Академический Документы

Профессиональный Документы

Культура Документы

GEK-105281B (Guia de Seleccion de Motores)

Загружено:

Erick Daniel Toyo MarinИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

GEK-105281B (Guia de Seleccion de Motores)

Загружено:

Erick Daniel Toyo MarinАвторское право:

Доступные форматы

GE Industrial Systems

Motor Selection Guide

and Motor Application Matrix

Step 2: Power Supply

AC Alternating Current

Single Phase

(2)

:Volts 115 230 115/230 60 Hz

(1)

110 220 110/220 50 Hz

(2)

Polyphase

(1)

: Volts 200 230/460 575 60 Hz

(1)

220 380 220/380 50 Hz

(2)

DC Direct Current

(3)

Volts Battery: 12 - 24 - 36 - etc.

Generator: 115 - 230

Rectified: 90 - 180

Step 3: Horsepower Motor output

Step 4: Speed-RPM (Revolutions per minute)

3450

(1)

(2 pole) Jet pumps, washer extractors, wood

working tools.

1725

(2)

(4 pole) General usage,fans, pumps,

compressors, conveyors, feeders

1140

(3)

(6 pole) Fans, gears, conveyors

850

(4)

(8 pole) Direct drive fans

(other) Lower RPM and multi-speed

Step 5: Overload Protector

None

(1)

No motor overload is necessary if motor

is protected at the motor starter.

Automatic

(2)

Designed to reset and restart motor after

a cooling period. Typical uses are fans &

pumps. CAUTION: DO NOT USE

AUTOMATIC OVERLOAD WHERE

UNEXPECTED RESTARTING WOULD

BE HAZARDOUS TO EQUIPMENT OR

PERSONS.

Manual

(3)

Designed to prevent motor from

becoming reenergized until reset by hand.

Typical uses are shop tools & farm motors.

Step 6: Enclosure

Open dripproof

(1)

Use in clean, dry locations.

TENV-Air Over

(2)

Use in shaft-mounted fan applications where

foreign particles could get in motor.

Fan required to cool motor.

TEFC & TENV

(3)

Use in dirty and low moisture ares. Suitable

for most outdoor locations.

Severe duty

(4)

For areas with corrosive agents in the air and

high moisture locations.

Explosion proof

(5)

Use in areas where explosive agents are in

(hazardous duty) the atmosphere. Use when gases such as

ether and gasoline or dusts such as coal,

grain and metal are present.

Step 7: Bearing

Sleeve

(1)

Use where shaft is subject to moderate thrust

in any direction. Must be oiled periodically.

Ball

(2)

Use where high thrust is exerted on shaft and

where low maintenance is required. Use in

hard to relube locations.

Step 1: Motor Types

AC SINGLE PHASE AC DC

SHADED PERM. SPLIT CAP. CAP. THREE PERM. MAG.

MOTOR TYPES POLE SPLIT PHASE START START PHASE COMPOUND

CAP CAP. RUN SHUNT, SERIES

VERY LOW MOD- MOD- MOD- MOD- MOD-

Starting Torque LOW LOW HIGH HIGH HIGH VERY HIGH

GE Motor Types KSP (1) KCP (2) KH (2) KC (4) KCR (5) K (3) BC, CD

Typical applications BPB, BPA

Adjustable speed drives A A

Air moving (fans)

