Академический Документы

Профессиональный Документы

Культура Документы

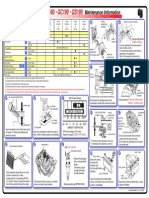

Cilindro C Gas Plus

Загружено:

Justo Paniagua ChampaИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Cilindro C Gas Plus

Загружено:

Justo Paniagua ChampaАвторское право:

Доступные форматы

001-028 Cylinder Liner

Table of Contents

Preparatory Steps

TOC

Preparatory Steps

Initial Check

Remove

Clean and Inspect for Reuse

Install

Finishing Steps

WARNING

Batteries can emit explosive gases. To reduce the possibility of personal

injury, always ventilate the compartment before servicing the batteries. To

reduce the possibility of arcing, remove the negative (-) battery cable first

and attach the negative (-) battery cable last.

WARNING

Do not remove the pressure cap from a hot engine. Wait until the coolant

temperature is below 50C [120F] before removing the pressure cap.

Heated coolant spray or steam can cause personal injury.

WARNING

Coolant is toxic. Keep away from children and pets. If not reused, dispose

of in accordance with local environmental regulations.

SMALL | MEDIUM | LARGE

Next

WARNING

This component or assembly weighs greater than 23 kg [50 lb]. To prevent

serious personal injury, be sure to have assistance or use appropriate

lifting equipment to lift this component or assembly.

WARNING

To reduce the possibility of personal injury, avoid direct contact of hot oil

with your skin.

WARNING

Some state and federal agencies have determined that used engine oil can

be carcinogenic and cause reproductive toxicity. Avoid inhalation of

vapors, ingestion, and prolonged contact with used engine oil. If not

reused, dispose of in accordance with local environmental regulations.

Close the fuel supply valve. Refer to the OEM instructions.

Disconnect the batteries. Refer to Procedure 013-009 in Section 13.

Drain the cooling system. Refer to Procedure 008-018 in Section 8.

Remove the cylinder head. FUse the following procedure for C Series

diesel engines. Refer to Procedure 002-004 in Section 2.

Drain the lubricating oil. Refer to Procedure 007-037 in Section 7.

Remove the lubricating oil pan. Refer to Procedure 007-025 in

Section 7.

Remove the piston and connecting rod assemblies. Refer to Procedure

001-043 in Section 1.

Initial Check

TOC

NOTE: Before removing the cylinder liners, inspect the condition to

determine reusability.

Inspect the inside of the liner for cracking, scuffing, or scoring.

Inspect the inside for vertical scratches deep enough to be felt with a fingernail.

NOTE: If a fingernail catches in a scratch, the liner must be replaced.

SMALL | MEDIUM | LARGE

Previous Next

Inspect the inside of the liner bore for polishing.

NOTE: A moderate polish produces a bright mirror finish in the worn

area with traces of the original hone marks or an indication of an etch

pattern.

NOTE: A heavy polish produces a bright mirror finish in the worn area

with no traces of hone marks or an etch pattern.

Do not reuse liners that have heavy polish or any indications of particle

embedment from failure.

Inspect the liners for a ridge near the top of the liner. Severely worn liners will

have a ridge near the top of the liner bore.

SMALL | MEDIUM | LARGE

Previous Next

If the wear pattern indicates the liner bore is not straight or not round, use a dial

bore gauge to measure the liner inside diameter in four places 90 degrees apart

at the top and bottom of the piston travel area.

Cylinder Liner Dimensions

mm

in

Out of Round 0.04 MAX 0.002

Taper 0.04 MAX 0.002

Bore Diameter 114.04 MAX 4.490

SMALL | MEDIUM | LARGE

Previous Next

NOTE: If the liner bore is not acceptable for reuse, it must be replaced.

Damaged liners can not be honed or deglazed. This will destroy the

crosshatch pattern needed for oil control.

NOTE: Do not remove or disturb the liner seals for liners that pass the

inspection criteria.

SMALL | MEDIUM | LARGE

Previous Next

Cylinder liner protrusion is the distance the liner protrudes above the block

face. Before removing the liners, check the protrusion, use the liner protrusion

gauge, Part Number 3823495, in the unclamped state.

