Академический Документы

Профессиональный Документы

Культура Документы

Stress-Strain Modelfor Grade275 Reinforcingsteel With Cyclic Loading

Загружено:

Heaven SinghОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Stress-Strain Modelfor Grade275 Reinforcingsteel With Cyclic Loading

Загружено:

Heaven SinghАвторское право:

Доступные форматы

101

STRESS- STRAI N MODEL FOR GRADE 275

REI NFORCI NG STEEL WI TH CYCLI C LOADI NG

K. J. Thomps on* and R. Park**

ABSTRACT

The stress-strain relationship of Grade 275 steel reinforcing bar

under cyclic (reversed) loading is examined using experimental results

obtained previously from eleven test specimens to which a variety of

axial loading cycles has been applied. A Ramberg-Osgood function is

fitted to the experimental stress-strain curves to follow the cyclic

stress-strain behaviour after the first load run in the plastic range.

The empirical constants in the function are determined by regression

analysis and are found to depend mainly on the plastic strain imposed

in the previous loading run. The monotonic stress-strain curve for the

steel, with origin of strains suitably adjusted, is assumed to be the

envelope curve giving the upper limit of stress. The resulting Ramberg-

Osgood expression and envelope is found to give good agreement with the

experimentally measured cyclic stress-strain curves.

INTRODUCTION

Severe earthquake loading may cause

structural elements to be subjected to cyclic

(reversed) loading well into the inelastic

range. It is well known that when steel is

subjected to reversals of load after first

yielding, the stress-strain curve becomes

non-linear over much of the loading range

due to the Bauschinger effect. Information on

the stress-strain relationships for rein-

forcing steel is required to accurately

predict the behaviour of structural concrete

members under cyclic loading. Such stress-

strain relationships are necessary in order

to accurately determine the theoretical m o m e n t -

curvature relationships for reinforced concrete

members subjected to cyclic loading ( D . This

leads to more precise determination of m o m e n t -

curvature models for use in the non-linear

dynamic analysis of reinforced concrete

structures responding to severe earthquake

motions. A l s o , such stress-strain data is

needed to determine the tangent modulus of

the steel at various levels of stress to

check the likelihood of buckling of reinforcing

bars in compression during cyclic loading.

Early work on the stress-strain behaviour

of reinforcing bars subjected to cyclic

loading w a s conducted by Singh, Gerstle and

Tulin ^ ^) w h o determined a simple empirical

expression which represented the average of

the family of measured reversed loading stress-

strain c u r v e s . The expression is an

experimental curve which is extended backwards

to meet an initial elastic slope. In more

recent w o r k by Kent and Park(3,4) a form of

the Ramberg-Osgood equation w a s used to

follow the reversed loading branches of the

stress-strain curve after the first yield

excursion. Linear unloading curves parallel

to the initial elastic slope were assumed.

The parameters in the Ramberg-Osgood equation

w e r e determined empirically for Grade 275

Senior Engineer, Ministry of Works and

D e v e l o p m e n t , Invercargill.

Professor of Civil Engineering, University

of C a n t e r b u r y , Christchurch.

reinforcing steel and were found to be a

function of the actual yield strength, the

plastic strain in the previous load run and

the loading run number. This method using

the Ramberg-Osgood equations was shown to

generally lead to better accuracy than the

method of Singh, Gerstle and T u l i n ( 3 , 4 ) m

A k t a n , Karlsson and S o z e n ^ ^ have also used

a form of the Ramberg-Osgood equations with

empirical constants to define both the load-

ing and unloading branches of the stress-

strain curve and obtained good agreement with

test results. They also devised an altern-

ative idealisation consisting of sets of

straight lines parallel to the elastic slope

and inclined to it. M a , Bertero and Popov

(6) have also obtained close fit with

experimental stress-strain data using a form

of the Ramberg-Osgood equation.

The study described in this paper

extends the existing work of Kent and Park

( 3 , 4 ) m The Ramberg-Osgood equations

determined in that early work had been found

to underestimate the stress at low strains

and to overestimate the stress at high

s t r a i n s ( 3 7 4 ) ^ in this paper the experimental

data collected by Kent and Park is reanalysed

and the assumptions of that early procedure

are re-examined in order to obtain a stress-

strain model which fits the experimental data

more closely. A more detailed account of

this work may be seen e l s e w h e r e ( ^ .

ENVELOPE STRESS-STRAIN CURVE FOR CYCLIC LOADING

Many investigators have shown that the

envelope stress-strain curve for cyclic load-

ing may be obtained from the appropriate part

of the stress-strain curve for monotonic

loading with the origin of coordinates

suitably adjusted.

The monotonic stress-strain curve assumed

in this study is the same as that proposed

by Kent(3) and is illustrated in Fig. 1.

The curve comprises three regions, which may

be represented by the following equations

using the notation of Fig. 1:

BULLETI N OF THE NEW ZEALAND NATI ONAL SOCi ETY FOR EARTHQUAKE ENGI NEERI NG, VOL. 11,NO. 2, JUNE 1978.

102

Region AB

Region BC

Region CD

S

s y

f = E

s s s

e ^ e e ,

y s sh

, ^ <

sh s su

s y

1

60 (e - . } + 2

1

s sh

. . (1)

. . (2)

e , ) (60 - m)

sh

2(30q + 1) '

where m =

and

( f

s u

/ f

y

) ( 3 0 q + 1 ) ' - 60q - 1

- ( 3)

15q

'sh

. (4)

. (5)

E q s . 1 to 5 are similar to those obtained

by Burns and S i e s s ^ ) except that they follow

a generalised form for steel with different

f

S

U

/

f

S y

a n d

su

v a

^

u e S e

The monotonic stress-strain curve has

been shown in tests by Leslie

(9)

to approx-

imately describe the envelope stress-strain

curve for cyclic loading providing the cyclic

straining occurs either all in the tensile

region or all in the compression region.

