Академический Документы

Профессиональный Документы

Культура Документы

Chapter 3 - Iron and Steel Production

Загружено:

Ijal Haizal0 оценок0% нашли этот документ полезным (0 голосов)

296 просмотров43 страницыnotes

Оригинальное название

Chapter 3 - Iron and Steel Production (1)

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документnotes

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

296 просмотров43 страницыChapter 3 - Iron and Steel Production

Загружено:

Ijal Haizalnotes

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 43

Mechanical Engineering Department

JF302 MATERIAL TECHNOLOGY 1 CHAPTER 3 : IRON AND STEEL PRODUCTION

Types of Iron Ore 1

Characteristics of Iron Ore 2

Iron Production Process 3

Steel Production Process 4

Iron is an element in the periodic table that

has the symbol Fe and atomic number 26

metallic iron is produced from iron ore and

rare elements found in free

Iron is the main and most abundant metal

use

physical properties can be modified

price is cheap and easily available

most of the steel used was not in a pure

JF302 MATERIAL TECHNOLOGY 1 CHAPTER 3 : IRON AND STEEL PRODUCTION

rocks that contain minerals of iron and other

elements

composed of elements or compounds such

as oxides, sulfides, sulfur, silicon, etc.

have different color

is the main ingredient in the production of

pig iron

It was not in its pure form

JF302 MATERIAL TECHNOLOGY 1 CHAPTER 3 : IRON AND STEEL PRODUCTION

JF302 MATERIAL TECHNOLOGY 1 CHAPTER 3 : IRON AND STEEL PRODUCTION

have 40% - 65% iron content

is the highest of all iron ore is found

black to reddish brown

JF302 MATERIAL TECHNOLOGY 1 CHAPTER 3 : IRON AND STEEL PRODUCTION

has 72.4% iron content

available in the form of land or a brick

have magnetic properties

blackish color

JF302 MATERIAL TECHNOLOGY 1 CHAPTER 3 : IRON AND STEEL PRODUCTION

iron content of 50% and 50% sulfur

color is golden

found in crystal form

JF302 MATERIAL TECHNOLOGY 1 CHAPTER 3 : IRON AND STEEL PRODUCTION

containing iron sebayak 20% - 55% and a

water content of 40%

yellow color is brown, but when the water is

removed it will change the color of

haematite ore

JF302 MATERIAL TECHNOLOGY 1 CHAPTER 3 : IRON AND STEEL PRODUCTION

have 25% - 30% iron content

color reddish or blackish

obtained in the form of bricks

JF302 MATERIAL TECHNOLOGY 1 CHAPTER 3 : IRON AND STEEL PRODUCTION

iron content of less than 30% and is

otherwise carbon and phosphorus content

Color gray ore

JF302 MATERIAL TECHNOLOGY 1 CHAPTER 3 : IRON AND STEEL PRODUCTION

has a sulfur content of 50%

golden

obtained in the form of bricks

JF302 MATERIAL TECHNOLOGY 1 CHAPTER 3 : IRON AND STEEL PRODUCTION

with 50% silicon content

can be divided into several types, namely

kamosite, stillprunit, gururite and

minnesotite

JF302 MATERIAL TECHNOLOGY 1 CHAPTER 3 : IRON AND STEEL PRODUCTION

iron content of 30%

yellowish brown

can be classified according to the type of

`gauge 'which existed as to whether` gauge

that is rich in silica-rich or calcium oxide

(CaO)

JF302 MATERIAL TECHNOLOGY 1 CHAPTER 3 : IRON AND STEEL PRODUCTION

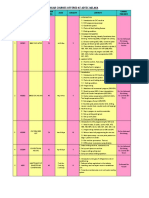

1. grade

- Contains as much iron oxide

2. density

- Not too heavy or too fragile.

3. genuineness

- Have the lowest content of foreign material may

4. uniformity

- Have a uniform composition of the group to

another group

JF302 MATERIAL TECHNOLOGY 1 CHAPTER 3 : IRON AND STEEL PRODUCTION

JF302 MATERIAL TECHNOLOGY 1 CHAPTER 3 : IRON AND STEEL PRODUCTION

JF302 MATERIAL TECHNOLOGY 1 CHAPTER 3 : IRON AND STEEL PRODUCTION

Step 1 :

Concentration

Step 2 :

Calcination

Step 3 :

Smelting

The ore is crushed in

crushers and is

broken to small

pieces. It is

concentrated with

gravity separation

process in which it is

washed with water to

remove clay, sand,

etc.

