Академический Документы

Профессиональный Документы

Культура Документы

#3 Design

Загружено:

Kashif KaziОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

#3 Design

Загружено:

Kashif KaziАвторское право:

Доступные форматы

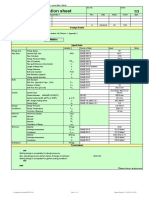

ASME Section VIII

Design

2

Outline

Basic Design Philosophy

Design Loadings

Responsibilities for Design Parameters

J oint Type and Limitations

Design Requirements for Radiography

Special Service Vessels

Corrosion Considerations

3

Outline (contd.)

Vessel Minimum Wall Requirements

Head and Shell Formulas

Shell Openings and Exemptions to

Reinforcement Calculation

Inspection Openings

4

Basic Design Philosophy

5

Bases of Code Design

Fabrication type

Material type

6

Code Requirements

Code formula, when applicable, shall

be used

Owner must specify type of service

and other pertinent information for

the required service conditions

7

Service Types

Lethal Service

Low Temperature Service

Unfired Steam Boiler

Directly Fired Vessels

No Restriction

8

Design Loadings

9

Design Loadings

Pressure Loads

Temperature Gradient

Vessel Weight and Content

Localized Stresses

Impact Loads

Wind and Earthquake Loads

Note: Section VIII provides rules for

calculating pressure loads only

10

Responsibilities for

Design Parameters

11

Who is Responsible?

The Manufacturer is responsible for

assuring compliance with all

applicable Code requirements

12

Users Responsibility

Information supplied to the

Manufacturer by the Owner/User:

Design Pressure and Temperature

Loadings

Corrosion Allowance

PWHT or Radiography if not required by

Code

13

Vessel Design

Design may be performed by:

Customer or Customers agent

Certificate Holder (Manufacturer)

Subcontractors

Manufacturer who stamps the vessel

is responsible for complying with

the Code

14

J oint Type and Limitations

15

J oint Type

J oint Design

Types 1 thru 3 are Butt J oints

Types 4 thru 6 are Fillet J oints

16

Type 1 Weld J oint

J oint welded on both sides

17

Type 1 Weld J oint

NOTE:

Only when the thickness is greater than

5/8 or the outside diameter is over 24

and meets UW-35 of the Code

18

Type 2 Weld J oint

Backing Ring or Strip

19

Type 3 J oint

UW-2 Service Restrictions

Circumferential joints only t<5/8, OD<24

J oint Efficiency: No; RT = 0.60

Categories = A, B, and C

20

Type 4 J oint

UW-2 Service Restrictions

Longitudinal J oint t<3/8, Category A

Circumferential J oint t<5/8,

Categories B & C

J oint Efficiency: No; RT=0.55

21

Type 5 J oint

UW-2 Service Restrictions

Head-to-Shell Attachment Category B with head

<24 OD to shell with t<1/2

Circumferential joint for attachment of shell to

jacket with t<5/8

Distance from center of plug to plate edge is not 1.5

times plug diameter

J oint Efficiency: No; RT=.50;

Category C

22

Type 6 J oint

UW-2 Service Restrictions

Head convex to pressure to shell t<5/8; fillet

weld on inside of shell

Head-to-shell attachment with shell t<1/4 and

OD<24, fillet weld on outside of head flange

J oint efficiency: No; RT=0.45

Categories A and B

23

Type 7 J oint

Angle >30Deg

Service Restrictions

As limited by UW 13.2 & figure UW-16.1

For J oint Categories C&D

J oint efficiency: No. When required a value of E <1.00

may be used

Categories A and B

Full penetrations, partial penetration, and/or fillet

welded

24

Type 8 J oint

Angle Joints

Design per U-2 (G) for category B & C joints

J oint Efficiency : No

Covers B, C and D category joints

25

Limitations on J oint Type

J oint

Type

Thickness Circumfer.

