Академический Документы

Профессиональный Документы

Культура Документы

HP-LP Bypass System Advantages

Загружено:

karuna346Исходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

HP-LP Bypass System Advantages

Загружено:

karuna346Авторское право:

Доступные форматы

Highpressure(HP)andLowpressure(LP)bypasssystemsareusedforquickstartupoftheunitaswell

asduringtripout,whereloadrejectionattheturbinedoesnotautomaticallyleadtoaboilertrip.Witha

bypasssystem,startupisquicker.ThesystemdivertsthesteamgeneratedbytheboilertotheRe

heater/Condenser,atthesametimereducingthepressureandtemperatureofsteam,thusmaintaining

aminimumcirculationofsteamthroughtheboiler.Thisenablesrunningtheboilerwithouttheturbine

inservice,ensuringflowthroughreheatercoils.HPLPbypasssystemhasthefollowingadvantages:

1.Theprolongedventingofsafetyvalvestoatmosphereisavoided,therebyreducingDMwaterlossand

cuttingnoiseemission.2.Sustainedflowthroughtheboilerheatingsurfacesisassured,ensuringRe

heaterprotectionduringstartupofunits.3.Ifthegridcannotacceptpower,theunitcanbekept

runningonhouseload.

HP LP BYPASS SYSTEM IN THERMAL POWER PLANTS:

HP LP BYPASS SYSTEM IN THERMAL POWER PLANTS

OBJECTIVE:

OBJ ECTIVE The most important feature of this system is to allow operation of the boiler

independent of the availability of the turbine. In the event of turbine trip, the boiler can be kept in

operation and the bypass system provides an alternative path for flow of steam from boiler to

condenser. Thus the boiler need not be relighted during restarting of the unit and a considerable

time & oil is saved.

PURPOSE:

PURPOSE Initial warming up of steam pipe line etc. during cold start-up. Keeps the boiler on

fire even during large load throw-off. Minimizes safety valve operation during sudden load

throw-off thereby reducing D. M. water loss from the cycle. Control main steam and reheat

steam pressure.

HP BYPASS:

HP BYPASS The HP Bypass valve can handle a maximum of 60 %of the full load turbine steam

flow.. This system controls the steam pressure at HP turbine inlet before and during turbine start-

up as well as during turbine trip and shut-down conditions by the pressure control valves.

HPLP BYPASS SYSTEM:

HPLP BYPASS SYSTEM

HP BYPASS SYSTEM:

HP BYPASS SYSTEM The system consists of two parallel paths that direct steam from main

steam line to cold reheat line. The steam passes through these branches and is regulated by

hydraulically actuated control valves on each branch. These valves maintain upsteam pressure at

desired set level. The steam at outlet of the pressure reducing valves is desuperheated in order to

keep steam temperature within limits.

HP BYPASS:

HP BYPASS For this purpose two (2) nos. spray water temperature control valves one for each

branch are provided. One (1) no. spray water pressure control valve has been provided for

adjusting pressure to achieve favourable conditions for spray injection. The HP bypass valves

and spray water valves are provided with hydraulic actuators to provide adequate forces for

quick action of the final control elements. The hydraulic fluid is supplied from the oil supply

unit.

INTERLOCKS FAST OPENING:

INTERLOCKS FAST OPENING The following will activate the Fast Opening Signal :-

Generator breaker open. Turbine load shedding relay operated Pressure controller deviation more

(+) 10 %. Depressing of the FAST OPEN push button from UCB.

HP BYPASS SYSTEM:

HP BYPASS SYSTEM

LP BYPASS SYSTEM :

LP BYPASS SYSTEM The LP bypass controller is designed to control the pressure in the reheat

system under specified operating condition. The steam which cannot be accepted by the

intermediate and low pressure turbines, must be bypassed to the condenser during start-up and

shutdown of the turbine, on partial load below the boiler minimum load and in occurrence of

faults i. e. load rejection, turbine trip etc.

LP BYPASS :

LP BYPASS The LP bypass controller operates the bypass stop valve and control valve by

means of the electrohydraulic converter and various intermediate linkage elements in the

hydraulic section. The protective and safety elements for the condenser are integrated in the LP

bypass controller. In the event of the injection water pressure being insufficient or the condenser

pressure being excessive, the bypass stop valves are closed. The opening of the LP bypass

control valves is limited on excessive LP bypass steam flow.

