Академический Документы

Профессиональный Документы

Культура Документы

138

Загружено:

Tirta Budiawan0 оценок0% нашли этот документ полезным (0 голосов)

30 просмотров4 страницы138 Fig. 176--Horizontal DUPLEX STEAM PUMP Longitudinal Cross Section NOMENCLATURE of PARTS HORIZONTAL, DUPLEX STEAM PUMP 1. Inlet to Steam Chest 2. Valve Nut or tappet 3. "D" Type Slide Valve 4. Valve Rod Stuffing Box 5. Valve Rod 7. Valve Rod Knuckle end 8. Valve Rod Connecting Link 9. Cross Shaft 11. Lever (See Note) 12. Crank (

Исходное описание:

Авторское право

© © All Rights Reserved

Доступные форматы

DOCX, PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документ138 Fig. 176--Horizontal DUPLEX STEAM PUMP Longitudinal Cross Section NOMENCLATURE of PARTS HORIZONTAL, DUPLEX STEAM PUMP 1. Inlet to Steam Chest 2. Valve Nut or tappet 3. "D" Type Slide Valve 4. Valve Rod Stuffing Box 5. Valve Rod 7. Valve Rod Knuckle end 8. Valve Rod Connecting Link 9. Cross Shaft 11. Lever (See Note) 12. Crank (

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате DOCX, PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

30 просмотров4 страницы138

Загружено:

Tirta Budiawan138 Fig. 176--Horizontal DUPLEX STEAM PUMP Longitudinal Cross Section NOMENCLATURE of PARTS HORIZONTAL, DUPLEX STEAM PUMP 1. Inlet to Steam Chest 2. Valve Nut or tappet 3. "D" Type Slide Valve 4. Valve Rod Stuffing Box 5. Valve Rod 7. Valve Rod Knuckle end 8. Valve Rod Connecting Link 9. Cross Shaft 11. Lever (See Note) 12. Crank (

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате DOCX, PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 4

138

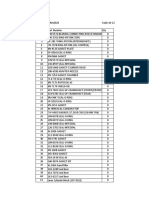

Fig. 176--Horizontal Duplex Steam Pump Longitudinal Cross Section

NOMENCLATURE OF PARTS

HORIZONTAL, DUPLEX STEAM PUMP

1. Inlet to Steam Chest

2. Valve Nut or Tappet

3. "D" Type Slide Valve

4. Valve Rod Stuffing Box

5. Valve Rod Stuffing Box Gland

6. Valve Rod

7. Valve Rod Knuckle End

8. Valve Rod Knuckle Pin

9. Valve Rod Connecting Link

10. Cross Shaft

*11. Lever (See Note)

*12. Crank (See Note)

13. Cross Shaft Stand or Pedestal

14. Cradle

15. Liquid Piston Rod Stuffing Box

Gland

16. Liquid End Stuffing Box

17. Liquid End Cylinder Casting

18. Discharge Valve Plate or Diaphragm

19. Discharge Cap or Head

20. Discharge Valve Spring Guard

21. Discharge Valve Spring

22. Discharge Valve Disc

23. Discharge Valve Seat

24. Suction Valve Spring

25. Suction Valve Disc

26. Discharge Outlet

28. Liquid Cylinder With Pressed-in Liner of

Bronze

29. Liquid Cylinder Head Cover

30. Suction Inlet

31. Piston Follower Nut

32. Piston Follower

33. Piston Body

34. Liquid Piston Rings (Hydraulic Duck-Metallic

or Rock-Hard Fibrous) Depending on service

35. Piston Rod

36. Piston Rod Spool or (Threaded, Split-Type

Crosshead)

37. Steam Piston Rod Stuffing Box Gland

38. Steam Piston Rod Stuffing Box

39. Steam Inlet Ports

40. Exhaust Ports

41. Steam Cylinder Piston With Cast Iron Rings

42. Steam Cylinder Head

43. Supporting Bases

*NOTE: Levers and Cranks

A long lever on right side connects to long crank

on left side to left steam cylinder valve.

A short lever on left side connects to short crank

on right steam cylinder valve.