Cylinder Liner Protrusion

mm

in

New Block and Liners 0.025 MIN 0.001

0.122 MAX 0.005

Used Block and Liners 0.000 MIN 0.000

0.122 MAX 0.005

New Block Used Liners 0.025 MIN 0.001

0.122 MAX 0.005

Used Block New Liners 0.000 MIN 0.000

0.122 MAX 0.005

NOTE: If the liner was installed correctly and the liner protrusion is out-

of-limits, it will be necessary to machine the counterbore and add shims to

restore to the original specifications.

SMALL | MEDIUM | LARGE

Previous Next

Remove

TOC

NOTE: Use clean shop rags to cover the crankshaft to prevent debris

from falling into the main journal area or into the connecting rod

journal oil drilling.

SMALL | MEDIUM | LARGE

Previous Next

CAUTION

The liner puller must be installed and used as described to avoid damage

to the cylinder block. The puller must not contact the block casting at

points (1), (2), (3), or (4).

Insert the cylinder liner puller, Part Number 3376015, into the top of the

cylinder block.

SMALL | MEDIUM | LARGE

Previous Next

NOTE: The liner puller must be centered on the top of the cylinder

block.

Turn the puller jackscrew clockwise to loosen the liner from the cylinder

block.

Use both hands to remove the liner.

SMALL | MEDIUM | LARGE

Previous Next

Mark the cylinder number on each liner.

SMALL | MEDIUM | LARGE

Previous Next

Clean and Inspect for Reuse

TOC

CAUTION

Do not use any abrasives in the ring travel area of the liner. The liner can

be damaged.

Use a soft wire brush or a fine fibrous abrasive pad such as Scotch-Brite

7448, Part Number 3823258, to clean the flange seating area.

SMALL | MEDIUM | LARGE

Previous Next

WARNING

When using a steam cleaner, wear safety glasses or a face shield, as well

as protective clothing. Hot steam can cause serious personal injury.

WARNING

When using solvents, acids, or alkaline materials for cleaning, follow the

manufacturer's recommendations for use. Wear goggles and protective

clothing to reduce the possibility of personal injury.

WARNING

Some solvents are flammable and toxic. Read the manufacturer's

instructions before using.

WARNING

Wear appropriate eye and face protection when using compressed air.

Flying debris and dirt can cause personal injury.

Use solvent or steam to clean the cylinder liners.

Dry the cylinder liners with compressed air.

SMALL | MEDIUM | LARGE

Previous Next

Use clean engine oil to lubricate the inside of the liners.

Allow the oil to soak in the liner for 5 to 10 minutes.

NOTE: Use lint-free paper towels to wipe the oil from the inside of the

liners.

Continue to lubricate the inside surfaces of the liners and wipe clean until the

paper towel shows no gray or black residue.

SMALL | MEDIUM | LARGE

Previous Next

Inspect the liners for cracks on the inside and outside surfaces.

SMALL | MEDIUM | LARGE

Previous Next

Inspect for cracks under the flange.

SMALL | MEDIUM | LARGE

Previous Next

Inspect the outside and seat area for excessive corrosion or pitting.

NOTE: Pits must not be more than 1.6 mm [0.06 in] deep.

Replace the liner if the pits are too deep or if the corrosion can not be

removed with Scotch-Brite 7448, Part Number 3823258.

NOTE: Cylinder liner pitting is caused by poor coolant composition.

SMALL | MEDIUM | LARGE

Refer to the Operation and Maintenance Manual, GTA8.3

CM558/CM2358, Bulletin 4021640, for coolant specifications.

Previous Next

Inspect the inside surface for vertical scratches deep enough to be felt with a

fingernail.

NOTE: If a fingernail catches in the scratch, the liner must be replaced.

Inspect the inside surface for scuffing or scoring.

SMALL | MEDIUM | LARGE

Previous Next

Inspect the inside surface for liner bore polishing.

NOTE: A moderate polish produces a bright mirror finish in the worn

area with traces of the original hone marks or an indication of an etch

pattern.

NOTE: A heavy polish produces a bright mirror finish in the worn area

with no traces of hone marks or an etch pattern.