Belt drive A A B A A

Direct drive A A A B B A A

Condenser A A A B B A A

Evaporator B A A B B A A

Farm/areation A A A

Farm/ventilating A A A A A

Industrial A A A A A

Rooftop ventilator B B A B B A

Checkout counters B A A A A

Centrifuges A A A

Compressors

Air/small A B B A A

Air/large A A A A

Paint sprayers A A A A A

Refrigeration A A A

Concrete mixers A A A A

Conveyors A A A A

Door operators A A A A A A

Exercise equipment A B B A A

Farm equipment

Barn cleaners A A A

Bunk feeders A A A

Dryers (grain) A A A

Elevators A A A

Grain augers A A A

Milking machines A A A

Silo unloaders A A A

Floor polishers A A A A

Food processing

Blenders A B B A

Grain mills A A A

Grinders A A A

Ice cream makers A A A

Ice makers B A A A

Slicing machines A A A A

Gear motors B A A A A A

Hospital

Beds B A B B A

Suction pumps A B B A

X-ray machines A B B A A

Laundry equipment

Dryers A A A A

Extractors A A A

Washers A A A

Material handling

Conveyors A A A A

Cranes A A A A

Elevators A A A A

Hoists A A A A

Oil burners A A

Pumps

Centrifugal A A A A A

Contractor drainage A A A A

Gasoline B A A A

Hot Water Circulator A A A A

Industrial A A A A A

Jet A B B A

Sump B A A B B A

Sewage Extractor B A A A A

Swimming pool filter A B B

Submersible Sump B A A A A A

Vacuum A A A A

Water, high pressure A A A A

Poultry processing A A A

Textile machinery A A A A

Tools, machine A A A A A

Vending machines A B B A A

Battery power

Golf carts A

Fork trucks A

Lawn mowers A

Motorized wheelchairs A

Floor care equipment A

NOTES: Superscripts (1), (2), (3), etc. denote

relative cost with (1) being least cost.

A = Suggested

B = Alternate

Step 8: Mounting

Extended thru bolts

(1)

Use to mount motor or fan guard. Can be

provided with or without base.

Base mounting

(3)

Resilient cradle

(3)

. Rubber rings between

motor and base to isolate vibration and

reduce noise.

Welded

(2)

. A solid base option for strong

construction.

C-face

(4)

Standard mount for some gears and

pumps. Face has a machined rabbet.

Step 9: Ambient Temperature of air around an operating

motor.

40C (104F)

(1)

Standard

65C (149F)

(2)

Optional, special for motors operating

in high temperature areas.

Step 10: Service Factor (S.F.)

S.F. of 1.15 to 1.4

(2)

Standard on general purpose motors.

These motors are designed to operate

with additional load of 15% to 40% over

nameplate Hp without overheating the

motor.

S.F. of 1.0

(1)

Standard on special service open and all

standard totally enclosed motors.

Not designed for over nameplate Hp.

Step 11: Other Considerations

Rotation Standard is CCW facing motor opposite

shaft end. Motors are usually

reconnectable for either rotation.

Duty cycle (running time from start to stop)

Continuous Motor runs for more than one hour.

Short time 1 hour, 30 min., 15 min., 5 min. Run this

long without overheating. Then must

cool.

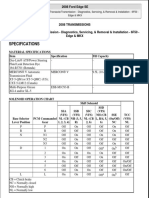

Step 12: NEMA Frame Sizes (Ref. single phase)

Step 13: NEMA Motor Frame Dimension Standards

Step 14: Hp Range Frame/Motor Types

Step 15: See Motor Catalog for:

1. Installation

2. Maintenance

3. Safety Precautions

4. Terminology

5. Additional Application Information

Hp

3450 1725 1140 850

1/20 42 42

48 48 48 48

1/12 42 42

48 48 48 48

1/8 42 42

48 48 48 56

1/6 42

48 48 48 56

1/4 48 48 56 56

1/3 48 48

56 56 56

1/2 48 56 56 143T

3/4 56 56 56 145T

1 56 56 145T 182T

1-1/2 56 56 182T 184T

2 56 145T 184T

3 145T 182T

5 182T 184T

7-1/2 184T

Frame sizes may vary with different motor types & enclosures.

RPM

NOTES: Superscripts (1), (2), (3), etc. denote

relative cost with (1) being least cost.

