Академический Документы

Профессиональный Документы

Культура Документы

Spesifikasi Alat Berat Pemotong Pohon Otomatis

Загружено:

YudaPurnama BrooОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Spesifikasi Alat Berat Pemotong Pohon Otomatis

Загружено:

YudaPurnama BrooАвторское право:

Доступные форматы

901

901TX.1

GB

Thinning specialist offering

unbeatable proftability

H

A

R

V

E

S

T

E

R

Protable and economical

901TX.1

The Komatsu 901TX.1 is the new version of our market-leading thinning

harvester. With new technologies and our inherent design advantages, Komatsu

now provides an unmatched combination of production, low environmental impact

and economical operation in a thinning harvester. Here are a few of the essential new

features and benefts:

Economic operation

High reliability, simplifed

maintenance and low fuel

consumption provide a very

manageable cost of ownership.

Handling

Komatsu Comfort Bogies deliver a

smooth ride while providing superb

mobility and maneuverability.

New engine

New powerful engine that minimizes

NOx emissions (nitrogen oxides) and

provides exceptional fuel economy.

Ground clearance

High ground clearance, 635 mm

(25) enhances mobility while

reducing the machines impact in

the forest.

Operator environment

Generously sized cab, large win-

dows and the ideal relation of the

side-mounted crane creates a high

performance work environment.

Hydraulics

ORFS couplings on critical hydraulic

components create tight seals which

minimize the potential for leaks

reducing down time and protecting

the environment.

MAXIMUM

PERFORMANCE AND

FUEL EFFICIENT.

Tomorrows engine

today

Unbeatable fuel economy.

Minimized environmental impact.

Lower service costs. Less engine

noise. These advantages are

thanks to the new SCR engine

developed with our E3-Power

technology.

Powerful and

fast crane

options, 10 m

(32.8) and 11

m (36) provide

ideal reach and

handling charac-

teristics.

Information system

The MaxiXplorer information

system offers the markets most

comprehensive machine control,

as well as status and production

reports.

Handling

Equipped with Komatsu Comfort

Bogie to provide superb mobility

and maneuverability.

How do you improve a thinning machine

that is already considered the most ef-

fcient and environmentally friendly in the

world? The answer is the new Komatsu

901TX.1, which delivers additional green

and economic benefts. The explanation

is the completely new SCR-based engine,

which dramatically reduces both emis-

sions and fuel consumption.

And it doesnt end with emissions well

below legal requirements and world-

leading fuel economy! With our E3-Power

technology, operating costs are further re-

duced thanks to a number of factors from

control systems that ensure operation

through long service intervals to cleaner

engine oil. A new feature improving ser-

viceability is that all critical hydraulics use

ORFS couplings, which reduce the risk

of leaks. Another important part of this

901TX.1

Cab and crane

leveling and

stabilizer coupling

for optimum reach

and stability. Crane

placement close to

the cab ensures that

the head is always

directly in front of

you. Extremely pro-

ductive for thinning.

The generously

sized high-

performance

operating

environment

features large

windows, low

noise levels and

a smooth ride

thanks in part

to the full-circle

slewing platform.

machines cost effciency comprises the

detailed status and production reports

from the powerful MaxiXplorer computer

system.

The proven characteristics of the

901TX.1 include the optimal combination

of high productivity and low environmen-

tal impact. A considerable factor in this is

the crane, which is one of the strongest

on the market and provides an advantage

when working at long reaches. Add to this

the low total weight, high ground clear-

ance, and fantastic maneuverability, and

you soon realize that no other thinning

harvester gets as much done with so little

impact on the forest foor and surround-

ing forest.

Similarly, the 901TX.1 combines human

effciency and ergonomics. The cab is an

extremely high performance operating

environment with generous proportions

and large surround windows. The relation

of the side-mounted crane to the full-circle

slewing and leveling cab also maximizes

operator visibility. Choose the Komatsu

901TX.1, with either 6 or 4 wheels, for

optimal thinning proftability. The kind of

proftability modern forestry demands.

