simulation study where a component is free to translate or rotate

in a given direction without any deformation because no restraints or bonding have been defined that would stabilize

or prevent that specific motion. This is a source of instability and can cause solver failure.

6

3. Appendix: Usage of multiple CPUs and cores, and influence on

solution time

a) Static Study performance comparison when using 1 through 12 cores

Tests were performed using SolidWorks Simulation 2012 SP4.0 on several 64 bit machines with

dual hex (six) core processors resulting in a range of 1 to 12 physical cores available to the solver

(with hyper-threading disabled). These results are presented in the graph below as normalized

factors, where a normalized performance factor of 1.0 corresponds to the base benchmark

single core solve time for each solver. The tests were composed of static studies in several

different models, so the result value for each number of cores data point below is the mean of

the normalized factor results for various models, across several machines. The data is presented

in a single concise and simplified graph, showing results for both the Direct Sparse and FFEPlus

Iterative solvers. Please note that this data is not a comparison of absolute solve times between

Direct Sparse and FFEPlus, but rather to highlight the effect of multiple cores on the relative

benchmark single core solve time of the respective solver.

The results of these tests suggest that running Static studies using the Direct Sparse solver gives

a significant improvement in performance with an increasing number of CPU cores for

instance, the time to solve with 6 cores was less than 1/3 the time to solve with 1 core. Beyond 6

cores, however, the performance improvement with each additional core becomes rather

diminishing. It should be noted, however, that the time to solve with 12 cores was about half of

the solve time with 6 cores so no persistent performance bottleneck was observed. The

FFEPlus Iterative Solver on the other hand does not show a consistent improvement in Static

0.00

0.10

0.20

0.30

0.40

0.50

0.60

0.70

0.80

0.90

1.00

1 2 3 4 5 6 7 8 9 10 11 12

N

o

r

m

a

l

i

z

e

d

S

o

l

v

e

T

i

m

e

Number of Physical CPU Cores

Solve Time Comparison for Static Studies

FFEPlus Solver

Direct Sparse Solver

7

study performance beyond 4 cores. Furthermore, the time to solve with 4 cores was about 2/3 the

time to solve with 1 core.

b) Quad core versus single core comparison for Static, Frequency,

Buckling, Thermal, and Nonlinear Studies

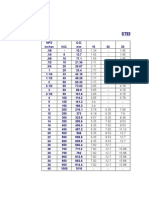

The table below shows the percentage improvement in time taken to complete solving of various

static for several models when four cores were allowed compared to when just one core was

permitted for the respective solver. The data was obtained using test cases in SolidWorks

Simulation 2012 SP4.0 on a Windows 7 x64 Dell Precision T5500 with Quad Core Intel Xeon

X5550 @ 2.66 GHz, 12 GB RAM.

The following formula was used to compute percent improvement in time to solve when

comparing the use of four cores versus only one:

% Improvement = [(solve_time_1core) (solve_time_4core)] / (solve_time_1core)

Study Type % Improvement in time to solve

when using 4 cores vs. 1 core

Direct Sparse FFEPlus

Static 72% 5% 35% 10%

Frequency 6% 1% 46% 1%

Buckling 6% 1% 53% 3%

Thermal 70% 10% (none)

Nonlinear (none) 10% 10%

The results of these studies suggest that the Direct Sparse solver shows the biggest potential for

improved multicore performance when running Static and Thermal studies. The FFEPlus solver

on the other hand shows the significant benefits for multicore performance in Frequency and

Buckling studies. For Nonlinear studies, in some cases the FFEPlus solver showed slight

improvement in time to solve. However, in general, the Direct Sparse solver is preferred for

Nonlinear problems since it can handle nonlinearities better than FFEPlus and is generally less

prone to convergence difficulties.

c) Drop Test Studies

Only one solver type available, test model used only one core.