A = Suggested

B = Alternate

GE NEMA Motor Types

Frame Frame KSP KCP KH KC KCR K

29 42 1/35 - 1/3 1/30 - 1/3

30 48 1/10 - 1/4 1/10 - 3/4 1/12 - 3/4 1/6 - 1/2 1/4 - 1/3

40 56 1/3 - 3/4 1/2 - 3/4 1/3 - 1 1/2 1/3 - 3 1/3 - 3

40 140 1 - 2 1 - 2 1 - 2

180 180 2 - 10 2 - 10 3 - 7 1/2

Hp range is listed for 4 pole motor. Hp will vary with motor speed

N-W

W

U

H

2F BA

D

E E

D

E E

2F

H

BA

U

N-W

W

DIMENSIONS

SOLID BASE

RESILIENT (OR SOLID

CRADLE) BASE

NEMA FACE MOUNT DIMENSIONS

182TC, 184TC-FRAME

56C, 143TC, 145TC-FRAME 56J-FRAME

NEMA All Dimensions V Key

Frame D 2E 2F BA H N-W U Min. Wide Thick Long

42 2-5/8 3-1/2 1-11/16 2-1/16 9/32 slot 1-1/8 3/8 3/64 flat

48 3 4-1/4 2-3/4 2-1/2 11/32 slot 1-1/2 1/2 3/64 flat

56 3-1/2 4-7/8 3 2-3/4 11/32 slot 1-7/8 5/8 3/16 3/16 1-3/8

56H 3-1/2 4-7/8 3 & 5 2-3/4 11/32 slot 1-7/8 5/8 3/16 3/16 1-3/8

143T 3-1/2 5-1/2 4 2-1/4 11/32 dia. 2-1/4 7/8 2 3/16 3/16 1-3/8

145T 3-1/2 5-1/2 5 2-1/4 11/32 dia. 2-1/4 7/8 2 3/16 3/16 1-3/8

182T 4-1/2 7-1/2 4-1/2 2-3/4 13/32 dia. 2-3/4 1-1/8 2-1/2 1/4 1/4 1-3/4

184T 4-1/2 7-1/2 5-1/2 2-3/4 13/32 dia. 2-3/4 1-1/8 2-1/2 1/4 1/4 1-3/4

45

5

7

/

8

DIA BC

3

/

8

UNC - 28 TAP -

5

/

8

DEEP - 4 HOLES

2

1

/

16

- 56C

2

3

/

8

- 143 TC . 145TC

5

/

32

MAX

4

1

/

2

DIA

1

7

/

8

- 56C

2

1

/

8

- 143TC . 145TC

5

/

8

- 56C

7

/

8

- 143TC . 145TC

2

7

/

16

5

/

32

MAX

4

1

/

2

DIA

1

7

/

8

MAX

7

/

16

- 20 UNF - 2A

THREAD

1

/

2

DIA

45

7

1

/

4

DIA BC

1

/

2

- 13 UNC - 28 TAP

-

3

/

4

DEEP -

2

5

/

8

KEY

1

1

/

8

Motor Application Matrix

AC

GEK-105281B (5M 5/99) Fort Wayne, Indiana 46802

DC

Motor Hp Speed Starting Torque Characteristics Typical uses

Type Range Range as a percent of

full load torque

Shaded Pole 1/80 - 1/4 variable very low Light duty for small loads. Small fans & blowers Freezer blowers

(KSP) 1050 50 -100% Low in efficiency - usually Hair dryers Small vent fans

1550 air over required. Generally Unit heaters Small exhaust fans

3000 single voltage. Non-reversible. Space heaters Window fans

Humidifiers Floor fans

Seed cleaners Portable evap. coolers

Permanent 1/30 - 3/4 variable low Has a higher efficiency Shaft mounted fans Animal confinement

Split 825 75 - 150% and power factor than shaded and blowers fans

Capacitor 1075 pole. Not recommended Room & central Window fans

(KCP) 1625 for belt drive. air conditioners Unit heaters

3250 Normally single voltage and -condenser fans Garage door openers

rotation. Adapts to solid -evaporator fans

state speed control. Furnace blowers

Split Phase 1/2 - 3/4 850 moderate Use where low to medium Belted fans Oil burners