Diameter

Longitudinal

Thickness

Notes

1 All All All

2

For offset joints

<5/8 unless a hemi

head then <3/8

All All

3 <5/8 <24 OD Not Permitted

4 <5/8 All <3/8

5

Head to Shell <1/2 <24 OD

Not Permitted

Not Permitted on

Hemi Head

Shell/J ackets <5/8 All

6

Head convex to

pressure <5/8

All heads

All

<24 OD

26

J oint Category

J oint Location

J oint Categories

A

Ellipsoidal

A

A

B

A

D

C

B

A

C

28

Design Requirements

for Radiography

Full, Spot and J oint Efficiencies

29

UW-11(a) Full Radiography

1. Vessel contains lethal substance

2. All butt welds in shell longitudinal &

circumferential joints over 1-1/2 or

the lesser as prescribe in the material

subsection

3. Unfired steam boiler over 50 psi

30

Table UCS-57

P Numbers

1

3

4

5A,5B

9A,9B

10A,10F

10B,10C

Minimum T

1 1/4

3/4

5/8

0

5/8

3/4

5/8

31

UW-11(a) (contd.)

4. Categories B and C butt welds in

nozzles and communicating

chambers, which are attached to a

vessel, and are to be fully

radiographed do not require

radiographic examination if the

diameter does not exceed 10NPS or

1 1/8 thick

32

5. Categories A and D butt welds, on

joint efficiency in UW-12(a), in which

case:

a. Category A or B welds connecting the

vessel section or heads shall be of

Type 1 or 2

UW-11(a) (contd.)

33

UW-11(a) (contd.)

b. Category B or C welds (not including

nozzle or communicating chambers)

which intersect with Category A welds or

seamless vessel sections or heads shall

meet the spot radiography of UW-52.

Spot radiographs required by this paragraph

shall not be used to satisfy spot radiography

as applied to other weld increments

34

UW-11(a), (contd.)

6. All butt welds joined by electrogas

welding of butt joints >1-1/2 in a

single pass and all joined by

electroslag welding

7. Ultrasonic examination (UW-53) may

be substituted for radiography on

final closure seam weld if

radiography is not practical

35

UW-11(b) Spot Radiography

Types 1and 2 butt welds which are not

required to be fully radiographed in

accordance with UW-11(a) above, may

be spot radiographed (UW-52)

Spot radiography is not required for

nozzles and communicating chambers

having no more than 10NPS and

t<1-1/8

36

Spot Radiography

One spot radiograph (min. 6) required

for each 50 ft. increment or fraction

thereof

Must include work of each Welder or

Welding Operator

Location chosen by the Authorized

Inspector

J oint Categories

Ellipsoidal

Spot R.T.

Flange

A

A

D

C

B

C

A

A

B

38

UW-11(c) No Radiography

Vessels designed for external pressure

only and the joint design complies

with UW-12(c)

39

UW-12: J oint Efficiencies

J oint Type Full Spot None

1 1.00 0.85 0.70

2 0.90 0.80 0.65

3 - - 0.60

4 - - 0.55

5 - - 0.50

6 - - 0.45

4

40

Stress Multiplier

E - a stress multiplier which may be

either a J oint Efficiency or

Quality Factor

41

UW-12(d) (contd.)

When calculating circumferential

stress in seamless vessel sections or

seamless head, E = 1.0 when spot

radiography requirements of

UW-11(a)(5) are met

42

UW-12(d) (contd.)

E = 0.85 when spot radiography of

UW-11(a)(5) is not met, or when the

connecting welds are Types 3, 4, 5 or

6 of Table UW-12

43

UW-12 (d) (contd.)

Quality Factors in UW-12(d) are used

to determine the efficiencies for

calculations in seamless shells made

from forgings, pipe, or formed

seamless heads

Note: Electric resistance welded pipe

(ERW) is considered seamless pipe for

this matter (see UW-12e)

44

Special Service Vessels

45

Special Requirements

for Radiography

Service Full Radiography Reqd.

