Академический Документы

Профессиональный Документы

Культура Документы

Quality Control: Chapter 11-Reliability

Загружено:

Mohsin Munawar0 оценок0% нашли этот документ полезным (0 голосов)

76 просмотров44 страницыQuality Control

Оригинальное название

Reliability

Авторское право

© © All Rights Reserved

Доступные форматы

DOCX, PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документQuality Control

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате DOCX, PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

76 просмотров44 страницыQuality Control: Chapter 11-Reliability

Загружено:

Mohsin MunawarQuality Control

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате DOCX, PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 44

Quality Control

Chapter 11- Reliability

PowerPoint presentation to accompany

Besterfield

Quality Control, 8e

PowerPoints created by Rosida Coowar

Outline

D Fundamental Aspects

D Additional Statistical Aspects

D Life and Reliability Testing Plans

D Availability and Maintainability

Besterfield: Quality Control, 8

th

ed.. 2009 Pearson Education, Upper Saddle River, NJ 07458.

All rights reserved

Learning Objectives

When you have completed this chapter you should

be able to:

D Know the definition of reliability and the

factors associated with it.

D Know the various techniques to obtain reliability.

D Understand the probability distributions, failure

curves, and reliability curves as a factor of time.

Besterfield: Quality Control, 8

th

ed.. 2009 Pearson Education, Upper Saddle River, NJ 07458.

All rights reserved

Learning Objectives contd.

When you have completed this chapter you

should be able to:

D Calculate the failure rate under different

conditions.

D Construct the life history curve and describe its

three phases.

D Calculate the normal, exponential, and Weibull

failure rate.

Besterfield: Quality Control, 8

th

ed.. 2009 Pearson Education, Upper Saddle River, NJ 07458.

All rights reserved

Learning Objectives contd.

When you have completed this chapter you

should be able to:

D Construct the OC Curve

D Determine life and reliability test curves

D Calculate the normal, exponential, and Weibull failure rate

D Understand the different types of test design

D Understand the concepts of availability and maintainability

Besterfield: Quality Control, 8

th

ed.. 2009 Pearson Education, Upper Saddle River, NJ 07458.

All rights reserved

Reliability

D Generally defined as the ability of a product to

perform as expected over time.

D Formally defined as the probability that a

product, piece of equipment, or system will

perform its intended function for a stated period

of time under specified operating conditions.

Besterfield: Quality Control, 8

th

ed.. 2009 Pearson Education, Upper Saddle River, NJ 07458.

All rights reserved

Reliability

D Means quality over the long run.

D A product that works for a long period

of time is a reliable one.

D Since all units of a product will fail at

different times, reliability is a

probability.

Besterfield: Quality Control, 8

th

ed.. 2009 Pearson Education, Upper Saddle River, NJ 07458.

All rights reserved

Reliability

There are four factors associated with Reliability:

1. Numerical Value.

D The numerical value is the probability that

the product will function satisfactorily

during a particular time.

Besterfield: Quality Control, 8

th

ed.. 2009 Pearson Education, Upper Saddle River, NJ 07458.

All rights reserved

Reliability

There are four factors associated with Reliability:

2. Intended Function.

D Product are designed for particular

applications and are expected to be able to

perform those applications.

Besterfield: Quality Control, 8

th

ed.. 2009 Pearson Education, Upper Saddle River, NJ 07458.

All rights reserved

Reliability

There are four factors associated with Reliability:

3. Life.

D How long the product is expected to last.

Product life is specified as a function of

usage, time, or both.

Besterfield: Quality Control, 8

th

ed.. 2009 Pearson Education, Upper Saddle River, NJ 07458.

All rights reserved

Reliability

There are four factors associated with Reliability:

4. Environmental Conditions

D Indoors.

D Outdoors.

D Storage.

D Transportation.

Besterfield: Quality Control, 8

th

ed.. 2009 Pearson Education, Upper Saddle River, NJ 07458.