SMALL | MEDIUM | LARGE

Previous Next

Replace the liner if:

A heavy polish is present over 20 percent of the piston ring travel

area.

Both moderate and heavy polish over 30 percent of the piston ring

travel area and one half (15 percent) is heavy polish.

SMALL | MEDIUM | LARGE

Previous Next

Measure the liner inside diameter with dial bore gauge, Part Number

3375072, in four places 90 degrees apart at the top and bottom of the piston

travel area.

Cylinder Liner Inside Diameter

mm

in

SMALL | MEDIUM | LARGE

114.00 MIN 4.488

114.04 MAX 4.490

Previous Next

Measure the outside diameter of the liner top press fit area.

Cylinder Liner Outside Diameter (Top Press Fit)

mm

in

130.938 MIN 5.1550

130.958 MAX 5.1558

SMALL | MEDIUM | LARGE

Previous Next

Measure the cylinder liner bore in the block.

Cylinder Liner Bore in Block (Press-Fit Bore)

mm

in

130.90 MIN 5.154

130.95 MAX 5.156

SMALL | MEDIUM | LARGE

Previous Next

Install

TOC

WARNING

When using solvents, acids, or alkaline materials for cleaning, follow the

manufacturer's recommendations for use. Wear goggles and protective

clothing to reduce the possibility of personal injury.

WARNING

Some solvents are flammable and toxic. Read the manufacturer's

instructions before using.

SMALL | MEDIUM | LARGE

Previous Next

Clean all deposits and debris from the sealing surfaces (A), (B), and (C). Use

Scotch-Brite 7448, Part Number 3823258, and cleaning solvent to polish

the surfaces. Due to the critical machined tolerances, care must be

taken not to remove any additional material.

If surface (C) has cracks or signs of extreme wear, the counterbore will

require machining and the installation of shims for the correct liner

protrusion.

Cylinder liner shims are available as follows:

Measurements

mm in

Cylinder Liner

Shim Thickness -

By Part Number

3924445 0.25 0.010

3924446 0.38 0.015

3924447 0.51 0.020

3924448 0.76 0.030

3924449 1.00 0.040

Use a maximum of one shim.

SMALL | MEDIUM | LARGE

Previous Next

Machine the counterbore with counterbore machining tool, Part Number

3823558; cutter plate, Part Number 3823567; and cutter bit, Part Number

3823570.

SMALL | MEDIUM | LARGE

Previous Next

WARNING

When using solvents, acid, or alkaline materials for cleaning, follow the

manufacturer's recommendations for use. Wear goggles and protective

clothing to reduce the possibility of personal injury.

WARNING

SMALL | MEDIUM | LARGE

Previous Next

Some solvents are flammable and toxic. Read the manufacturer's

instructions before using.

Clean the combustion deck with a gasket scraper or Scotch-Brite 7448, Part

Number 3823258, and solvent.

WARNING

Wear appropriate eye and face protection when using compressed air.

Flying debris and dirt can cause bodily injury.

WARNING

Some solvents are flammable and toxic. Read the manufacturer's

instructions before using.

Thoroughly flush the block with mineral spirits or cleaning solvent.

Remove the shop rags and clean the crankshaft with a cleaning solvent.

SMALL | MEDIUM | LARGE

Previous Next

Blow the cylinder bores and crankshaft dry, and wipe clean with a lint-free

cloth.

Lubricate surfaces (A) and (B) with clean engine oil.

SMALL | MEDIUM | LARGE

Previous Next

Use clean engine oil to coat the liner o-ring seals.

Install the new lubricated o-ring seals on the cylinder liners.

SMALL | MEDIUM | LARGE

Previous Next

NOTE: When reusing liners, install them in the same cylinder from

where they were removed, and rotate the liner 45 degrees (1/8 of a turn)

from their original position. When correctly installed, any liner pitting

can be positioned as illustrated so the pitted surface is rotated away from

the location where pitting occurs.

SMALL | MEDIUM | LARGE

Previous Next

Install the cylinder liners into the bore of the cylinder block, use cylinder

liner driver, Part Number ST-1229, and a leather mallet.