This is also evident from the work of Aktan,

Karlsson and Sozen(5) . For more symmetrical

tension - compression straining (i.e.

approximately equal strain excursions in

tension and compression in each cycle) the

monotonic stress-strain curve approximately

describes the envelope curve only if the

origin of the monotonic curve is displaced

horizontally.

In this study it will be assumed that the

stress-strain envelope for cyclic loading is

the same as the stress-strain curve for m o n o -

tonic loading, except that the origin is

translated horizontally during loading such

that the new origin is ( ,0) for tensile

zmx

loading (see Fig. 2 ) , where

0 " E~ (6)

where

Q

is the maximum compressive strain

and f

Q

is the stress at the maximum compressive

strain. For compressive loading the modified

origin is ( ,0)

zmn

where

(7)

=

zmn o

where eQ is the maximum tensile strain and

f

0

is the stress at the m a x i m u m tensile

strain. The assumed envelope is shown in

Fig. 2. Note that when the origin is

displaced it m u s t always be in the directions

shown in Fig. 2. For example, the current

stress envelope for tensile loading must

always commence at the original origin (0,0)

or to the left of it as shown in Fig. 2. Thus

for repeated loading of the same sign the

origin of the envelope always remains at

( 0 , 0 ) . The steel stresses are not permitted

to exceed the envelope values during loading.

STRESS-STRAIN CURVE FOR CYCLIC LOADING

A s s u m e d Form of Stress-Strain Relationship

For cyclic loading at stresses less than

the envelope v a l u e s , the following modified

form of the Ramberg-Osgood function is

assumed to give the stress-strain curve

after the first yeild excursion

(i

S

1 +

f - f

S o

ch

r-1"

- (.8)

where

s

, f

s

are the strain and stress values

at the point on the stress-strain curve;

0

, f o are the strain and stress values at

the beginning of the stress-strain curve;

f

C

h is the characteristic stress; E

s

is

the value of the modulus of elasticity from

the initial elastic loading run and r is the

Ramberg-Osgood parameter. Eq. 8 is assumed

to give the cyclic stress-strain curves

which lie within the envelope values (see

Fig. 2 ) .

The characteristics of the Ramberg-

Osgood function, Eq. 8, are illustrated in

Fig. 3. It is noted that values of r

between 1 and

0 0

give a range of sweeping

curves which vary between a straight line

when r = 1 to a bilinear relationship w i t h

initial slope E

s

when r = .

Regression Analysis for f ^ and r

(3 4)

Kent and Park ' have reported the

results of tests on eleven specimens of

Grade 275 ( f

y

= 316 to 339 MPa) deformed

steel reinforcing bars. The chemical

composition of the steel complied with

NZSS 1693:1962 (10) . The specimens were of

bar size No. 4,5,6 and 7 (12.7, 15.9 , 19.0

and 22.2 m m diameter, respectively) . In

the region of the strain measurement the

specimens had been machined to a smaller

diameter. The loads were applied statically

and axially, taking considerable care to

ensure that eccentricity of load did not

become significant during the loading r u n s .

A variety of loading cycles was applied to

study a range of initial strains and unload-

ing and reloading sequences. The maximum

compressive strains applied were much

smaller than the maximum tensile strains

applied, in order that the strain histories

would be similar to that of flexural r e i n -

forcing steel at a plastic hinge region in

a reinforced concrete beam with cyclic

(reversed) flexure.

The stress-strain results of each of

the cyclic loading runs of the eleven test

specimens were reanalysed in the present

study by a regression analysis in order to

obtain more accurate values for fch and r

than had been obtained previously. To

perform this analysis Eq. 8 was first made

linear in r and f

c

h ^ ' using the first

three terms of the Taylor series as

described by Draper and Smith ( H ) . Then a

general regression analysis was conducted

to determine f

c

j

1

and r for each cyclic load

run of each specimen so that the sum of the

squares of the differences between the

experimentally measured strain and the strain

predicted by Eq. 8 at particular stress

levels was m i n i m i z e d ( ^ '

9

The results of

this regression analysis for f

c

^ and r are

shown in Table 1, where fch is shown as a

function of the steel yield strength fy.

The steel yield strength was measured m the

first yield excursion.

The method used by Kent and Park (3,4)

to linearise the Ramberg-Osgood function for

103

regression analysis was to take logarithms

on both sides of a rearranged Eq. 8. However

in this approach, when f c j 1 and r were

determined by minimizing the sum of the

squares of the differences between the

experimental results and those predicted

by Eq. 8, the difference used was in fact

the difference between the logarithms of

the experimental and predicted deviation

from the line through point ( e 0 , f 0 ) with

slope E s . For low stress values the

logarithms will be large negative numbers

tending towards infinity as the deviation

from this line tends towards zero. The

effect of this was to weight disporportionately

the lower stress v a l u e s , and thus to fit

mainly the lower stress values. As a result,

the previous expressions derived by Kent and

Park ( 3 , 4 ) 3-^3 not fit the experimental

curves very well once a significant amount

of plastic strain had been imposed.

Empirical Equation for the Characteristic

Stress, f ,

By plotting the values of the ration

f c h / f y given in Table 1 against the possible

dependent variables it was observed that

the value of f c n / f y in each loading run

was apparently dependent on the plastic

strain imposed in the previous loading run,

p] _ . The trend was for the ratio f c n / f y

to decrease with increasing prior plastic

strain. The values for the ratio of f c n / f y

from Table 1 are shown plotted against

r>i in Fig. 4. Because of the wide scatter

or points there seemed little purpose in

seeking too complicated an empirical equation

to fit these points and a linear relationship

relating f c h / f y to pi was fitted, weighted

according to the inverse of the stress

standard deviation for the particular loading-

run . The following relationship was obtained

f , = f (0.973 - 9.806 e -) .. (9)

ch y p l

y

for within the range 0 < p]_ < 0.025 , and is

shown plotted in Fig. 4. The values for the

ratio fch/fy given by Eq. 9 for each of the

cyclic loading runs of the eleven test

specimens are shown in Table 1.