All rights reserved

Achieving Reliability

Emphasis:

1. The Consumer Protection Act of 1972.

2. Products are more complicated.

3. Automation.

Besterfield: Quality Control, 8

th

ed.. 2009 Pearson Education, Upper Saddle River, NJ 07458.

All rights reserved

System Reliability

D As products become more complex (have more

components), the chance that they will not

function increases.

D The method of arranging the components affects

the reliability of the entire system.

D Components can be arranged in series, parallel,

or a combination.

Besterfield: Quality Control, 8

th

ed.. 2009 Pearson Education, Upper Saddle River, NJ 07458.

All rights reserved

Series System

D For a series systems, the reliability is the

product of the individual components.

1 2 n

R

S

= R

1

R

2

... R

n

D As components are added to the series, the

system reliability decreases.

Besterfield: Quality Control, 8

th

ed.. 2009 Pearson Education, Upper Saddle River, NJ 07458.

All rights reserved

Parallel System

1

2

n

R

s

= 1 - (1 - R

1

) (1 - R

2

)... (1 - R

n

)

D When a component does not function, the product

continues to function, using another component,

until all parallel components do not function.

Besterfield: Quality Control, 8

th

ed.. 2009 Pearson Education, Upper Saddle River, NJ 07458.

All rights reserved

R

Series-Parallel System

C

R

A

R

B

R

D

C

A B D

C

R

C

D Convert to equivalent series system

R

A

R

B

R

D

A B C D

R

C

= 1 (1-R

C

)(1-R

C

)

Besterfield: Quality Control, 8

th

ed.. 2009 Pearson Education, Upper Saddle River, NJ 07458.

All rights reserved

Design

D The most important aspect of reliability is the

design.

D It should be as simple as possible.

D The fewer the number of components, the

greater the reliability.

D Another way of achieving reliability is to have a

backup or redundant component (parallel

component).

Besterfield: Quality Control, 8

th

ed.. 2009 Pearson Education, Upper Saddle River, NJ 07458.

All rights reserved

Design

D Reliability can be achieved by overdesign.

D The use of large factors of safety can increase the

reliability of a product.

D When an unreliable product can lead to a fatality

or substantial financial loss, a fail-safe type of

device should be used.

D The maintenance of the system is an important

factor in reliability.

Besterfield: Quality Control, 8

th

ed.. 2009 Pearson Education, Upper Saddle River, NJ 07458.

All rights reserved

Production

D The second most important aspect of

reliability is the production process.

D Emphasis should be placed on those

components which are least reliable.

D Production personnel.

Besterfield: Quality Control, 8

th

ed.. 2009 Pearson Education, Upper Saddle River, NJ 07458.

All rights reserved

Transportation

D The third most important aspect of reliability

is the transportation.

D Packaging

D Shipment

D Performance of the product by the customer

is the final evaluation.

D Good packaging techniques and shipment

evaluation are essential.

Besterfield: Quality Control, 8

th

ed.. 2009 Pearson Education, Upper Saddle River, NJ 07458.

All rights reserved

Additional Statistical Aspects

Distributions Applicable to Reliability:

D Exponential distribution.

D Normal distribution.

D Weibull distribution.

Reliability Curves:

D The curves as a function of time.

Besterfield: Quality Control, 8

th

ed.. 2009 Pearson Education, Upper Saddle River, NJ 07458.

All rights reserved

Additional Statistical Aspects

Reliability Curves:

D The reliability curves for the exponential,

normal and Weibull distributions as a

function of time are given in Figure 11-2(b) .

Besterfield: Quality Control, 8

th

ed.. 2009 Pearson Education, Upper Saddle River, NJ 07458.

All rights reserved

Additional Statistical Aspects

Failure-Rate Curve:

D It is important in describing the life-history

curve of a product.

D See Figure 11-2.

Besterfield: Quality Control, 8

th

ed.. 2009 Pearson Education, Upper Saddle River, NJ 07458.

All rights reserved

Life History Curve

D The curve, sometimes referred to as the

bathtub curve, is a comparison of failure

rate with time.

D It has three distinct phases:

D The debugging phase.

