Академический Документы

Профессиональный Документы

Культура Документы

Operating Instructions (December, 2006 Rev 4) PDF

Загружено:

Miguel Carpio0 оценок0% нашли этот документ полезным (0 голосов)

714 просмотров292 страницыFT8 Gas Turbine Power Plant Operating Instructions for MicroNet(tm) Digital Controllers United Technologies Corporation. This document is the property of United Technologies Corporation (UTC). You may not possess, use, copy, or disclose this document or any other information in it, without UTC's express written permission.

Исходное описание:

Оригинальное название

Operating Instructions ( December, 2006 Rev 4).pdf

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документFT8 Gas Turbine Power Plant Operating Instructions for MicroNet(tm) Digital Controllers United Technologies Corporation. This document is the property of United Technologies Corporation (UTC). You may not possess, use, copy, or disclose this document or any other information in it, without UTC's express written permission.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

714 просмотров292 страницыOperating Instructions (December, 2006 Rev 4) PDF

Загружено:

Miguel CarpioFT8 Gas Turbine Power Plant Operating Instructions for MicroNet(tm) Digital Controllers United Technologies Corporation. This document is the property of United Technologies Corporation (UTC). You may not possess, use, copy, or disclose this document or any other information in it, without UTC's express written permission.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 292

FT8 Gas Turbine Power Plant

Operating Instructions For

MicroNet Digital Controllers

United Technologies Corporation

Pratt & Whitney Power Systems

80 Lamberton Road

Windsor, CT 06095

Revision 4

December 2006 Part Number: TPMD 371

Homepage Previous Document

2

FOR ADDITIONAL COPIES OF THIS MANUAL

Contact PWPS After Market Sales Group to purchase additional copies of

this manual.

Previous Document Homepage

3

PROPRIETARY WARNING

This document is the property of United Technologies Corporation (UTC).

You may not possess, use, copy, or disclose this document or any other

information in it, for any purpose including without limitation to design,

manufacture, or repair parts, or to obtain FAA or other government

approval to do so, without UTCs express written permission. Neither

receipt nor possession of this document alone, from any source,

constitutes such permission. Possession, use, copying, or disclosure by

anyone without UTCs express written permission is not authorized and

may result in criminal and/or civil liability.

Previous Document Homepage

4

OPERATING INSTRUCTIONS REVISION RECORD

REVISION NUMBER

DATE OF ISSUE

ISSUED BY

Initial Issue K. Nagy

Rev 1 9/20/2003 K. Nagy / M. Cowan

Rev 2 4/1/2004 M. Cowan

Rev 3 5/25/2005 K. Nagy / M. Cowan

Rev 4 12/14/2006 R. Hunter

Previous Document Homepage

5

NAVIGATING THIS DOCUMENT

This document uses hyperlinks for navigational purposes. Clicking a Section or Paragraph identified in

the Table of Contents will automatically direct the user to the selected Section or Paragraph.

The phrase See Screen XX is used throughout the text of this document to identify screens found in

Appendix A. Clicking on the See Screen XX reference will automatically link the user to the

referenced screen. The navigational arrows found on the upper tool bar can be used to return to the

original paragraph.

Previous Document Homepage

6

OPERATING INSTRUCTIONS TABLE OF CONTENTS

FOR ADDITIONAL COPIES OF THIS MANUAL............................................................................ 2

PROPRIETARY WARNING............................................................................................................3

OPERATING INSTRUCTIONS REVISION RECORD..................................................................... 4

NAVIGATING THIS DOCUMENT ................................................................................................... 5

OPERATING INSTRUCTIONS TABLE OF CONTENTS................................................................ 6

WARNING, CAUTION AND NOTES DEFINED............................................................................ 15

DEFINITIONS OF FT8 CONTROL HOUSE COUNTERS............................................................. 16

SECTION 1 - PURPOSE............................................................................................................... 17

1.0 Introduction ........................................................................................................................ 17

SECTION 2 - APPLICABLE PUBLICATIONS and DOCUMENTS .............................................. 18

2.0 Introduction ........................................................................................................................ 18

SECTION 3 - MAN-MACHINE INTERFACE (MMI) OPERATION ................................................ 19

3.0 Introduction ........................................................................................................................ 19

3.1 Starting the Monitoring System........................................................................................ 19

3.2 CITECT Screen Basics.......................................................................................................19

3.3 Manipulating the Screens.................................................................................................. 20

3.3.1 Zooming ....................................................................................................................... 20

3.3.2 Printing......................................................................................................................... 20

3.3.3 Close Screen................................................................................................................ 20

3.3.4 Scroll Alarms ............................................................................................................... 20

3.3.5 Display Alarm Screen.................................................................................................. 20

3.3.6 Display Alarm Summary ............................................................................................. 20

3.3.7 Scroll-Through Screens .............................................................................................. 20

3.3.8 Function Key F4........................................................................................................... 20

3.3.9 Function Key F5........................................................................................................... 20

3.3.10 Function Key F11....................................................................................................... 20

3.3.11 Main ............................................................................................................................ 20

3.4 Navigating the Screens .....................................................................................................20

3.4.1 Earth Icon (Display Site Overview) ............................................................................ 21

3.4.2 Power Station Icon (Display BOP Overview)............................................................. 21

3.4.3 Street Light Icon (Display Sequence Start/Stop Menu) ............................................ 21

3.4.4 Turbine Icon ................................................................................................................. 21

3.4.5 Scales Icon (Display Calibration Menu)..................................................................... 22

3.4.6 Graph Icon (Display Trends Menu) ............................................................................ 23

3.4.7 Pump Icon (Display P&I Diagram Menu) ................................................................... 24

3.4.8 Data Display Icon (Display Systems Menu)............................................................... 25

3.4.9 PLC Icon (Display System Diagnostics) .................................................................... 26

3.4.10 Systems Menu Icon ................................................................................................... 28

