Академический Документы

Профессиональный Документы

Культура Документы

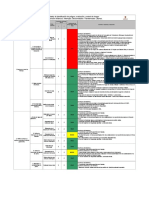

Diferencias de Eficiencias

Загружено:

Carlos0 оценок0% нашли этот документ полезным (0 голосов)

23 просмотров3 страницыАвторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

23 просмотров3 страницыDiferencias de Eficiencias

Загружено:

CarlosАвторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 3

Cul es la diferencia ms importante entre un motor IE1 de

eficiencia estndar y un motor IE2 de alta eficiencia?

Un motor de mayor eficiencia o rendimiento consume menos energa

para desarrollar la misma potencia mecnica. Si un motor se

utiliza ms de 2000horas al ao, el tiempo de amortizacin de la

diferencia de precios es relativamente rpido. Un ejemplo con

nmeros. Un motor de 15kW 4 polos con clase IE1 tiene un

rendimiento de 88,7% y el equivalente en IE2 un rendimiento de

90,6%. Para desarrollar los 15kW, el motor IE1 consumir

15/0,887=16,91kW y el motor IE2 consumir 15/0,906=16,56kW, es

decir, 0,35kW menos. Suponiendo que ambos motores trabajan a

plena carga durante 3000 horas al ao, el motor IE1 habr

consumido 0,35x3000=1050kW.h ms al ao, que a un precio de

0,08/kWh resulta en 84 ms de energa al ao. Si se compara

con la diferencia de precios de adquisicin de uno y otro motor,

se ver que el tiempo de amortizacin es del orden de dos aos.

Equivalen las nuevas clases de eficiencia IE1/IE2 a las viejas EFF1/EFF2?

La aparicin de las nuevas normas IEC 60034-2-1:2007 y 60034-30:2008 armoniz a nivel mundial el criterio de medicin del rendimiento o eficiencia de los motores de baja tensin (<1000V) con rotor de jaula de

0,75 a 375kW de 2, 4 y 6 polos, y fij las nuevas clases de eficiencia (IE= International Efficiency), que de menor a mayor rendimiento son las siguientes:

- IE1 (standard efficiency, similar al antiguo EFF2)

- IE2 (high efficiency, similar al antiguo EFF1)

- IE3 (premium efficiency)

Por qu cuesta ms un motor IE2 que un motor IE1?

La mayor eficiencia se consigue bsicamente con ms cantidad y ms calidad de materiales. Es por eso que un motor IE2 es un motor con un precio entre un 40% y un 10% superior, segn tamaos.

Merece la pena la inversin en un motor IE2?

La diferencia de precio entre un motor IE1 y un motor IE2 se amortiza rpidamente si el motor se utiliza ms de 2000 horas al ao. Si uno analiza los costes totales durante la vida til de un motor de baja tensin,

ver que los costes energticos representan un 97%, el coste de adquisicin del motor un 2% y los costes de mantenimiento un 1% de los costes totales. Al incrementar el coste de adquisicin pasando de un

motor IE1 a un motor IE2, empeoramos la pequea partida del coste de adquisicin pero mejoramos la partida ms importante que son los costes energticos.

Qu otras ventajas tiene un motor IE2 frente a un motor IE1?

Por un lado, la ventaja econmica debida al menor consumo energtico. Al amortizarse rpidamente la diferencia de precio, se aumenta la productividad del cliente final (mejora directa de la cuenta de

resultados).Por otro lado, el mantenimiento es mejor, pues estos motores poseen mejor factor de servicio y mayor reserva trmica.

The efficiency of an electric motor can only be improved through

a reduction in motor losses. Improvement in the design,

materials, and construction have resulted in efficiency gains of

2 to 6 percent which translates into a 25 percent reduction in

losses. A small gain in efficiency can produce significant

energy savings and lower operating costs over the life of the

motor. Consequently, the higher purchase price of high-

efficiency motors (15 to 30 percent) can, in most cases,

be recovered in 2 years through cost savings in energy and

operation.

The efficiency of a motor is the ratio of the mechanical power output to the electrical power

input. This may be expressed as:

Output/ Input

Efficiency = Output/ Input

Input = Output + Losses

Efficiency = Output/ Output + Losses

Design changes, better materials, and manufacturing improvements reduce motor losses,

making premium or energy-efficient motors more efficient than standard motors. Reduced

losses mean that an energy-efficient motor produces a given amount of work with less energy

input than a standard motor.2

Motor Losses and Loss Reduction

Techniques

A motors function is to convert electrical energy to mechanical energy to perform useful work.

The only way to improve motor efficiency is to reduce motor losses. Even though standard

motors operate efficiently, with typical efficiencies ranging between 83 and 92 percent, energy-

efficient motors perform significantly better. An efficiency gain from only 92 to 94 percent

results in a 25 percent reduction in losses. Since motor losses result in heat rejected into the

atmosphere, reducing losses can significantly reduce cooling loads on an industrial facilitys air

conditioning system. Motor energy losses can be segregated into five major areas, each of

which is influenced by design and construction decisions.9 One design consideration, for

example, is the size of the air gap between the rotor and the stator. Large air gaps tend to

maximize efficiency at the expense of power factor, while small air gaps slightly compromise

efficiency while significantly improving power factor.10 Motor losses may be categorized

as those which are fixed, occurring whenever the motor is energized, and remaining constant for

a given voltage and speed, and those which are variable and increase with motor load.11 These

losses are described below.