D The chance failure phase.

D The wear-out phase.

Besterfield: Quality Control, 8

th

ed.. 2009 Pearson Education, Upper Saddle River, NJ 07458.

All rights reserved

Life History Curve

Infant

mortality

period

Debugging

Phase

Chance Failure

Phase

Wear Out

Phase

Besterfield: Quality Control, 8

th

ed.. 2009 Pearson Education, Upper Saddle River, NJ 07458.

All rights reserved

Life History Curve

1. The debugging phase:

It is characterized by marginal and short-life

parts that cause a rapid decrease in the

failure rate.

It may be part of the testing activity prior to

shipment for some products.

The Weibull distribution <1 is used to

describe the occurrence of failures.

Besterfield: Quality Control, 8

th

ed.. 2009 Pearson Education, Upper Saddle River, NJ 07458.

All rights reserved

Life History Curve

2. The chance failure phase:

Failures occur in a random manner due to the

constant failure rate. The Exponential and the

Weibull distributions = 1 are best suited to

describe this phase.

3. The wear-out phase:

Is depicted by a sharp raise in failure rates. The

Normal distribution and the Weibull distribution

>1 are used to describe this phase.

Besterfield: Quality Control, 8

th

ed.. 2009 Pearson Education, Upper Saddle River, NJ 07458.

All rights reserved

Normal Failure Analysis

D The Weibull distribution is usually uses.

D The Normal distribution.

R(t): Reliability at time t

P(t): Probability of failure or area of the

normal curve to the left of time t. Table A.

Besterfield: Quality Control, 8

th

ed.. 2009 Pearson Education, Upper Saddle River, NJ 07458.

All rights reserved

Exponential Failure Analysis

Exponential distribution:

Rt = e

t/

Where:

t: Time or cycles.

: Mean life.

Besterfield: Quality Control, 8

th

ed.. 2009 Pearson Education, Upper Saddle River, NJ 07458.

All rights reserved

Weibull Failure Analysis

D Can be used for the debugging phase (<1)

and the chance failure phase (=1).

D By setting = 1, the Weibull equals the

exponential.

D By setting =3.4, the Weibull approximates

the Normal.

Rt = e

(t/)

Where is the Weibull slope.

Besterfield: Quality Control, 8

th

ed.. 2009 Pearson Education, Upper Saddle River, NJ 07458.

All rights reserved

OC Curve Construction

Steps:

1. Assume values for the mean life .

2. These values are converted to the failure

rate, l =1/ .

3. Calculate the expected average number of

failures nTl.

4. From Table C of the Appendix using nTl and

c value, get Pa.

Besterfield: Quality Control, 8

th

ed.. 2009 Pearson Education, Upper Saddle River, NJ 07458.

All rights reserved

Life and Reliability Testing Plans

Type of Tests:

D Failure-Terminated: These life-test sample

plans are terminated when a preassigned

number of failures occurs to the sample.

D Time-Terminated: This life-test sampling

plan is terminated when the sample obtains

a predetermined test time.

Besterfield: Quality Control, 8

th

ed.. 2009 Pearson Education, Upper Saddle River, NJ 07458.

All rights reserved

Life and Reliability Testing Plans

Type of Tests contd.:

D Sequential: A third type of life-testing

plan is a sequential life-test sampling

plan whereby neither the number of

failures nor the time required to reach

a decision are fixed in advance.

Besterfield: Quality Control, 8

th

ed.. 2009 Pearson Education, Upper Saddle River, NJ 07458.

All rights reserved

Life and Reliability Testing Plans

Tests are based on one or more of the

following characteristics:

D Mean life: the average life of the product.

D Failure rate: the percentage of failures per

unit time or number of cycles.

Besterfield: Quality Control, 8

th

ed.. 2009 Pearson Education, Upper Saddle River, NJ 07458.

All rights reserved

Life and Reliability Testing Plans

Test are based on one or more of the following

characteristics contd.:

D Hazard rate: the instantaneous failure rate

at a specified time.