Lethal All Butt Welds

Unfired Steam Boiler >

50 psi

All Butt Welds

Butt Welds >Specified

thickness UW-11(a)(2)

All Electroslag Welds

All Butt Welds

46

Special Service Vessels

Lethal Service

Category Type

A 1

B 1 or 2

C 1 or 2

D Full Penetration

47

Special Service Vessels

Unfired Steam Boilers

Category Type

A 1

B 1 or 2

C -------

D -------

48

Special Service Vessels

Low Temperature

Category Type

A 1

B 1 or 2

C Full Penetration

D Full Penetration

49

Special Service Vessels

Directly Fired Steam Boilers

Category Type

A 1

B 1 or 2

C -------

D -------

Categories of J oints

J oint location

A

D

A

A

D

D

B

B

C

?

A

C

?

?

?

?

?

J oint location

A

D

A

A

D

D

B

B

C

A

A

C

B

A

A

C

B

Categories of J oints

52

Corrosion Allowance

53

Corrosion Allowance

The Owner is responsible for

specifying corrosion allowance due to

service conditions

NOTE: Corrosion allowance is not

considered in strength

calculations

54

UG-25 (f)

Vessels subject to corrosion shall

be provided with a drain at the

lowest point

55

Minimum Wall Requirements

for Vessels

56

UG-16

Minimum wall thickness is generally

1/16, with exceptions

57

Thickness of shells and heads of

unfired steam boilers shall be at least

1/4, excluding corrosion allowances

Compressed air service, steam

service and water services shall be at

least 3/32, including any corrosion

allowances

Minimum Wall Thickness

Exceptions

58

Tubes in air-cooled and cooling tower

heat exchangers provided the

following are met:

Tubes are not used for lethal service

Tubes shall be protected by fins or other

means

Tube OD must be between 3/8 1-1/2

Minimum Wall Thickness

Exceptions

59

Tube minimum wall thickness shall not

be less than that calculated from the

formula using 500 psi at 70

o

F, or

0.022 whichever is greater

Minimum Wall Thickness

Exceptions

60

Minimum Wall Thickness

Exceptions

Not applicable to

Heat transfer plates of plate-type heat

exchangers

Inner pipe of double pipe heat

exchangers

Tubes in shell-and-tube heat exchangers

61

Head and Shell Formulas

62

Minimum Wall Thickness

Shell Calculation

P SE

PR

t

P SE

PR

t

4 . 0

6 . 0

= Inside Radius

UG-27

Outside Radius

App.1-1

63

UG-31

Pipe may be used as shell with the

required wall thickness using the

formula in UG-27 for internal pressure

and UG-28 for external pressure

Thickness must be increased for:

corrosion, erosion or wear

threaded connections

64

Type of Head Design

Four (4) types of head design in

Section VIII, Div.1 included in the

exam:

Ellipsoidal

Torishperical

Hemispherical

Flat

65

Ellipsoidal Head

P SE

PD

t

2 . 0 2

=

Inside Diameter

UG-32(d)

Outside Diameter

App.1

t

PD

SE P

o

=

+ 2 02 .

ASME Code Section VIII, Div.1:

UG-32(d) Ellipsoidal Head

Major Axis

Minor Axis

2:1 Semi-Ellipsoidal

1Unit

Minor

Axis

2 Units

Major Axis 4 Units

2:1 Semi-Ellipsoidal Head

1Unit

Major Axis 4 Units

1/2 Minor Axis

2:1 Semi-Ellipsoidal Head

Tangent Line

Major Axis

1/2 Minor Axis

(head depth)

2:1 Head

Minor Axis = Major Axis

2 4

Skirt

70

UG-32(e) Torispherical Head

When the knuckle radius is 6% of the

inside crown radius (L) and the inside

crown radius is equal to the skirt O.D.

t

PL

SE P

=

0885

01

.

.

P

SET

L t

=

= 0885 01 . .

Torispherical Head

UG-32(e) Crown radius is equal to the

outside diameter of the skirt

Outside

Radius

L

72

Torispherical Head

L = Outside radius

of the skirt.

C

L

73

Torispherical Head

C

L

The corner radius,

measured on the

concave side, shall be

0.06L

L

74

Torispherical Head

C

L

L = Radius Knuckle

or

Corner

Radius

75

Torispherical Head

L

Tangent Line

skirt

Knuckle

radius

C

L

76

UG-32(f) Hemispherical Head

When t does not exceed 0.356L or

p does not exceed 0.665 SE, then:

t

PL

SE P

=

2 02 .