Forestry Quality Productivity

650

1850 1650

22 20

7065

3740

650

1650 1650

22 20

6359

3740

17 17

A

TECHNICAL SPECIFICATIONS

Tire Width, mm (feet inches)

4WD (front/rear) 600/65 x 34 2,730 (8'11")

710/55 x 34 2,900 (9'6")

6WD (rear) 600/65 x 34 2,730 (8'11")

710/55 x 34 2,990 (9'10")

Tire Width, mm (feet inches)

6WD (front) 650/45 x 24,5 2,760 (9'1")

710/40 x 24,5 2,890 (9'6")

NOTE: Stated dimensions are nominal and may vary slightly.

WEIGHT

4 WD 6 WD

Curb weight

1)

: 16,200 kg 16,800 kg

(35,715 lb) (37,038 lb)

1)

Applies to 600/650 tires.

WHEEL OPTIONS AND MACHINE WIDTH (A) WITH DIFFERENT TIRES

ENGINE

66 AWI. 6-cylinder, turbo with Commonrail. EU

Stage IIIB and EPA Tier 4 Interim. DEF/SCR

after-treatment (not applicable for all markets).

Stroke volume: 6.6 l (403 cu in)

Power, max.: 150 kW DIN (201 hp) at 1,900 rpm

Torque: 950 Nm (701 lbf-ft) at 1,500 rpm

Fuel tank: approx. 370 l (98 gal)

POWER TRANSMISSION/TRANSMISSION

. Hydrostatic-mechanical, controlled by

MaxiXplorer. Transfer gearbox with 2 positions.

Disengageable front-wheel drive.

Differential locks: Mechanical electro-hydraulic control

Driving speed: 0-25 km/h (0-15.5 mph)

Traction force: 152 kN

HYDRAULIC SYSTEM

Load sensing/high-low balanced constant

pressure, variable piston pump

Flow: 270 l/min (70 gal/min) at 1,700 rpm

System pressure: 250 bar (3,626 psi)

Working pressure, crane: CRH16: 248 bar (3,597 psi)

Hydraulic oil tank: approx. 200 l (53 gal)

Miscellaneous: Pressure flter for hydrostatic drive circuit.

Return oil flter for hydrostatic drive and hydrau-

lics. Hydraulic oil level warning. Vacuum pump.

FRAME/AXLES

Axle, front: Sturdy geared bogie (Comfort bogie).

Differential with mechanical differential lock.

Permanently lubricated bearings.

Axle, rear: Swing axle with hub reduction. Differential with

mechanical differential lock. Hydraulic swing

axle override with leveling.

Available options: Wear guard, bogie

BRAKE SYSTEM

Fully-hydraulic multi-disc brakes. Hydraulic

accumulator charging valve.

Driving brake/ Multi-disc brakes in oil bath.

Working brake: Automatically engaged when working.

Parking brake: Spring-action brake with electro-hydraulic

control. Emergency brake

Braking performance: Conforms to ISO 11169 and VVFS 2003:27

CRANE

Model: CRH 16 CRH16DT

Reach: 10 m (32'10") 11 m (36'1")

Lifting torque, gross: 174 kNm (128,336 lbf-ft) 174 kNm (128,336 lbf-ft)

Slewing torque, gross: 40.8 kNm (30,092 lbf-ft) 40.8 kNm (30,092 lbf-ft)

Head: 350.1 340

1000 1100 1200 1300 1400 1600 1800 1700 1500 1900 2000 2100

T

o

r

q

u

e

(

N

m

)

P

o

w

e

r

(

k

W

)

Speed (rpm)

600

650

700

750

800

850

900

950

100

90

80

110

120

130

140

150

901TX.1

STEERING

Hydraulic articulated joint.