The ore is then

heated in absence of

air (calcined). This

results in

decomposition of

carbonates into

oxides and then

ferrous oxide is

converted into Ferric

Oxide.

The concentrated ore

is mixed with

calculated quantity of

coke, limestone and

the mixture is put in

the Blast Furnace

from top.

3 2 2

2 3

CO Fe 2 O FeO 4

CO FeO FeCO

Blast furnace consists of a vertical steel shell ~100 ft

high & ~ 21 ft dia and lined with refractory material.

It has a charging arrangement (Bell & Cone) at the top.

Raw material is charged by a skip car through this

charging mechanism into the blast furnace.

It has a means of running off Pig iron & Slag at the

bottom.

Air is blown in near the bottom of the furnace. This

forced draught increases the speed of combustion &

maintains the necessary high temperature.

Cooling water is circulated around the Bosh area in

order to protect the furnace from high temp.

JF302 MATERIAL TECHNOLOGY 1 CHAPTER 3 : IRON AND STEEL PRODUCTION

JF302 MATERIAL TECHNOLOGY 1 CHAPTER 3 : IRON AND STEEL PRODUCTION

raw material brought to the top of the

furnace by car penangkut

it is inserted into the furnace through the

distributor moves and through the use of a

bell

This bell function for controlling the gas load

loss

continuous hot air sprayed through a number

of openings called `TUYER '

boiler used to heat the air up to 1100 C.

JF302 MATERIAL TECHNOLOGY 1 CHAPTER 3 : IRON AND STEEL PRODUCTION

air cooled and hot gas flow repeated in the

opposite direction through the boiler

to supply continuous hot spray, each boiler

furnaces have some work on a rotational

basis

iron is removed from the furnace every 2

hours

molten iron and prop separately removed

through a hole in the bottom of filter

JF302 MATERIAL TECHNOLOGY 1 CHAPTER 3 : IRON AND STEEL PRODUCTION

JF302 MATERIAL TECHNOLOGY 1 CHAPTER 3 : IRON AND STEEL PRODUCTION

JF302 MATERIAL TECHNOLOGY 1 CHAPTER 3 : IRON AND STEEL PRODUCTION

Iron ore + coke + limestone + air

iron + slag + gas

carbon in coke combustion with oxygen in

the air spray

reduction of iron oxide to

flush `gauge iron ore and ash with limestone.

JF302 MATERIAL TECHNOLOGY 1 CHAPTER 3 : IRON AND STEEL PRODUCTION

capital and operating costs are high

regulation of iron composition is

relatively weak

small furnace that uses coke is not

efficient

JF302 MATERIAL TECHNOLOGY 1 CHAPTER 3 : IRON AND STEEL PRODUCTION

To produce one ton of pig iron, we need raw

materials as follows:

2 tone iron ore+ 1 tone coke+ 1/2 tone limestone

1 tone iron

* Raw materials must be added all at once

JF302 MATERIAL TECHNOLOGY 1 CHAPTER 3 : IRON AND STEEL PRODUCTION

used for smelting iron ore to make pig iron.

pig iron containing 93% pure iron, 3% - 5%

carbon, silica, sulfur, phosphorus and

manganese.

main ingredients for cast iron, wrought iron

and steel.

props used for road and building blocks.

JF302 MATERIAL TECHNOLOGY 1 CHAPTER 3 : IRON AND STEEL PRODUCTION

JF302 MATERIAL TECHNOLOGY 1 CHAPTER 3 : IRON AND STEEL PRODUCTION

JF302 MATERIAL TECHNOLOGY 1 CHAPTER 3 : IRON AND STEEL PRODUCTION

In the beginning, it is IRON ...

Then, it became IRON Chartered ...