8

d) Fatigue Studies

Only one solver type available. Although the fatigue solver itself uses only one core, preparing to

run a fatigue study involves setting up and running one or more static studies. Since static studies

do benefit from multiple cores, users doing this type of analysis would see an overall

improvement in time to perform a fatigue analysis on a multi-core machine.

e) Optimization Studies

The majority of time spent solving an optimization analysis is taken up by running design

iterations of other Simulation studies based on linked variables (parameters), constraints, and

goals. Since the user can specify which solver type they wish to use for each of the studies,

performing an optimization analysis on a multi-core machine would typically show improvement

in performance over using just a single core machine.

f) Linear Dynamic Studies

The actual dynamic analysis and stress calculations use special solvers that used only one core in

testing. However, performing a linear dynamic analysis involves first finding resonant

frequencies, which did show performance improvement when implementing more than one core

if using the FFEPlus solver.

g) Pressure Vessel Design Studies

The majority of the time taken to complete a pressure vessel analysis is running the respective

static studies that you wish to combine. When performed on a single core, the actual calculations

for combination of results only make up a small percentage of the total analysis time. As a result,

a user with a multi-core machine would see an overall improvement in time to perform a

pressure vessel design analysis.

h) Notes

When looking at CPU usage in Task Manager on a system that has one CPU with four

cores for instance, 100% indicates that all four CPUs are being used at maximum

capacity. 25% indicates that one CPU is being used at full capacity.

Direct Sparse showed the greatest improvement in performance during the matrix

decomposition stage of solving, where the total CPU usage was 99% for most of the

testing.

Even for solver stages or study types which use only one core, there is still a minor

benefit to having more than one CPU since it makes it possible to allocate an entire core

to the solver while leaving background applications and system processes to use their

own separate cores.

Hyper-Threading (splitting a physical core into two virtual cores) is not recommended.

No significant performance benefit has been observed in testing, while on the other hand

9

there have been some known solver stability issues caused by hyper-threading. This

setting can typically be disabled through the system BIOS.

Some studies show usage of more than one CPU only for certain stages of the solver.

Multistep analysis such as nonlinear can have significant differences in multi-core

performance between models depending on geometry, setup, number of contacts, etc.

Вам также может понравиться

- Analysis and Design of Marine Structures V Digital PDFДокумент4 страницыAnalysis and Design of Marine Structures V Digital PDFNurul Huda0% (1)

- Designmodeler: Workshop 5.1 3D CurveДокумент8 страницDesignmodeler: Workshop 5.1 3D CurveNurul HudaОценок пока нет

- Elastic BeaconsДокумент9 страницElastic BeaconsNurul HudaОценок пока нет

- Steel Pipes - Pipe Schedule ChartДокумент3 страницыSteel Pipes - Pipe Schedule ChartNurul HudaОценок пока нет

- 25 Abaqus ODBДокумент6 страниц25 Abaqus ODBNurul HudaОценок пока нет

- Asme B30Документ1 страницаAsme B30Nurul Huda100% (1)

- Fatigue Analysis Tool 1.0Документ2 страницыFatigue Analysis Tool 1.0Nurul HudaОценок пока нет

- Response Spectra GenerationДокумент16 страницResponse Spectra GenerationNurul HudaОценок пока нет

- Spring Analysis Tool3Документ4 страницыSpring Analysis Tool3Nurul HudaОценок пока нет

- 3.4 Finite Element Analysis of Wind Induced Buckling of Steel TankДокумент4 страницы3.4 Finite Element Analysis of Wind Induced Buckling of Steel TankNurul HudaОценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- MATLAB Statistics AssignmentДокумент5 страницMATLAB Statistics AssignmentAhsan NaeemОценок пока нет

- Characterizing and Correcting For The Effect of Sensor Noise in The Dynamic Mode DecompositionДокумент25 страницCharacterizing and Correcting For The Effect of Sensor Noise in The Dynamic Mode DecompositionFABIANCHO2210Оценок пока нет

- Data Science Tips and Tricks To Learn Data Science Theories EffectivelyДокумент208 страницData Science Tips and Tricks To Learn Data Science Theories Effectivelyenock-readersОценок пока нет