3.4.11 Pratt & Whitney Logo Icon........................................................................................ 28

3.5 Stopping the Monitoring System...................................................................................... 28

3.5.1 Shutting Down a Monitoring Location....................................................................... 29

3.6 Rebooting the Monitor ....................................................................................................... 29

3.6.1 Rebooting CITECT....................................................................................................... 29

3.6.2 Rebooting the Monitor PC .......................................................................................... 29

SECTION 4 REBOOTING THE MICRONET.............................................................................. 31

Previous Document Homepage

7

4.0 Introduction ........................................................................................................................ 31

4.1 Rebooting From the CPU .................................................................................................. 31

4.2 Rebooting From AppManager ........................................................................................... 32

4.3 Rebooting By Cycling Power ............................................................................................ 32

SECTION 5 RESETTING DEVICES AND SYSTEM.................................................................. 34

5.0 Resetting Devices and Systems ....................................................................................... 34

5.1 MCC Buckets ...................................................................................................................... 34

5.1.1 Molded Case Breakers ................................................................................................ 34

5.1.2 Overloads ..................................................................................................................... 34

5.2 Lockout Relays................................................................................................................... 34

5.3 Beckwith 3420, 3425 or 3430 Protective Relays .............................................................. 34

5.4 Auxiliary Overspeed, 12-1 ................................................................................................. 35

5.5 Fire Protection System...................................................................................................... 35

5.5.1 Strobes and Horns ...................................................................................................... 35

5.5.2 Local Panel Alarm ....................................................................................................... 35

5.5.3 Fire Valves ................................................................................................................... 35

5.5.4 Pressure Switches....................................................................................................... 35

5.5.5 Fire Pull Stations. ........................................................................................................ 35

5.6 Controlled Drive-back Reset ............................................................................................. 36

5.7 Software Reset ................................................................................................................... 36

5.8 Resetting Systems ............................................................................................................. 36

5.9 Resetting Devices .............................................................................................................. 36

5.10 SCR Emergency Shutdown Reset .................................................................................. 36

5.11 Vibration Monitor ............................................................................................................. 36

SECTION 6 WORKING WITH ALARMS AND EVENTS LOGS ................................................ 37

6.0 Introduction ........................................................................................................................ 37

6.1 Alarm Tabulation Screen................................................................................................... 37

6.1.1 Alarm Tabulation Screen Left Hand Column............................................................. 37

6.1.2 Alarm Screen Filters.................................................................................................... 41

6.1.3 Tag Information ........................................................................................................... 41

6.1.4 Highlighted Alarms...................................................................................................... 41

6.1.5 Printing Alarms............................................................................................................ 42

6.1.6 Stored Alarms .............................................................................................................. 42

6.1.7 Alarm Summary ........................................................................................................... 42

SECTION 7 SETTING OPERATING PARAMETERS................................................................ 43

7.0 Introduction ........................................................................................................................ 43

7.1 Operating Parameters........................................................................................................ 43

7.2 Start/Stop Screen Operator Settings................................................................................ 43

7.3 Operator Panel Operator Settings .................................................................................... 46

SECTION 8 SYSTEM SETUP.................................................................................................... 48

8.0 Introduction ........................................................................................................................ 48

8.1 Standby for Normal Operations ........................................................................................ 48

8.1.1 Fire Protection System Ready.................................................................................... 48

8.1.2 Generator ..................................................................................................................... 48

8.1.3 GG/PT Lube Oil - Engines A and B ............................................................................ 49

8.1.4 Inlet Air System - Engines A and B............................................................................ 49

8.1.5 Gas Fuel System - Engines A and B .......................................................................... 49

8.1.6 Liquid Fuel Systems A and B ..................................................................................... 49

Previous Document Homepage

8

8.1.7 Enclosures Engines A, B and Generator ................................................................ 50

8.1.8 Motor Control Center .................................................................................................. 50

8.1.9 Control System Reset. ................................................................................................ 53

8.1.10 Operating Parameters Set ........................................................................................ 53

8.1.11 MOBILEPAC Only .................................................................................................. 55

8.2 Secure for Maintenance.....................................................................................................55

8.2.1 Start Lockout ............................................................................................................... 55

8.2.2 Motor Lockout.............................................................................................................. 55

8.2.3 Circuit Lockout ............................................................................................................ 55

8.2.4 Lockout the Main 52G Circuit Breaker....................................................................... 55

8.2.5 Removing the Main Breaker ....................................................................................... 56

8.2.6 Fire Protection System ............................................................................................... 56

8.2.7 MOBILEPAC Only .................................................................................................... 56

SECTION 9 NORMAL SYSTEMS OPERATION........................................................................ 57

9.0 Introduction ........................................................................................................................ 57

9.1 Auto Start for Power Production from the Standby Mode.............................................. 57

9.1.1 Alternate Auto Start for Power Production from the Standby Mode....................... 58

9.2 Auto Stop............................................................................................................................ 58

9.2.1 Alternate Auto Stop..................................................................................................... 59

9.3 Manual Start. ...................................................................................................................... 59

9.4 Manual Synchronization.................................................................................................... 60

9.5 Manual Stop........................................................................................................................ 62

9.5.1 Manual Stop from Sync Idle........................................................................................ 62

9.5.2 Manual Stop from MANUAL On Line Power Generation.......................................... 62

9.5.3 Manual Stop from AUTOMATIC On-Line Power Generation.................................... 62

9.6 Single Engine Operation ................................................................................................... 62

9.6.1 Single Engine Operation With Other Engine Coupled (Windmilling) ...................... 62

9.6.2 Single Engine Operation With Other Engine De-coupled ........................................ 63

9.7 Fuel Transfers .................................................................................................................... 63