NOTE: If the liner does not rest on the cylinder block counterbore seat,

remove the liner. Inspect the counterbore seat and liner for nicks, burrs,

or dirt. Install the liner again.

SMALL | MEDIUM | LARGE

Previous Next

Use two cylinder head capscrews and position the two liner clamps, Part

Number 3822503, as illustrated.

Tighten the capscrews.

Torque Value: 68 n.m [50 ft-lb]

Remove the clamps and repeat this procedure until all liners have been

clamped and released.

SMALL | MEDIUM | LARGE

Previous Next

Liner protrusion is the distance the liner protrudes above the block face.

Measure the liner protrusion with the liner protrusion gauge, Part Number

3823495, at four points 90 degrees apart.

Cylinder Liner Protrusion

SMALL | MEDIUM | LARGE

mm

in

0.025 MIN 0.001

0.122 MAX 0.005

Previous Next

NOTE: If the cylinder liner protrusion varies more than 0.025 mm

[0.001 in] in 180 degrees:

Install and tighten the cylinder liner clamps again.

SMALL | MEDIUM | LARGE

Previous Next

Check the cylinder liner protrusion again.

SMALL | MEDIUM | LARGE

Previous Next

NOTE: If the protrusion still varies more than 0.025 mm [0.001 in]:

Remove the cylinder liner.

SMALL | MEDIUM | LARGE

Previous Next

Inspect the cylinder liner sealing edge for burrs, dirt, or damage.

Replace the cylinder liner if it is damaged.

Install the cylinder liner again.

Check the cylinder liner protrusion.

SMALL | MEDIUM | LARGE

Previous Next

Service Tip: If the out-of-limit condition is minimal, tolerance stackup will

allow the protrusion limits to be obtained by installing other new liners in the

out-of-limit bore.

SMALL | MEDIUM | LARGE

Previous Next

NOTE: If the liner protrusion still does not meet the specifications,

machine the cylinder block liner bore for shims.

SMALL | MEDIUM | LARGE

Previous Next

Use a feeler gauge to inspect the liner to block clearance at the four block

casting points.

Cylinder-Liner-to-Block Clearance

mm

in

0.23 MIN 0.009

SMALL | MEDIUM | LARGE

Previous Next

NOTE: If the clearance is less than 0.23 mm [0.009 in]:

Inspect the liner and cylinder block for dirt or damage.

Remove the liner.

SMALL | MEDIUM | LARGE

Previous Next

Replace the liner if it is damaged.

Install the liner again.

SMALL | MEDIUM | LARGE

Previous Next

Measure the liner bore for out-of-roundness at points (C), (D), (E), (F), and

(G).

Measure each point in the direction (AA) and (BB). The bore must not be

more than 0.08-mm [0.003-in] out of round.

SMALL | MEDIUM | LARGE

Previous Next

NOTE: If the bore is more than 0.08-mm [0.003-in] out of round:

Remove the liner so the cylinder block liner bore can be measured.

SMALL | MEDIUM | LARGE

Previous Next

Finishing Steps

TOC

WARNING

Batteries can emit explosive gases. To reduce the possibility of personal

injury, always ventilate the compartment before servicing the batteries. To

reduce the possibility of arcing, remove the negative (-) battery cable first

and attach the negative (-) battery cable last.

NOTE: Do not interchange pistons from the original cylinder location.

Install the piston and connecting rods. Refer to Procedure 001-043 in

Section 1.

Install the lubricating oil pan and suction tube. Refer to Procedure

007-025 in Section 7.

Install the cylinder head. Use the following procedure for C Series

diesel engines. Refer to Procedure 002-004 in Section 2.

Fill the cooling system. Refer to Procedure 008-018 in Section 8.

Fill the lubricating system. Refer to Procedure 007-037 in Section 7.

Connect the batteries. Refer to Procedure 013-009 in Section 13.

Open the fuel supply valve. Refer to the OEM instructions.

Operate the engine until the coolant temperature reaches 82C

[180F], and check for leaks and proper operation.