Lever steering: Load-sensing (LS) proportional steering from

crane controls/rocker

Steering angle: +/- 40 Electric end limit damping

Available options: Steering wheel.

ELECTRICAL SYSTEM

Voltage: 24 V

Battery capacity: 2 x 140 Ah

Generator: 2 x 100 A

LIGHTING

More than 30 lux in work area. Halogen cab,

crane, and reversing lights.

Available options: Xenon lights on cab and crane. Roof-mounted

work lights, halogen or xenon. Long-distance

lights, Xenon. Side lights.

ERGONOMICS

Comfort-enhancing leveling. Stabilizer coupling

on cab. Crane and cab on horizontal, rotating

platform. Autolev fully-automatic cab and

crane leveling. Hydraulic stabilization when

maneuvering.

Horizontal leveling: Longitudinal 20/22 and lateral 17

Rotation: 315

Available options: Crane damping. Slew damping

CAB

Safety tested. Auto-leveling. Thermal and

acoustic insulation. Sun blinds.

Safety: Conforms to ROPS ISO 8082, FOPS ISO 8083,

and OPS ISO 8084

Seat: Choice of ergonomically designed seat for

individual adjustment of the seat cushion, back

and lumbar support, arm rests, and control

panels.

Windshields: Windshield and side windows of 15 mm (0.6")

safety glass.

Heating/ventilation: Heating and cooling unit ECC. Filtered intake

air.

Noise level: As per ISO standard.

Vibrations: As per ISO standard.

Miscellaneous: Manual tilt. Multi-position safety lock. Electrical

kit for com-radio and telephone (12-24 V).

Windshield wiper and washer on front and roof

windows.

Available options: Swivel seat. Electrically-controlled platform

under cab. Radio with MP3 player and USB

port. Air-ventilated BeGe seat with head rest.

Allergen flter on air intake. Cooler box. Lunch-

box heater

CONTROL AND INFORMATION SYSTEM

MaxiXplorer Integrated system for machine and head

control. Operator-specific settings for head,

crane, and machine functions. Cross-cutting

information and machine status display.

Production registration. Administrative tools.

PC

Processor, clock speed: 1.4 GHz

Internal memory: 1 GB RAM

Hard drive, size: 40 GB

Color display: 12", anti-reflective glass

DVD player: Option

USB ports: 8, with one of the ports on the front of the

display for easy access.

Serial ports: 2

Operating system: Windows XP Pro

Keyboard with trackball: Included

Available options: A4 printer. GPS antenna. Production reports.

Computer caliper. Backup function. Fortrax.

HEADS

Komatsu 340 Komatsu 350.1

Weight, from: 760 kg (1,676 lb) 960 kg (2,116 lb)

Felling/cutting diameter: 530 mm (20.9") 600 mm (23.6")

Feed speed: 0-5 m/s (0-16.4 ft/s) 0-5 m/s (0-16.4 ft/s)

Feed force, gross: 18 kN (4,047 lbf) 16.5-25.3 kN (3,709-5,688 lbf)

Opening, upper knives,

max.: 450 mm (17.7") 600 mm (23.6")

Roller opening, max.: 420 mm (16.5") 520 mm (20.5")

Rotator: Roller slewing with hydraulic motor.

Control and info system: MaxiXplorer

DOCUMENTATION

Printed operating and starting instructions. Operators Manual and Spare

Parts Catalog on CD.

AVAILABLE OPTIONS

Sprinkler system. Semi-automatic, water-based fire extinguishing.

Conforms to RUS 127.

Hand-held powder-based fire extinguishers 2 x 6 kg (13.2 lb)

(ABE-3), fitted externally.

Hand-held powder-based fire extinguisher 2 kg (4.4 lb) (F2GM), fitted in

cab.

Printed instruction manual (also electronic in Maxi)

Printed spare parts catalog (also electronic in Maxi)

Diesel heater 9.1 kW incl. timer and hydraulic oil heater.