(KH) 1140 to low starting torque suffices. Not and blowers Poultry feeders

1725 130-170% adaptable to variable speed Air conditioning fans Attic fans

3450 control. Usually single and blowers Furnace blowers

voltage, dual rotation. Office machines Small tools

Centrifugal pumps Lathes

Home appliances Door operators

Capacitor 1/6 - 5 850 Moderate All purpose motors for high Compressors Vacuum pumps

Start 1140 to high starting torque applications. Conveyors Manure pumps

(KC) 1725 200-400% Suitable for most heavy duty Pumps Milk coolers

3450 applications. Usually dual Augers (grain, etc.) Elevators

voltage, dual rotation. Cranes & hoists Cattle feeders

Capacitor is used to give high Machine tools Drying fans

starting torque. Grain stirrers Aeration fans

Ventilating fans Gear motors

Food equipment

Capacitor 1/3 - 10 850 Moderate The addition of a run capacitor Essentially all capacitor start motors above

Start 1140 to high improves efficiency, power 1 Hp are capacitor start, capacitor run.

Capacitor 1725 200-400% factor and reduces load current. Same typical uses as capacitor start.

Run 3450 The run capacitor may be Barn cleaners

(KCR) added just to improve Silo unloaders

efficiency, or to match motor Feed mills

losses with the cooling system. Large bucket elevators

Three 1/4 - 250+ 850 Moderate For applications where Same typical uses as capacitor start

Phase 1140 to high three phase power is and capacitor start, capacitor run.

(K) 1725 200-300% available. Relatively simple May be used on AC variable speed drive

3450 construction with no switch, applications with appropriate inverter control.

centrifugal mechanism,

capacitors, or start windings.

Permanent 1/20 - 3 variable Moderate Moderate starting torque Adjustable speed drives Fans

Magnet 1140 200-300% and good running speed regu- -Industrial Personnel carriers

1725 lation. High efficiency since no production equipt. Wheelchairs

2500 field losses; therefore, good for -Machine tools EV power steering

battery and rectified power -Tape reel drives Elevator door

operation. Simple, reliable con- Machinery Commercial door

struction. Replacing shunt -Material handling operators

wound field motors to a great -Medical equipment Electric vehicle

extent. Easy to reverse. -Textile equipment accessories

-Agricultural equipt.

Shunt 1/12 - 250+ variable High High starting torque. Business equipment Presses

Wound 1140 700-800% Used where constant speed is Conveyors Packaging machines

1725 needed at any control setting Machine tools

2500 or where large speed range Material handling

is required. Operated from Feed drives

adjustable voltage power Textile machines

supplies.

NOTE: There are many other types of DC motors available, such as compound, compensated shunt, and series. Application of these may require factory help.

GE Industrial Systems

http://www.ge.com

Вам также может понравиться

- Cop TrainingДокумент5 страницCop TrainingCrystal StoneОценок пока нет

- 2012 ENGINE PERFORMANCE Electronic Throttle Control System - TL PDFДокумент64 страницы2012 ENGINE PERFORMANCE Electronic Throttle Control System - TL PDFsoftallОценок пока нет

- 2006 LX PartsДокумент859 страниц2006 LX PartsJon Scot Garrison100% (1)

- Codigos FordДокумент66 страницCodigos FordavffОценок пока нет

- Rondo 2.7L 2007 Service ManualДокумент2 489 страницRondo 2.7L 2007 Service ManualĐạt ThànhОценок пока нет

- GM Automatic Transmission IdenificationДокумент4 страницыGM Automatic Transmission Idenificationr12smith597Оценок пока нет

- Neighbourhood Policing HandbookДокумент17 страницNeighbourhood Policing HandbookStargate CommandОценок пока нет

- 2015 Ford EscapeДокумент1 страница2015 Ford EscapetouchvikrantОценок пока нет

- A518 04 WДокумент10 страницA518 04 WJustin DiMambroОценок пока нет

- Converter Cat1 2 PDFДокумент242 страницыConverter Cat1 2 PDFMarcos MontesОценок пока нет