9.7.1 Transfer from Gas Fuel to Liquid Fuel ....................................................................... 64

9.7.2 Transfer from Liquid Fuel to Gas Fuel ....................................................................... 64

9.8 Synchronous Condenser Operation................................................................................. 64

9.8.1 Synchronous Condenser Operation In VAR or Power Factor Control Mode ......... 65

9.8.2 Synchronous Condenser Mode Operating Options ................................................. 65

9.8.3 Entering Synchronous Condenser Mode From Power Generation Mode .............. 65

9.9 Black Start. ......................................................................................................................... 65

9.9.1 Isolated Droop Mode................................................................................................... 65

9.9.2 Isolated Precise Mode................................................................................................. 65

9.9.3 Sequence of Operation for Automatic Isolated Droop Black Start Operation........ 66

9.9.4 Sequence of Operation for Automatic Isolated Precise Black Start Operation ..... 68

9.9.5 Shutdown Following Black Start Operation .............................................................. 70

9.10 Fire Protection System Operation .................................................................................. 71

9.10.1 Normal Condition. ..................................................................................................... 71

9.10.2 Alarm Condition.........................................................................................................71

9.10.3 Supervisory Notification. .......................................................................................... 71

9.10.4 Trouble Notification................................................................................................... 72

SECTION 10 MANUAL OPERATION OF SYSTEMS................................................................ 73

10.0 Introduction ...................................................................................................................... 73

Previous Document Homepage

9

10.1 Engine Wash..................................................................................................................... 73

10.1.1 Detergent Wash ......................................................................................................... 73

10.1.2 Water Wash ................................................................................................................ 74

10.2 Spin Engine ...................................................................................................................... 75

10.2.1 Spin Engine - Alternate Method ............................................................................... 76

10.3 Power Turbine (PT) Lube Oil System ............................................................................. 76

10.4 Generator Lube Oil System............................................................................................. 76

10.5 Fans and Pumps .............................................................................................................. 77

10.6 Electric Valves.................................................................................................................. 77

10.7 Overspeed Test ................................................................................................................ 78

10.7.1 Overspeed Test Preparations ................................................................................ 78

10.7.2 Overspeed Test Procedure....................................................................................... 78

10.8 Cold Buffer ....................................................................................................................... 80

10.9 Thrust Balance ................................................................................................................. 81

10.9.1 Engine Bleed detection ................................................................................................ 81

10.10 BOP Devices................................................................................................................... 81

10.11 Power Turbine (PT) Tests .............................................................................................. 81

10.11.1 Power Turbine (PT) Breakaway and PT Break-In.................................................. 81

SECTION 11 DATA SYSTEMS.................................................................................................. 83

11.0 Introduction ...................................................................................................................... 83

11.1 Fast Data Logger .............................................................................................................. 83

11.1.1 Operator Recorded Data Options............................................................................. 83

11.2 Trends Data System......................................................................................................... 84

11.2.1 Trends Screens..........................................................................................................84

11.2.2 Custom Trends Screens ........................................................................................... 84

11.2.3 Trend Screen Data..................................................................................................... 85

11.2.4 Trend Screen Time .................................................................................................... 85

11.2.5 Calculate Trend Statistics......................................................................................... 86

11.2.6 Printing Trends .......................................................................................................... 87

11.2.7 Individual Parameter Trends .................................................................................... 87

11.3 FT8 Engine Log ................................................................................................................ 87

SECTION 12 ABNORMAL OPERATING CONDITIONS........................................................... 89

12.0 Introduction. ..................................................................................................................... 89

12.1 Alarms............................................................................................................................... 89

12.2 Controlled Drive-back (CDB)........................................................................................... 89

12.3 Controlled Shutdown (CSD) ............................................................................................ 89

12.4 Trips. ................................................................................................................................. 90

12.5 Failed Devices or Sensors .............................................................................................. 90

12.6 Monitoring System Failure.............................................................................................. 91

SECTION 13 MAINTENANCE AND TROUBLESHOOTING..................................................... 92

13.0 Introduction. ..................................................................................................................... 92

13.1 Battery System. ................................................................................................................ 92

13.1.1 General Operating Procedure................................................................................... 92

13.1.2 Battery Charger Alarms ............................................................................................ 93

13.2 GG/PT Lube Oil Systems ................................................................................................. 94

13.2.1 GG/PT Lube Oil System Functional Test ................................................................. 94

(TWINPAC, SWIFTPAC and POWERPAC Installations Only) .................................... 94

13.2.2 Adjusting Power Turbine (PT) Lube Oil Pressure................................................... 95

Previous Document Homepage

10

13.2.3 Adjusting Gas Generator (GG) Lube Oil Pressure.................................................. 95

13.3 Generator Lube Oil System (TWINPAC, SWIFTPAC and POWERPAC

Installations Only) .................................................................................................................... 95

13.3.1 Generator Lube Oil System Functional Test ........................................................... 96

13.3.2 Adjusting Generator Lube Oil Pressure .................................................................. 96

13.4 Generator Lube Oil System (MOBILEPAC Installations Only) ..................................... 96

13.4.1 Adjusting Generator Lube Oil Pressure............................................................... 97

13.4.2 Adjusting Generator Lube Oil Tank Pressure...................................................... 97

13.5 Watch Windows II Operation........................................................................................... 97

13.5.1 Viewing a Tunable ..................................................................................................... 97

13.5.2 View a Tag Name ....................................................................................................... 98

13.5.3 Editing or Changing a Tunable Value...................................................................... 98

13.5.4 Saving a Tunable Value After a Change.................................................................. 99

13.5.5 Calibration of Transducers. ...................................................................................... 99

13.5.6 Customizing an Inspector......................................................................................... 99

13.5.7 Exiting Watch Windows II ....................................................................................... 100

13.6 Control Assistant ........................................................................................................... 100

13.7 AppManager. .................................................................................................................. 101

13.7.1 Stopping a Running Application On the Micronet ................................................ 101

13.7.2 Starting An Application On the Micronet............................................................... 101

13.8 Micropanel. ..................................................................................................................... 101

13.9 Network Troubleshooting.............................................................................................. 102