... finally, STEEL

is a very valuable metal

most types of metal and widely used

produced through the oxidation process that

reduces the amount of carbon, silicon,

manganese, and sulfur forforus in a mixture of

molten pig iron and steel scrap

JF302 MATERIAL TECHNOLOGY 1 CHAPTER 3 : IRON AND STEEL PRODUCTION

JF302 MATERIAL TECHNOLOGY 1 CHAPTER 3 : IRON AND STEEL PRODUCTION

1. In the field of construction and

building bridges .....

2. In the automotive sector ....

3. For daily use:

cans, pots, containers, etc.

JF302 MATERIAL TECHNOLOGY 1 CHAPTER 3 : IRON AND STEEL PRODUCTION

it uses pure oxygen

can move horizontally and vertically

while leaning state, furnace filled with molten iron

and scrap iron 30%

during the vertical, boost oxygen with high-speed

fluid is directed kepermukaan content

Oxygen is cooled with water

JF302 MATERIAL TECHNOLOGY 1 CHAPTER 3 : IRON AND STEEL PRODUCTION

Some carbon is converted into gaseous oxides

An old result when the oxide reacts with limestone

furnace is tilted to the horizontal position to produce

mild steel melting

furnace reversed to remove the prop

able to produce high quality steel quickly of 80

tonnes per hour

JF302 MATERIAL TECHNOLOGY 1 CHAPTER 3 : IRON AND STEEL PRODUCTION

JF302 MATERIAL TECHNOLOGY 1 CHAPTER 3 : IRON AND STEEL PRODUCTION

have a high capacity and easy to operate

low oxygen consumption rate

appropriate to increase the grade of steel

using the supplied natural oxygen jet

produce 120 tons of steel in the first 4 hours.

JF302 MATERIAL TECHNOLOGY 1 CHAPTER 3 : IRON AND STEEL PRODUCTION

has a curve shape as a convex cylinder

made of steel and coated with heat-resistant brick

The cap can be removed and there is a three-way, or

opening where carbon electrodes can be moved freely

use coolant through channels outside the furnace

copper

JF302 MATERIAL TECHNOLOGY 1 CHAPTER 3 : IRON AND STEEL PRODUCTION

1. charging

charge materials containing steel scrap, pig

iron, iron oxide and lime added to the furnace

electric current is passed to the carbon

electrodes for electric arc supply

JF302 MATERIAL TECHNOLOGY 1 CHAPTER 3 : IRON AND STEEL PRODUCTION

2. smelting

electric arc with high heat will melt the charge

material oxygenated

silicon, and phosphorus mangganes start oxidized

and mixed with lime to form the basic prop

no metal is lost as carbon electrodes burn

JF302 MATERIAL TECHNOLOGY 1 CHAPTER 3 : IRON AND STEEL PRODUCTION

3. isolation

phosphorus transfer depends on the basic prop in

calcium oxide

lime, iron oxide flourospar and mixed to form a

fulcrum that react with impurities

composed of steel required to developFeS + CaO +

C CaS + Fe + CO

JF302 MATERIAL TECHNOLOGY 1 CHAPTER 3 : IRON AND STEEL PRODUCTION

4. closure

Oxidized steel using aluminum, Ferro-Silicon or

Ferro-Mangganes

To take steel, prop knitted or poured from the

surface first and then removed or drained through

the hole / channel exit by tilting furnace

JF302 MATERIAL TECHNOLOGY 1 CHAPTER 3 : IRON AND STEEL PRODUCTION

sulfur transfer or change is appropriate.

combustion can be controlled and managed

effectively.

no oxidizing gas to produce high quality steel.

temperature can be precisely controlled.

addition of alloy elements can be made correctly.

furnaces are free from dirt and smoke.

JF302 MATERIAL TECHNOLOGY 1 CHAPTER 3 : IRON AND STEEL PRODUCTION

1. Briefly explain THREE (3) types of iron ore on the

surface of the earth.

2. Mention THREE (3) types of furnaces to produce the

production.

i. Iron.

ii. Steel.

3. What is the charge material is included in the

following furnaces:

i. Bagas furnace.

ii. Electric arc furnace.