Hemispherical Head

L

R= Radius

ID=2L

inner height=L

78

Flat Heads

Welded Circular

Bolted Circular

Welded Non-circular

Bolted Non-circular

79

UG-34

SE CP d t =

The minimum thickness of a flat,

unstayed, circular head is:

t

s t

f

t

r =3t

f

min.

d

Flat Head (b-1)

t

f

min. = 2t

s

C=0.17

t

f =

nominal thickness of flange

ts =nominal thickness of shell

81

Design of

Bolted Flanged Connection

Two Methods:

Standard rated flanges

ANSI Standards

Manufacturers Standards

Design calculations, per Appendix 2

Gasket must be enclosed by bolt holes

No contact of flanges outside bolt holes

82

Openings and Reinforcements

Circular

Ellipsoidal

Obround

Other Shapes

83

Maximum Size

Vessel Shell Size Maximum Openings

ID < 60 1/2 vessel ID, but not to

exceed 20

ID > 60 1/3 vessel ID but not to

exceed 40

84

UG-36 (c)(2)

Reinforcement may be waived for

welded connections:

3-1/2 (89 mm) in diameter in vessel

shells or heads <3/8 thick minimum

required thickness

2-3/8 (60 mm) in diameter in vessel

shells or heads > 3/8 thick minimum

required thickness

85

Inspection Openings

86

UG-46 Openings

Pressure vessels used for compressed

air and those subject to corrosion shall

be provided with sufficient manhole,

handhole or other inspection openings

for inspection and cleaning.

87

Exemptions

Vessels with non-corrosive products

Telltale holes are used in lieu of

inspection openings

88

Minimum Size Openings

Manway

Elliptical - 12 x 16 or 10 x 16

Circular - 16 ID

Handhole Openings

Elliptical - 2 x 3

89

UG-45 Nozzle Neck Thickness

UG-45 is used to determine the

wall thickness of the nozzle

based on loading

90

The thickness is specified by UG-22,

based on loading and corrosion.

However, in no case less than:

The required thickness of the attached

shell or head, plus the corrosion

allowances. (Efficiency used is always

100%)

The minimum thickness of standard wall

pipe, plus corrosion allowance.

UG-45 Nozzle Neck Thickness

91

UG-45 Nozzle Neck Thickness

Remember to consider the

manufacturing tolerance which is

approximately 12.5%

92

Questions?

Вам также может понравиться

- Flange Calculation ASMEVIII-Custom WNRF (Alternate Check)Документ11 страницFlange Calculation ASMEVIII-Custom WNRF (Alternate Check)Kashif Kazi100% (1)

- The Impact Testing Enigma: A Review of ASME Section VIII, Division 1, Subsection C, Part UCS, Impact Testing RequirementsДокумент13 страницThe Impact Testing Enigma: A Review of ASME Section VIII, Division 1, Subsection C, Part UCS, Impact Testing Requirementssanjaypatel25Оценок пока нет

- ASME Joint EfficiencyДокумент49 страницASME Joint Efficiencygateauxboy95% (39)

- The Impact Testing Enigma: A Review of ASME Section VIII, Division 1, Subsection C, Part UCS, Impact Testing RequirementsДокумент13 страницThe Impact Testing Enigma: A Review of ASME Section VIII, Division 1, Subsection C, Part UCS, Impact Testing Requirementssanjaypatel25Оценок пока нет

- The Impact Testing Enigma: A Review of ASME Section VIII, Division 1, Subsection C, Part UCS, Impact Testing RequirementsДокумент13 страницThe Impact Testing Enigma: A Review of ASME Section VIII, Division 1, Subsection C, Part UCS, Impact Testing Requirementssanjaypatel25Оценок пока нет

- Introduction MeshingДокумент20 страницIntroduction Meshingbotan_mihaiОценок пока нет

- Corrosion Under Insulation - Detection and Monitroing MECCOCT18-12254Документ16 страницCorrosion Under Insulation - Detection and Monitroing MECCOCT18-12254Kashif KaziОценок пока нет