Additional water separator, diesel

Stump treatment equipment

Biodegradable hydraulic oil

Mini joysticks with sequential control

Service ladders

Toolbox with tools

Rearview camera as standard (in EES countries in compliance with EU

Directive 2006/42/EU).

Platform at side of cab and ladder on left side of rear frame as standard (in

EES countries in compliance with EU Directive 2006/42/EU).

Belt guard for fat belt as standard (in EES countries in compliance with EU

Directive 2006/42/EU).

901TX.1

Komatsu Forest AB

www.komatsuforest.com

WHY CHOOSE A KOMATSU HARVESTER?

High productivity, low operating costs, innovative technology, superb operator environment these are

just some of the features that make Komatsu forestry machines some of the best in the world. Behind all

this is a highly-focused strategy to continually build upon the advantages of owning a Komatsu harvester.

A strategy based on the following principal ideas.

Ergonomics

Your forestry equipment and its mobile work environment

is critical to an operators ability to maximize production

without fatigue and is a key factor for success. This is an

important reference point used in developing the unique

egronomic designs of Komatsu harvesters. Automatic

leveling cabs, side mounted booms and large operator

compartments work together to keep the harvesting head

centered in the operators feld of vision.

Economy

The ambition to maximize proftability is one of the most

important forces driving the development of Komatsu

harvesters. Each small improvement that increases

productivity and reliability, reduces costs, or saves time

is of interest. Tangible and quantifable examples from

todays Komatsu harvesters include energy-effcient

engines, highly effcient hydraulics, fast heads, and

unsurpassed productivity.

Productivity

More work in less time a comment we often hear

from contractors who switch from competing brands to

Komatsu. There are many reasons, large and small. The

most important include extremely high-performance

operator environments, great maneuverability, effective

heads, powerful control and information systems, and

large work areas from stationary positions.

Customer Support

Fast and competent service bears directly on forestry

machine performance and economy. An extensive service

network provides the Komatsu owner with a sense of

security. Well-trained technicians provide additional

assurance, as they are Komatsu experts. Another

beneft is ProSelect, our special line of accessories

and consumables. The range is based on a selection of

items that are all of the highest quality and designed for

both Komatsu and other brands of professional forest

machinery.

Environment

Forests are an essential and fragile element of the global

ecology. Consequently, every new Komatsu product, and

all its component parts, is considered from both short-

term and long-term environmental perspectives. This

has resulted in real environmental improvements such as

highly-effective exhaust emission control and low, evenly-

distributed ground pressure in Komatsu harvesters.

Environmental considerations also permeate our broad

range of accessories and consumables, such as in our

special, rapidly biodegradable oils.

Global Experience

Komatsu harvesters are found the world over.

Consequently, they are designed to deliver optimum

proftability regardless of conditions. The same

fundamental concept is applied to our global service and

dealer network which supports thousands of Komatsu

owners everyday.

k901TX_1_b_gb_111213 TF Feklanbyra / Agrenshusel

Вам также может понравиться

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (120)

- Caminos, Jr. v. PeopleДокумент13 страницCaminos, Jr. v. PeoplesophiaОценок пока нет

- Personal ConveyanceДокумент2 страницыPersonal ConveyanceMorris TruckingОценок пока нет

- Md/phders 2013aДокумент40 страницMd/phders 2013adavid0184Оценок пока нет

- Aeg Lav 4742Документ21 страницаAeg Lav 4742valehan526Оценок пока нет

- 86 Chevrolet Caprice Monte Carlo El Camino SM PDFДокумент1 479 страниц86 Chevrolet Caprice Monte Carlo El Camino SM PDFmminer84100% (1)

- Imo Msc1 Circ1473 Policy On Use of Ais AtonДокумент7 страницImo Msc1 Circ1473 Policy On Use of Ais AtonBă AnduleОценок пока нет

- LF Ebook PC S S H-L 2012 inДокумент330 страницLF Ebook PC S S H-L 2012 in11tata100% (1)