27. Suction Valve Seat

139

PISTON ROD MOTION

The motion of the piston rod is controlled

by the slide valves in the steam chest. See

Fig. 177 At "c-c". The slide valves are so

adjusted that the steam is admitted to one

end of the cylinder to force the piston in

one direction. See Fig. 178. The slots in

the cylinder body at the base of the steam

chest are the steam ports. Slots "a-a" are

inlet ports, one on each end of the cylinder

which makes it double-acting. Slots "b-b"

are exhaust ports. Slot "f" is the main

exhaust port, cored through the casting to

exhaust discharge connection. The

mechanic is holding a slide valve in each

hand at "d" and "e" in Fig. 178.

VALVE TAPPET

The valve nut or tappet, Fig. 176 at "2", is placed

between the two IT-shaped lugs shown on the back

of the slide valve in Fig. 178 at "d". The tappet is

narrower in width than the space between these lugs,

giving a designed lost motion, usually 1/2", the

width of the inlet port on each side of the nut. When

the valve is set in central position or dead center as

in Fig. 176, it is in position for adjustment. This

condition can never occur in actual operation

because every port (inlet) is closed.

This lost motion designed in slide valves is provided

to eliminate a positive "dwell" on both cylinders

simultaneously, which would give a pulsating action

to the water discharge. The lost motion keeps one piston in motion at all times, eliminating

the undesirable surge which would be caused by the overlapping action.

As this sequence of motion continues, the plunger in the liquid-end of the pump forces the

water or oil to move in a continuous flow. This continuous flow is possible because one

plunger is going ahead when the plunger beside it is backing up. One plunger sucks the liquid

into the chamber, and the other plunger pushes the liquid that was sucked in on the previous

stroke out of the chamber. Figure 179 shows the liquid-end of the pump with the bonnet

removed. The mechanic is holding the discharge valve plate. One valve stem, valve, and

spring assembly have been removed.

Fig. 177-Adjusting Valve Slide Rods

Fig. 178-Checking Valve

Slide for Fit

140

PISTON ROD SPOOL

The piston rod carries 3. spool, Fig. 176 at

"36" and Fig. 180 at "f", located in a central

position between the steam and liquid ends.

The spool is fastened by a tapered, fitted pin

and a set screw; and it is cut out to form a U-

shaped opening which actuates the valve-

operating lever and also prevents the piston

rod from revolving. This revolving action

will occur if the piston rings bind in the

steam-piston grooves. (The action of the

steam on the diagonal-cut gaps of the piston

rings is similar to a screw or twisting thrust

as in a Mitchell-Thrust slipper-action.)

CYLINDRICAL SPOOL

Some pump manufacturers use a cylindrical

spool without a milled flat as in Fig. 180 at "f",

and to prevent the piston rod's turning they

employ a slotted extension on the spool which

engages a rib extension. The rib extension is cast

integral with the cradle casting, directly under

the piston-rod spool.

VALVE OPERATING LEVERS

The upper end of the valve operating lever (11,

Fig. 176) is keyed to a cross-shaft (10, Fig. 176).

The cross-shaft operates in bronze bushings in the cross-shaft stand (13, Fig. 176). The other

end of the shaft carries the crank (12, Fig. 176) which is connected by a pin through the

drilled end of the valve rod connecting link (9, Fig. 176). The other end of this link is

connected to the forked end of the valve rod called the valve rod knuckle end (7, Fig. 176) by

a knuckle pin (8, Fig. 176). The tappet (2, Fig. 176) is adjustable on the threaded valve rod

(6, Fig. 176) to permit adjustment of slide valves by disengaging knuckle pin and turning the

valve rod in or out, as required.