- Wotbox Instructions 2010mustangДокумент14 страницWotbox Instructions 2010mustangAlejandro Da CostaОценок пока нет

- Auto TransmissionДокумент444 страницыAuto TransmissionCicerón RomeroОценок пока нет

- F6Документ2 страницыF6namduong368Оценок пока нет

- Coil-On-Plug Wiring and Install With Pics - DSMtuners PDFДокумент11 страницCoil-On-Plug Wiring and Install With Pics - DSMtuners PDFEmilio J PardoОценок пока нет

- Weedeater One Service ManualДокумент20 страницWeedeater One Service ManualBrandon HarveyОценок пока нет

- ZG Chime/Buzzer Warning Systems 8U - 1Документ4 страницыZG Chime/Buzzer Warning Systems 8U - 1ensmartisОценок пока нет

- ClutchesДокумент2 страницыClutchesAlonzo Ribera100% (1)

- Trailer Connector Wiring DiagramsДокумент1 страницаTrailer Connector Wiring Diagramsjesus silvaОценок пока нет

- RXV2065 HTR6295Документ163 страницыRXV2065 HTR6295Milan JovićОценок пока нет

- Auto TransmissionДокумент61 страницаAuto Transmissionlamping_apОценок пока нет

- 5R55N Seminar InfoДокумент18 страниц5R55N Seminar InfocarlosОценок пока нет

- 5R110W Assembly PDFДокумент16 страниц5R110W Assembly PDFLuis VelazquezОценок пока нет

- Torqshift 6Документ8 страницTorqshift 6acmemail583100% (1)

- Ac Tech Form - Re5r05aДокумент4 страницыAc Tech Form - Re5r05aossoskiОценок пока нет

- Technical Service Information: Daimler/Chrysler 40te, 41te, 42le, 42rle, 45RFE & 545RFEДокумент2 страницыTechnical Service Information: Daimler/Chrysler 40te, 41te, 42le, 42rle, 45RFE & 545RFEJose garcua vargas 2006401321Оценок пока нет

- Z TT Plus ManualДокумент44 страницыZ TT Plus ManualHerbert Frota CuradoОценок пока нет

- Timing Belt (Timing Belt) - ALLDATA Repair StratusДокумент10 страницTiming Belt (Timing Belt) - ALLDATA Repair StratusFran SanchezОценок пока нет

- Enclave 2014 3.6L PDFДокумент269 страницEnclave 2014 3.6L PDFRulo Bolaños Plascencia100% (1)

- Ford Ignition Tfi EditДокумент5 страницFord Ignition Tfi EditRafa Perez Hernandez100% (2)

- General Motors Universal External Wire Harness Repair Kit & Test Harness General Motors Universal External Wire Harness Repair Kit & Test HarnessДокумент1 страницаGeneral Motors Universal External Wire Harness Repair Kit & Test Harness General Motors Universal External Wire Harness Repair Kit & Test Harnessdavid100% (1)

- C4 General DataДокумент1 страницаC4 General DataGypsyRОценок пока нет

- JPAT Converter GuideДокумент37 страницJPAT Converter Guideสัญญา สุรเมธีОценок пока нет

- MP12 Probe System Installation and User's GuideДокумент146 страницMP12 Probe System Installation and User's GuideleonОценок пока нет

- Front Drive AxleДокумент19 страницFront Drive AxleGeraldo Pozos VazquezОценок пока нет

- 6T40 Gen III - Start StopДокумент3 страницы6T40 Gen III - Start Stopchoco84Оценок пока нет

- Index: Fordc-6Документ78 страницIndex: Fordc-6cjmОценок пока нет

- Four Wheel Drive (4WD) Controls - TaggedДокумент40 страницFour Wheel Drive (4WD) Controls - TaggedNatty NuggetОценок пока нет

- Transmission Report: The Right Kit For The Rebuild Is A Genuine SONNAX KitДокумент7 страницTransmission Report: The Right Kit For The Rebuild Is A Genuine SONNAX KitAwan dwi cahyo100% (1)