SMALL | MEDIUM | LARGE

Previous

Вам также может понравиться

- Manua de Servicio para Motor Cummins C Gas PlusДокумент13 страницManua de Servicio para Motor Cummins C Gas PlusJusto Paniagua ChampaОценок пока нет

- Damper RemovalДокумент15 страницDamper RemovalJose DAniel FigueroaОценок пока нет

- Manual de Reparacion de Motor Cummins A Gas Parte 3Документ5 страницManual de Reparacion de Motor Cummins A Gas Parte 3Justo Paniagua ChampaОценок пока нет

- Armado y Desarmado de Motor Cummis K19Документ148 страницArmado y Desarmado de Motor Cummis K19Marcos Astete Egoavil91% (11)

- Manual de Reparacion de Motor Cummins A Gas Parte 4Документ8 страницManual de Reparacion de Motor Cummins A Gas Parte 4Justo Paniagua ChampaОценок пока нет

- AssemblyДокумент105 страницAssemblyVinh TrinhvinhubОценок пока нет

- Lubrication: Necessity of Lubrication Lubricating PointsДокумент3 страницыLubrication: Necessity of Lubrication Lubricating PointsrccanarimОценок пока нет

- Ajuste de Carburador Honda ATCДокумент3 страницыAjuste de Carburador Honda ATCRigobertoОценок пока нет

- QuickServe Online - (3666087) B3.9, B4.5, B4.5 RGT, and B5.9 Service ManualДокумент21 страницаQuickServe Online - (3666087) B3.9, B4.5, B4.5 RGT, and B5.9 Service Manualshashiraj50% (2)

- QuickServe Online - (3666003) C Series Troubleshooting and Repair Manual LINERДокумент14 страницQuickServe Online - (3666003) C Series Troubleshooting and Repair Manual LINERKrisman SimanjuntakОценок пока нет

- 1 Service Information: Cautions For Operation Safety CautionsДокумент22 страницы1 Service Information: Cautions For Operation Safety CautionsTabОценок пока нет

- CfMoto CF150T-5I Echarm EFI Main ManualДокумент243 страницыCfMoto CF150T-5I Echarm EFI Main ManualAnna Ryan0% (1)

- XL 125 v1Документ33 страницыXL 125 v1Oscar SolanoОценок пока нет

- CF250T-5 (V5) Maintenance ManualДокумент236 страницCF250T-5 (V5) Maintenance ManualmoorerhouseОценок пока нет

- CF150T-5I (E-Charm EFI) Maintenance ManualДокумент243 страницыCF150T-5I (E-Charm EFI) Maintenance ManualjoeОценок пока нет

- Install The ATF (Automatic Transaxle Fluid) Oil Cooler Hoses (C) - Page 116 of 138Документ15 страницInstall The ATF (Automatic Transaxle Fluid) Oil Cooler Hoses (C) - Page 116 of 138flash_24014910Оценок пока нет

- Service Manual 157QMJДокумент60 страницService Manual 157QMJGeert Verfaillie67% (3)

- Motor 2.0 Diesel Journey 2009Документ177 страницMotor 2.0 Diesel Journey 2009Injeletro Diesel100% (1)

- CFmoto - 150T - E-Jewel - Maintenance - Manual PDFДокумент241 страницаCFmoto - 150T - E-Jewel - Maintenance - Manual PDFAnna Ryan33% (3)

- Engine 3.0 v6Документ130 страницEngine 3.0 v6Wlises GonzalezОценок пока нет

- Daelim B-Bone 125cc Service Manual 27MBДокумент246 страницDaelim B-Bone 125cc Service Manual 27MBLuis GasparОценок пока нет

- Medidas Cigüeñal KTA 38Документ20 страницMedidas Cigüeñal KTA 38Chardy Jarith Piragua AlvaradoОценок пока нет

- Liner IsleДокумент8 страницLiner IsleKonstantinDubenkoОценок пока нет

- Brembo CatalogДокумент54 страницыBrembo CatalogHandrito YudoОценок пока нет

- Camisa de CilindroДокумент16 страницCamisa de CilindroFelipe CarranzaОценок пока нет