SLIDE VALVES

The two valve slides are shown at 1 and m, Fig. 182. Notice 1 slide is forward while the

adjoining slide is to the rear. Two steam ports may be seen at opposite ends of the steam

chest. Figure 185, "n" and "o",

Fig. 179--Liquid End of Pump with

Bonnet Removed

Fig. 180--Horizontal Pump

Valve Mechanism

141

Вам также может понравиться

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Honda Goldwing 1800 Service ManualДокумент3 страницыHonda Goldwing 1800 Service ManualTyson17% (6)

- New Generation Volvo Diesel Engine Fundamentals Classroom Training enДокумент408 страницNew Generation Volvo Diesel Engine Fundamentals Classroom Training enmliugong95% (43)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- Motor IO-240B PDFДокумент220 страницMotor IO-240B PDFoctavio jaramillo aОценок пока нет

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Bauer Drilling Rig Spare Parts CataloguesplДокумент9 страницBauer Drilling Rig Spare Parts Cataloguespljeeva100% (1)

- S90me-C9 2Документ367 страницS90me-C9 2Htet Myat SoeОценок пока нет

- 938g PDFДокумент24 страницы938g PDFLuis Fernando Vasquez Ramos100% (1)

- 700rc Ops ManualДокумент120 страниц700rc Ops ManualMalebrán Giovanni100% (2)

- Harry Fenton On Continental EnginesДокумент107 страницHarry Fenton On Continental EnginesJessie BechaydaОценок пока нет

- BMW M5254 Checking Camshaft Timing (M52TU - M54)Документ6 страницBMW M5254 Checking Camshaft Timing (M52TU - M54)head_masterОценок пока нет

- YEC Technical LetterДокумент163 страницыYEC Technical LetterBj Benitez0% (1)

- Engineering 2018 UG Admissions PolicyДокумент8 страницEngineering 2018 UG Admissions PolicyBudes DanielОценок пока нет

- Reman Catalogus CNHДокумент145 страницReman Catalogus CNHMMM-MMM100% (2)

- Detroit Diesel Two-Cycle Engines PDFДокумент492 страницыDetroit Diesel Two-Cycle Engines PDFMOHD NAJMAN BIN MUDA100% (1)

- 48 60B Project GuideДокумент520 страниц48 60B Project Guidenckpourlas100% (2)

- Peugeot 404 Owners Workshop Manual 1960-1975Документ136 страницPeugeot 404 Owners Workshop Manual 1960-1975Jonathan Bernabé González Medina100% (1)

- Lion Air Eticket Itinerary / Receipt: Rusli/Henry MRДокумент4 страницыLion Air Eticket Itinerary / Receipt: Rusli/Henry MRgavinasutionОценок пока нет

- Lagu 2 GNR Yg MantafДокумент1 страницаLagu 2 GNR Yg MantafTirta BudiawanОценок пока нет

- MCWP Master Jan 21Документ1 страницаMCWP Master Jan 21Tirta BudiawanОценок пока нет

- MCWP Master Jan 21Документ1 страницаMCWP Master Jan 21Tirta BudiawanОценок пока нет

- Hosts UmbrellaДокумент1 страницаHosts UmbrellaFabsor SoralОценок пока нет

- A LG Iwan Fals A5Документ1 страницаA LG Iwan Fals A5Tirta BudiawanОценок пока нет

- Bridgestone tire catalogДокумент11 страницBridgestone tire catalogTirta BudiawanОценок пока нет

- Knuth Universal HeavyДокумент9 страницKnuth Universal HeavyTirta BudiawanОценок пока нет

- Westlake ZX7045Документ1 страницаWestlake ZX7045Tirta BudiawanОценок пока нет

- A Lagu 2 Slank 4Документ1 страницаA Lagu 2 Slank 4Tirta BudiawanОценок пока нет

- A Presiden6Документ1 страницаA Presiden6Tirta BudiawanОценок пока нет

- Aisi 4140 From Cast MetalДокумент4 страницыAisi 4140 From Cast MetalTirta BudiawanОценок пока нет

- Makmur Sentosa JayaДокумент1 страницаMakmur Sentosa JayaTirta BudiawanОценок пока нет

- A Presiden4Документ1 страницаA Presiden4Tirta BudiawanОценок пока нет

- Lagu 2 GNR Yg BaikДокумент1 страницаLagu 2 GNR Yg BaikTirta BudiawanОценок пока нет

- Lagu 2 GNR YgcadasДокумент1 страницаLagu 2 GNR YgcadasTirta BudiawanОценок пока нет

- Aneka Training Safety (Dep Kelautan FMIPA-UI)Документ5 страницAneka Training Safety (Dep Kelautan FMIPA-UI)Idil FitriОценок пока нет