- VibrationДокумент6 страницVibrationchandan_j4uОценок пока нет

- CV Module 1Документ166 страницCV Module 1Yogesh GargОценок пока нет

- Gentle Introduction To MathMLДокумент27 страницGentle Introduction To MathMLtoba_sayedОценок пока нет

- Further Maths 3 Revision Notes Feb 2016Документ56 страницFurther Maths 3 Revision Notes Feb 2016ayomideadare13Оценок пока нет

- USAF Test Pilot School Flying QualitiesTextbook Volume 2 Part 1Документ704 страницыUSAF Test Pilot School Flying QualitiesTextbook Volume 2 Part 1David Russo100% (3)

- tmp4BCD TMPДокумент260 страницtmp4BCD TMPFrontiersОценок пока нет

- Mesh Segmentation Via Spectral Embedding and Contour AnalysisДокумент10 страницMesh Segmentation Via Spectral Embedding and Contour AnalysiscmaestrofdezОценок пока нет

- Stiffness Matrix MethodДокумент102 страницыStiffness Matrix MethodAkash PaudelОценок пока нет

- Class 12 Math Chep - Chap 3 - Matrices, Chapter 4 - DeterminentsДокумент23 страницыClass 12 Math Chep - Chap 3 - Matrices, Chapter 4 - DeterminentsEr Piyush ThaganОценок пока нет

- Dissertation Proposal: Greg Coombe University of North Carolina August 22, 2005Документ17 страницDissertation Proposal: Greg Coombe University of North Carolina August 22, 2005LambertОценок пока нет

- C++ Lab Worksheet 6.1Документ15 страницC++ Lab Worksheet 6.1Aryaman SharmaОценок пока нет

- Product Design and Development On Dual TableДокумент27 страницProduct Design and Development On Dual TableBerihu GirmayОценок пока нет

- Dhvsu-Architectural Thesis Manual 2020-2021Документ5 страницDhvsu-Architectural Thesis Manual 2020-2021Allain Judd CentenoОценок пока нет

- CE REVIEW Adv Math Post TestДокумент2 страницыCE REVIEW Adv Math Post TestAlaine SobredoОценок пока нет

- KGCE SyllabusДокумент49 страницKGCE SyllabusRenganathanPadmanabhanОценок пока нет

- Chapter 9 Data MiningДокумент147 страницChapter 9 Data MiningYUTRYU8TYURTОценок пока нет

- Linear Algebra MATLABДокумент4 страницыLinear Algebra MATLABSharmistha MukherjeeОценок пока нет

- K.S.Rangasamy College of Technology BE EEE II (Secong Year) SyllabusДокумент68 страницK.S.Rangasamy College of Technology BE EEE II (Secong Year) SyllabusSuganthan HarmlessОценок пока нет

- Unit 3Документ169 страницUnit 3RaskshannaОценок пока нет

- Syllabus PDFДокумент3 страницыSyllabus PDFSaketh SentinalОценок пока нет

- EE 559 Midterm From S11Документ12 страницEE 559 Midterm From S11chrisc885597Оценок пока нет

- Parametric Study of A Dog Clutch Used in A Transfer Case For TrucksДокумент46 страницParametric Study of A Dog Clutch Used in A Transfer Case For TrucksCesar VasquesОценок пока нет

- Pretest MatrixДокумент4 страницыPretest MatrixCristy AyusoОценок пока нет

- An Introduction To Markovchain PackageДокумент39 страницAn Introduction To Markovchain Packageratan203Оценок пока нет

- တက္ကသိုလ်ဝင်တန်း သင်္ချာမေးခွန်းဟောင်း အဖြေပါဝင်Документ184 страницыတက္ကသိုလ်ဝင်တန်း သင်္ချာမေးခွန်းဟောင်း အဖြေပါဝင်Hanny Zaw MinОценок пока нет

- Wu Et Al 1989 Validity of Smith Model in Pile Driving AnalysisДокумент18 страницWu Et Al 1989 Validity of Smith Model in Pile Driving Analysis叶晓平Оценок пока нет

- Computer Programming LabДокумент235 страницComputer Programming LabVunnam MadhuriОценок пока нет