- TGB Outback 425 - Service ManualДокумент229 страницTGB Outback 425 - Service ManualLau Tuijnman100% (5)

- ZT 6000 VSДокумент14 страницZT 6000 VSdesign_artОценок пока нет

- Small Engine Day 2Документ18 страницSmall Engine Day 2Selazinap LptОценок пока нет

- DAELIM vjf125Документ288 страницDAELIM vjf125Fabricio Costa0% (1)

- 1ge PDFДокумент8 страниц1ge PDFJoko SukarionoОценок пока нет

- TGB Blade 250 Service ManualДокумент217 страницTGB Blade 250 Service Manualyornletard100% (3)

- General Information: With Mechanically Actuated InjectorДокумент12 страницGeneral Information: With Mechanically Actuated InjectorChardy Jarith Piragua AlvaradoОценок пока нет

- 500 Service ManualДокумент2 страницы500 Service ManualLars Koch100% (2)

- Cummins Ism QSM PDFДокумент11 страницCummins Ism QSM PDFEng-AhmedRashadОценок пока нет

- Cummins Ism, QSMДокумент11 страницCummins Ism, QSMibnu67% (6)

- Shimano M44x Disk Brakes SI-8J50A-002-00-Eng v1 m56577569830747469Документ1 страницаShimano M44x Disk Brakes SI-8J50A-002-00-Eng v1 m56577569830747469LuisClementeОценок пока нет

- LinersДокумент4 страницыLinersjengandxbОценок пока нет

- EA888.3 Port Injection Install Guide r2Документ20 страницEA888.3 Port Injection Install Guide r2eliasbjrОценок пока нет

- Ection Aintenance and Ervice: Revision November 2009Документ24 страницыEction Aintenance and Ervice: Revision November 2009ddrb23Оценок пока нет

- ISX 871 Flywheel RunoutДокумент13 страницISX 871 Flywheel RunoutJ.T. NoneyaОценок пока нет

- MY19 Mattoc Comp Service Guide and Travel Change 1Документ31 страницаMY19 Mattoc Comp Service Guide and Travel Change 1Anonymous DabMRntnОценок пока нет

- KTA50 - PistonДокумент9 страницKTA50 - PistonSebastian Nicușor PărăoanuОценок пока нет

- Service Lefty 2011 PBR-XLR Eng - 2Документ8 страницService Lefty 2011 PBR-XLR Eng - 2geert janОценок пока нет

- KLR 685cc Kit-InstructionsДокумент4 страницыKLR 685cc Kit-InstructionsNoel LabuschagneОценок пока нет

- 18SP635Документ8 страниц18SP635giovanni ampueroОценок пока нет

- TM 120 MaintenanceДокумент24 страницыTM 120 Maintenanceahmedsaid85Оценок пока нет

- S300Документ4 страницыS300Inkanata SacОценок пока нет

- Lubricating Oil Filter Bypass ValveДокумент7 страницLubricating Oil Filter Bypass ValveJulio GámezОценок пока нет

- Electric MotorsДокумент2 страницыElectric MotorsElectromecanica ConalepОценок пока нет

- GC135 GC160 GC190 GS190: Maintenance InformationДокумент1 страницаGC135 GC160 GC190 GS190: Maintenance InformationGoran MojsilovicОценок пока нет

- Engine Repair PDFДокумент970 страницEngine Repair PDFJosé Roberto Vircents100% (2)

- VLX ManualДокумент448 страницVLX ManualHawkeye3321100% (2)

- Kohler Command CV680 - CV23 Service ManualДокумент88 страницKohler Command CV680 - CV23 Service ManualJames Porter75% (4)

- Motorcycle Brake MaintenanceДокумент10 страницMotorcycle Brake MaintenanceShashank KumarОценок пока нет

- Mecanizado Asiento Camisa de Cilindro PDFДокумент10 страницMecanizado Asiento Camisa de Cilindro PDFhamilton mirandaОценок пока нет

- TS TR 0075 D PDFДокумент2 страницыTS TR 0075 D PDFromanjcОценок пока нет

- Motor Maintenance - SCHEDULED ROUTINE CARE: Bearing LubricationДокумент7 страницMotor Maintenance - SCHEDULED ROUTINE CARE: Bearing LubricationRM HaroonОценок пока нет

