Академический Документы

Профессиональный Документы

Культура Документы

Shell & Tube Heat Exchanger Design: Help File

Загружено:

ingjoselara0 оценок0% нашли этот документ полезным (0 голосов)

55 просмотров60 страницОригинальное название

STHexhelp

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

55 просмотров60 страницShell & Tube Heat Exchanger Design: Help File

Загружено:

ingjoselaraАвторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 60

WEBBUSTERZ ENGINEERING SOFTWARE

Shell & Tube Heat

Exchanger Design

Help File

Version 1.6.0

Khaled Aljundi

Copyright 2011 Khaled Aljundi WeBBusterZ Engineering Software

http://www.webbusterz.com

http://www.webbusterz.net

Copyright 2011 Khaled Aljundi WeBBusterZ Engineering Software

http://www.webbusterz.com

http://www.webbusterz.net

2

Table of Contents

About....................................................................................................................................................... 4

Main Features ......................................................................................................................................... 5

Version History ........................................................................................................................................ 6

License Agreement.................................................................................................................................. 8

System Requirements ........................................................................................................................... 10

Acknowledgements ............................................................................................................................... 10

Software Support .................................................................................................................................. 10

Main Screen .......................................................................................................................................... 11

Design Mode ......................................................................................................................................... 12

Tool bar ............................................................................................................................................. 12

Step 1 ................................................................................................................................................ 13

Step 2 ................................................................................................................................................ 14

Step 3 ................................................................................................................................................ 15

Step 4 ................................................................................................................................................ 16

Step 5 ................................................................................................................................................ 17

Step 6 ................................................................................................................................................ 18

Step 7 ................................................................................................................................................ 19

Step 8 ................................................................................................................................................ 21

Step 9 ................................................................................................................................................ 23

Step 10 .............................................................................................................................................. 24

Step 11 .............................................................................................................................................. 26

Step 12 .............................................................................................................................................. 27

Step 13 .............................................................................................................................................. 29

Summary ........................................................................................................................................... 32

Temperature Prediction ........................................................................................................................ 34

Copyright 2011 Khaled Aljundi WeBBusterZ Engineering Software

http://www.webbusterz.com

http://www.webbusterz.net

3

Rating Mode .......................................................................................................................................... 35

Step 1 ................................................................................................................................................ 35

Step 2 ................................................................................................................................................ 36

Step 3 ................................................................................................................................................ 37

Step 4 ................................................................................................................................................ 38

Step 5 ................................................................................................................................................ 38

Step 6 ................................................................................................................................................ 39

Step 7 ................................................................................................................................................ 40

Step 8 ................................................................................................................................................ 40

Step 9 ................................................................................................................................................ 41

Summary ........................................................................................................................................... 42

Engineering Data sheet ......................................................................................................................... 43

Databases .............................................................................................................................................. 47

User Database ................................................................................................................................... 48

Components .................................................................................................................................. 48

Tubes Database ............................................................................................................................. 49

Overall Heat Transfer Coefficient (Uo) Database ......................................................................... 50

Software Databases .......................................................................................................................... 51

Fouling Factors Database .............................................................................................................. 51

Tube Counts .................................................................................................................................. 52

Overall Heat Transfer Coefficients ................................................................................................ 53

Tools ...................................................................................................................................................... 54

Import ............................................................................................................................................... 54

Ms Excel ........................................................................................................................................ 54

Physical properties file .................................................................................................................. 55

Export ................................................................................................................................................ 57

MS Excel ........................................................................................................................................ 57

Engineering Data sheet ................................................................................................................. 58

Save/Load Project ............................................................................................................................. 58

Test Software .................................................................................................................................... 59

Troubleshooting Errors ..................................................................................................................... 60

Copyright 2011 Khaled Aljundi WeBBusterZ Engineering Software

http://www.webbusterz.com

http://www.webbusterz.net

4

About

Welcome to S&THex

This help file will explain in details all software features and any common errors that the

software may generate.

S&THex is a software tool that is made to demonstrate the chemical design and rating

calculations of Shell & Tube Heat Exchangers.

The software unlike other tools, ensures that the calculations are performed step by step to

help in understanding the calculations.

Copyright 2011 Khaled Aljundi WeBBusterZ Engineering Software

http://www.webbusterz.com

http://www.webbusterz.net

5

Main Features

Software Features

Step by step design and rating calculations

Support S.I Units and English (U.S) Units of measurement

Rating and Design Modes

Save/Load results.

Results:

Export Results to Shell & Tube Engineering Data sheet. You can print the data sheet or

export it to pdf format or Microsoft Excel for editing

Export Results summary to Microsoft Excel, Print Results summary.

Calculations:

Duty, Shell/Tube velocities, Unknown shell or tube side temperatures, also calculate

unknown exit temperatures in rating mode

Number of Baffles and Baffle spacing, Scale resistance (dirt factor)

Overall heat transfer coefficient for both Clean and Fouled conditions

Select from different correlations to calculate shell or tube heat transfer coefficient

Shell/Tube side Reynolds & Nusselt numbers

Pressure Drops.

Recommended minimum shell thickness, minimum recommended number & diameter

of rods.

Calculate Shell/Nozzle/Channel/Head/Tube sheet Thickness..

Number of transfer units, Effectiveness, Thermal capacity ratio

Pumping power / Inlet and Exit Nozzles pressure losses / Scale resistance Calculators

Ability to import properties to Shell/Tube sides form Microsoft Excel very useful if you

want to import your own physical properties

Included Databases:

Estimate the Physical properties of pure components for more than 1450 components;

the database has the ability to estimate Thermal Conductivity, Density, Heat Capacity

and Viscosity. The database also included critical properties, boiling and melting points

and come as a standalone interface but easily integrated with the software.

Estimate mixture properties. (ALL ESTIMATION METHODS CURRENTLY SUPPORT LIQUIDS

ONLY)

Ability to add your own properties in the additional user databases.

Fixed tube sheet counts and standard tube sizes tables

Fouling factors and Overall heat transfer coefficients included.

Copyright 2011 Khaled Aljundi WeBBusterZ Engineering Software

http://www.webbusterz.com

http://www.webbusterz.net

6

Version History

Product minor revisions have been omitted from version history

S&THex v1.6 May 2010

Physical properties database separate interface

Export Physical properties to Ms Excel or XML file.