13.9.1 Other Useful Information ........................................................................................ 102

13.10 IGV/VSV Static Calibration ..................................................................................... 103

13.11 Fire Protection System................................................................................................ 105

13.11.1 Fire Protection System and Components Periodic Inspections ....................... 106

13.11.2 Detection and Actuating Devices......................................................................... 106

APPENDIX A SCREENS ......................................................................................................... 107

SCREEN 1............................................................................................................................... 108

SCREEN 1A ............................................................................................................................ 109

SCREEN 2............................................................................................................................... 110

SCREEN 2A ............................................................................................................................ 111

SCREEN 3............................................................................................................................... 112

SCREEN 3A ............................................................................................................................ 113

SCREEN 4............................................................................................................................... 114

SCREEN 4A ............................................................................................................................ 115

SCREEN 4B ............................................................................................................................ 116

SCREEN 4C ............................................................................................................................ 117

SCREEN 4D ............................................................................................................................ 118

SCREEN 4E............................................................................................................................. 119

SCREEN 4F............................................................................................................................. 120

SCREEN 5............................................................................................................................... 121

SCREEN 6............................................................................................................................... 122

SCREEN 6A ............................................................................................................................ 123

SCREEN 6B ............................................................................................................................ 124

SCREEN 6C ............................................................................................................................ 125

SCREEN 7............................................................................................................................... 126

SCREEN 8............................................................................................................................... 127

Previous Document Homepage

11

SCREEN 9............................................................................................................................... 128

SCREEN 10............................................................................................................................. 129

SCREEN 10A .......................................................................................................................... 130

SCREEN 11............................................................................................................................. 131

SCREEN 12............................................................................................................................. 132

SCREEN 13............................................................................................................................. 133

SCREEN 13A .......................................................................................................................... 134

SCREEN 14............................................................................................................................. 135

SCREEN 15............................................................................................................................. 136

SCREEN 15A .......................................................................................................................... 137

SCREEN 16............................................................................................................................. 138

SCREEN 17............................................................................................................................. 139

SCREEN 18............................................................................................................................. 140

SCREEN 19............................................................................................................................. 141

SCREEN 20............................................................................................................................. 142

SCREEN 21............................................................................................................................. 143

SCREE 21A............................................................................................................................. 144

SCREEN 22............................................................................................................................. 145

SCREEN 22A .......................................................................................................................... 146

SCREEN 23............................................................................................................................. 147

SCREEN 23A .......................................................................................................................... 148

SCREEN 24............................................................................................................................. 149

SCREEN 24A .......................................................................................................................... 150

SCREEN 25............................................................................................................................. 151

SCREEN 25A .......................................................................................................................... 152

SCREEN 26............................................................................................................................. 153

SCREEN 26A .......................................................................................................................... 154

SCREEN 27............................................................................................................................. 155

SCREEN 28............................................................................................................................. 156

SCREEN 29............................................................................................................................. 157

SCREEN 30............................................................................................................................. 158

SCREEN 31............................................................................................................................. 159

SCREEN 32............................................................................................................................. 160

SCREEN 33............................................................................................................................. 161

SCREEN 34............................................................................................................................. 162

SCREEN 35............................................................................................................................. 163

SCREEN 36............................................................................................................................. 164

SCREEN 37............................................................................................................................. 165

SCREEN 38............................................................................................................................. 166

SCREEN 39............................................................................................................................. 167

SCREEN 40............................................................................................................................. 168

SCREEN 41............................................................................................................................. 169

SCREEN 42............................................................................................................................. 170

SCREEN 43............................................................................................................................. 171

SCREEN 44............................................................................................................................. 172

SCREEN 45............................................................................................................................. 173

SCREEN 46............................................................................................................................. 174

SCREEN 47............................................................................................................................. 175

Previous Document Homepage

12

SCREEN 48............................................................................................................................. 176

SCREEN 49............................................................................................................................. 177

SCREEN 49A .......................................................................................................................... 178

SCREEN 50............................................................................................................................. 179

SCREEN 50A .......................................................................................................................... 180

SCREEN 51............................................................................................................................. 181

SCREEN 52............................................................................................................................. 182

SCREEN 53............................................................................................................................. 183

SCREEN 53A .......................................................................................................................... 184

SCREEN 54............................................................................................................................. 185

SCREEN 55............................................................................................................................. 186

SCREEN 56............................................................................................................................. 187

SCREEN 57............................................................................................................................. 188

SCREEN 57A .......................................................................................................................... 189

SCREEN 58............................................................................................................................. 190

SCREEN 59............................................................................................................................. 191

SCREEN 60............................................................................................................................. 192

SCREEN 61............................................................................................................................. 193

SCREEN 62............................................................................................................................. 194

SCREEN 63............................................................................................................................. 195

SCREEN 63A .......................................................................................................................... 196

SCREEN 64............................................................................................................................. 197

SCREEN 65............................................................................................................................. 198

SCREEN 65A .......................................................................................................................... 199

SCREEN 65B .......................................................................................................................... 200

SCREEN 65C .......................................................................................................................... 201

SCREEN 65D .......................................................................................................................... 202

SCREEN 65E........................................................................................................................... 203

SCREEN 66............................................................................................................................. 204

SCREEN 67............................................................................................................................. 205

SCREEN 68............................................................................................................................. 206

SCREEN 69............................................................................................................................. 207

SCREEN 70............................................................................................................................. 208

SCREEN 71............................................................................................................................. 209

SCREEN 72............................................................................................................................. 210

SCREEN 73............................................................................................................................. 211

SCREEN 74............................................................................................................................. 212

SCREEN 75............................................................................................................................. 213

SCREEN 76............................................................................................................................. 214

SCREEN 77............................................................................................................................. 215

SCREEN 78............................................................................................................................. 216

SCREEN 79............................................................................................................................. 217

SCREEN 80............................................................................................................................. 218

SCREEN 81............................................................................................................................. 219