- 6R80 Transmission Valve Body Bolt Torque SequenceДокумент1 страница6R80 Transmission Valve Body Bolt Torque SequencematuteОценок пока нет

- Oil Chart UsДокумент3 страницыOil Chart UsJoeCruzОценок пока нет

- 4 L 60 EgroundДокумент2 страницы4 L 60 EgroundDavid RosadoОценок пока нет

- VW Oil Sludge Settlement Documents - 2010-12-24Документ18 страницVW Oil Sludge Settlement Documents - 2010-12-24David Foltz100% (1)

- Cables Bujias MSDДокумент15 страницCables Bujias MSDbicioxpОценок пока нет

- ZF5hp24 Valve Body TSB PDFДокумент3 страницыZF5hp24 Valve Body TSB PDFDavid RosadoОценок пока нет

- PGM Fi SystemДокумент217 страницPGM Fi Systemmkisa70Оценок пока нет

- j1850 WP PDFДокумент15 страницj1850 WP PDFMikeОценок пока нет

- Ls Installation InstructionsДокумент14 страницLs Installation Instructionsdalekilgore84Оценок пока нет

- Ford Ranger Bronco II TFI Ignition Diagnostics PDFДокумент10 страницFord Ranger Bronco II TFI Ignition Diagnostics PDFMatthester100% (1)

- Model Indentifiction For Cars TestsДокумент454 страницыModel Indentifiction For Cars TestsRichard Thodé JrОценок пока нет

- How To Test A RelayДокумент13 страницHow To Test A Relaybyukusenge yves BonheurОценок пока нет

- 303-01 - 2.3L EcoBoost - Removal and Installation - Oil PumpДокумент22 страницы303-01 - 2.3L EcoBoost - Removal and Installation - Oil PumpCARLOS LIMADAОценок пока нет

- ADS Manual 5310Документ9 страницADS Manual 5310extremesfire1571Оценок пока нет

- Generator SetДокумент4 страницыGenerator Setbiz2721Оценок пока нет

- FuelPurifier WestfaliaДокумент193 страницыFuelPurifier WestfaliaHorst100% (2)

- Taylor Power SystemsДокумент4 страницыTaylor Power SystemsTeresa CarterОценок пока нет

- Hansen p4 Qvrc2 Cun 9Документ21 страницаHansen p4 Qvrc2 Cun 9lcazac100% (1)

- Unesco - Eolss Sample Chapters: Mathematical Models in Electric Power SystemsДокумент9 страницUnesco - Eolss Sample Chapters: Mathematical Models in Electric Power SystemsErick Daniel Toyo MarinОценок пока нет

- Contactores IecДокумент258 страницContactores IecErick Daniel Toyo MarinОценок пока нет

- Ger3973 (Calculo de TC para Proteccion)Документ16 страницGer3973 (Calculo de TC para Proteccion)Erick Daniel Toyo MarinОценок пока нет

- Catalogo de ProductosДокумент2 страницыCatalogo de ProductosErick Daniel Toyo MarinОценок пока нет

- GE Power Relay Application GuideДокумент24 страницыGE Power Relay Application GuidehajianamirОценок пока нет

- Finan ZazДокумент1 страницаFinan ZazErick Daniel Toyo MarinОценок пока нет

- Comparative Superlative With Key PDFДокумент1 страницаComparative Superlative With Key PDFAnonymous 8AHCMsPuОценок пока нет

- Masterseal 530: Surface Applied Capillary Waterproofing For Concrete and MortarДокумент2 страницыMasterseal 530: Surface Applied Capillary Waterproofing For Concrete and MortarHoang An ViОценок пока нет

- 6 Chapter 6 9781786393814Документ41 страница6 Chapter 6 9781786393814yunicenjeОценок пока нет

- A Very Old MachineДокумент20 страницA Very Old MachineSwathi G. SalemОценок пока нет