D Reliable life: the life beyond which some

specified portion of the items in the lot will

survive.

Besterfield: Quality Control, 8

th

ed.. 2009 Pearson Education, Upper Saddle River, NJ 07458.

All rights reserved

Handbook H108

D Quality Control Reliability Handbook H108 gives

sampling procedures and tables for life and

reliability testing.

D Sampling plans in the handbook are based on

the exponential distribution.

D Provides for the three different types of test:

failure-terminated, time-terminated, and

sequential.

Besterfield: Quality Control, 8

th

ed.. 2009 Pearson Education, Upper Saddle River, NJ 07458.

All rights reserved

Handbook H108

D The handbook is over 70 pages long.

D The time-terminated plan:

1. Stipulated producers risk, consumers

risk, and sample size.

2. Stipulated producers risk, rejection

number, and sample size.

3. Stipulated producers risk, consumers

risk, and test time.

Besterfield: Quality Control, 8

th

ed.. 2009 Pearson Education, Upper Saddle River, NJ 07458.

All rights reserved

Reliability Management

D Define customer performance requirements.

D Determine important economic factors and

relationship with reliability requirements.

D Define the environment and conditions of

product use.

Besterfield: Quality Control, 8

th

ed.. 2009 Pearson Education, Upper Saddle River, NJ 07458.

All rights reserved

Reliability Management

D Select components, designs, and

vendors that meet reliability and cost

criteria.

D Determine reliability requirements for

machines and equipments.

D Analyze field reliability for

improvement.

Besterfield: Quality Control, 8

th

ed.. 2009 Pearson Education, Upper Saddle River, NJ 07458.

All rights reserved

Availability and Maintainability

For long-lasting products and services such as

refrigerators, electric power lines, and front-line

services, the time-related factors of availability,

reliability, and maintainability are interrelated.

Besterfield: Quality Control, 8

th

ed.. 2009 Pearson Education, Upper Saddle River, NJ 07458.

All rights reserved

Availability

D It is a time-related factor that measures

the ability of a product or service to

perform its designated function.

D The product or service is available when it

is in the operational state, which includes

active and standby use.

Besterfield: Quality Control, 8

th

ed.. 2009 Pearson Education, Upper Saddle River, NJ 07458.

All rights reserved

Availability

Where:

MTBM = mean time between

maintenance

MDT = mean down time

MTBF = mean time between failures

MTTR = mean time to repair

Besterfield: Quality Control, 8

th

ed.. 2009 Pearson Education, Upper Saddle River, NJ 07458.

All rights reserved

Maintainability

Maintainability is the probability that a system

or product can be retained in, or one that has

failed can be restored to, operating condition in

a specified amount of time.

Besterfield: Quality Control, 8

th

ed.. 2009 Pearson Education, Upper Saddle River, NJ 07458.

All rights reserved

Maintainability

D Maintainability is the totality of design

factors that allows maintenance to be

accomplished easily.

D Preventive maintenance reduces the risk of

failure.

D Corrective maintenance is the response to

failures.

Besterfield: Quality Control, 8

th

ed.. 2009 Pearson Education, Upper Saddle River, NJ 07458.

All rights reserved

Вам также может понравиться

- Introduction to Computational Science: Modeling and Simulation for the Sciences - Second EditionОт EverandIntroduction to Computational Science: Modeling and Simulation for the Sciences - Second EditionРейтинг: 3 из 5 звезд3/5 (2)

- Quality Engineering: "Reliability"Документ38 страницQuality Engineering: "Reliability"Fong Wei JunОценок пока нет

- Quality ControlДокумент89 страницQuality ControlZahir RayhanОценок пока нет

- Ansi Z1.4Документ64 страницыAnsi Z1.4Chetan DОценок пока нет

- Quality Control Quality Control: Chapter 5-Control Charts For Variables Chapter 5 - Control Charts For VariablesДокумент45 страницQuality Control Quality Control: Chapter 5-Control Charts For Variables Chapter 5 - Control Charts For VariablesHafiz AbdulRehmanОценок пока нет