- 8 Major Types of Cargo Transported Through The Shipping IndustryДокумент10 страниц8 Major Types of Cargo Transported Through The Shipping IndustryGiorgi KandelakiОценок пока нет

- FV-A 1800 5 Ply Corrugated Cardboard Production LineДокумент20 страницFV-A 1800 5 Ply Corrugated Cardboard Production LineJunaid MazharОценок пока нет

- Analytical-Empirical Pavement Evaluation Using The FWD PDFДокумент9 страницAnalytical-Empirical Pavement Evaluation Using The FWD PDFGang Liu100% (1)

- Booking Confirmation On IRCTC, Train: 15273, 05-Mar-2023, 3A, RXL - ANVTДокумент1 страницаBooking Confirmation On IRCTC, Train: 15273, 05-Mar-2023, 3A, RXL - ANVTAnkit ashuОценок пока нет

- Genie Model TML-4000 / TML-4000N, Parts ManualДокумент107 страницGenie Model TML-4000 / TML-4000N, Parts ManualPrejit Radhakrishna0% (1)

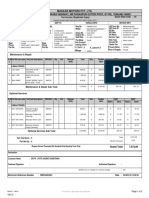

- Makkar Motors Pvt. LTD.: Kotkalan, Jalandhar Phagwara Highway, NR Paragpur Octroi Post, GT RD, Punjab-144001Документ2 страницыMakkar Motors Pvt. LTD.: Kotkalan, Jalandhar Phagwara Highway, NR Paragpur Octroi Post, GT RD, Punjab-144001baljit singhОценок пока нет

- FPD Unit-2 Material HandlingДокумент58 страницFPD Unit-2 Material HandlingVinay KorekarОценок пока нет

- TRIANGLE Tire Catalog Auto CamionДокумент27 страницTRIANGLE Tire Catalog Auto CamionJulio Barreno50% (2)

- Nepal FurnitureДокумент50 страницNepal FurnitureAwash Banjade100% (1)

- Automotive AerodynamicsДокумент3 страницыAutomotive AerodynamicsManoj PradhanОценок пока нет

- Cma-Cgm Taxas Detetion PDFДокумент2 страницыCma-Cgm Taxas Detetion PDFmarcelloairesОценок пока нет

- Training Scania 2Документ6 страницTraining Scania 2Kharis Mahfudz0% (1)

- Brochure Range Rover 2010Документ44 страницыBrochure Range Rover 2010Beepin JeОценок пока нет

- Booking Confirmation Jetblu 01 SepДокумент2 страницыBooking Confirmation Jetblu 01 SepFreddy Gustavo GallardoОценок пока нет

- WalknBike Plan FinalДокумент61 страницаWalknBike Plan FinalFOX 17 NewsОценок пока нет

- Vector Shipping Cor V Adelfo MacasaДокумент2 страницыVector Shipping Cor V Adelfo Macasasmtm06100% (2)

- English Test For Marine EngineerДокумент9 страницEnglish Test For Marine EngineerMarineroad Vallen AngkasaОценок пока нет

- Question Bank C To BДокумент211 страницQuestion Bank C To Bsushiljp1984Оценок пока нет

- Location Theory - The Foundation of PlanningДокумент6 страницLocation Theory - The Foundation of PlanningBenjie LatrizОценок пока нет

- QRH 02-Aug-22Документ154 страницыQRH 02-Aug-22aashesh puriОценок пока нет

- Ghana PortДокумент36 страницGhana PortRavi KumarОценок пока нет

- 005 - OBA-QAC-MST-DIS-REV - R00 - Dismantling WorksДокумент11 страниц005 - OBA-QAC-MST-DIS-REV - R00 - Dismantling WorksDritan PeshtaniОценок пока нет

- ALTO PS4HA-AMP DiagramДокумент1 страницаALTO PS4HA-AMP DiagramMarco Pedrosa100% (3)