Empirical Equation for the Ramberg-Osgood

Parameter, r

Using the values for f c n given by

Eq. 9, a second regression analysis was

performed to find the best value of r for

the stress-strain results of each of the

cyclic loading runs of the eleven test

specimens. To perform this analysis Eq. 8

was first made linear in r using the Taylor

series, as described by Draper and S m i t h ( I D .

Then general regression analysis was

conducted to determine r for each cyclic

load run for each specimen so that the sum

of the squares of the differences between

the experimentally measured strain and the

strain predicted by Eq. 8 at particular

stress levels was m i n i m i s e d (

7

>. The results

of this second regression analysis for r

are shown in Table 1.

The values for r so determined were

then p l o t t e d against various possible depend-

e n t factors. It was observed that r was

apparently dependent on the plastic strain

imposed i n the previous loading r u n , pi,

and that the correlation of r with other

possible variables was poor. Fig. 5 shows

the values of r plotted against pi The

observation that r shows reasonable

correlation with Zpj_ is different to that

made previously by Kent and Park ( 3 , 4 ) f

who had observed that r was apparently

dependent on the number of previous p o s t -

elastic loading runs and whether the

loading run number was odd or even. N e v e r -

theless there was significant scatter in

their plotted data, and it was based on less

accurate f c ^ values than the present data.

Hence in the present work r w i l l be assumed

to be related to p]_ alone.

An empirical relationship relating r

to p]_ was fitted using the values of r

obtained from the second regression a n a l y s i s ,

weighted according to the inverse of the

stress standard deviation for the particular

loading run. - The following relationship was

obtained

1 9 ~~ 45.07 9,77

r + e x p ( 1 0 0 0 c p l ) l o g e (1000z + 2)

..(10)

for within the range 0 < p-j_ < 0.025 , and is

shown plotted in Fig. 5.

Application of Cyclic Stress-Strain Equations

The proposed model for the cyclic stress-

strain behaviour is described by Eqs. (1) to

(10 ). Eqs. (1) to (5) define the monotonic

stress-strain curve and hence apply to the

first loading run into the post-yield range.

Subsequent reversed loading runs are described

by Eqs. (8, ) , (9) and (10) , with the

stipulation that the stress level reached

should not exceed that given by the current

stress envelope described by the monotonic

stress-strain curve with the zero stress

origin given by either Eq. (6) or ( 7 ) .

In order to allow for small stress reversals

which do not significantly effect the stress-

strain history, it was further assumed that

if the plastic strain imposed in a loading

run is small (less than 0 . 0 0 0 5 ) , then on

reloading the new loading curve is only

continued until the previous loading curve

in that direction is reached and then the

previous loading curve is followed. The

constraints on the cyclic stress-strain

relationships are illustrated in Fig. 6.

COMPARISON OF EXPERIMENTAL RESULTS W I T H

PROPOSED CYCLIC STRESS-STRAIN MODELS

Figs. 7 to 10 compare the stress-strain

curves derived from the model presented in

this paper and the model of Kent and Park

( 3 , 4 ) with the experimental stress-strain

curves. The curves derived from the stress-

strain models were calculated between the

experimental strain values at which stress

reversals took place.

In F i g s . 7 to 10 the tensile stress and

strain are initially in the first q u a d r a n t ,

and the cyclic (tension - compression)

stresses applied to the test specimens w e r e

such as to cause much greater tension strains

than compressive strains. This test loading

was used in order to approximately simulate

the strain history in a longitudinal r e i n -

forcing bar in a plastic hinge region of

reinforced concrete beam subjected to cyclic

flexure. In such a beam if cracking of

104

concrete and yielding of tension steel occurs

due to bending moment applied in one direction,

when the directon of bending moment is

reversed these open cracks will remain in

what is now the concrete "compression zone"

and w i l l only close if the force in the

tension steel is large enough to yield the

steel in compression. If the cracks in the

compression zone do close, the concrete in

the compression zone will prevent the develop-

ment of extremely high compressive strains

in the steel, as is evident from the neutral

axis position in the section, whereas when

the steel is yielding in tension, extremely

high tensile strains can develop, as is

evident from wide cracks in the concrete W .

Hence the strains in the reinforcing bars

will occur mainly in the tension range.

The curves of Figs. 7 to 10 illustrate

the degree of accuracy w i t h which the derived

stress-strain models fit the experimental

behaviour. Generally, the stress-strain

curves derived using the model presented in

this paper follow the experimental curves

with good accuracy, and the accuracy

achieved is significantly better than that

from the curves derived using the model of

Kent and Park which tends to overestimate

the stress at high strains and to under-

estimate the stress at low strains.

It should be noted that the use of an

accurate stress-strain model for steel is

important because if the difference between

the predicted and experimental stresses

immediately prior to stress reversal is

large, the predicted curve becomes out of

phase with the experimental curve and

significant errors can arise.

It should also be emphasized that the

empirical equations for the proposed cyclic

stress-strain model have been derived from

experimental results obtained from steel

reinforcing bars with strains imposed mainly

in the tension region, for maximum imposed

strains less than "that at the commencement

of strain hardening, for steels with a yield

strength in the range 316 to 339 MPa (46 to

4 9 k s i ) , and for slow (static) strain rates.

Further tests are required, particularly to

investigate the effect of high rates of

loading such as in a structure subjected to

seismic ground m o t i o n s , and to investigate

the possible change in steel mechanical

properties due to strain ageing after cyclic

loading in the inelastic range.

A P P L I C A T I O N OF THE CYCLIC STRESS-STRAIN MODEL

The proposed model for the stress-strain

behaviour of cyclically loaded reinforcing

steel in the inelastic range emphasizes that

after the first yield excursion the yield

stress of steel as usually defined loses its

significance since the stress-strain curve

becomes nonlinear over m u c h of the loading

range. The proposed stress-strain model

has three main applications. The first

application is the determination of the

theoretical moment-curvature characteristics

of reinforced concrete members subjected to

cyclic f l e x u r e ( 1 , 1 2 ) . it has been found

p r e v i o u s l y ( D that for large portions of

the moment-curvature loop after the first

yield excursion the shape of the m o m e n t -

curvature loop is very dependent on the

shape of the stress-strain curve for the

steel. A second application is the determ-

ination of the buckling loads of reinforcing

bars in reinforced concrete members with

cyclic flexure. It is evident that after

the first yield excursion of the longitudinal

steel the tangent modulus of the steel at

stresses less than the initial yield

strength can be considerably lower than the

modulus of elasticity of the steel and that

this could lead to buckling of bars at

lower levels of compressive stress than

expected from monotonic loading tests. A

third application is the calculation of

the stresses in reinforcing bars from the

strain histories measured during cyclic

loading.