Import Physical properties from XML file.

Export Summary to Shell & Tube Engineering Data sheet to Ms Excel or pdf format

Fouling Factors

Improved user interface

Fixed few programming bugs

S&THex v1.5 July 2007

Added Fixed Tube sheet tube counts

Added general Tube Sizes

Added Rating mode

Added Overall heat transfer coefficient calculations for clean and fouled conditions

Added Effectiveness, Number of transfer units and Thermal capacity ratio calculation

Added Pumping power calculation

Added the ability to enter Nusselt number in the correlations section

Added Gnielinski correlation to tube side

Improved user interface

Fixed few programming bugs

S&THex v1.4 July 2005

Added Software property estimation database (liquids property estimation only)

Added Overall Heat Transfer Coefficients Table

Added new saving function

Ability to import and export to Microsoft Excel

Improved user interface

Estimation of Jh (heat transfer factor) - in correlations section

Added Shell/Nozzle/Channel/Head/Tube sheet Thickness Calculation

Fixed few programming bugs

S&THex v1.3 May 2004

Added Databases (empty user databases)

Improved saving functionality

Added print screen functions

Fixed some common programming bugs

S&THex v1.2 Feb 2004

Added English (U.S. Units)

Added Shell diameter calculation

Added Scale resistance calculation/calculator

Copyright 2011 Khaled Aljundi WeBBusterZ Engineering Software

http://www.webbusterz.com

http://www.webbusterz.net

7

Added Nozzle pressure drop calculation/calculators

Added drawing summary

Added some mechanical calculation

S&THex v1.1 Dec 2003

Improved software interface

Added more correlations

S&THex v1.0 Jan 2003

First Release

Copyright 2011 Khaled Aljundi WeBBusterZ Engineering Software

http://www.webbusterz.com

http://www.webbusterz.net

8

License Agreement

Use of SHELL & TUBE HEAT EXCHANGER DESIGN [S&THex] (This SOFTWARE) is contingent on your

agreement to the following terms:

1. GRANT OF LICENSE

The AUTHOR of this SOFTWARE (Khaled Aljundi) and WeBBusterZ Engineering Software

(WeBBusterZ or webbusterz.com/webbusterz.net/webbusterz.co.uk), grants you a limited, non-

exclusive license to use the SOFTWARE if you have purchased a copy or obtained the demo version.

2. DISCLAIMER:

While reasonable care has been exercised in the collection of data and testing of this software,

WeBBusterZ Engineering Software (WeBBusterZ or

webbusterz.com/webbusterz.net/webbusterz.co.uk) and Khaled Aljundi (the AUTHOR of this

software) disclaims any warranty, expressed or implied, as to the accuracy or reliability of the data

or calculations contained therein.

The physical properties obtained from this software yield approximate results, which will not always

be suitable for every application. The software is designed for use by trained professional personnel

and is not a substitute for sound professional judgment. It is the sole responsibility of the user to

validate the data presented by this software and to determine whether the results are accurate and

suitable for any specific purpose. No guarantee of accuracy or fitness for any purpose is expressed or

implied. WeBBusterZ strongly recommends that the data be checked against other sources and/or

methods before use and application.

THE SOFTWARE IS PROVIDED AS IS WITHOUT WARRANTY OF ANY KIND. TO THE MAXIMUM EXTENT

PERMITTED BY APPLICABLE LAW, (WeBBusterZ or

webbusterz.com/webbusterz.net/webbusterz.co.uk) AND THE AUTHOR FURTHER DISCLAIMS ALL

WARRANTIES, INCLUDING WITHOUT LIMITATION ANY IMPLIED WARRANTIES OF MERCHANTABILITY,

FITNESS FOR A PARTICULAR PURPOSE, AND NON INFRINGEMENT. THE ENTIRE RISK ARISING OUT OF

THE USE OR PERFORMANCE OF THE PRODUCT AND DOCUMENTATION REMAINS WITH RECIPIENT.

TO THE MAXIMUM EXTENT PERMITTED BY APPLICABLE LAW, IN NO EVENT SHALL (WeBBusterZ or

webbusterz.com/webbusterz.net/webbusterz.co.uk) OR THE AUTHOR BE LIABLE FOR ANY

CONSEQUENTIAL, INCIDENTAL, DIRECT, INDIRECT, SPECIAL, PUNITIVE, OR OTHER DAMAGES

WHATSOEVER (INCLUDING, WITHOUT LIMITATION, DAMAGES FOR LOSS OF BUSINESS PROFITS,

BUSINESS INTERRUPTION, LOSS OF BUSINESS INFORMATION, OR OTHER PECUNIARY LOSS) ARISING

OUT OF THIS AGREEMENT OR THE USE OF OR INABILITY TO USE THE PRODUCT, EVEN IF (WeBBusterZ

or webbusterz.com/webbusterz.net/webbusterz.co.uk) AND THE AUTHOR HAS BEEN ADVISED OF

THE POSSIBILITY OF SUCH DAMAGES THE SOFTWARE IS PROVIDED AS IS WITHOUT WARRANTY OF

ANY KIND. TO THE MAXIMUM EXTENT PERMITTED BY APPLICABLE LAW, (WeBBusterZ or

webbusterz.com/webbusterz.net/webbusterz.co.uk) AND THE AUTHOR FURTHER DISCLAIMS ALL

WARRANTIES, INCLUDING WITHOUT LIMITATION ANY IMPLIED WARRANTIES OF MERCHANTABILITY,

FITNESS FOR A PARTICULAR PURPOSE, AND NON INFRINGEMENT. THE ENTIRE RISK ARISING OUT OF

THE USE OR PERFORMANCE OF THE PRODUCT AND DOCUMENTATION REMAINS WITH RECIPIENT.