- Casting MaterialsДокумент42 страницыCasting MaterialsTirta BudiawanОценок пока нет

- ReadmeДокумент1 страницаReadmetom_heffernanОценок пока нет

- Report Cilacap 1 November 2013Документ1 страницаReport Cilacap 1 November 2013Tirta BudiawanОценок пока нет

- Top 3 Guns N' Roses SongsДокумент1 страницаTop 3 Guns N' Roses SongsTirta BudiawanОценок пока нет

- Casting MaterialsДокумент42 страницыCasting MaterialsTirta BudiawanОценок пока нет

- Flowerve PumpДокумент76 страницFlowerve PumpTirta BudiawanОценок пока нет

- Lion Air eTicket Itinerary Receipt CGK-PLM-CGKДокумент2 страницыLion Air eTicket Itinerary Receipt CGK-PLM-CGKTirta BudiawanОценок пока нет

- Perincian Biaya Operasional Kendaraan Merk / TipeДокумент1 страницаPerincian Biaya Operasional Kendaraan Merk / TipeTirta BudiawanОценок пока нет

- 316 Stainless Steel Round Rod 2Документ56 страниц316 Stainless Steel Round Rod 2Tirta BudiawanОценок пока нет

- Ei Practicing Final Pack EnglishДокумент23 страницыEi Practicing Final Pack EnglishTirta BudiawanОценок пока нет

- Energy Isolation GRACE - ElectricalДокумент8 страницEnergy Isolation GRACE - ElectricalTirta BudiawanОценок пока нет

- Ei Practicing Final Pack IndoДокумент24 страницыEi Practicing Final Pack IndoTirta BudiawanОценок пока нет

- Efficient EGS generator sets for all your power needsДокумент5 страницEfficient EGS generator sets for all your power needsJohn Garnet100% (1)

- Nippon Piston RingsДокумент26 страницNippon Piston Ringsadam_nell_1Оценок пока нет

- Construction Equipment Performance OptimizationДокумент10 страницConstruction Equipment Performance OptimizationBolivar LemaОценок пока нет

- Parts list for Kado 10-12 cylinder engine rebuildДокумент7 страницParts list for Kado 10-12 cylinder engine rebuildangga andi ardiansyahОценок пока нет

- Parts Engine Cummins QSL9-G3Документ1 страницаParts Engine Cummins QSL9-G3Defly GustiОценок пока нет

- QuickServe en Línea - (4310736) ISX15 CM2250 SN Manual de ServicioДокумент14 страницQuickServe en Línea - (4310736) ISX15 CM2250 SN Manual de ServicioHamilton mirandaОценок пока нет

- D830 Generator Technical SpecificationsДокумент5 страницD830 Generator Technical SpecificationsJovan KosticОценок пока нет

- Compressor Oils: Product Kin. Viscosity CST at 40 C Vi Min. Flash Point Coc, C Min. Description / ApplicationДокумент2 страницыCompressor Oils: Product Kin. Viscosity CST at 40 C Vi Min. Flash Point Coc, C Min. Description / ApplicationRajput PratiksinghОценок пока нет

- Load Test On Single Cylinder 4s Diesel EngineДокумент8 страницLoad Test On Single Cylinder 4s Diesel EngineMathew JohnОценок пока нет

- Reciprocating Pumps at DMMMSU Mid La Union CampusДокумент21 страницаReciprocating Pumps at DMMMSU Mid La Union CampusLorenz BanadaОценок пока нет

- 1418881285399-Wdg-3a (English)Документ172 страницы1418881285399-Wdg-3a (English)Manpreet SinghОценок пока нет

- Seminar PPT On Pollution Less EngineДокумент24 страницыSeminar PPT On Pollution Less Engineashwin41732Оценок пока нет

- 03 Engine Bottom EndДокумент31 страница03 Engine Bottom EndRohit Raj100% (1)

- M.I.E.T. Thermal Engineering Course MaterialДокумент197 страницM.I.E.T. Thermal Engineering Course MaterialJohann Roy CruzОценок пока нет

- Piston y Anillos2Документ5 страницPiston y Anillos2Carlos Eduardo VargasОценок пока нет