CONCLUSIONS

Equations defining the stress-strain

characteristics of Grade 275 steel rein-

forcing bars under cyclic (reversed)

loading after the first yield excursion

have been presented using the Ramberg-

Osgood function with empirical constants

which depend on the plastic strain in the

previous loading run. The stress-strain

curve for monotonic loading, w i t h suitably

adj usted origin of co-ordinates, is used

to describe the envelope which the steel

stresses cannot exceed. The stress-strain

model is shown to be capable of describing

cyclic stress-strain curves w i t h good

accuracy.

ACKNOWLEDGEMENTS

The financial assistance of the New

Zealand University Grants Committee, Ministry

of Works and Development, Building Research

Association, Prestressed Concrete Institute,

and the University of Canterbury is g r a t e -

fully acknowledged.

REFERENCES

1. Park, R., Kent, D. C. and Sampson,

R. A. , "Reinforced Concrete Members

with Cyclic Loading", Journal of

Structural Division, A m e r i c a n Society

of Civil Engineers, V o l . 9 8 , No. S T 7 ,

July 1972, pp. 1341-1360.

2. Singh, A., Gerstle, K. H. and Tulin,

L. G., "The Behaviour of Reinforcing

Steel Under Reversed L o a d i n g " , Journal

of American Society of Testing M a t e r i a l s ,

Materials Research and S t a n d a r d s ,

V o l . 5, N o . 1, January 19 65, pp. 1 2 - 1 7 .

3. K e n t , D. C. ,

11

Inelastic Behaviour of

Reinforced Concrete M e m b e r s with

Cyclic Loading", thesis presented to

the University of Canterbury, Christ-

church , New Zealand, in partial fulfil-

m e n t of the requirements for the degree

of Doctor of Philosophy, 1969.

4. Kent, D. C. and Park, R., "Cyclic

Load Behaviour of Reinforcing Steel" ,

Strain, V o l . 9, No. 3, July 19 73, pp.

98-103.

5. A k t a n , A. E., Karlsson, B. J. and

Sozen, M. A., "Stress-Strain Relation-

ships of Reinforcing Bars Subjected to

Large Strain Reversals" , Civil

Engineering Studies, Structural

Research Series No. 39 7 , University

of Illinois, June 1973.

6. M a , S-Y.M., Bertero, V. V. and Popov,

E. P., "Experimental and Analytical

Studies of the Hysteretic Behaviour

of Reinforced Concrete Rectangular

and T-Beams", Earthquake Engineering

105

Research Center, Report No. EERC 7 6 - 2 ,

University of California, Berkeley, 1976.

7. Thompson, K. J., "Ductility of Concrete

Frames under Seismic Loading", thesis

presented to the University of Canterbury,

Christchurch, New Zealand in partial

fulfilment of the requirements for the

degree of Doctor of Philosophy, 19 75.

8. B u r n s , N. H. and Siess, C. P., "Load-

Deformation Characteristics of Beam-

Column Connections in Reinforced

Concrete

1 1

, Civil Engineering Studies,

Structural Research Series No. 2 3 4 ,

University of Illinois, January 19 62.

9. Leslie, P. D., "Ductility of Reinforced

Concrete Bridge P i e r s " , report presented

to the University of Canterbury,

Christchurch, in partial fulfilment

of the requirements for the degree of

Master of Engineering, 1974.

10. NZSS 1693 : 1962 "Deformed Steel Bars

of Structural Grade for Reinforced

Concrete" , New Zealand Standards

Institute, Wellington.

11. Draper, N. R. and Smith, N., "Applied

Regression Analysis" , John Wiley and

Sons Inc., New York, 1966, 407pp.

12. Park, R. , "Constitutive Relations of

Steel:Effects on Hysteretic Behaviour

of Structural Concrete Members and on

Strength Considerations in Seismic

Design", Proceedings of Workshop on

Earthquake Resistant Reinforced

Concrete Building Construction,

University of California, Berkeley,

July 1 9 7 7 .

Paper received 17 A p r i l , 1978.

NOTATION

The following symbols are used in this

p a p e r :

m o d u l u s of elasticity of steel

obtained from the monotonic loading

curve

characteristic stress used in Ramberg-

Osgood function

steel stress at beginning of a loading

curve

steel stress

yield strength of steel obtained

from the monotonic loading curve

Ramberg-Osgood parameter

steel strain at beginning of a loading

run

plastic strain in steel produced in

p r e v i o u s loading run

steel strain

steel strain at commencement of strain

h a r d e n i n g obtained from the monotonic

loading curve

ultimate steel strain obtained from

the monotonic loading curve

steel strain at the yield strength

o b t a i n e d from the monotonic loading

curve

strain origin for steel stress-strain

e n v e l o p e for compressive loading

strain origin for steel stress-strain

e n v e l o p e for tensile loading

106

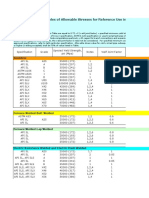

TABLE 1: RESULTS OF ANALYSI S FOR f

c

h and r

Specimen

Loading

Run

N u m b e r

From First Regression

Analysis

f _ /f

ch y

r

given by Second

Regression Analysis

and Eq. 9

( 3 , 4 )