1 . Core loss represents energy required to magnetize the core material (hysteresis) and includes

losses due to creation of eddy currents that flow in the core. Core losses are decreased through

the use of improved permeability electromagnetic (silicon) steel and by lengthening the core to

reduce magnetic flux densities. Eddy current losses are decreased by using thinner steel

laminations.

2. Windage and friction losses occur due to bearing friction and air resistance. Improved

bearing selection, air-flow, and fan design are employed to reduce these losses. In an energy-

efficient motor, loss minimization results in reduced cooling requirements so a smaller fan can

be used. Both core losses and windage and friction losses are independent of motor load.

3. Stator losses appear as heating due to current flow

4. Rotor losses appear as I2R heating in the rotor

5. Stray load losses are the result of leakage fluxes (I) through the resistance (R) of the stator

winding. This is commonly referred to as an I2R loss. I2R losses can be decreased by modifying

the stator slot design or by decreasing insulation thickness to increase the volume of wire in the

stator winding. Rotor losses can be reduced by increasing the size of the conductive bars and

end rings to produce a lower resistance, or by reducing the electrical current.induced by load

currents. Both stray load losses and stator and rotor I2R losses increase with motor load. Motor

loss components are summarized in Table 5. Loss distributions as a function of motor

horsepower are given in Table 6 while variations in losses due to motor loading are shown in

Figure 4.

How Much Can You Save?

The amount of money you can save by purchasing an energy-efficient motor instead of a

standard motor depends on motor size, annual hours of use, load factor, efficiency mprovement,

and the serving utilitys charges for electrical demand and energy consumed Three pieces of

information are required to evaluate the economic feasibility of procuring an energy-efficient

motor instead of a standard motor. First, obtain a copy of your utilitys rate schedule. Then

determine load factor or percentage of full rated output. Finally, determine the number of motor

operating hours at rated load With this information you can determine your annual energy and

cost savings.

Вам также может понравиться

- ServomotoresДокумент1 страницаServomotoresCarlosОценок пока нет

- 05 Coblanca Catalogo SIEMENS 2015 Lavado SecadoДокумент28 страниц05 Coblanca Catalogo SIEMENS 2015 Lavado SecadoCarlosОценок пока нет

- Capitulo 8 Motores de InduccionДокумент47 страницCapitulo 8 Motores de Induccionjosedavid327100% (1)

- Cat Tecnico3Документ1 страницаCat Tecnico3CarlosОценок пока нет

- CmaДокумент1 страницаCmaCarlosОценок пока нет

- Curso Alineacion de Maquinaria IndustrialДокумент1 страницаCurso Alineacion de Maquinaria IndustrialCarlosОценок пока нет

- AlineaciónДокумент1 страницаAlineaciónCarlosОценок пока нет

- 2014 DIC - Tipos de Recintos en Motores ElectricosДокумент4 страницы2014 DIC - Tipos de Recintos en Motores ElectricosaracfenixОценок пока нет

- Cat Tecnico4Документ1 страницаCat Tecnico4CarlosОценок пока нет

- Cat Tecnico2Документ1 страницаCat Tecnico2CarlosОценок пока нет

- Calentamiento Por Induccion PDFДокумент24 страницыCalentamiento Por Induccion PDFCarlosОценок пока нет

- Resistencias de Calefacción MotoresДокумент1 страницаResistencias de Calefacción MotoresCarlosОценок пока нет

- Cat TecnicoДокумент1 страницаCat TecnicoCarlosОценок пока нет

- Aplicaciones de Calentamiento Por InduccionДокумент1 страницаAplicaciones de Calentamiento Por InduccionCarlosОценок пока нет

- Alineacindeejesdemaquinariarotativaemgesa 130716223127 Phpapp01Документ1 страницаAlineacindeejesdemaquinariarotativaemgesa 130716223127 Phpapp01CarlosОценок пока нет

- Causas de Desalineamiento AbbДокумент1 страницаCausas de Desalineamiento AbbCarlosОценок пока нет

- H IDROELÉCTRICAДокумент1 страницаH IDROELÉCTRICACarlosОценок пока нет

- Vibrción Técnica AbbДокумент1 страницаVibrción Técnica AbbCarlosОценок пока нет

- Turbo GeneradorДокумент1 страницаTurbo GeneradorCarlosОценок пока нет

- Tablas PDFДокумент15 страницTablas PDFCarlos100% (1)