TO THE MAXIMUM EXTENT PERMITTED BY APPLICABLE LAW, IN NO EVENT SHALL (WeBBusterZ or

webbusterz.com/webbusterz.net/webbusterz.co.uk) OR THE AUTHOR BE LIABLE FOR ANY

CONSEQUENTIAL, INCIDENTAL, DIRECT, INDIRECT, SPECIAL, PUNITIVE, OR OTHER DAMAGES

WHATSOEVER (INCLUDING, WITHOUT LIMITATION, DAMAGES FOR LOSS OF BUSINESS PROFITS,

BUSINESS INTERRUPTION, LOSS OF BUSINESS INFORMATION, OR OTHER PECUNIARY LOSS) ARISING

OUT OF THIS AGREEMENT OR THE USE OF OR INABILITY TO USE THE PRODUCT, EVEN IF (WeBBusterZ

or webbusterz.com/webbusterz.net/webbusterz.co.uk) AND THE AUTHOR HAS BEEN ADVISED OF

THE POSSIBILITY OF SUCH DAMAGES

Copyright 2011 Khaled Aljundi WeBBusterZ Engineering Software

http://www.webbusterz.com

http://www.webbusterz.net

9

LICENSE:

3. SCOPE OF GRANT

You may not reverse engineer, decompile or disassemble the SOFTWARE. WeBBusterZ and the

AUTHOR shall retain title and all ownership rights to the SOFTWARE.

4. COPYRIGHT

This SOFTWARE is protected by copyright laws and international copyright

treaties, as well as other intellectual property laws and treaties.

5. MAINTENANCE

WeBBusterZ and the AUTHOR are not obligated to provide maintenance or updates for the

SOFTWARE. However, any maintenance or updates provided by WeBBusterZ and the AUTHOR shall

be covered by this Agreement.

6. DISTRIBUTION

The Demo version of this SOFTWARE may be freely distributed provided that it is not modified and

the original archive remains intact with all accompanying files, and provided that no fee is charged.

Should a fee be charged or any of the distribution

package need to be modified you must contact WEBBUSTERZ for explicit written permission.

YOU MUST AGREE TO AND ACCEPT THESE TERMS IF YOU WISH TO USE THIS SOFTWARE

Copyright 2011 Khaled Aljundi WeBBusterZ Engineering Software

http://www.webbusterz.com

http://www.webbusterz.net

10

System Requirements

S&THex needs the following computer configuration to run:

Microsoft Windows operating system.

64MB RAM;

30MB free disk space;

.Net Framework

Tested Windows XP, Windows Vista & Windows 7.

Acknowledgements

1. Standards of Tubular Exchanger Manufacturers Association, 6th Edition, TEMA Incorporated,

Tarry town, Newyork, 1978

2. Sinnott, R.K., Coulson and Richardson's Chemical Engineering Design, Vol. 6 , Third edition,

Butterworth-Heinemann

3. D. Q. Kern, Process Heat Transfer, McGraw-Hill, International Edition, 19504

Software Support

The support provided with this software is limited to NON Technical software issues. Please only

contact us if you would like to report a software bug or problem.

It is highly recommended that you test the demo version of this software before purchasing the full

version.

Copyright 2011 Khaled Aljundi WeBBusterZ Engineering Software

http://www.webbusterz.com

http://www.webbusterz.net

11

Main Screen

This will guide you through how to use the software, and how to avoid errors.

S&THex is easy to use as long as you follow the instructions provided in this document:

All calculations performed and screen captured are for demonstration

purpose only and

shouldn't be used as a reference. Many screens have been modified due to

upgrades to newer version.

The software currently supports two units of measurement; S.I units and English (U.S) units.

The software will use S.I units as default units. Before proceeding to do any analysis you

must set the units of measurement.

You have now different options to proceed.

1. You can load components from your user database.

Copyright 2011 Khaled Aljundi WeBBusterZ Engineering Software

http://www.webbusterz.com

http://www.webbusterz.net

12

2. You can load components from the software database

3. You can enter components to the software manually

To load components from your user database, point to Database located at the top menu

then select User. Your components are located under Components.

To load components from the software database (contains 1495 components) click on the

button labelled Estimation or simple point your cursor to Database and select

Software.

If you are entering the data manually, click on the button labelled Start

Design Mode

Tool bar

From the left

1. New - This button will clear all text boxes for a new project.

2. Open- Load your saved project

3. Save - save your project

4. Back to main - The arrow will show the software main screen

5. Import an XML format file or a physical properties file

6. Import from Microsoft Excel

7. Help - This will access this help file.

8. Steps Navigation - Will show the window below.

All buttons are numbered and must be clicked in order to avoid errors.

Copyright 2011 Khaled Aljundi WeBBusterZ Engineering Software

http://www.webbusterz.com

http://www.webbusterz.net

13

Step 1

1. Enter Shell/Tube side components

2. Select physical state

3. Temperatures, units - 'C, 'K if using SI units in this case.

4. Only one check box from either the Shell side or Tube side can be checked - this will

allow for the Temperature prediction! - You can only ask the software to estimate only

one temperature on both shell/tube sides.

5. Enter Flow rate - in kg/hr or m3/hr

6. Only one check box from either the Shell side or Tube side can be checked if you want to

calculate an unknown flow rate.

7. Click the "Done" button.

Copyright 2011 Khaled Aljundi WeBBusterZ Engineering Software

http://www.webbusterz.com

http://www.webbusterz.net

14

Step 2

1. Enter ALL values

2. You can check the checkboxes to calculate Prandtl Number.

3. If you have e.g. Steam then you must check the checkbox to enter the Specific Enthalpy

Copyright 2011 Khaled Aljundi WeBBusterZ Engineering Software

http://www.webbusterz.com

http://www.webbusterz.net

15

Step 3

1. Click the "Calculate" button to calculate the duty

2. Enter assumed Uo value - this can also be obtained from Uo database by clicking "Open

Database"

3. This will show as below - every entry you select will be automatically aligned to the opposite one

in the database.

Copyright 2011 Khaled Aljundi WeBBusterZ Engineering Software

http://www.webbusterz.com

http://www.webbusterz.net

16

Step 4

Copyright 2011 Khaled Aljundi WeBBusterZ Engineering Software

http://www.webbusterz.com

http://www.webbusterz.net

17

1. Enter the Shell Diameter - Values can be found from literature. However the Shell

Diameter (Ds) and the Bundle Diameter (Db) can be estimated if the check box is

checked the screen below would appear. You can adjust the clearance value by checking

the "adjust clearance check box" then enter the clearance value and click the "adjust

button", click the "Back button" to send the Ds value to the main screen.