Loading

Run

N u m b e r ch' y

r

given by

Eq. 9

r

given by Second

Regression Analysis

and Eq. 9

6 1 1 . 0 4 0 1 1 . 4 0 3 0 . 9 0 2 6 . 3 6 0

8 1 0 , 9 7 7 1 5 . 5 8 4 0 . 9 4 0 1 1 . 9 4 4

2 1 . 0 1 3 4 8 . 1 8 5 0 . 9 2 8 2 1 . 0 6 6

3 0 . 733 9 . 9 6 6 0 . 7 7 0 1 1 . 8 4 2

9 1 1 . 3 7 7 6 . 3 6 8 0 . 9 5 6 1 7 . 3 3 0

2 1 . 0 7 6 5 0 . 7 0 8 0 . 9 6 6 1 5 . 0 2 3

3 0 . 8 8 3 1 0 . 1 4 0 0 . 8 6 0 9 . 0 1 8

1 1 1 0 . 8 5 6 1 0 . 9 8 8 0 . 9 3 8 9 . 3 3 0

12 1 0 . 8 3 1 1 0 . 6 0 1 0 . 8 7 9 9 . 0 1 2

2 0 . 9 9 3 5 3 . 2 0 1 0 . 9 6 0 3 1 . 4 5 0

17 1 1.118 6 . 3 0 1 0 . 9 1 9 8 . 4 3 4

2 1 . 0 0 7 5 3 . 3 8 1 0 . 9 6 7 1 4 . 2 6 3

3 0 . 946 8. 8 9 5 0 . 9 5 1 8 . 8 1 5

4 . 1 , 0 0 7 4 1 . 2 6 2 0 . 9 6 8 1 4 . 1 9 7

5 0 . 896 8 . 4 3 0 0 . 9 5 0 7 . 6 2 2

6 1 . 0 0 3 2 4 . 0 3 2 0 . 9 6 6 1 3 . 2 8 0

7 0 . 9 2 3 6 . 8 1 4 0 . 9 4 6 6 . 5 6 3

8 0 . 8 2 3 3 7 . 7 4 0 0 . 9 6 4 2 9 . 6 7 1

20 1 0 . 8 1 0 1 2 . 1 4 7 0 . 917 9 . 3 8 4

2 0 . 986 4 5 . 6 9 3 0 . 9 6 7 5 4 . 9 9 1

3 0 . 8 2 8 1 0 . 4 8 8 0 . 9 5 7 8 . 0 1 4

4 1 . 0 1 6 2 1 . 8 0 7 0 . 9 6 7 3 0 . 9 0 7

5 0 . 817 1 0 . 9 3 5 0 . 9 5 9 8 . 0 5 1

6 1 . 0 1 0 2 0 . 8 4 2 0 . 9 6 7 2 9 . 4 6 0

7 0 . 791 1 0 . 7 8 6 0 . 9 5 7 7 . 4 8 9

8 1 . 0 3 1 1 4 . 9 1 8 0 . 9 6 6 2 4 . 6 2 5

9 0 . 8 2 4 9 . 743 0 . 9 5 8 6 . 0 0 0

21 1 1 . 6 5 7 6 . 562 0 . 9 6 1 1 9 . 4 5 4

2 1 . 0 4 9 6 0 . 0 0 0 0 . 9 7 0 9 . 0 2 7

3 2 . 1 2 5 6. 0 0 0 0 . 9 6 5 1 5 . 9 7 6

4 1 . 0 7 3 3 9 . 5 2 7 0 . 9 6 9 9 . 9 8 8

5 1 . 4 0 8 7 . 9 6 0 0 . 9 6 4 1 8 . 7 9 7

6 1 . 0 5 8 6 0 . 0 0 0 0 . 9 6 9 8 . 2 6 7

7 1 . 0 6 9 1 3 . 8 6 5 0 . 9 6 6 1 9 . 5 5 0

8 1 . 0 6 6 5 9 . 4 2 9 0 . 9 6 9 1 9 . 3 4 1

25 1 0 . 9 1 5 1 0 . 0 3 5 0 . 9 2 9 1 0 . 5 8 5

2 0 . 9 9 6 3 5 . 5 0 5 0 . 9 2 3 2 0 . 0 8 3

3 0 . 7 3 7 9 . 7 0 5 0 . 758 1 0 . 2 5 3

29 1 1 . 3 8 8 6 . 0 0 2 0 . 9 5 4 1 3 . 3 7 5

2 1 . 0 4 6 6 0 . 0 0 0 0 , 9 6 7 7 . 4 4 5

3 1 . 0 9 3 6 . 6 2 4 0 . 9 4 7 9 . 2 8 2

4 1 . 0 4 3 3 6 . 9 6 8 0 . 9 6 2 7 . 4 1 0

5 0 . 9 5 1 8 . 3 9 0 0 . 9 4 1 8 . 6 5 0

6 1 . 0 5 5 2 3 . 5 9 0 0 . 9 5 9 6 . 8 3 2

7 0 / 9 1 3 7 . 4 0 5 0 . 9 4 4 6 . 7 7 3

8 1 . 0 3 1 4 2 . 8 7 0 0 . 9 5 5 1 1 . 5 6 5

30 1 1 . 4 3 6 6 . 9 1 6 0 . 9 6 4 1 9 . 5 4 3

2 1 . 4 6 3 7 . 3 2 4 0 . 9 6 3 6 0 . 0 0 0

3 1 . 4 7 5 7 . 7 8 0 0 . 9 6 7 1 6 . 1 6 8

1

4

1

1 . 0 7 5

1

6 0 . 0 0 0

1

0 . 9 6 6 1 0 . 8 8 7

N o t e : Loading runs were numbered 0 , 1 , 2 , 3 , . . . . , w h e r e first yield occurs at

run n u m b e r 0, the first post-elastic stress reversal is run number 1 ,

the second post-elastic stress reversal is run number 2 , etc.

107

Stress, fs

Strain, Es

FIGURE 1: MONOTONI C STRESS-STRAIN RELATIONSHIP FOR STEEL

Tension

Stress Js

Current stress

strain envelope

for tensile

loading

9 7 for compressive

loading

Tension

TanO

(Z0<

f

o

}

for tensile

loading ^

Strain, Zs

r*-Current stress-

I strain envelope

for compressive

loading.