SCREEN 82............................................................................................................................. 220

SCREEN 83............................................................................................................................. 221

SCREEN 84............................................................................................................................. 222

SCREEN 85............................................................................................................................. 223

Previous Document Homepage

13

SCREEN 86............................................................................................................................. 224

SCREEN 87............................................................................................................................. 225

SCREEN 88............................................................................................................................. 226

SCREEN 89............................................................................................................................. 227

SCREEN 90............................................................................................................................. 228

SCREEN 91............................................................................................................................. 229

SCREEN 92............................................................................................................................. 230

SCREEN 93............................................................................................................................. 231

SCREEN 94............................................................................................................................. 232

SCREEN 95............................................................................................................................. 233

SCREEN 96............................................................................................................................. 234

SCREEN 97............................................................................................................................. 235

SCREEN 98............................................................................................................................. 236

SCREEN 99............................................................................................................................. 237

SCREEN 100........................................................................................................................... 238

SCREEN 101........................................................................................................................... 239

SCREEN 102........................................................................................................................... 240

SCREEN 103........................................................................................................................... 241

SCREEN 104........................................................................................................................... 242

SCREEN 105........................................................................................................................... 243

SCREEN 106........................................................................................................................... 244

SCREEN 107........................................................................................................................... 245

SCREEN 108........................................................................................................................... 246

SCREEN 109........................................................................................................................... 247

SCREEN 110........................................................................................................................... 248

SCREEN 111........................................................................................................................... 249

SCREEN 112........................................................................................................................... 250

SCREEN 113........................................................................................................................... 251

SCREEN 114........................................................................................................................... 252

SCREEN 115........................................................................................................................... 253

SCREEN 116........................................................................................................................... 254

SCREEN 117........................................................................................................................... 255

SCREEN 118........................................................................................................................... 256

SCREEN 119........................................................................................................................... 257

SCREEN 120........................................................................................................................... 258

SCREEN 121........................................................................................................................... 259

SCREEN 122........................................................................................................................... 260

105........................................................................................................................................... 261

SCREEN 124........................................................................................................................... 261

SCREEN 124A ........................................................................................................................ 262

SCREEN 125........................................................................................................................... 263

SCREEN 126........................................................................................................................... 264

SCREEN 127........................................................................................................................... 265

SCREEN 128........................................................................................................................... 266

SCREEN 128A ........................................................................................................................ 267

SCREEN 129........................................................................................................................... 268

SCREEN 130........................................................................................................................... 269

SCREEN 131........................................................................................................................... 270

Previous Document Homepage

14

SCREEN 132........................................................................................................................... 271

SCREEN 133........................................................................................................................... 272

SCREEN 134........................................................................................................................... 273

SCREEN 135........................................................................................................................... 274

SCREEN 136........................................................................................................................... 275

SCREEN 137........................................................................................................................... 276

SCREEN 138........................................................................................................................... 277

SCREEN 139........................................................................................................................... 278

SCREEN 140........................................................................................................................... 279

SCREEN 141........................................................................................................................... 280

Previous Document Homepage

15

WARNING, CAUTION AND NOTES DEFINED

The following definitions apply to WARNINGS, CAUTIONS and NOTES found throughout this manual:

WARNING

A procedure, practice or condition, etc. which may result in injury or death if not

carefully observed or followed.

CAUTION

A procedure, practice, or condition, etc. which may result in damage to

equipment if not carefully observed or followed.

NOTE

A procedure or condition, etc. which is essential to emphasize or expand

upon.

Previous Document Homepage

16

DEFINITIONS OF FT8 CONTROL HOUSE COUNTERS

The following counters are used for FT8 gas turbines. If the unit is a TWINPAC or a SWIFTPAC,

then each engine (A and B) will have separate counters. POWERPAC and MOBILEPAC

installations are equipped with a single set of counters.

START Counter The START counter cycles when light-off is detected (a 25F rise

in average EGT).

CYCLE Counter Cycles when the gas generator average EGT reaches 80 percent

of base-load EGT.

TOTAL FIRED HOURS Operates when the second fuel shutoff valve, either liquid or gas,

opens. Stops when the second fuel shutoff valve closes.

LIQUID FUEL FIRED HOURS Operates when the second liquid fuel shutoff valve opens. Stops

when the second liquid fuel shutoff valve closes.

GAS FUEL FIRED HOURS Operates when the second gas fuel shutoff valve opens. Stops

when the second gas fuel shutoff valve closes.

NOTE

The FIRED HOURS timers record straight time only. They do not record

equivalent hours that are referenced in Pratt and Whitney Power

Systems Service Bulletin 96B03.

Previous Document Homepage

17

SECTION 1 - PURPOSE

1.0 Introduction

This manual is intended to be used by personnel who will be conducting day-to-day operations and

minor maintenance tasks associated with the operation of the FT8 TWINPAC, SWIFTPAC,

POWERPAC and MOBILEPAC electric power generating units.

The operator must have prior knowledge of and specific training on, the equipment. Details of the

systems involved, required specifications, specific maintenance schedules and procedures are

contained in other publications. Refer to SECTION 2 - TWINPAC, SWIFTPAC, POWERPAC

and MOBILEPAC APPLICABLE PUBLICATIONS AND DOCUMENTS for a list of applicable

publications and documents.

A prerequisite for the successful application of this manual is that all equipment has been fully checked-

out, commissioned, accepted by the owner and certified for normal operation.

This manual covers the latest updated TWINPAC, SWIFTPAC, POWERPAC and

MOBILEPAC FT8 engine configurations with dual fuel, water injection and remote monitor and

control. Not all sites will be equipped with all the options covered in this manual.

The TWINPAC is a dual engine field assembled unit. All interconnection wiring is field terminated

and much of the piping is field fabricated and installed. Complete systems integration, calibrations and

checkout are accomplished at the installation site.