LP BYPASS SYSTEM:

LP BYPASS SYSTEM

HP LP BYPASS VALVES:

HP LP BYPASS VALVES

Startup Curve:

Startup Curve Cut in HPLP Bypass

HP TURBINE BYPASS VALVE (500 MW):

HP TURBINE BYPASS VALVE (500 MW) Design press 189.5/55 kg/sq cm Design temp---

545/500 deg c Body material- SA 182 F22 CL 3 Nozzle material- SA 182 F22 CL3 Code - TRD

Flow max -647 t/hr Leakage class -MSS SP 61 Actuator -hydraulic OPERATING

PARAMETERS (normal) Press before valve-170 kg/sq cm Press after valve - 45 kg/sq cm Temp

before valve- 535 deq c Temp after valve- 326 deg c Flow per valve 575 t/hr

HP BYPASS: ELECTRO HYDRAULIC SYSTEM:

HP BYPASS: ELECTRO HYDRAULIC SYSTEM

ELECTRO HYDRAULIC SYSTEM:

ELECTRO HYDRAULIC SYSTEM Performance requirements for turbine bypass valves quick

opening and closing and precise plug positioning. For demanding applications ,valves are driven

by hydraulic piston actuators . The electro hydraulic system ,which includes fluid reservoir

,redundant oil supply pumps and motors, fluid filtering system.

STANDARD:

STANDARD ANSI/ISA -77.13.01 :Fossil fuel power plant steam turbine bypass system. (www.

isa. org)

THANKING YOU :

THANKING YOU

Вам также может понравиться

- Introduction to the simulation of power plants for EBSILON®Professional Version 15От EverandIntroduction to the simulation of power plants for EBSILON®Professional Version 15Оценок пока нет

- HP-Bypass and LP BypassДокумент3 страницыHP-Bypass and LP Bypassdinesh7136100% (1)

- 5 HRSG 11 12Документ7 страниц5 HRSG 11 12M Moarraf Naeem100% (1)

- HP-LP Bypass FДокумент16 страницHP-LP Bypass FSolaiОценок пока нет

- HP LP Bypass System (Turbine)Документ9 страницHP LP Bypass System (Turbine)Debasish Dewan67% (3)

- HP/LP Bypass Automation: Function DescriptionДокумент14 страницHP/LP Bypass Automation: Function DescriptionMohit GohilОценок пока нет

- 330mw DEHДокумент22 страницы330mw DEHkeerthi dayarathnaОценок пока нет

- HPBPДокумент14 страницHPBPrnumesh1Оценок пока нет

- Cold Srat UpДокумент21 страницаCold Srat Upthiagu1989100% (1)

- HP BypassДокумент14 страницHP BypassdatastageОценок пока нет

- Chapter 9Документ15 страницChapter 9Harjith Vaibav100% (1)

- Tripping of Turbine On High Differential PressureДокумент3 страницыTripping of Turbine On High Differential Pressureatulbhogare7Оценок пока нет

- Turbine Start UpДокумент15 страницTurbine Start UprobiansahОценок пока нет

- TTD PerformanceДокумент5 страницTTD PerformanceSriraja RajapОценок пока нет

- Unit Normal Shutdown To ColdДокумент100 страницUnit Normal Shutdown To Coldishak100% (1)

- Turbine Bypass SystemsДокумент10 страницTurbine Bypass SystemsZaqPoilmОценок пока нет

- Unit Emergencies: Condensate Desk Emergencies Can BeДокумент9 страницUnit Emergencies: Condensate Desk Emergencies Can Bealoknitp04Оценок пока нет

- C&I Part of SCДокумент28 страницC&I Part of SCLakshmi Narayan100% (1)

- Bhel - Trichy: Training Programme FOR Power Sector Executives ON CFBC BoilersДокумент41 страницаBhel - Trichy: Training Programme FOR Power Sector Executives ON CFBC Boilersrashm006ranjanОценок пока нет