- Manual de Servicio Motor FPT n60 Ent GДокумент172 страницыManual de Servicio Motor FPT n60 Ent GJusto Paniagua ChampaОценок пока нет

- PDFДокумент190 страницPDFJusto Paniagua ChampaОценок пока нет

- 3 301 PDFДокумент32 страницы3 301 PDFJusto Paniagua ChampaОценок пока нет

- Manual de Servicio Motor FPT n60 Ent GДокумент172 страницыManual de Servicio Motor FPT n60 Ent GJusto Paniagua ChampaОценок пока нет

- 018-001 Specifications: General InformationДокумент5 страниц018-001 Specifications: General InformationJusto Paniagua ChampaОценок пока нет

- 853bf5b8da051debf8768ded11a14160Документ518 страниц853bf5b8da051debf8768ded11a14160Justo Paniagua ChampaОценок пока нет

- Manual de Reparacion de Motor Cummins A Gas Parte 1Документ18 страницManual de Reparacion de Motor Cummins A Gas Parte 1Justo Paniagua ChampaОценок пока нет

- C Gas Plus 250-280 Horsepower INSITE™ Electronic Service Tool Parameter Value Ranges Service Description Units Low Idle StallДокумент3 страницыC Gas Plus 250-280 Horsepower INSITE™ Electronic Service Tool Parameter Value Ranges Service Description Units Low Idle StallJusto Paniagua ChampaОценок пока нет

- Manual de Reparacion de Motor Cummins A Gas Parte 5Документ19 страницManual de Reparacion de Motor Cummins A Gas Parte 5Justo Paniagua ChampaОценок пока нет

- Codigos de Falla Del BHMДокумент14 страницCodigos de Falla Del BHMJusto Paniagua ChampaОценок пока нет

- Manual de Reparacion de Motor Cummins A Gas Parte 2Документ12 страницManual de Reparacion de Motor Cummins A Gas Parte 2Justo Paniagua ChampaОценок пока нет

- Illustrated Parts List: FSB-5406B November 2012Документ20 страницIllustrated Parts List: FSB-5406B November 2012Justo Paniagua ChampaОценок пока нет

- XML6125J13CNДокумент151 страницаXML6125J13CNJusto Paniagua ChampaОценок пока нет

- Herramientas para Reparacion de Motor Cummins C Gas PlusДокумент19 страницHerramientas para Reparacion de Motor Cummins C Gas PlusJusto Paniagua ChampaОценок пока нет

- Group 3 - RДокумент196 страницGroup 3 - RJusto Paniagua Champa67% (3)

- 9-165 Data Link Circuit, SAE J1939: General InformationДокумент17 страниц9-165 Data Link Circuit, SAE J1939: General InformationJusto Paniagua ChampaОценок пока нет

- XML6125J13CNДокумент151 страницаXML6125J13CNJusto Paniagua ChampaОценок пока нет

- ProStar® Chassis Built June 14, 2010 and After - ELECTRICAL CIRCUIT DIAGRAMS S08344Документ353 страницыProStar® Chassis Built June 14, 2010 and After - ELECTRICAL CIRCUIT DIAGRAMS S08344Justo Paniagua Champa92% (13)

- 3100 Bus Starting October, 2009 - Electrical Circuit Diagrams s08342Документ62 страницы3100 Bus Starting October, 2009 - Electrical Circuit Diagrams s08342Justo Paniagua ChampaОценок пока нет

- Hino Common Rail J05d-J08eДокумент50 страницHino Common Rail J05d-J08eJusto Paniagua Champa94% (50)

- Voith Diwa.3 Trouble ShootingДокумент70 страницVoith Diwa.3 Trouble ShootingJusto Paniagua Champa93% (15)

- UNA-620A - Operating InstructionREV02 by B.bennettДокумент27 страницUNA-620A - Operating InstructionREV02 by B.bennettcysauts100% (2)

- Garbage Record BookДокумент9 страницGarbage Record BookEngr AMbrose NdaeyoОценок пока нет