The SWIFTPAC is a version of the TWINPAC specifically designed for fast installation in the field.

Many of the components are modular, the interconnecting wiring is pre-manufactured with quick

disconnect cables and the piping is prefabricated. Partial systems integration, calibrations and

checkout are accomplished at the factory thus reducing construction time at the installation site.

The POWERPAC is a similar generating unit with a smaller generator and a single engine.

The MOBILEPAC is a trailer mounted single engine generating unit. The generator, gas generator,

power turbine and lube oil systems are mounted on one trailer. The control house and hydraulic start

unit are mounted on a second trailer. The trailers are positioned at the site, interconnecting cables and

prefabricated hoses are connected. After connection to fuel and water supplies as required and

connection to the high voltage distribution system, the unit is ready to generate power. Systems

integration, calibrations and checkout are accomplished at the factory. The unit is readily relocated.

The overall operation of the unit and sub systems is very similar between the various configurations.

Comments are added where specific functions or operations differ for a particular configuration.

The various screens appearing on the Man Machine Interface (MMI) are similar in function but may

differ in appearance between unit types and sites. Screens are identified in this manual by a number

(1, 2, 3, etc). Where functionality is similar but appearances differ the screens are identified with the

same number but with an alpha suffix (1A, 1B, 2A, 3A, 3B, 3C, etc).

Several of the button icons have replaced the functional text description with symbols. The function of

these buttons is described by popup windows when the curser is positioned over the button.

Previous Document Homepage

18

SECTION 2 - APPLICABLE PUBLICATIONS and DOCUMENTS

2.0 Introduction

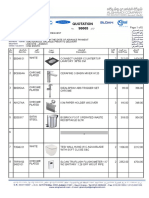

Table 1 is provided as a means of identifying which Pratt & Whitney Power Systems (PWPS) technical

publications and documents are used to operate and maintain PWPS sites and equipment.

SUBJECT MATTER PUBLICATION OR DOCUMENT TITLE

Equipment Operation

TWINPAC, SWIFTPAC, POWERPAC and

MOBILEPAC OPERATING INSTRUCTIONS

Commissioning and Checkout

Procedures

FT8 Commissioning Manual

Commissioning and Checkout

Documentation

FT8 Commissioning Manual Sign-Off Sheets

Initial Calibrations FT8 Commissioning Manual Sign-Off Sheets

Installation Process

FT8 TWINPAC CONSTRUCTION MANUAL,

SWIFTPAC INSTALLATION MANUAL or MOBILEPAC

INSTALLATION and REMOVAL MANUAL (As applicable)

and

TWINPAC SITE CONSTRUCTION PICTURE BOOK or

SWIFTPAC SITE CONSTRUCTION PICTURE BOOK

(As applicable)

Equipment Assembly Details PWPS and/or Vendor drawings (As Applicable)

System Description Ancillary Systems Maintenance Manual (Project Specific)

Operating Limits

Ancillary Systems Maintenance Manual (Project Specific)

and Alarms and Trips List

Alarms and Trips Alarms and Trips Lists (XXXX-189-C005L)

GG Maintenance Procedures GG Maintenance Manual (P/N 807421)

PT Maintenance Procedures PT Maintenance Manual (P/N 807424)

GG Components GG Illustrated Parts Catalog (P/N 807423)

PT Components PT Illustrated Parts Catalog (P/N 807426)

Ancillary Systems Components Systems Maintenance Manual (Project Specific)

Table 1 - Publications Cross-Reference Table

Previous Document Homepage

19

SECTION 3 - MAN-MACHINE INTERFACE (MMI) OPERATION

3.0 Introduction

The site monitoring system, the Industrial Control Equipment (ICE) monitor is a Windows based PC

network running proprietary software in a CITECT equipment-operating program. The system consists

of a local Adek CPU and monitor (AS01) located in the control house, a remote CPU and monitor

(AR01) and the standby remote CPU and monitor (AR02) located in an alternate building.

NOTE

In the following paragraphs, icons and pushbutton controls are shown in

Bold. Pull down menu items are shown Underlined. Commands, switch

states or system states are shown in CAPITOLS.

Screens shown are typical and may not exactly duplicate the screens at a

specific site.

Where significant revisions have been made to individual screens, such

as Screen 2, the alternate screens are referenced as Screen 2A, Screen

2B, etc.

3.1 Starting the Monitoring System

To start the PC, open the front panel and toggle the power switch to the ON (I) position. On power

up, the PC will initialize and display a standard Windows desktop screen. If the unit is not set-up to

automatically start CITECT, double click on the CITECT icon. See Screen 1. In order to operate the

TWINPAC or SWIFTPAC, CITECT must be up and running.

The program will initialize and present a blank CITECT screen. See Screen 2, Screen 2A.

The MOBILEPAC will present Screen 2A. The function of each of the eleven (11) icon buttons shown

along the top of the Screen 2A are detailed in Paragraph 3.4.

3.2 CITECT Screen Basics

Operation of the PC from the standard Windows desktop screen is the same as any other Windows

based PC program and allows the Operator to use several different applications needed for

maintenance of the TWINPAC system. Icons for the various programs are located on the desktop.

Operation of the Windows operating system is not covered in this manual. Other applications are

addressed in individual paragraphs.

The CITECT program uses standard Windows operating procedures. The Operator clicks on the

desired icon or menu item and selects an operation from the various pull down menus. Details of the

operations are covered in individual paragraphs. More than one window (or screen) may be open and

actively displaying information at the same time.

Screen 2, Screen 2A is the basic blank ICE monitor screen. The toolbar across the top of the screen

presents a choice of eleven (11) pull down menus for access by the Operator. Clicking on a toolbar

icon will open that category and result in a screen or a pull down menu listing other screens. Clicking

Previous Document Homepage

20

on a topic in the pull down menu will open that screen. Some screens will contain information only.

Other screens will have Operator accessible control functions. Details of Operator functions are

covered in separate paragraphs.