- Division - E HP Bypass System Volume - E1 Control Valves, Actuator and Accessories Contents ListДокумент150 страницDivision - E HP Bypass System Volume - E1 Control Valves, Actuator and Accessories Contents ListAnonymous ZnuMEWN1Оценок пока нет

- Esp Ash Hopper & Blow Tank SystemДокумент13 страницEsp Ash Hopper & Blow Tank SystemZaid ChelseaОценок пока нет

- Ir-Cfbc Boiler Drive Start/Stop LogicДокумент6 страницIr-Cfbc Boiler Drive Start/Stop Logicsambhu100% (1)

- Turbine RollingДокумент3 страницыTurbine RollingAnudeep Chittluri100% (1)

- C&I Part of SCДокумент28 страницC&I Part of SCSam100% (1)

- Technical DiaryДокумент45 страницTechnical DiarysambhuОценок пока нет

- 28990-Turbinebypass Prds PDFДокумент12 страниц28990-Turbinebypass Prds PDFbuddhivasu100% (2)

- 500MW-Boiler - Salient FeatureДокумент7 страниц500MW-Boiler - Salient FeatureAhemadОценок пока нет

- Schemes TalcherДокумент206 страницSchemes TalcherSam100% (1)

- StartupДокумент28 страницStartupAjay Chauhan100% (1)

- Write Up On EHA & HPSU SystemДокумент9 страницWrite Up On EHA & HPSU Systemraaj bharath100% (1)

- DehДокумент34 страницыDehAnand Swami100% (1)

- Cold Start Up - CSTPS PDFДокумент19 страницCold Start Up - CSTPS PDFAhemadОценок пока нет

- Closed Cooling Water System (Sample)Документ37 страницClosed Cooling Water System (Sample)shahidaОценок пока нет

- Proper Steam Bypass System Design Avoids Steam Turbine OverheatingДокумент6 страницProper Steam Bypass System Design Avoids Steam Turbine Overheatingsanjeevnn100% (1)

- HP LP Bypass System: Ravi Pal SinghДокумент36 страницHP LP Bypass System: Ravi Pal SinghMinh Hoang NguyenОценок пока нет

- Cold-Start Up of Coal Fired PowerplantsДокумент6 страницCold-Start Up of Coal Fired PowerplantsAbdulyunus AmirОценок пока нет

- Operating Manual 670 MW Coal Fired Power Plant Training SimulatorДокумент134 страницыOperating Manual 670 MW Coal Fired Power Plant Training SimulatorsprotkarОценок пока нет

- Turbine Trip LogicДокумент2 страницыTurbine Trip Logicdilbagh_scribd50% (2)

- Technical Diary-KMPCLДокумент221 страницаTechnical Diary-KMPCLChandrahas SahuОценок пока нет

- Mill Reject SystemДокумент22 страницыMill Reject SystemgangatharanОценок пока нет

- CRH Drain Pot LevelДокумент30 страницCRH Drain Pot LevelBibhash SinghОценок пока нет

- Boiler ProtectionДокумент36 страницBoiler ProtectionAshish Lanjewar100% (1)

- Introduction To Steam Seal System of 800Mw Kudgi TurbineДокумент10 страницIntroduction To Steam Seal System of 800Mw Kudgi TurbineSCEKUDGI 800Оценок пока нет

- Hỏi Đáp Về Tuabin HơiДокумент46 страницHỏi Đáp Về Tuabin Hơihoangduythanhqb100% (1)

- Boiler Protections, Emergencies and EfficiencyДокумент40 страницBoiler Protections, Emergencies and EfficiencyAnirudh MeshramОценок пока нет

- NTPC PresentationДокумент222 страницыNTPC PresentationReaderRRGHT100% (2)

- Low Pressure Governing SystemДокумент113 страницLow Pressure Governing SystemBalgopal Raju75% (4)

- Steam Circulation SystemДокумент36 страницSteam Circulation Systemnavdeeplakhera100% (1)

- 500mw Checking and Setting of Hydraulic and ElectroДокумент15 страниц500mw Checking and Setting of Hydraulic and Electrothangarajm1984Оценок пока нет

- LPbypass SystemДокумент43 страницыLPbypass Systemamulya1981Оценок пока нет

- Steam TurbinesДокумент45 страницSteam TurbinesHaseeb Bokhari100% (1)