- Biogas Production From Anaerobic Co-Digestion of Spent Mushroom Substrate With Different Livestock ManureДокумент15 страницBiogas Production From Anaerobic Co-Digestion of Spent Mushroom Substrate With Different Livestock ManureKentner Chavez CorreaОценок пока нет

- Environmental and Economic Life Cycle Analysis of Plastic Waste Management Options PDFДокумент6 страницEnvironmental and Economic Life Cycle Analysis of Plastic Waste Management Options PDFSarah Syamimi RozaliОценок пока нет

- The Effect of Waste Glass Bottles As An AlternativДокумент10 страницThe Effect of Waste Glass Bottles As An AlternativJannayrah LawansaОценок пока нет

- War On WasteДокумент25 страницWar On WasteFabiana VasquesОценок пока нет

- Modular Uasb For Anaerobic Treatment of Soluble WastewatersДокумент4 страницыModular Uasb For Anaerobic Treatment of Soluble WastewatersvdrishОценок пока нет

- Five Counties Regional Energy From Waste Facility Concept ReportДокумент12 страницFive Counties Regional Energy From Waste Facility Concept ReportPeterborough ExaminerОценок пока нет

- Asfour Dense CastableДокумент7 страницAsfour Dense CastableMohamed LotfyОценок пока нет

- Atlas Copco CiocaneДокумент88 страницAtlas Copco Ciocaneleandrod28Оценок пока нет

- Tle 7 and 8Документ5 страницTle 7 and 8Charmain J. DequitoОценок пока нет

- Day Cream: Material Safety Data SheetДокумент2 страницыDay Cream: Material Safety Data SheetRachmawati AfridaОценок пока нет

- 3 - Environment Compliance CertificateДокумент4 страницы3 - Environment Compliance Certificateevrian peruchoОценок пока нет

- Kuta Weekly - Edition 663 Bali's Premier NewspaperДокумент19 страницKuta Weekly - Edition 663 Bali's Premier NewspaperPaul WrightОценок пока нет

- Septic Tank Design - LessonДокумент4 страницыSeptic Tank Design - Lessonadera1Оценок пока нет

- Questions and Answers PlumbingДокумент5 страницQuestions and Answers PlumbingČhhïtОценок пока нет

- Preliminary Impacts of The Ban On Plastic Bags in Antipolo City Final PDFДокумент54 страницыPreliminary Impacts of The Ban On Plastic Bags in Antipolo City Final PDFjoseph lu33% (3)

- CHE572 Air Pollution Control Assignment 1Документ2 страницыCHE572 Air Pollution Control Assignment 1Khong Hui ShanОценок пока нет

- 4 AcknowledgementДокумент7 страниц4 AcknowledgementjatinОценок пока нет

- Corrugated Boxes1Документ8 страницCorrugated Boxes1abhi050191Оценок пока нет

- Waste Management Research in Romania - 0Документ72 страницыWaste Management Research in Romania - 0Bianca RadutaОценок пока нет

- Sanika - There Are Different Sepration Techniques Involved in Sewage Treatment PlantДокумент3 страницыSanika - There Are Different Sepration Techniques Involved in Sewage Treatment PlantSANIKA TALATHIОценок пока нет

- Introduction To Gold Panning: Step by Step GuideДокумент1 страницаIntroduction To Gold Panning: Step by Step GuidePaulo CostaОценок пока нет

- IWRG631Документ10 страницIWRG631Tina YeganehОценок пока нет

- 2006AFS SandCastingLCAДокумент16 страниц2006AFS SandCastingLCAdesurkarbОценок пока нет

- Submission No. 1 Literature 1Документ13 страницSubmission No. 1 Literature 1ejlОценок пока нет

- Voided SlabДокумент35 страницVoided SlabPallepatiShirishRaoОценок пока нет

- Asphalt Fast FactsДокумент3 страницыAsphalt Fast FactsAzhar MohamedОценок пока нет

- HydroponicsДокумент40 страницHydroponicsAndré Brincat100% (2)

- Globe: Environmental PolicyДокумент52 страницыGlobe: Environmental PolicyKlang B.Оценок пока нет