2. Click "Done" button

3. If you click on "Standard pipe sizes" the screen below will appear, you can also find the

sizes you need if you are using fixed tube sheet heat exchanger

The tube counts for this can be found if you go to the main screen then click on "Tube

counts"

Step 5

Copyright 2011 Khaled Aljundi WeBBusterZ Engineering Software

http://www.webbusterz.com

http://www.webbusterz.net

18

1. Select Flow profile then click "Calculate" button

2. Select to either enter or estimate the true temperature correction factor then click "Calculate"

button

Step 6

1. Calculate the Heat Transfer Area

2. Also in some cases if any of the checkboxes in step1 was checked for estimating the Flow rate,

then another "Calculate" button will appear for this purpose as shown below

Copyright 2011 Khaled Aljundi WeBBusterZ Engineering Software

http://www.webbusterz.com

http://www.webbusterz.net

19

Step 7

1. All you need to do here is to click on the calculate button.

2. A check box to adjust the Number of Tubes will appear.

3. Adjust the Number of Tubes and click on the Calculate button again to re-calculate the

Copyright 2011 Khaled Aljundi WeBBusterZ Engineering Software

http://www.webbusterz.com

http://www.webbusterz.net

20

rest of the information.

4. When you click the Calculate button the screen below will also popup - Click on calculate

to calculate the shell diameter (you can choose to adjust the clearance value by checking

the check box and entering the new value then click on Adjust button

5. If the Checkbox for estimating the initial Design Overall Coefficient (Ud), the screen

below will appear - Click the "Calculate" button to estimate.

Note: The Ud estimation must be completed in order to enable the estimation of the dirt

factor in later step.

Copyright 2011 Khaled Aljundi WeBBusterZ Engineering Software

http://www.webbusterz.com

http://www.webbusterz.net

21

Step 8

1. Click the "Calculate" buttons in order

2. When Correlation Screen appears select the correlation.

o First decide if you are ignoring the viscosity at wall or no - if it's ignored then check the

checkbox provided.

o For this case - Check the checkbox to calculate the Jh (heat transfer factor) - You can

also select to enter the Nusselt number if you prefer

o Click "Done" to go back to Step 8 Screen and calculate the Heat transfer coefficient

Copyright 2011 Khaled Aljundi WeBBusterZ Engineering Software

http://www.webbusterz.com

http://www.webbusterz.net

22

Copyright 2011 Khaled Aljundi WeBBusterZ Engineering Software

http://www.webbusterz.com

http://www.webbusterz.net

23

Step 9

1. Select the Baffle cut and Type then click on the Done button to calculate the Cut.

2. Baffle diameter can be estimated after select (Pipe or Plate Shells).

3. You can edit the Baffle diameter value by checking the check box to edit the clearance,

enter the value then click the "Calculate button" to calculate the Baffle diameter.

Copyright 2011 Khaled Aljundi WeBBusterZ Engineering Software

http://www.webbusterz.com

http://www.webbusterz.net

24

Step 10

1. Select a correlation to enable the calculation of the Heat Transfer Coefficient.

2. The same procedure will apply for the correlation screen below

Copyright 2011 Khaled Aljundi WeBBusterZ Engineering Software

http://www.webbusterz.com

http://www.webbusterz.net

25

3. You can estimate the Scale resistance or Dirt factor. A screen like the one below will

appear.

Copyright 2011 Khaled Aljundi WeBBusterZ Engineering Software

http://www.webbusterz.com

http://www.webbusterz.net

26

Step 11

Enter the material of construction and the thermal conductivity then click calculate.

Copyright 2011 Khaled Aljundi WeBBusterZ Engineering Software

http://www.webbusterz.com

http://www.webbusterz.net

27

Step 12

1. Jf is a dimensionless friction factor (the same as the friction factor for pipes) and can be

obtained from literature (e.g. Reynolds number vs. Jf Charts).

2. Enter Jf and click the Calculate button.

Note: Shell & Tube sides Nozzles pressure drop can be estimated by checking the check

boxes provided. The screens below would appear.

3. Clicking on the other data button; will enable you to calculate (tube holes in baffles

diameter, shell thickness, number of tie rods & diameter and baffle plate thickness). The

estimations only are in fact recommendations based on TEMA Standards, so please check

with the manufacturers for accuracy. The screen for "other data" can be seen below

Copyright 2011 Khaled Aljundi WeBBusterZ Engineering Software

http://www.webbusterz.com

http://www.webbusterz.net

28

Copyright 2011 Khaled Aljundi WeBBusterZ Engineering Software

http://www.webbusterz.com

http://www.webbusterz.net

29

Pumping Power can also be calculated for fluids only

Step 13

This Part of the software will only do some basic mechanical calculations

After filling in all the data required the results button must be clicked to see the results.

Copyright 2011 Khaled Aljundi WeBBusterZ Engineering Software

http://www.webbusterz.com

http://www.webbusterz.net

30

Results screens

Click the calculate button to show all answers

Because the screen below only makes recommendations, if your Ds value is < 6 in the

software won't be able to generate the results.

Copyright 2011 Khaled Aljundi WeBBusterZ Engineering Software

http://www.webbusterz.com

http://www.webbusterz.net

31

Copyright 2011 Khaled Aljundi WeBBusterZ Engineering Software

http://www.webbusterz.com

http://www.webbusterz.net

32

Summary

For Engineering data sheet please click here

1. Note that every time you make a change to any entry in the problem specification you

need to re-click the show button and scroll down to the new set of results

2. The summary also can be seen with only basic Graphical illustration, other CAD or

drawing packages should be used for more accurate illustrations.

Copyright 2011 Khaled Aljundi WeBBusterZ Engineering Software

http://www.webbusterz.com

http://www.webbusterz.net

33

Copyright 2011 Khaled Aljundi WeBBusterZ Engineering Software

http://www.webbusterz.com

http://www.webbusterz.net

34

Temperature Prediction

1. Your first Specific heat capacity value is filled in by the software

2. Click the Calculate button to calculate the first trial

3. Use the average temperature generated for the second trial to obtain the Specific Heat Capacity

for the second trial.