- QualityДокумент64 страницыQualityZahir RayhanОценок пока нет

- Introduction To QualityДокумент30 страницIntroduction To QualityZainОценок пока нет

- Chapter 6 Control Charts For Variables (1) 2021Документ133 страницыChapter 6 Control Charts For Variables (1) 2021khalil alhatabОценок пока нет

- Chapter 1quality ReviewДокумент25 страницChapter 1quality Reviewkem SanОценок пока нет

- Chapter 6Документ36 страницChapter 6Amroz AfzalОценок пока нет

- Ch01 - Introduction To QualityДокумент48 страницCh01 - Introduction To QualityOfentse RanalaОценок пока нет

- Quality ControlДокумент87 страницQuality ControlZahir RayhanОценок пока нет

- CH 01Документ22 страницыCH 01Nsovo ShimangeОценок пока нет

- Quality ControlДокумент46 страницQuality ControlZahir RayhanОценок пока нет

- Ch014 - Taguchi's Quality EngineeringДокумент59 страницCh014 - Taguchi's Quality EngineeringOfentse RanalaОценок пока нет

- Chapter 1Документ38 страницChapter 1Muhammad Abubakar Muhammad ShoaibОценок пока нет

- Introduction To Quality: (Formerly Titled Quality Control 8th Edition)Документ48 страницIntroduction To Quality: (Formerly Titled Quality Control 8th Edition)yas ziaОценок пока нет

- Lec # 3, 4, 5 (Total Quality Management) (Compatibility Mode)Документ31 страницаLec # 3, 4, 5 (Total Quality Management) (Compatibility Mode)Hafiz AbdulRehmanОценок пока нет

- QC Students MaterialДокумент254 страницыQC Students MaterialSugrib K ShahaОценок пока нет

- Chapter 1 - Instructors NotesДокумент26 страницChapter 1 - Instructors NotesShubham MahajanОценок пока нет

- Heizer - 06 AddedДокумент94 страницыHeizer - 06 AddedYoutubers WajihaОценок пока нет

- TOtal Quality ControlДокумент54 страницыTOtal Quality ControlSAMGPROОценок пока нет

- Lec # 3, 4, 5 (Total Quality Management) - EdittedДокумент50 страницLec # 3, 4, 5 (Total Quality Management) - EdittedUsamaIjazОценок пока нет

- Lecture 8 ReliabilityДокумент48 страницLecture 8 ReliabilityUves AnsariОценок пока нет

- Managing Quality 14012021 112347pm 10022021 104850pmДокумент36 страницManaging Quality 14012021 112347pm 10022021 104850pmnuman choudharyОценок пока нет

- chap 17.pptصيانة وادارةДокумент35 страницchap 17.pptصيانة وادارةmohammedОценок пока нет

- HR Om11 ch07 PPTДокумент62 страницыHR Om11 ch07 PPTNinik SiindoroputriiОценок пока нет

- Introduction To Materials ManagementДокумент50 страницIntroduction To Materials ManagementrknanduriОценок пока нет

- HR Om11 ch07Документ62 страницыHR Om11 ch07ForkensteinОценок пока нет

- Office Equipment and FurnitureДокумент23 страницыOffice Equipment and FurnitureDevilZaaОценок пока нет

- Production Planning SystemДокумент52 страницыProduction Planning SystemShahadОценок пока нет

- Pp01aДокумент32 страницыPp01aAlexandra NeacsuОценок пока нет

- Heizer - 06 AddedДокумент94 страницыHeizer - 06 AddedAbbas Haider AliОценок пока нет

- Chapt 06Документ23 страницыChapt 06JG EusebioОценок пока нет

- 09 Lot-By-lot Acceptance Sampling For AttributesДокумент46 страниц09 Lot-By-lot Acceptance Sampling For AttributesHarsh DeshmukhОценок пока нет

- Appraising Performance of Office EmployeesДокумент32 страницыAppraising Performance of Office EmployeesDevilZaaОценок пока нет