- ASME Section VIII, Division 2Документ23 страницыASME Section VIII, Division 2Saeed Rehman100% (1)

- ASME Joint EfficiencyДокумент49 страницASME Joint Efficiencygateauxboy95% (39)

- The Impact Testing Enigma: A Review of ASME Section VIII, Division 1, Subsection C, Part UCS, Impact Testing RequirementsДокумент13 страницThe Impact Testing Enigma: A Review of ASME Section VIII, Division 1, Subsection C, Part UCS, Impact Testing Requirementssanjaypatel25Оценок пока нет

- Nozzle Design - Codeware-Compress FAQsДокумент9 страницNozzle Design - Codeware-Compress FAQsKashif KaziОценок пока нет

- WIS Plate Exe 05Документ13 страницWIS Plate Exe 05Kashif KaziОценок пока нет

- Jump Start Shell TubeДокумент14 страницJump Start Shell TubetrantheanОценок пока нет

- Intro DesignModelerДокумент19 страницIntro DesignModelerAlex DanielОценок пока нет

- Weld Neck Flange Design Raised Face Bolt CalculationsДокумент2 страницыWeld Neck Flange Design Raised Face Bolt CalculationsKashif KaziОценок пока нет

- UT of Pressure Vessel Construction WeldsДокумент30 страницUT of Pressure Vessel Construction WeldsKashif KaziОценок пока нет

- The Impact Testing Enigma: A Review of ASME Section VIII, Division 1, Subsection C, Part UCS, Impact Testing RequirementsДокумент13 страницThe Impact Testing Enigma: A Review of ASME Section VIII, Division 1, Subsection C, Part UCS, Impact Testing Requirementssanjaypatel25Оценок пока нет

- ASME U-Stamp Fabrication Shop Best Practices Rev 0Документ36 страницASME U-Stamp Fabrication Shop Best Practices Rev 0Kashif KaziОценок пока нет

- UT of Pressure Vessel Construction WeldsДокумент30 страницUT of Pressure Vessel Construction WeldsKashif KaziОценок пока нет

- Getting Started - Aspen Shell and Tube ExchangerДокумент12 страницGetting Started - Aspen Shell and Tube ExchangerSean ChoiОценок пока нет

- Spence SRVsДокумент132 страницыSpence SRVsKashif KaziОценок пока нет

- Photoshop CS5 Read MeДокумент11 страницPhotoshop CS5 Read Meali_mohammed_18Оценок пока нет

- Beams OverviewДокумент18 страницBeams OverviewrbhavishОценок пока нет

- What's New - PV Elite 2018Документ28 страницWhat's New - PV Elite 2018SathiyaseelanОценок пока нет

- 51e64ae0e4b08833fb23efa5 Shkrina 1374061788922 SfbmdiagramsДокумент17 страниц51e64ae0e4b08833fb23efa5 Shkrina 1374061788922 SfbmdiagramsAiman AmirОценок пока нет

- What's New - PV Elite 2018Документ28 страницWhat's New - PV Elite 2018SathiyaseelanОценок пока нет

- Aws Preheat Calculations From HardnessДокумент6 страницAws Preheat Calculations From HardnessElias KapaОценок пока нет

- DOCUMENT Sample Vessel CalculationsДокумент10 страницDOCUMENT Sample Vessel CalculationsCristian Camilo Zapata PardoОценок пока нет

- Brochure Roll Bonded Clad Plates EДокумент36 страницBrochure Roll Bonded Clad Plates EAries MarteОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Appraisal Form TemplateДокумент7 страницAppraisal Form TemplateShilpa PandeyОценок пока нет

- Manitowoc 111 80 Product GuideДокумент24 страницыManitowoc 111 80 Product GuideZian HennОценок пока нет

- 1 SM401Документ55 страниц1 SM401Yennhi NguyenОценок пока нет

- Autodesk Revit 2010 Exam-Guide 0709 Env3Документ7 страницAutodesk Revit 2010 Exam-Guide 0709 Env3oksbgtОценок пока нет

- Manual de Partes Catar Pillar Cargador Frontal 950 LДокумент1 009 страницManual de Partes Catar Pillar Cargador Frontal 950 Ljuan100% (4)