4. Click the "Calculate" button to calculate the Temperature.

5. Follow steps 3 and 4 except that you will use the average temperature generated for the third trial

to obtain the Specific Heat Capacity value.

6. when you decide to stop, check the checkbox opposite to the trial number, then click the "Done"

button to continue.

Copyright 2011 Khaled Aljundi WeBBusterZ Engineering Software

http://www.webbusterz.com

http://www.webbusterz.net

35

Rating Mode

Fluids Rating only!

The software will present you with 9 steps, the first 4 are intended to add the rating problem data, the

last 4 are the rating calculations.

Step 1

Enter all data in step 1

To change the temperature from "'C" to "'K" in SI measurement units you must check the check

box

Click step 2 to continue

Copyright 2011 Khaled Aljundi WeBBusterZ Engineering Software

http://www.webbusterz.com

http://www.webbusterz.net

36

Step 2

Enter all physical properties details

Prandtl number can be calculated by checking the check box provided

Copyright 2011 Khaled Aljundi WeBBusterZ Engineering Software

http://www.webbusterz.com

http://www.webbusterz.net

37

Step 3

Select flow arrangement

You can choose to calculate the area or duty however since this is rating of existing heat

exchanger it's always better to have all such information available at hand, this will help in

producing better results

Thermal conductivity value for materials of constructions are available in literature

Copyright 2011 Khaled Aljundi WeBBusterZ Engineering Software

http://www.webbusterz.com

http://www.webbusterz.net

38

Step 4

Enter exchanger layout and type

Enter Tube details then click "1- Done" button - this will calculate the inside diameter

Clicking on the "Standard pipe sizes" to show the pipe sizes database

Enter Shell diameter

Step 5

Enter all baffle information

Copyright 2011 Khaled Aljundi WeBBusterZ Engineering Software

http://www.webbusterz.com

http://www.webbusterz.net

39

Step 6

This is the tube side rating calculation screen - You must click the buttons in order

Before clicking on "3- Calculate" button the check box must be checked to use a correlation to

calculate Nusselt number

Copyright 2011 Khaled Aljundi WeBBusterZ Engineering Software

http://www.webbusterz.com

http://www.webbusterz.net

40

Step 7

This is the shell side rating calculation screen

Before clicking on "4- Calculate" button the check box must be checked to use a correlation to

calculate nusselt number

Step 8

The results screen below is revealed after clicking of the Calculate button present in step 7

Copyright 2011 Khaled Aljundi WeBBusterZ Engineering Software

http://www.webbusterz.com

http://www.webbusterz.net

41

Step 9

This is the final step to calculate the pressure drops, this step also account for the inlet and exit

losses

Copyright 2011 Khaled Aljundi WeBBusterZ Engineering Software

http://www.webbusterz.com

http://www.webbusterz.net

42

Summary

Summary screen - Click the "Show" button to show thee summary of results

If you make changes to the results you will need to click on the "Show" button again and scroll

down to the new set of results

Copyright 2011 Khaled Aljundi WeBBusterZ Engineering Software

http://www.webbusterz.com

http://www.webbusterz.net

43

Engineering Data sheet

The software can also generate an engineering data sheet that includes a summary of Rating /

Design.

On the summary screen the button below will allow you to export to a data sheet

When you click the button you will be presented with the screen below where you can type in any

extra information before you generate the data sheet

The datasheet can be generated and exported directly to Ms Excel or can be generated and

previewed as a report before exporting to Ms Excel

The data sheet should look as shown in the screen below. You have the ability to save the data

sheet as a pdf file or export it to Ms Excel for editing. You can also print the data sheet, all options

are explored below

Copyright 2011 Khaled Aljundi WeBBusterZ Engineering Software

http://www.webbusterz.com

http://www.webbusterz.net

44

Zoom in/out Export html

format

Copyright 2011 Khaled Aljundi WeBBusterZ Engineering Software

http://www.webbusterz.com

http://www.webbusterz.net

45

The Ms Excel should look the same as above see below

Copyright 2011 Khaled Aljundi WeBBusterZ Engineering Software

http://www.webbusterz.com

http://www.webbusterz.net

46

Copyright 2011 Khaled Aljundi WeBBusterZ Engineering Software

http://www.webbusterz.com

http://www.webbusterz.net

47

Databases

The software offers a collection of databases for your own convenience, the screen below can

be accessed via the main screen buy clicking on the button or

Please note: all estimation techniques will sometimes result in error factor. Professional

judgment should be exercised with reference to all estimation made. We recommend

checking properties against a literature source if in doubt.

For Mixture Estimation - The following limitations apply:

o Mixture Viscosity is only valid for Organic liquids only,

o Mixture Thermal Conductivity only valid for non polar liquids only

Copyright 2011 Khaled Aljundi WeBBusterZ Engineering Software

http://www.webbusterz.com

http://www.webbusterz.net

48

User Database

All data are stored in sthex.mdb file and this can file can also be accessed from Microsoft

Access. if you prefer.

Components

The database function is to help in saving you time through projects. All you need to do is

enter the component and its physical properties. When you are done, add the component. As

you progress through adding the components you can load any component to any side (i.e.

Hot or Cold side) by clicking the appropriate button.

Before loading any component always make sure that you have selected the correct units of

measurements from the software's main screen. This is simply to avoid conflicts between

units of measurements.

Edit, Delete Refresh, Find, Filter, Sort ....etc.

All above mentioned are there for your convenience and they can be used as you add more items to

the software.

Copyright 2011 Khaled Aljundi WeBBusterZ Engineering Software

http://www.webbusterz.com

http://www.webbusterz.net

49

Tubes Database

The tube database has similar functions to the components database - again the most important issue

is the units,

Copyright 2011 Khaled Aljundi WeBBusterZ Engineering Software

http://www.webbusterz.com

http://www.webbusterz.net

50

Overall Heat Transfer Coefficient (Uo) Database

This database is extra, the software now have values Uo and they can be accessed from the main

screen.

The database should be used the same way as the components database, all buttons have the same

functions.

Copyright 2011 Khaled Aljundi WeBBusterZ Engineering Software

http://www.webbusterz.com

http://www.webbusterz.net

51

Software Databases

Please open the User Guide for the physical properties database provided with the Physical

properties database

Fouling Factors Database

Accessed from the main screen. It's not required to run the software in order to access this database.