- Ch07 Process StrategyДокумент63 страницыCh07 Process StrategyFayza FauziahОценок пока нет

- Chapter 1 (Introduction To Quality)Документ24 страницыChapter 1 (Introduction To Quality)AsjadОценок пока нет

- Managing Quality: Mesfin & Eshetu © 2004 by Prentice Hall, Inc., Upper Saddle River, N.JДокумент75 страницManaging Quality: Mesfin & Eshetu © 2004 by Prentice Hall, Inc., Upper Saddle River, N.JHundee GadaaОценок пока нет

- W14 EnterpriseДокумент38 страницW14 EnterpriseArizky Margo AgungОценок пока нет

- Introduction To Materials Management: Chapter 4 - Material Requirements PlanningДокумент33 страницыIntroduction To Materials Management: Chapter 4 - Material Requirements PlanningNaveen Jacob JohnОценок пока нет

- Acceptance Sampling Types TrainingДокумент64 страницыAcceptance Sampling Types TrainingJerry GoetzОценок пока нет

- D. Summers Chap 12 Cost of Quality SlidesДокумент23 страницыD. Summers Chap 12 Cost of Quality SlidesmawandeОценок пока нет

- W13 Cost AnalysisДокумент51 страницаW13 Cost AnalysisArizky Margo AgungОценок пока нет

- Topic6 - Managing Quality - ch06 - 240220Документ32 страницыTopic6 - Managing Quality - ch06 - 240220fatimaОценок пока нет

- Preventive Maintenance and ReliabilityДокумент33 страницыPreventive Maintenance and ReliabilityKrislyn Ann Austria AldeОценок пока нет

- Total Quality ManagementДокумент83 страницыTotal Quality Managementfakhar alamgirОценок пока нет

- OM ch06-TQMДокумент72 страницыOM ch06-TQMkhan aghaОценок пока нет

- Chapter 4-Statistical Process Control: Powerpoint Presentation To AccompanyДокумент33 страницыChapter 4-Statistical Process Control: Powerpoint Presentation To AccompanyTricia Alianna SungaОценок пока нет

- MHSW 5 - Bab 6 - Manajemen KualitasДокумент45 страницMHSW 5 - Bab 6 - Manajemen KualitasAryo AxxeОценок пока нет

- Maintenance and ReliabilityДокумент55 страницMaintenance and ReliabilityAkash_C1992Оценок пока нет

- 6.quality ManagementДокумент80 страниц6.quality Managementangeladeocampo27Оценок пока нет

- Design of Goods and ServicesДокумент97 страницDesign of Goods and ServicesThreehunglows Best OfОценок пока нет

- CH - 5Документ43 страницыCH - 5ende workuОценок пока нет

- 5 ReliabilityДокумент17 страниц5 ReliabilityP.T. SaleendranОценок пока нет

- Introduction To Materials Management: Chapter 3 - Master SchedulingДокумент29 страницIntroduction To Materials Management: Chapter 3 - Master SchedulingShahadОценок пока нет

- Design of Goods and ServicesДокумент97 страницDesign of Goods and ServicesAhmed SherebaОценок пока нет

- Heizer 17Документ33 страницыHeizer 17Vanness HalimОценок пока нет

- Minggu 15 - Spatial Decision Support SystemДокумент30 страницMinggu 15 - Spatial Decision Support SystemAldaОценок пока нет

- Green Modern Ecology Ecosystem PresentationДокумент10 страницGreen Modern Ecology Ecosystem PresentationJoaquin PalominoОценок пока нет

- ec6011-1-HAndwritten Notes PDFДокумент165 страницec6011-1-HAndwritten Notes PDFSakthi VelОценок пока нет

- SAP IntroductionДокумент7 страницSAP Introductionsaurabh.rai83Оценок пока нет

- As IEC 61511.2-2004 Functional Safety - Safety Instrumented Systems For The Process Industry Sector GuidelineДокумент10 страницAs IEC 61511.2-2004 Functional Safety - Safety Instrumented Systems For The Process Industry Sector GuidelineSAI Global - APACОценок пока нет