The three (3) lines of active display along the left hand bottom section of the screen display the last

three (3) alarms sent to the alarm screen and will update as alarms occur.

On multi-unit sites, this display may include alarms from other units or systems. The source of the

alarm will be identified in the first column as originating from a particular unit with a tag name preface of

AO1 from Unit #1, AO2 from Unit #2 etc. The alarm may be identified by system as SCR or BOP. See

Screen 93 for typical alarms originating from the SCR or BOP. See Screen 46 for a typical alarm

originating from Unit #1.

3.3 Manipulating the Screens

3.3.1 Zooming. An open screen may be zoomed in or out by using the Magnifying Glass icons in

the lower left hand portion of the screen.

3.3.2 Printing. The screen may be printed by clicking on the Printer icon in the lower right hand

portion of the screen and following the Windows print options.

3.3.3 Close Screen. The screen is closed by clicking on the Open Book icon in the lower right hand

corner of the screen.

3.3.4 Scroll Alarms. The Up Arrow and Down Arrows to the right of the display allow the Operator

to scroll through alarms.

3.3.5 Display Alarm Screen. The Alarm Clock icon in the lower right hand corner of the screen

calls up the Alarm Page. See Screen 102.

3.3.6 Display Alarm Summary. The Alarm Clock over a Tabulation icon calls up the Alarm

Summary page. See Screen 103.

3.3.7 Scroll-Through Screens. The CW or CCW icons located at the bottom of the Analog screens

allows the Operator to scroll forwards or backwards through the three (3) screens.

3.3.8 Function Key F4. The F4 key toggles the display between Tag Names and Tag Descriptions.

3.3.9 Function Key F5. The F5 key toggles the display between English and Metric units.

3.3.10 Function Key F11. The F11 key toggles the ICE monitor screen to the Windows Desktop

screen.

3.3.11 Main. The Main icon on the Windows desktop screen toggles to the ICE monitor screen.

3.4 Navigating the Screens

A breakdown of each pull down tool bar icon follows. Cross-references are made to screen views and

Operating Procedures. See Screen 2, Screen 2A.

Previous Document Homepage

21

3.4.1 Earth Icon (Display Site Overview). Selecting the Earth icon will cause the Station

Overview window to be displayed. The Station Overview window shows a brief summary of unit

operating parameters and set points. The operator can manually start or stop the evaporative coolers

or select automatic operation. On multi-unit sites, each unit will have a small window. Each unit may be

started or stopped from its associated window. See Screen 3, Screen 3A.

3.4.2 Power Station Icon (Display BOP Overview). Selecting the Power Station icon will cause

the balance of plant (BOP) Main window to be displayed. The BOP Main window provides the Operator

with access to the various components of the BOP equipment. See Screen 4, Screen 4A, Screen 4B,

Screen 4C, Screen 4D, Screen 4E, Screen 4F, Screen 18, Screen 19, Screen 20, Screen 21 and

Screen 22. By clicking on the GO TO SCREEN the Operator can access the operating conditions of

that system. In addition, if the cursor is placed over a command such as START, STOP, OPEN,

CLOSE, ON, OFF, AUTO, MANUAL or RESET and that function is outlined by a red box, the Operator

may perform that operation by clicking on the command and responding to the standard Yes/No

prompt. Refer to SECTION 10 MANUAL OPERATION OF SYSTEMS, Paragraph 10.11 - BOP

Devices.

3.4.3 Street Light Icon (Display Sequence Start/Stop Menu). Selecting the Street Light icon

will display the Start/Stop pull down menu. See Screen 5.

3.4.3.1 Start/Stop. See Screen 6, Screen 6A, Screen 6B, Screen 6C and SECTION 9 NORMAL

SYSTEMS OPERATION. Versions of the Start/Stop screen derived from the MOBILEPAC have the

ability to display selected analog values, start sequence and stop sequence by clicking on the Tools

icon on that page. See Screens 6A and Screen 6B.

3.4.3.2 Unit Control. See Screen 7 and SECTION 9 NORMAL SYSTEMS OPERATION,

Paragraph 9.1 Auto Start for Power Production from the Standby Mode and Paragraph 9.2 Auto

Stop.

3.4.3.3 Start Sequence. See Screen 8, Screen 6B and SECTION 9 NORMAL SYSTEMS

OPERATION, Paragraph 9.1, Auto Start for Power Production from the Standby Mode.

3.4.3.4 Stop Sequence. See Screen 9 and Screen 6B and SECTION 9 NORMAL SYSTEMS

OPERATION, Paragraph 9.2 Auto Stop.

3.4.3.5 Permissives. All permissives for an engine, the auxiliary systems and the generator must be

green (READY) in order to achieve a READY TO START condition. See Screen 10, Screen 10A.

3.4.3.6 Digital Status. A red LED indicates the active state of the digital output. It does not indicate

an alarm, trouble or abnormal condition. See Screen 11.

3.4.4 Turbine Icon. See Screen 12.

3.4.4.1 A-Overview Screen. See Screen 13, Screen 13A. The A-Overview screen gives the

Operator a general view of A engine system operating parameters and a cutaway view of both the GG

and PT. This view is useful when explaining system operation to visitors. In addition, direct access to

other screens is available by clicking on one of the buttons along the right hand edge of the screen.

Previous Document Homepage

22

3.4.4.2 A-Loop Screen. See Screen 14. The A-Loop screen gives the Operator a graphic

representation of A engine Loop In Control (LIC) showing the reference and operation point for the NH,

NL, NP, EGT and ACCEL/DECEL loops.

3.4.4.3 A-EGT Profile Screen. See Screen 15. The A-EGT Profile screen gives the Operator a

graphic representation of the operating EGT profile of the A engine with bars indicating individual

thermocouple temperature shown above and below the EGT average.

See Screen 15A. Screen 15A replaces the bar graph screen in mid-2005. The superimposed graphics

show the Operator where the individual EGTs are operating compared to fleet wide limits. This screen

is useful in diagnosing problems.