You can access this from the start menu.

Copyright 2011 Khaled Aljundi WeBBusterZ Engineering Software

http://www.webbusterz.com

http://www.webbusterz.net

52

Tube Counts

Tube Counts can be accessed through the main screen,

The counts below are valid for FIXED TUBE SHEET EXCHANGERS

The database can be navigated by clicking on the "Next or Prev" buttons

If you want a copy to print out, you can click on the PDF image button to open up the pdf file in

Adobe viewer

The find button can be used to search the database, this can be performed by searching by field

Data Grid button will adjust the columns based on the longest field

You can scroll to view records Horizontally as well as Vertically

Copyright 2011 Khaled Aljundi WeBBusterZ Engineering Software

http://www.webbusterz.com

http://www.webbusterz.net

53

Overall Heat Transfer Coefficients

Can be accessed from the software during design mode or the main screen.

Copyright 2011 Khaled Aljundi WeBBusterZ Engineering Software

http://www.webbusterz.com

http://www.webbusterz.net

54

Tools

Import

The import feature is give you more flexibility. There is two ways that you can import data to the

software. When you click on the import button present on the main screen

The screen below will popup

Ms Excel

The First method is to import from Ms Excel. You must have Microsoft Excel installed on your

computer before you use this feature.

The Import wizard will allow you to import ANY values from ANY Excel Spreadsheet to the software

1. Click "Browse" to select the spreadsheet.

2. Ensure that the Sheet name is correct.

3. Specify the Cell references - only enter references as A1 or B14 ...etc. in the cell number textbox

4. Select the mode (rating mode / design mode)

5. Leave blank the cell that you don't want to use.

6. Click on the "Import" button to continue, the software will open the spreadsheet and import the

values you specified then the speadsheet will be closed, you can also do this while the

spreadsheet is open or running.

7. The software will also allow you to save the Sheet Cell numbers for future reference. To save:

1. Click on "Browse to Save"

2. Enter the name you want to save the Cell numbers under

3. Click on Save button to go back to the import screen

4. Click on the "Save" button provided to save all your values

Important: You must make sure that you are importing value with the correct measurement

units because the software will not convert your units

8. To Load your saved file:

1. Click "Browse to Open" button

2. select the saved document from the location you saved it under

3. Click "open" to go back to the import main screen

4. Click the "open" button provided to load your file.

Copyright 2011 Khaled Aljundi WeBBusterZ Engineering Software

http://www.webbusterz.com

http://www.webbusterz.net

55

Physical properties file

The second method is to import from an XML file. This file is associated with the Physical properties

database. Once you followed the instructions in physical properties user guide and generate an XML

file you will need to import it using the tool below.

Copyright 2011 Khaled Aljundi WeBBusterZ Engineering Software

http://www.webbusterz.com

http://www.webbusterz.net

56

The first step is to browse to the XML file, you will need to click on the "Browse" button then find the

XML file, the browse will usually start from the software default installation directory, so if you saved

your properties file in the same directory you it should look similar to the one below.

When you open the file all the properties you generated will appear as below

Copyright 2011 Khaled Aljundi WeBBusterZ Engineering Software

http://www.webbusterz.com

http://www.webbusterz.net

57

Select the component and the units of measurements then assign the components to

Shell/Tube/Hot/Cold side.

Then go to the main screen and continue to Step 1. All the properties should be loaded in Step 2.

Export

MS Excel

This function will only work if you have Microsoft Excel installed on your PC!

The Export wizard can only export your summary of results obtained from the summary screen not

the graphical summary.

1. Click on "Show" button to see the summary first.

2. Click on "Export" button to export your results.

Copyright 2011 Khaled Aljundi WeBBusterZ Engineering Software

http://www.webbusterz.com

http://www.webbusterz.net

58

Engineering Data sheet

For Exporting to Engineering data sheet please click here

Save/Load Project

Save Function 1

This will only save your values not your results.

Saving files

1. Enter the Project Name

2. Enter the location of the project including your file name

This can be like: C:\Program Files\webbusterz\project1.txt

Where project1.txt is the name of your project file.

3. Click "Save" button

Loading Files

1. Click "Open" to select the file (e.g. project1.txt)

2. Click "Open" button again to load your file

Save Function 2

Will save your results and values.

Saving files

1. Click "Browse to save" button - and type in the name of your project

2. Click "save" to go back to saving screen

3. Click "Save" button on saving screen to save.

Loading files

1. Click "Browse to open" button - this button will be enabled when you select "open" from the file

menu on the main screen.

2. Select your file e.g. project1.dat

3. Click "open" to go back.

4. Click "Open" button to load your project.

Copyright 2011 Khaled Aljundi WeBBusterZ Engineering Software

http://www.webbusterz.com

http://www.webbusterz.net

59

Test Software

This is the best way to gain some practice before running the software: You can also view the online

demo video.

To load a test file do the following:

1. In the main screen set the measurement units first

2. Select "Open" from the main screen file menu, you can choose from opening a rating file or

design file

3. Click on the "open file" button located at Save function frame

4. You can select either the SI units test file or the US English units file

5. Click the "open" button again

6. You must go through the steps accordingly and click all the "Done" and "Calculate buttons in

order.

Copyright 2011 Khaled Aljundi WeBBusterZ Engineering Software

http://www.webbusterz.com

http://www.webbusterz.net

60

Troubleshooting Errors

Errors that may occur and how to handle them

Division by zero

This error may occur under different conditions, if this error occur while thermal calculations

are performed then check the figures you entered in to the data entry screens. It's more likely

that you forgot to enter a figure or you entered an incorrect figure format.

Make sure that all your text boxes are filled correctly and you are clicking all buttons in

order.

Click on Calculate button and the results given is Zero

Try to close the screen then reload it again and click the calculate button, this method will

refresh the software controls.