FIGURE 2: STRESS-STRAI N ENVELOPE FOR CYCLIC LOADING

108

Experiment

- Kent and Park's analysis

Author's analysis

0-016 0018 0020

Strain

0 022

W' -50 L _JT- -

FI GURE 7: COMPARI SON OF PREDI CTED AND EXPERI -

MENTAL STRESS-STRAI N CURVES FOR STEEL SPECIMEN

8 ( 1 k i p / i n

2

- 6.89 MPa)

FI GURE 9: COMPARI SON OF PREDI CTED AND EXPERI MENTAL STRESS-

STRAI N CURVES FOR STEEL SPECI MEN 9 (1 k i p / i n

2

= 6.89 MPa).

c 1.0

\

10

Q.

~* 30

10

10

<u

20

-0002

FI GURE 8: COMPARI SON OF PREDI CTED AND EXPERI -

MENTAL STRESS-STRAI N CURVES FOR STEEL SPECI MEN

9 (1 k i p / i n

2

= 6.89 MPa)

FI GURE 10: COMPARI SON OF PREDI CTED AND EXPERI MENTAL STRESS-

STRAI N CURVES FOR STEEL SPECI MEN 25 (1 k i p / i n

2

= 6.89 MPa).

o

CD

Вам также может понравиться

- The Effect of Initial Curvature On The Strength of An Inelastic ColumnДокумент18 страницThe Effect of Initial Curvature On The Strength of An Inelastic ColumnrjtcostaОценок пока нет

- Karsan y JirsaДокумент10 страницKarsan y JirsaDiego SosaОценок пока нет

- An Unloading and Reloading Stress-Strain Model For Concrete Confined by Tie ReinforcementsДокумент8 страницAn Unloading and Reloading Stress-Strain Model For Concrete Confined by Tie ReinforcementsAminsОценок пока нет

- Axisymmetric and Bifurcation Creep Buckling of Externally Pressurised Spherical Shells P. C. JonestДокумент18 страницAxisymmetric and Bifurcation Creep Buckling of Externally Pressurised Spherical Shells P. C. JonestalifaramarzОценок пока нет

- Fatigue Life Estimation of Bellows Based On Elastic-Plastic CalculationsДокумент18 страницFatigue Life Estimation of Bellows Based On Elastic-Plastic Calculationssagar1503Оценок пока нет

- Gesund, Dikshit - 1971 - Yield Line Analysis of The Punching Problem at SlabColumn IntersectionsДокумент25 страницGesund, Dikshit - 1971 - Yield Line Analysis of The Punching Problem at SlabColumn IntersectionsThai Dam100% (1)

- FatigueДокумент20 страницFatiguevivekОценок пока нет

- Hopper DesignДокумент7 страницHopper DesignRohan Malkar100% (1)

- Corrected True Stress - True Strain CurvДокумент3 страницыCorrected True Stress - True Strain CurvPunith MlОценок пока нет

- Axial Load Frequencies BeamsДокумент33 страницыAxial Load Frequencies BeamsKhristiam AlvarezОценок пока нет

- Brown, Miller - Biaxial Cyclic Deformation Behaviour of SteelsДокумент14 страницBrown, Miller - Biaxial Cyclic Deformation Behaviour of SteelsDavid C Houser100% (1)

- Anticlastic Action of Flat Sheets in BendingДокумент5 страницAnticlastic Action of Flat Sheets in Bendingalfakir fikriОценок пока нет

- Duncan - ChangДокумент25 страницDuncan - Changsisisi8100% (2)

- Nonlinear Kinematic Hardening Under Non-Proportional LoadingДокумент24 страницыNonlinear Kinematic Hardening Under Non-Proportional LoadingAnirudh NehraОценок пока нет

- Full-Range Stress-Strain Curves For Stainless SteelДокумент15 страницFull-Range Stress-Strain Curves For Stainless SteelNurul HudaОценок пока нет

- Fatigue Life Evaluation of Welded Joints Based On Nominal Stress and Finite Element AnalysisДокумент6 страницFatigue Life Evaluation of Welded Joints Based On Nominal Stress and Finite Element AnalysiscamichuckОценок пока нет

- Lateral-Torsional Buckling of Beams and The Southwell PlotДокумент15 страницLateral-Torsional Buckling of Beams and The Southwell PlotPablo Augusto Krahl0% (1)

- Salençon, J. and Pecker EC8 Foundation Bearing CapacityДокумент20 страницSalençon, J. and Pecker EC8 Foundation Bearing CapacityYang LuОценок пока нет

- Lab Report 4Документ13 страницLab Report 4vigneshwarimahamuniОценок пока нет

- Wood - ArmerДокумент6 страницWood - ArmerNovak Novaković100% (1)

- Stress and Velocity Fields in The Gravity Flow of Bulk SolidsДокумент8 страницStress and Velocity Fields in The Gravity Flow of Bulk SolidsFelipe MascayanoОценок пока нет

- MAE 212: Spring 2001 Module III: Material Property Characterization Using Strain Gage InstrumentationДокумент7 страницMAE 212: Spring 2001 Module III: Material Property Characterization Using Strain Gage InstrumentationChulbul PandeyОценок пока нет

- Slip-Line Field TheoryДокумент21 страницаSlip-Line Field TheoryDiahAyuSafitriОценок пока нет

- Fulltext-13 (10) Aydan Kawamoto 1992 Flexural TopplingДокумент23 страницыFulltext-13 (10) Aydan Kawamoto 1992 Flexural TopplingRodrigo Peluci de FigueiredoОценок пока нет

- 111Документ5 страниц111Ajeet KerkettaОценок пока нет

- Stability Analysis of Tunnel OpeningsДокумент11 страницStability Analysis of Tunnel OpeningsBhaskar ReddyОценок пока нет

- Lecture 2 (Behaviour of Member Subjected To Axial Loads)Документ4 страницыLecture 2 (Behaviour of Member Subjected To Axial Loads)Touhid AhamedОценок пока нет