NOTE

B screens are not shown in POWERPAC or MOBILEPAC

installations.

3.4.4.4 B-Overview Screen. The B-Overview screen is similar to A-Overview screen, but for B

engine. Refer to paragraph 3.4.4.1 above.

3.4.4.5 B-Loop Screen. The B-Loop screen is similar to A-Loop screen, but for B engine. Refer to

paragraph 3.4.4.2 above.

3.4.4.6 B-EGT Profile Screen. The B-EGT Profile screen is similar to A-EGT screen, but for B

engine. Refer to paragraph 3.4.4.3 above.

3.4.5 Scales Icon (Display Calibration Menu). See Screen 16.

3.4.5.1 Ancillary Site Configuration. See Screen 20. The Ancillary Site Configuration screen

provides specific site equipment data including installed equipment options, fuels and GG and PT serial

numbers. The serial numbers may be revised by the Operator if there is a GG or PT change by moving

the curser over the parameter to be changed, (the box will be outlined in red) typing in the new number

and pressing ENTER.

3.4.5.2 Electric Valves. See Screen 21, Screen 21A and SECTION 10 MANUAL OPERATION OF

SYSTEMS, Paragraph 10.7 - Electric Valves.

3.4.5.3 Overspeed Test. See Screen 22, Screen 22A and SECTION 10 MANUAL OPERATION

OF SYSTEMS, Paragraph 10.8 - Overspeed Test.

3.4.5.4 Cold Air Buffer. See Screen 24 and SECTION 10 MANUAL OPERATION OF SYSTEMS,

Paragraph 10.9 Cold Buffer.

3.4.5.5 A Thrust Balance. See Screen 26 and SECTION 10 MANUAL OPERATION OF

SYSTEMS, Paragraph 10.10 Thrust Balance.

3.4.5.6 B Thrust Balance. See Screen 26 and SECTION 10 MANUAL OPERATION OF

SYSTEMS, Paragraph 10.10 Thrust Balance.

Previous Document Homepage

23

3.4.6 Graph Icon (Display Trends Menu). See Screen 27. The Graph icon opens up the trending

function menu that is useful for systems maintenance and diagnostics. Details of this system are

covered in SECTION 11 DATA SYSTEMS, Paragraph 11.2 Trends Data System.

3.4.6.1 Unit. See Screen 28. The Unit selection opens up a menu of pre-configured trends screens

pertaining to unit systems.

3.4.6.1.1 Generator. See Screen 29.

3.4.6.1.2 Generator Lube Oil. See Screen 30.

3.4.6.1.3 Hydraulic Start. See Screen 31.

3.4.6.1.4 Generator Cooling. See Screen 32.

3.4.6.1.5 Generator Vibration. See Screen 33.

3.4.6.2 Engine A. See Screen 34. The Engine A selection opens up a menu of pre-configured trends

screens pertaining to Engine A systems.

3.4.6.2.1 EGT 1-7. See Screen 35.

3.4.6.2.2 EGT 3-9. See Screen 36.

3.4.6.2.3 Selected Speeds. See Screen 37.

3.4.6.2.4 Speed Derivatives. See Screen 38.

3.4.6.2.5 Engine Run. See Screen 39.

3.4.6.2.6 IGV /VSV. See Screen 40.

3.4.6.2.7 Start-Up. See Screen 41.

3.4.6.2.8 Vibration. See Screen 42.

3.4.6.2.9 GT Oil Temps. See Screen 43.

3.4.6.2.10 GT Lube Oil Press. See Screen 44.

3.4.6.2.11 Cold Buffer. See Screen 45.

3.4.6.3 Engine B. The Engine B selection opens up a menu of pre-configured trends screens

pertaining to Engine B systems similar to those listed in Paragraph 3.4.6.2 - Engine A.

3.4.6.4 User Defined. This selection opens up a menu of trends screens configured and saved by

the Operator. See Screen 93.

Previous Document Homepage

24

3.4.6.5 Process Analyst

3.4.6.5.1 Process Anal yst trending display See Screen 139 The Process Analyst screen allows

trending of multiple inputs using the same trend-able tags used in Citect trending. The trend can scroll

with independent variable display, allowing the user to unlock or lock scrolling features. Adding

variables is done using a search string. The button is used for this purpose. Unknown

variables can be substituted in the string with an asterisk.

3.4.7 Pump Icon (Display P&I Diagram Menu). See Screen 46.

3.4.7.1 Unit. See Screen 47. The Unit selection opens a sub-menu of screens which show schematic

outlines of three unit associated systems. These screens provide special Operator selectable

operations and system data.

3.4.7.1.1 Generator. See Screen 48. The Ancillary Generator screen presents a pictorial view of the

generator and approximate physical locations of the stator temperatures. It allows the Operator access

to the Power Factor and VAR control function. See SECTION 9 NORMAL SYSTEMS OPERATION,

Paragraph 9.1 Auto Start for TWINPAC Power Production from the Standby Mode and Paragraph

9.4 Manual Synchronization.

3.4.7.1.2 Generator Lube Oil. See Screen 49, Screen 49A. The Ancillary Generator Lube screen

shows a schematic view of the generator lube oil system and the system operating parameters. It

allows the Operator to perform the SYSTEMS TEST, SWITCH PUMPS and RESET control functions.

See SECTION 10 MANUAL OPERATION OF SYSTEMS, Paragraph 10.5 - Generator Lubrication

System.

3.4.7.1.3 Hydraulic Start. See Screen 50, Screen 50A. The Ancillary Hydraulic Start screen shows

a schematic view of the hydraulic starting system and the system operating parameters. It allows the

Operator to perform the SPIN ENGINE A, SPIN ENGINE B and RESET control functions. See

SECTION 10 MANUAL OPERATION OF SYSTEMS, Paragraph 10.3 Spin Engine.