Вам также может понравиться

- Administrator's Guide To VMware Virtual SANДокумент63 страницыAdministrator's Guide To VMware Virtual SANHoang KhuyenОценок пока нет

- Cisco CCNA/CCENT Exam 640-802, 640-822, 640-816 Preparation KitОт EverandCisco CCNA/CCENT Exam 640-802, 640-822, 640-816 Preparation KitРейтинг: 2.5 из 5 звезд2.5/5 (8)

- Admin Guide Cloud PDFДокумент370 страницAdmin Guide Cloud PDFsrisylamОценок пока нет

- Fujitsu M12 Server Installation Specialist Online AssessmentДокумент60 страницFujitsu M12 Server Installation Specialist Online AssessmentTitus Kernel Maestria100% (1)

- Vxworks BSP Developers Guide 6.0Документ189 страницVxworks BSP Developers Guide 6.0finiОценок пока нет

- NetWorker 19.3 Installation GuideДокумент134 страницыNetWorker 19.3 Installation Guideasma merzouguiОценок пока нет

- Microsoft Windows Server 2008 R2 Administrator's Reference: The Administrator's Essential ReferenceОт EverandMicrosoft Windows Server 2008 R2 Administrator's Reference: The Administrator's Essential ReferenceРейтинг: 4.5 из 5 звезд4.5/5 (3)

- Advantech CODESYS User ManualДокумент132 страницыAdvantech CODESYS User Manualamiry1373Оценок пока нет

- Implementing 802.11, 802.16, and 802.20 Wireless Networks: Planning, Troubleshooting, and OperationsОт EverandImplementing 802.11, 802.16, and 802.20 Wireless Networks: Planning, Troubleshooting, and OperationsРейтинг: 4.5 из 5 звезд4.5/5 (2)

- OpenStack Installation Guide For (RHEL, CentOS, Fedora)Документ140 страницOpenStack Installation Guide For (RHEL, CentOS, Fedora)kinamedebo100% (1)

- Cortex Xpanse User GuideДокумент156 страницCortex Xpanse User Guidemrbiggs43Оценок пока нет

- CCNA Practical Cisco RoutersДокумент400 страницCCNA Practical Cisco RoutersDo Hieu93% (14)

- Grade 10 DLPДокумент5 страницGrade 10 DLPlhuk banaag100% (1)

- Firebird Developer Guide Beta Delphi FiredacДокумент162 страницыFirebird Developer Guide Beta Delphi FiredacDanilo CristianoОценок пока нет

- Instructions For CX ProgrammerДокумент1 403 страницыInstructions For CX Programmergustavoxr650Оценок пока нет

- NetX Studio CDT - NetX 90 Development GS 08 enДокумент220 страницNetX Studio CDT - NetX 90 Development GS 08 enshrutiОценок пока нет

- Database Design DocumentДокумент22 страницыDatabase Design DocumentOSCAR ALBERTO CHUMPITAZ PERALTAОценок пока нет

- Dspace System DocumentationДокумент111 страницDspace System DocumentationRaquel FerreiraОценок пока нет

- Ftac gr002 - en eДокумент110 страницFtac gr002 - en eCarlos Andres Morales PovedaОценок пока нет

- Cdhde Ethercat Fw2.1.x Rev.0.0.1-EnДокумент255 страницCdhde Ethercat Fw2.1.x Rev.0.0.1-Enpham linhОценок пока нет

- NW P Security Config Guide 19 9 en UsДокумент150 страницNW P Security Config Guide 19 9 en Us김명규Оценок пока нет

- Taopix Technical Requirements 2015r1 27 Feb 2015Документ31 страницаTaopix Technical Requirements 2015r1 27 Feb 2015Fernando CarneiroОценок пока нет

- DcproДокумент76 страницDcproȘtefania FloreaОценок пока нет

- Odi Best Practices Data Warehouse WhitepaperДокумент219 страницOdi Best Practices Data Warehouse WhitepaperArvinder SinghОценок пока нет

- EZConvert 6 UGДокумент440 страницEZConvert 6 UGanonøs NonasøОценок пока нет

- KofaxAnalyticsForCaptureAdministratorsGuide ENДокумент209 страницKofaxAnalyticsForCaptureAdministratorsGuide ENpatelhaОценок пока нет

- Factorytalk Assetcentre Getting Results GuideДокумент112 страницFactorytalk Assetcentre Getting Results GuideKracinОценок пока нет

- Docu91467 - VxRail Appliance Software 4.7.x Release Notes Rev36Документ71 страницаDocu91467 - VxRail Appliance Software 4.7.x Release Notes Rev36phongnkОценок пока нет

- Shell & Tube Heat Exchanger Design: Help FileДокумент60 страницShell & Tube Heat Exchanger Design: Help FilePriti Manoj PatilОценок пока нет

- Storagetek sl3000Документ166 страницStoragetek sl3000Gabriel Sánchez BriceñoОценок пока нет

- Oracle® Real-Time Decisions: Platform Developer's Guide Release 3.2Документ326 страницOracle® Real-Time Decisions: Platform Developer's Guide Release 3.2Papas FoodsОценок пока нет

- Factory Suite ManualДокумент116 страницFactory Suite ManualLuis Angel0% (1)

- I O Server Toolkit User's GuideДокумент350 страницI O Server Toolkit User's GuideJayModiОценок пока нет

- Wonderware I O Server Toolkit User's GuideДокумент350 страницWonderware I O Server Toolkit User's GuideWarwick AudetОценок пока нет

- I O Server Toolkit User's GuideДокумент350 страницI O Server Toolkit User's GuideAnonymous fGks5Kpz3SОценок пока нет

- EmbeddedStudio ManualДокумент440 страницEmbeddedStudio ManualJames NelsonОценок пока нет

- www.cypress.com -Документ109 страницwww.cypress.com -Mohsin Shaheer AliОценок пока нет

- Oracle Fusion Middleware Developer GuideДокумент1 422 страницыOracle Fusion Middleware Developer GuideahsunОценок пока нет

- Cell I Cad B Anywhere Server User GuideДокумент144 страницыCell I Cad B Anywhere Server User GuideLarreinetaОценок пока нет

- Ecomat 100 Mobile Cr0301Документ213 страницEcomat 100 Mobile Cr0301mario kostovОценок пока нет

- Readynas Os 6.2: Software ManualДокумент241 страницаReadynas Os 6.2: Software ManualLA-ZOUBE GAELОценок пока нет

- PacketFence Administration Guide-4.2.0Документ106 страницPacketFence Administration Guide-4.2.0angelo68000Оценок пока нет