- International Sxs Ser ManДокумент104 страницыInternational Sxs Ser ManaderlochОценок пока нет

- Guide For Interpreting Life Cycle Assessment ResultДокумент60 страницGuide For Interpreting Life Cycle Assessment ResultSharah Yunihar SaputraОценок пока нет

- GW 1.5MW PMDD Wind Turbine Technical OverviewДокумент4 страницыGW 1.5MW PMDD Wind Turbine Technical Overviewdiegoxis24Оценок пока нет

- JN1AR5EF3GM290485Документ3 страницыJN1AR5EF3GM290485Anonymous MefbpaV9xzОценок пока нет

- Electrical Load Estimation - Part One Electrical KnowhowДокумент9 страницElectrical Load Estimation - Part One Electrical KnowhowRon NombriОценок пока нет

- Optical Transport Network Linear ProtectionДокумент40 страницOptical Transport Network Linear Protectionsanjay angadiОценок пока нет

- Contractor HSSE Management ProcessДокумент13 страницContractor HSSE Management ProcessAHMED AMIRAОценок пока нет

- New IEC 61850-Based Solutions: Client Functionality On All Device FamiliesДокумент8 страницNew IEC 61850-Based Solutions: Client Functionality On All Device FamiliesHung Cuong PhamОценок пока нет

- Mobile IPv6 SeminarДокумент34 страницыMobile IPv6 SeminarTinsu M Babu100% (1)

- Attach SignalingДокумент44 страницыAttach Signalingbrr.rezvaniОценок пока нет

- BBC TVP What Is IptvДокумент32 страницыBBC TVP What Is IptvMukhlis YuliantoОценок пока нет

- LCX244Документ14 страницLCX244Ahtesham KhanОценок пока нет

- 05 Technical Data h301 - 1009Документ14 страниц05 Technical Data h301 - 1009IRWIN_DSOUZAОценок пока нет

- At CommendsДокумент324 страницыAt CommendsAhmed Tarek MohamedОценок пока нет

- Fieldbook A1 - enДокумент2 страницыFieldbook A1 - enCarlos RiveraОценок пока нет

- Soil T-180 Moisture-Density TestДокумент3 страницыSoil T-180 Moisture-Density Testmalika_00Оценок пока нет

- Node Transponders: Mini - Medium Frequency, 4000 MДокумент4 страницыNode Transponders: Mini - Medium Frequency, 4000 MRafael LourençoОценок пока нет

- Risk Based Internal Auditing Within Greek Banks: A Case Study ApproachДокумент49 страницRisk Based Internal Auditing Within Greek Banks: A Case Study ApproachKUNAL GUPTAОценок пока нет

- 6 SQ - MM Standard Feed Through Terminal Blocks: Cat. No. Description Std. PackДокумент3 страницы6 SQ - MM Standard Feed Through Terminal Blocks: Cat. No. Description Std. PackKaran SanghviОценок пока нет

- Compressed Gases Self-Assessment Checklist 1/8/2019: All Purpose Checklist Page 1 of 4 PagesДокумент4 страницыCompressed Gases Self-Assessment Checklist 1/8/2019: All Purpose Checklist Page 1 of 4 PagesMusharaf ShahОценок пока нет

- WWW Araxxe Com P Our Services Revenue Assurance Inter OperatДокумент5 страницWWW Araxxe Com P Our Services Revenue Assurance Inter OperatErick Alexander Llanos BuitronОценок пока нет

- Modems Cdm-625-En Advanced Satellite Modem With Doubletalk Carrier-In-CarrierДокумент5 страницModems Cdm-625-En Advanced Satellite Modem With Doubletalk Carrier-In-CarrierarzeszutОценок пока нет

- Document and Records Management Procedure TemplateДокумент18 страницDocument and Records Management Procedure TemplateHussein AlkafajiОценок пока нет

- Z1 ManualДокумент6 страницZ1 ManualIvana JazidzijaОценок пока нет

- Repeater Installation and CommissioningДокумент34 страницыRepeater Installation and CommissioningTuan TocdaiОценок пока нет