- RH Fs Risk FactorsДокумент2 страницыRH Fs Risk FactorsfentroispОценок пока нет

- Chapter-01 Introduction: Sonadanga Residential Area (1st Phase)Документ17 страницChapter-01 Introduction: Sonadanga Residential Area (1st Phase)MAFRID HAYDARОценок пока нет

- Cambridge IGCSE: MATHEMATICS 0580/41Документ20 страницCambridge IGCSE: MATHEMATICS 0580/41TatiannahОценок пока нет

- General Wireless Design Considerations 1 PDFДокумент0 страницGeneral Wireless Design Considerations 1 PDFDurga TejaОценок пока нет

- Nursing Practice Skills: Adult Intensive Care Unit PatientsДокумент10 страницNursing Practice Skills: Adult Intensive Care Unit PatientsMona Doria67% (3)

- SuctioningДокумент58 страницSuctioningAyusa PradhanОценок пока нет

- Brunei 2Документ16 страницBrunei 2Eva PurnamasariОценок пока нет

- Ap Art and Design Drawing Sustained Investigation Samples 2019 2020 PDFДокумент102 страницыAp Art and Design Drawing Sustained Investigation Samples 2019 2020 PDFDominic SandersОценок пока нет

- Middle East ManufacturerДокумент6 страницMiddle East Manufacturerhsco rdОценок пока нет

- Compressed Air Pressure Drop DiagramДокумент4 страницыCompressed Air Pressure Drop DiagramycemalОценок пока нет

- Global Projects Organisation: Material Specification For 316/316L and 6mo Austenitic Stainless SteelДокумент33 страницыGlobal Projects Organisation: Material Specification For 316/316L and 6mo Austenitic Stainless SteelThiyagarajan JayaramenОценок пока нет

- Economics 526 - Mathematics For Economists: Day(s) Time LocationДокумент5 страницEconomics 526 - Mathematics For Economists: Day(s) Time LocationGaurav JakhuОценок пока нет

- Parker - Twin FilterДокумент6 страницParker - Twin FilterNAHASALI11Оценок пока нет

- Al Khudari Company Profile FP PDFДокумент14 страницAl Khudari Company Profile FP PDFAnonymous bgYdp4Оценок пока нет

- Unit-3: Grid FrameworkДокумент44 страницыUnit-3: Grid FrameworkMUKESH KUMAR P 2019-2023 CSEОценок пока нет

- CHEM333 Syllabus 2020 2021Документ4 страницыCHEM333 Syllabus 2020 2021lina kwikОценок пока нет

- Astro 429 Assignment 2 AlbertaДокумент2 страницыAstro 429 Assignment 2 AlbertatarakОценок пока нет

- Bilingual-Paper WДокумент4 страницыBilingual-Paper WzОценок пока нет

- XVI - Magneticpropertiesofmanganese ContainingsolidsolutionsofbismuthorthoniobateBiNiO4Документ7 страницXVI - Magneticpropertiesofmanganese ContainingsolidsolutionsofbismuthorthoniobateBiNiO4Chukwuebuka UgochukwuОценок пока нет

- CEBUANO ERNESTO CODINA (Astonaut Hardware Designer)Документ1 страницаCEBUANO ERNESTO CODINA (Astonaut Hardware Designer)Dessirea FurigayОценок пока нет

- Liquid SizingДокумент38 страницLiquid SizingChetan ChuriОценок пока нет

- Lake Superior RoadmapДокумент2 страницыLake Superior RoadmapWDIV/ClickOnDetroitОценок пока нет

- Gulika in Vedic AstrologyДокумент8 страницGulika in Vedic AstrologyCatchdgreen100% (1)

- Smart City Scheme GuidelinesДокумент48 страницSmart City Scheme GuidelinesKarishma Juttun100% (1)

- Government Schemes: Ministry of Agriculture and Farmers' WelfareДокумент29 страницGovernment Schemes: Ministry of Agriculture and Farmers' WelfareDushyant MudgalОценок пока нет

- Uptime KitsДокумент3 страницыUptime KitsMtto Materia PrimaОценок пока нет