- Altibase 7.1.0 GettingStarted Eng PDFДокумент84 страницыAltibase 7.1.0 GettingStarted Eng PDFddoruОценок пока нет

- DLive Firmware Reference Guide V1.9 2Документ141 страницаDLive Firmware Reference Guide V1.9 2elix.guidettiОценок пока нет

- 47 - Migration Workbench Reference Guide For Microsoft Access 2Документ88 страниц47 - Migration Workbench Reference Guide For Microsoft Access 2api-3702030100% (1)

- Packetfence Administration Guide: For Version 4.3.0Документ117 страницPacketfence Administration Guide: For Version 4.3.0MedAyhem KhОценок пока нет

- Postgresql 14 New Features With Examples (Beta 1)Документ86 страницPostgresql 14 New Features With Examples (Beta 1)KoushikKc ChatterjeeОценок пока нет

- Oracle® Application Server Installation GuideДокумент272 страницыOracle® Application Server Installation GuideManilka DiasОценок пока нет

- CodeVisionAVR User Manual PDFДокумент650 страницCodeVisionAVR User Manual PDFRiski FОценок пока нет

- Spru 523 KДокумент66 страницSpru 523 KMehmetОценок пока нет

- Oracle BeehiveДокумент340 страницOracle BeehiveNagendraОценок пока нет

- Hds Sms 100 Userguide enДокумент100 страницHds Sms 100 Userguide enmageshpattОценок пока нет

- EM 13c2 LifeCycle Management LCMДокумент1 276 страницEM 13c2 LifeCycle Management LCMvikОценок пока нет

- RegistryДокумент689 страницRegistryPrashant PrakashОценок пока нет

- Wonderware: Abtcp Daserver User'S GuideДокумент124 страницыWonderware: Abtcp Daserver User'S GuideHenry MoralesОценок пока нет

- Ether Net IPДокумент91 страницаEther Net IPعثمان الاغبزيОценок пока нет

- Data Exchange Wizard User ManualДокумент59 страницData Exchange Wizard User Manualglov11Оценок пока нет

- Intel Pentium 4 Processor 6x1 Sequence: DatasheetДокумент108 страницIntel Pentium 4 Processor 6x1 Sequence: DatasheetjjoaquimmartinsОценок пока нет

- Web Application and Web Services: Microsoft ConfidentialДокумент31 страницаWeb Application and Web Services: Microsoft ConfidentialJake CОценок пока нет

- Dell Emc Ready Architecture For Red Hat Hci Architecture GuideДокумент100 страницDell Emc Ready Architecture For Red Hat Hci Architecture GuideJosetheking CrackedsoftwaresОценок пока нет

- XST v6s6Документ483 страницыXST v6s6Konna_MОценок пока нет

- QSK60 Spec SheetДокумент6 страницQSK60 Spec Sheetbacuoc.nguyen356Оценок пока нет

- 2012-11!14!1 Jayacom InformationДокумент2 страницы2012-11!14!1 Jayacom InformationAl Attar FaizalrudinОценок пока нет

- Nand 2 Nor 2Документ19 страницNand 2 Nor 2Nagendra BoyellaОценок пока нет

- Case StudyДокумент33 страницыCase Studymarjory albertoОценок пока нет

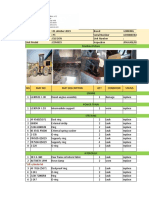

- PRS Lonking 833 CilegonДокумент4 страницыPRS Lonking 833 CilegonIrawan Budi SantosaОценок пока нет

- CRS328-24P-4S+RM - 28 Port 1GbE Switch with 24 PoE+ PortsДокумент2 страницыCRS328-24P-4S+RM - 28 Port 1GbE Switch with 24 PoE+ Portsargame azkaОценок пока нет

- Lab ManДокумент33 страницыLab Manapi-3693527Оценок пока нет

- Survey Batimetri Air Laut ProposalДокумент3 страницыSurvey Batimetri Air Laut ProposalMuh AnsariОценок пока нет

- Debugger PCPДокумент54 страницыDebugger PCPcarver_uaОценок пока нет

- W510tu EsmДокумент86 страницW510tu Esmselçuk avcıОценок пока нет

- Pending Call Report 09-02-2023Документ8 страницPending Call Report 09-02-2023ajay kannaujiaОценок пока нет

- Personal Driver Assistance System (PDAS) Based On Raspberry PiДокумент6 страницPersonal Driver Assistance System (PDAS) Based On Raspberry PierpublicationОценок пока нет

- Pumplab Operator'S ManualДокумент24 страницыPumplab Operator'S ManualMurad AlamОценок пока нет

- Support search-as-you-type queries using SQLДокумент15 страницSupport search-as-you-type queries using SQLAjay TaradeОценок пока нет

- CV Resume Word Template 552Документ1 страницаCV Resume Word Template 552Fabrisio NathanielОценок пока нет

- 2-IAS computer-05-Aug-2021Material - I - 05-Aug-2021 - IAS - COMPUTERДокумент14 страниц2-IAS computer-05-Aug-2021Material - I - 05-Aug-2021 - IAS - COMPUTERKONDETI NIKITHAОценок пока нет

- Tecnotion TBW Series SpecsheetДокумент2 страницыTecnotion TBW Series SpecsheetElectromateОценок пока нет

- Logging Levels and LoggersДокумент14 страницLogging Levels and LoggersAcsh SharmaОценок пока нет

- Dot Hill Assured San 24xx4-Fig-Guide-3q15-FinalДокумент44 страницыDot Hill Assured San 24xx4-Fig-Guide-3q15-FinalRichard WoodОценок пока нет

- DRV Dev IntroДокумент57 страницDRV Dev IntroĐinh LuậnОценок пока нет

- Unix Commands Cheat SheetДокумент6 страницUnix Commands Cheat SheetakdenizerdemОценок пока нет

- GigaSPEED X10D FTP Solution Guide PDFДокумент13 страницGigaSPEED X10D FTP Solution Guide PDFErick Requiz de la CruzОценок пока нет

- Compact Scalable System OverviewДокумент51 страницаCompact Scalable System OverviewmosaababbasОценок пока нет

- My Collection NET Framework 4Документ184 страницыMy Collection NET Framework 4geko1Оценок пока нет