- Turbine Control and Efficiency ImporovementДокумент6 страницTurbine Control and Efficiency ImporovementUdhayakumar Venkataraman100% (1)

- Write Up On Aux PrdsДокумент6 страницWrite Up On Aux PrdsYousuf AliОценок пока нет

- HP LP BypassДокумент34 страницыHP LP BypassharisankarОценок пока нет

- HP LP BypassДокумент20 страницHP LP BypassSara Lopez100% (2)

- HP LP BypassДокумент37 страницHP LP BypassSCE RIHANDОценок пока нет

- HP-LP by Pass SystemДокумент13 страницHP-LP by Pass Systemshashank das100% (1)

- HP & LPBP SystemДокумент47 страницHP & LPBP SystemKana Padmaja50% (2)

- HP & LPBP PresentationДокумент47 страницHP & LPBP Presentationdurga praveen100% (1)

- Expansion Joint in CAESARДокумент5 страницExpansion Joint in CAESARkaruna346Оценок пока нет

- If I Were You ExamplesДокумент1 страницаIf I Were You Exampleskaruna346Оценок пока нет

- Use of Branch Connections: Standard Practice ForДокумент5 страницUse of Branch Connections: Standard Practice ForFelix Rodriguez LiraОценок пока нет

- I Have To + Verb ExamplesДокумент1 страницаI Have To + Verb Exampleskaruna346Оценок пока нет

- How Was + (Noun)Документ1 страницаHow Was + (Noun)karuna346Оценок пока нет

- I Have + Noun ExamplesДокумент1 страницаI Have + Noun Exampleskaruna346Оценок пока нет

- Iam Good at ExaplesДокумент1 страницаIam Good at Exapleskaruna346Оценок пока нет

- Plant DesignДокумент17 страницPlant Designkaruna346Оценок пока нет

- Turbine Heat Rate CalculationДокумент2 страницыTurbine Heat Rate Calculationkaruna34650% (2)

- I Have +PP ExamplesДокумент1 страницаI Have +PP Exampleskaruna346Оценок пока нет

- I Am Gonna + Verb ExeДокумент1 страницаI Am Gonna + Verb Exekaruna346Оценок пока нет

- Component Material Equivalent ASTMДокумент1 страницаComponent Material Equivalent ASTMkaruna346Оценок пока нет

- Stress Analysis of Piping Systems and Pipelines - Harvard - UniversityДокумент542 страницыStress Analysis of Piping Systems and Pipelines - Harvard - Universitykaruna346100% (11)

- HRSG SimulationДокумент7 страницHRSG Simulationkaruna346Оценок пока нет

- CCI Power ApplicationsДокумент57 страницCCI Power Applicationssukanya_ravichandran100% (1)

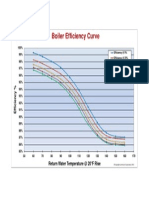

- Boiler Efficiency CurvesДокумент1 страницаBoiler Efficiency Curveskaruna346Оценок пока нет

- Specifying Waste Heat BoilersДокумент5 страницSpecifying Waste Heat Boilerskaruna346Оценок пока нет

- Design & Construction of Piping SystemsДокумент115 страницDesign & Construction of Piping SystemsSuresh Babu100% (13)

- 210MW PPS SimulationДокумент11 страниц210MW PPS Simulationkaruna346Оценок пока нет

- G-ST-P/OE: Elastomerlips ProfilesДокумент1 страницаG-ST-P/OE: Elastomerlips Profileskaruna346Оценок пока нет

- Archery Association of IndiaДокумент17 страницArchery Association of Indiakaruna346Оценок пока нет

- FRM Valuation & Risk Models Dowd, Chapter 2: - Hosted by David Harper Cfa, FRM, Cipm - Published April 22, 2012Документ19 страницFRM Valuation & Risk Models Dowd, Chapter 2: - Hosted by David Harper Cfa, FRM, Cipm - Published April 22, 2012BeastОценок пока нет

- Palf PDFДокумент16 страницPalf PDFKamal Nadh TammaОценок пока нет

- Monitoring AlkesДокумент41 страницаMonitoring AlkesEndangMiryaningAstutiОценок пока нет