- Back Analysis of Measured Displacements of Tunnels: TakeuchiДокумент8 страницBack Analysis of Measured Displacements of Tunnels: TakeuchieltunelОценок пока нет

- Elastic-Plastic Analysis For Surrounding Rock of Pressure Tunnel With Lining Based On Material Nonlinear SofteningДокумент6 страницElastic-Plastic Analysis For Surrounding Rock of Pressure Tunnel With Lining Based On Material Nonlinear SofteningfatimamolaeeОценок пока нет

- Tubular Joint Analysis in Jacket StructureДокумент43 страницыTubular Joint Analysis in Jacket StructureDaniel InemughaОценок пока нет

- True Stress Strain Curve PDFДокумент4 страницыTrue Stress Strain Curve PDFSelva BabuОценок пока нет

- Average Stress Strain Relations For ConcДокумент10 страницAverage Stress Strain Relations For ConcKorrapati Pratyusha 19PHD0497Оценок пока нет

- Variable Loading - Failure AnalysisДокумент8 страницVariable Loading - Failure AnalysisJavier Gaspar Lee RomeroОценок пока нет

- 1 s2.0 S1365160997800731 MainДокумент8 страниц1 s2.0 S1365160997800731 MainNeha RaniОценок пока нет

- SSRC 2008 CPL-RTДокумент20 страницSSRC 2008 CPL-RTchlamОценок пока нет

- Numerical Analysis of Load Test On Bored Pile (Wehnert & Veermer) PDFДокумент6 страницNumerical Analysis of Load Test On Bored Pile (Wehnert & Veermer) PDFAnonymous BuFjdLОценок пока нет

- A Lode Angle Dependent Formulation of The HS ModelДокумент8 страницA Lode Angle Dependent Formulation of The HS ModelGuido BentivoglioОценок пока нет

- Large Deflections of Cantilever BeamsДокумент4 страницыLarge Deflections of Cantilever BeamsHasan Ayouby100% (1)

- 7 Fatigue Failure W14Документ42 страницы7 Fatigue Failure W14lamborghini1991Оценок пока нет

- Transverse Earthquake-Induced Forces in Continuous Bridges: Technical NoteДокумент6 страницTransverse Earthquake-Induced Forces in Continuous Bridges: Technical NotealanadadОценок пока нет

- Modeling of Stress - Strain Curves of Drained Triaxial Test On Sand PDFДокумент6 страницModeling of Stress - Strain Curves of Drained Triaxial Test On Sand PDFHenry AbrahamОценок пока нет

- Strain-Life Approach Ek KaynakДокумент14 страницStrain-Life Approach Ek KaynakKALIDASS DОценок пока нет

- Young's Modulus, Shear Modulus, and Poisson's Ratio in Silicon and GermaniumДокумент5 страницYoung's Modulus, Shear Modulus, and Poisson's Ratio in Silicon and GermaniumMisti LucasОценок пока нет

- Re-Examination of Cumulative FatigueДокумент33 страницыRe-Examination of Cumulative FatigueArgel PorrelloОценок пока нет

- Analysis of Time of Collapse of Steel Columns Exposed T o FireДокумент12 страницAnalysis of Time of Collapse of Steel Columns Exposed T o FireMurali Krishna Reddy ArikatlaОценок пока нет

- Alloying Element Effect On Al Alloys Elastic Constant (Elastic Properties)Документ13 страницAlloying Element Effect On Al Alloys Elastic Constant (Elastic Properties)Ayman AydanОценок пока нет

- Hardin&Drnevich - 1972 - SM6ShearModulusandDampinginSoils-MeasurementandParameterEffects PDFДокумент23 страницыHardin&Drnevich - 1972 - SM6ShearModulusandDampinginSoils-MeasurementandParameterEffects PDFHector HachesОценок пока нет

- Pipe Bridgeby ZsДокумент15 страницPipe Bridgeby ZsShahram BehniaОценок пока нет

- Mróz - On The Description of Anisotropic WorkhardeningДокумент13 страницMróz - On The Description of Anisotropic WorkhardeningDavid C HouserОценок пока нет

- An Introduction To Mechanics of Solids - Chapter 6Документ21 страницаAn Introduction To Mechanics of Solids - Chapter 6vinaykumaryadavОценок пока нет

- Electricity and Magnetism: Problems in Undergraduate PhysicsОт EverandElectricity and Magnetism: Problems in Undergraduate PhysicsРейтинг: 5 из 5 звезд5/5 (1)

- Stress Analysis Problems in S.I. Units: The Commonwealth and International Library: Mechanical Engineering DivisionОт EverandStress Analysis Problems in S.I. Units: The Commonwealth and International Library: Mechanical Engineering DivisionРейтинг: 2.5 из 5 звезд2.5/5 (4)

- Nonlinear Elasticity: Proceedings of a Symposium Conducted by the Mathematics Research Center, the University of Wisconsin—Madison April 16—18, 1973От EverandNonlinear Elasticity: Proceedings of a Symposium Conducted by the Mathematics Research Center, the University of Wisconsin—Madison April 16—18, 1973R. W. DickeyОценок пока нет

- List of ELC GroupsДокумент4 страницыList of ELC GroupsHeaven SinghОценок пока нет

- Tool Used: Q2 of MST CLO 1: Calculate Deformation of Statically Determinate Structures Using Geometric and Energy MethodsДокумент59 страницTool Used: Q2 of MST CLO 1: Calculate Deformation of Statically Determinate Structures Using Geometric and Energy MethodsHeaven SinghОценок пока нет

- Unit 2 Influence Lines Statically Determinate Trusses: StructureДокумент24 страницыUnit 2 Influence Lines Statically Determinate Trusses: StructureHeaven SinghОценок пока нет

- 10.1007@978 3 319 91137 3 - 14Документ6 страниц10.1007@978 3 319 91137 3 - 14Heaven SinghОценок пока нет