- Percy ViegoДокумент9 страницPercy ViegoCarlosОценок пока нет

- Slotfill ExampleДокумент2 страницыSlotfill ExampleCarlosОценок пока нет

- Slotfill ExampleДокумент2 страницыSlotfill ExampleCarlosОценок пока нет

- P50-B SP PDFДокумент162 страницыP50-B SP PDFCarlosОценок пока нет

- WB350F SpanishДокумент172 страницыWB350F SpanishCarlosОценок пока нет

- WB350F SpanishДокумент172 страницыWB350F SpanishCarlosОценок пока нет

- Analisis de Firma de CorrienteДокумент8 страницAnalisis de Firma de CorrienteCarlosОценок пока нет

- WB350F SpanishДокумент172 страницыWB350F SpanishCarlosОценок пока нет

- Manual Mantenimiento de CorreasДокумент50 страницManual Mantenimiento de CorreasunmdpОценок пока нет

- Manual Mantenimiento de CorreasДокумент50 страницManual Mantenimiento de CorreasunmdpОценок пока нет

- Fallas AsimetricasДокумент82 страницыFallas Asimetricasluism_falconiОценок пока нет

- Central Majes Solar 20TДокумент2 страницыCentral Majes Solar 20TAntony Alexander AguilarОценок пока нет

- Rectificador semicontrolado de onda completaДокумент10 страницRectificador semicontrolado de onda completaAlejandro PelaezОценок пока нет

- El Motor de ArranqueДокумент28 страницEl Motor de ArranqueVruto Hinvezil HycnorantersОценок пока нет

- Calculo Del Costo Total y Unitario Según El ComportamientoДокумент6 страницCalculo Del Costo Total y Unitario Según El ComportamientoMultitareas OnlineОценок пока нет

- Ciclo CombinadoДокумент3 страницыCiclo CombinadoHéctor J. CajasОценок пока нет

- Electrificación asentamiento Nuevo Mirador Pachacutec VentanillaДокумент3 страницыElectrificación asentamiento Nuevo Mirador Pachacutec VentanillaJim Albarran LozanoОценок пока нет

- CLC ElectricДокумент2 страницыCLC ElectricJose Luis Gomez100% (1)

- Informe OGP Enero 2023 Inversión Próximos 5 AñosДокумент48 страницInforme OGP Enero 2023 Inversión Próximos 5 AñosContacto Ex-AnteОценок пока нет

- Transistores de conmutación en fuentes de TV SonyДокумент0 страницTransistores de conmutación en fuentes de TV SonyElcura EdgarОценок пока нет

- Turbomaquinas y Maquinas de ExpulsionДокумент38 страницTurbomaquinas y Maquinas de Expulsionjosmiguel_bvОценок пока нет

- BROCHUREДокумент8 страницBROCHUREandyОценок пока нет

- Alaska BGHДокумент35 страницAlaska BGHMariana De WendyОценок пока нет

- Bombas y CompresoresДокумент2 страницыBombas y CompresoresAlberto Perez100% (2)

- Tesis DFGA - Mejora Rendimiento Generador EolicoДокумент211 страницTesis DFGA - Mejora Rendimiento Generador EolicoCarlos Camacaro GonzalezОценок пока нет

- Matriz de Riesgos InstructivosДокумент9 страницMatriz de Riesgos InstructivosYohana Moya CisternaОценок пока нет

- New York Times. DescripciónДокумент10 страницNew York Times. DescripciónEnrique Alberto MartinelliОценок пока нет

- Física procesos biológicos seminario 4Документ3 страницыFísica procesos biológicos seminario 4Gabriel Pineda CastroОценок пока нет

- Identificación de elementos de una unidad de tratamiento de aireДокумент155 страницIdentificación de elementos de una unidad de tratamiento de aireKevin Anchelía PérezОценок пока нет

- Motoconformadora MaquinariaДокумент61 страницаMotoconformadora MaquinariaHéctor Leyte100% (1)

- Manejo de Las Herramientas de Etiquetado EnergéticoДокумент3 страницыManejo de Las Herramientas de Etiquetado EnergéticoAlejandro Aguirre Huertas50% (4)

- Cristalizador HowardДокумент4 страницыCristalizador HowardCarlos Alvarez GarciaОценок пока нет

- La Historia de Schneider ElectricДокумент2 страницыLa Historia de Schneider ElectricYair Ordoñez CaroОценок пока нет

- Ficha Tecnica MarmitaДокумент3 страницыFicha Tecnica MarmitaDafny GarciaОценок пока нет

- Sistema Interconectado NacionalДокумент11 страницSistema Interconectado NacionalFelipe AlvaradoОценок пока нет

- Normas AEN-CTN 23Документ37 страницNormas AEN-CTN 23silentidea8317Оценок пока нет

- Energía Ambiental (Energy Harvesting)Документ2 страницыEnergía Ambiental (Energy Harvesting)Dany MarquesОценок пока нет

- Top BrakeДокумент11 страницTop BrakeSebastian Pizarro75% (4)

- Trabajo Practico TermodinamicaДокумент8 страницTrabajo Practico TermodinamicaAndreita FedericoОценок пока нет

- Lineas de TransmisionДокумент8 страницLineas de TransmisionJessoccerОценок пока нет