- Sre Assignment 3Документ9 страницSre Assignment 3ALI ANWARОценок пока нет

- PreviewpdfДокумент61 страницаPreviewpdfUzair Khaleeq uz ZamanОценок пока нет

- Queuing Templates: This Worksheet Computes Queuing Results For The Following ModelsДокумент21 страницаQueuing Templates: This Worksheet Computes Queuing Results For The Following ModelsDavid Gasca FigueroaОценок пока нет

- BCA Railway Reservation SystemДокумент30 страницBCA Railway Reservation SystemSourav NathОценок пока нет

- 3-3-6 Plan Quality and IVV PlanДокумент5 страниц3-3-6 Plan Quality and IVV PlangridechОценок пока нет

- FeedbackДокумент43 страницыFeedbackJanmarc CorpuzОценок пока нет

- Develop A Narrative Solution To A Given Task Module 5.8Документ13 страницDevelop A Narrative Solution To A Given Task Module 5.8Jabari VialvaОценок пока нет

- SAP Material Management MRP Mechanics MRP Type "VB" Re-Order PointДокумент15 страницSAP Material Management MRP Mechanics MRP Type "VB" Re-Order PointmohhitОценок пока нет

- C Is 201 CH 2 Review AnswersДокумент5 страницC Is 201 CH 2 Review AnswersBigcat LoveОценок пока нет

- Origional HRMS Final Report Part3Документ32 страницыOrigional HRMS Final Report Part3Jatin Sharan0% (1)

- Chapter 5 ANNДокумент31 страницаChapter 5 ANNHafisIzranОценок пока нет

- CHANGE 2 BY GERD LEONHARD VideoДокумент2 страницыCHANGE 2 BY GERD LEONHARD VideoBotany KC Anne Sevilleja-BrionesОценок пока нет

- Software Architecture DesignДокумент39 страницSoftware Architecture DesignandyxiangОценок пока нет

- Preventive Maintenance ProgramДокумент15 страницPreventive Maintenance Programjayson bastian marchan sotoОценок пока нет

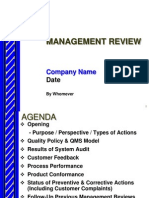

- Management ReviewДокумент17 страницManagement ReviewRamesh Acharya100% (4)

- Theoretical Approaches To Explaining Second Language Learning PDFДокумент2 страницыTheoretical Approaches To Explaining Second Language Learning PDFWALDO RUIZ LOPEZОценок пока нет

- Signal Flow Graph - GATE Study Material in PDFДокумент5 страницSignal Flow Graph - GATE Study Material in PDFAtul ChoudharyОценок пока нет

- CSC 1017 System Analysis and Design First AssignmentДокумент6 страницCSC 1017 System Analysis and Design First AssignmentAchyut NeupaneОценок пока нет

- Data ScienceДокумент16 страницData ScienceHarsh OjhaОценок пока нет

- Travel Time Prediction Using Random ForestДокумент55 страницTravel Time Prediction Using Random ForestynrakeshОценок пока нет

- Addis Ababa Science and Technology Department of Electrical and Computer Engineering Introduction To Control System Assignment ThreeДокумент1 страницаAddis Ababa Science and Technology Department of Electrical and Computer Engineering Introduction To Control System Assignment ThreehilmegnawОценок пока нет

- Wollo University KIOT Department of Software Engineering Agent Based Programming Assignment 1Документ6 страницWollo University KIOT Department of Software Engineering Agent Based Programming Assignment 1Software EngineerОценок пока нет

- Unified Funtional Testing Q1Документ12 страницUnified Funtional Testing Q1Alec BrentОценок пока нет

- Based Python Code Generator For CNNДокумент11 страницBased Python Code Generator For CNNVj KumarОценок пока нет

- Autopoiesis: A Review and A ReappraisalДокумент4 страницыAutopoiesis: A Review and A ReappraisalCarlos Guillermo Carrillo BolañosОценок пока нет