- Format For LabsДокумент2 страницыFormat For LabsHeaven SinghОценок пока нет

- Format For LabsДокумент2 страницыFormat For LabsHeaven SinghОценок пока нет

- 2.6.1 Details of PO's 1-12 - BE CivilДокумент2 страницы2.6.1 Details of PO's 1-12 - BE CivilHeaven SinghОценок пока нет

- Letter of RecommendationДокумент2 страницыLetter of RecommendationHeaven SinghОценок пока нет

- Department: CIVIL ENGINEERING (CED) ODD SemesterДокумент2 страницыDepartment: CIVIL ENGINEERING (CED) ODD SemesterHeaven SinghОценок пока нет

- PROOF OF INTERACTION WITH OUTSIDE WORLD - AbetДокумент10 страницPROOF OF INTERACTION WITH OUTSIDE WORLD - AbetHeaven SinghОценок пока нет

- Weinstock 2016Документ30 страницWeinstock 2016Heaven SinghОценок пока нет

- NearestДокумент1 страницаNearestHeaven SinghОценок пока нет

- Tut Test 1 MM: 10, TIME: 50 MinsДокумент1 страницаTut Test 1 MM: 10, TIME: 50 MinsHeaven SinghОценок пока нет

- Design and Cost Analysis of Multistoreyed Building Using Composite SectionДокумент2 страницыDesign and Cost Analysis of Multistoreyed Building Using Composite SectionHeaven SinghОценок пока нет

- CNG 291546Документ3 страницыCNG 291546ALEJANDROОценок пока нет

- NCSX Crit Bolt 00 SignedДокумент19 страницNCSX Crit Bolt 00 SignedaravinthОценок пока нет

- Concrete Formwork For Tunnel LiningДокумент58 страницConcrete Formwork For Tunnel LiningAlejandro Castañón0% (1)

- Armani Casa Penthouse Floor PlanДокумент4 страницыArmani Casa Penthouse Floor PlanSarah Elles BoggsОценок пока нет

- Train Embankment Loads in DeepEXДокумент8 страницTrain Embankment Loads in DeepEXM Sajid IqbalОценок пока нет

- Constant Volume - Constant Speed. Chilled Water Systems. Chillers Pumps & PiДокумент3 страницыConstant Volume - Constant Speed. Chilled Water Systems. Chillers Pumps & PiMohamed AdelОценок пока нет

- Water Ace R33SU Submersible PumpДокумент16 страницWater Ace R33SU Submersible PumpatereñoneОценок пока нет

- Toilet & Bath at Bedroom: Medicine Cabinet Counter Top Lavatory Installation Siphon Jet Water ClosetДокумент1 страницаToilet & Bath at Bedroom: Medicine Cabinet Counter Top Lavatory Installation Siphon Jet Water ClosetStephen Mark Garcellano DalisayОценок пока нет

- PO1541 - Ojas Infra GSF - MV Cable Marking and Drum Label v1.0Документ6 страницPO1541 - Ojas Infra GSF - MV Cable Marking and Drum Label v1.0Sanjay GadhaveОценок пока нет

- Allowable Stress in PipingДокумент6 страницAllowable Stress in PipingpelotoОценок пока нет

- Johnson Lee JWELL PresentationДокумент30 страницJohnson Lee JWELL PresentationRajiv SanghaviОценок пока нет

- Load Tables - Capacity Charts - Selective (VERY GOOD) PDFДокумент10 страницLoad Tables - Capacity Charts - Selective (VERY GOOD) PDFsarbiniОценок пока нет

- Pse 115a2512#dl PSDL D Com Proper 1 To 4Документ4 страницыPse 115a2512#dl PSDL D Com Proper 1 To 4Rinowan PanggoariОценок пока нет

- Ccaa Hot Weather ConcretingДокумент7 страницCcaa Hot Weather ConcretingHussain ElarabiОценок пока нет

- Final Indian Highways May - 2017Документ64 страницыFinal Indian Highways May - 2017Manmatha SahooОценок пока нет

- Gen TT Install InstructionsДокумент25 страницGen TT Install Instructionsspsperformance1Оценок пока нет

- ButalejaДокумент4 страницыButalejaSamuel WagemaОценок пока нет

- Concrete BasicsДокумент27 страницConcrete BasicsPradeepLokhandeОценок пока нет

- 2014.03.27 Volume 2 Design ENДокумент134 страницы2014.03.27 Volume 2 Design ENSalman KaziОценок пока нет

- Lsa DWG 190703 98 Ejm SignedДокумент1 страницаLsa DWG 190703 98 Ejm SignedAgung PerbowoОценок пока нет

- Kitchen AssignmentДокумент39 страницKitchen AssignmentKhiZra ShahZadОценок пока нет

- BS en Iso 14692-3-2017Документ46 страницBS en Iso 14692-3-2017SRIDHAR BABU KONADAОценок пока нет

- Forging AluminiumДокумент3 страницыForging Aluminiumnadeem_mechОценок пока нет

- 0 - BALAJI.E (Project Engineer) - Pages-DeletedДокумент5 страниц0 - BALAJI.E (Project Engineer) - Pages-DeletedEngr BalajiОценок пока нет

- 102 Strength of MaterialsДокумент48 страниц102 Strength of MaterialsPia Eleanor SantosОценок пока нет

- Bathroom RenovationДокумент3 страницыBathroom Renovationmohd faizОценок пока нет

- Prestressed Concrete Analysis and Design Fundamentals 2nd Ed CAP 10Документ78 страницPrestressed Concrete Analysis and Design Fundamentals 2nd Ed CAP 10Carlos Alberto Pacheco SierraОценок пока нет

- Transmission Tower Installation ProcessДокумент50 страницTransmission Tower Installation ProcessManoranjan Dash100% (8)

- Vibration PPV EstimationДокумент8 страницVibration PPV EstimationJensen TanОценок пока нет

- Installation Procedure EQOBRUSH For Heat Exchangers and CondensersДокумент16 страницInstallation Procedure EQOBRUSH For Heat Exchangers and CondensersWatco GroupОценок пока нет