- Readers Digest November 2021 PDF RD 2021 PDF EnglishДокумент172 страницыReaders Digest November 2021 PDF RD 2021 PDF EnglishIslam Gold100% (1)

- As 2419.1-2005 Fire Hydrant Installations System Design Installation and CommissioningДокумент9 страницAs 2419.1-2005 Fire Hydrant Installations System Design Installation and CommissioningSAI Global - APAC14% (7)

- Laughter, It Is Good For YouДокумент2 страницыLaughter, It Is Good For YouClaire B.L.Оценок пока нет

- Kenwood Report FinalДокумент43 страницыKenwood Report Finaltooba siddiquiОценок пока нет

- Soal 2-3AДокумент5 страницSoal 2-3Atrinanda ajiОценок пока нет

- Macroscopic Physics Chemistry HW #1Документ11 страницMacroscopic Physics Chemistry HW #1Akash ModyОценок пока нет

- Owner'S Manual: Explosion-Proof Motor Mf07, Mf10, Mf13Документ18 страницOwner'S Manual: Explosion-Proof Motor Mf07, Mf10, Mf13mediacampaigncc24Оценок пока нет

- Marine Advisory 03-22 LRITДокумент2 страницыMarine Advisory 03-22 LRITNikos StratisОценок пока нет

- Environmental Product Declaration: Plasterboard Knauf Diamant GKFIДокумент11 страницEnvironmental Product Declaration: Plasterboard Knauf Diamant GKFIIoana CОценок пока нет

- Erich FrommДокумент2 страницыErich FrommTina NavarroОценок пока нет

- Wa0016Документ3 страницыWa0016Vinay DahiyaОценок пока нет

- Manual Chiller Parafuso DaikinДокумент76 страницManual Chiller Parafuso Daiking3qwsf100% (1)

- Hippocrates OathДокумент6 страницHippocrates OathSundary FlhorenzaОценок пока нет

- FINALE Final Chapter1 PhoebeKatesMDelicanaPR-IIeditedphoebe 1Документ67 страницFINALE Final Chapter1 PhoebeKatesMDelicanaPR-IIeditedphoebe 1Jane ParkОценок пока нет

- To 33B-1-1 01jan2013Документ856 страницTo 33B-1-1 01jan2013izmitlimonОценок пока нет

- D05 Directional Control Valves EngineeringДокумент11 страницD05 Directional Control Valves EngineeringVentas Control HidráulicoОценок пока нет

- Waste Sector ProjectsДокумент5 страницWaste Sector ProjectsMrcoke SeieОценок пока нет

- Dam Lecture 14 - Design Criteria Earth DamsДокумент4 страницыDam Lecture 14 - Design Criteria Earth DamsCarolineMwitaMoseregaОценок пока нет

- Soil Chapter 3Документ67 страницSoil Chapter 3Jethrone MichealaОценок пока нет

- Analyzing Activity and Injury: Lessons Learned From The Acute:Chronic Workload RatioДокумент12 страницAnalyzing Activity and Injury: Lessons Learned From The Acute:Chronic Workload RatioLukas ArenasОценок пока нет

- Kern County Sues Governor Gavin NewsomДокумент3 страницыKern County Sues Governor Gavin NewsomAnthony Wright100% (1)

- CRM McDonalds ScribdДокумент9 страницCRM McDonalds ScribdArun SanalОценок пока нет

- Current and Voltage Controls 3-Phase AC Max. Current Control Type S 178Документ3 страницыCurrent and Voltage Controls 3-Phase AC Max. Current Control Type S 178Felipe FarfanОценок пока нет

- #1 - The World'S Oldest First GraderДокумент6 страниц#1 - The World'S Oldest First GraderTran Van ThanhОценок пока нет

- Reading Assignment Nuclear ChemistryДокумент2 страницыReading Assignment Nuclear Chemistryapi-249441006Оценок пока нет

- US Army Medical Course MD0722-100 - Microbiology For The Veterinary SpecialistДокумент114 страницUS Army Medical Course MD0722-100 - Microbiology For The Veterinary SpecialistGeorges100% (2)

- NCP On DiabetesДокумент2 страницыNCP On DiabetesShumaila AlviОценок пока нет