JF302 MATERIAL TECHNOLOGY 1 CHAPTER 3 : IRON AND STEEL PRODUCTION

Вам также может понравиться

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Impulse and MomentumДокумент18 страницImpulse and MomentumIjal HaizalОценок пока нет

- Healthiest Cooking Oil Smoke Point ChartДокумент6 страницHealthiest Cooking Oil Smoke Point ChartiegorjОценок пока нет

- Eni S.p.A. Agip Division Pressure Vessel RequirementsДокумент21 страницаEni S.p.A. Agip Division Pressure Vessel Requirementshalim_kaОценок пока нет

- FABRICATION and ERECTION of PIPING SYSTEMДокумент39 страницFABRICATION and ERECTION of PIPING SYSTEMIj Ooo100% (1)

- Organic I Reactions (Complete) PDFДокумент10 страницOrganic I Reactions (Complete) PDFStarrx714Оценок пока нет

- Hach Nitrate Method 10206 Final 01102013Документ10 страницHach Nitrate Method 10206 Final 01102013dunavko1Оценок пока нет

- Crude Oil Analysis ResultsДокумент18 страницCrude Oil Analysis Resultslutfi awnОценок пока нет

- General Characteristic of Crude OilДокумент20 страницGeneral Characteristic of Crude Oildassi99Оценок пока нет

- Rubric Practical TaskДокумент4 страницыRubric Practical TaskIjal Haizal100% (1)

- Senaraihospital PDFДокумент1 страницаSenaraihospital PDFIjal HaizalОценок пока нет

- AutocadДокумент92 страницыAutocadIjal HaizalОценок пока нет

- Mechanical Engineering Department: DJJ3053 - Engineering Mechanics LABДокумент1 страницаMechanical Engineering Department: DJJ3053 - Engineering Mechanics LABIjal HaizalОценок пока нет

- Sesi: JUN 2014 Seksyen: DKM 5C TarikhДокумент1 страницаSesi: JUN 2014 Seksyen: DKM 5C TarikhIjal HaizalОценок пока нет

- Practical Task 1Документ2 страницыPractical Task 1Ijal HaizalОценок пока нет

- Adtec Melaka PDFДокумент5 страницAdtec Melaka PDFIjal HaizalОценок пока нет

- Mechanical Engineering Department: DJJ3053 - Engineering Mechanics LABДокумент1 страницаMechanical Engineering Department: DJJ3053 - Engineering Mechanics LABIjal HaizalОценок пока нет

- Happy Holiday: Thank You For Choosing Sun Inns As Your Home Away Home..... Dengan Ingatan Tulus Ikhlas DariДокумент1 страницаHappy Holiday: Thank You For Choosing Sun Inns As Your Home Away Home..... Dengan Ingatan Tulus Ikhlas DariIjal HaizalОценок пока нет

- CadcamДокумент1 страницаCadcamIjal HaizalОценок пока нет

- Keputusan Projek Akhir Sesi Jun 2014 Kedudukan No Pendaftaran JohanДокумент3 страницыKeputusan Projek Akhir Sesi Jun 2014 Kedudukan No Pendaftaran JohanIjal HaizalОценок пока нет

- Chap 5Документ8 страницChap 5Ijal HaizalОценок пока нет

- SESI: JUN 2014 Seksyen: S1 Kursus: Jj512 - Pneumatic & Hydraulics Pensy. Kursus: Haizal Bin Mohd HamzahДокумент4 страницыSESI: JUN 2014 Seksyen: S1 Kursus: Jj512 - Pneumatic & Hydraulics Pensy. Kursus: Haizal Bin Mohd HamzahIjal HaizalОценок пока нет

- JADUAL KERJA BENGKEL MAKMAL KERJA LUARДокумент2 страницыJADUAL KERJA BENGKEL MAKMAL KERJA LUARIjal HaizalОценок пока нет

- Practical Task 1 Djj5062Документ2 страницыPractical Task 1 Djj5062Ijal HaizalОценок пока нет

- Eoc1 jj512Документ1 страницаEoc1 jj512Ijal HaizalОценок пока нет

- Chapter 2Документ84 страницыChapter 2Ijal HaizalОценок пока нет

- Surat Persetujuan 2Документ5 страницSurat Persetujuan 2Ijal HaizalОценок пока нет

- Engineering Mechanics Particle Equilibrium <40Документ31 страницаEngineering Mechanics Particle Equilibrium <40Ijal Haizal100% (1)

- JJ205 Engineering Mechanics: Prepared By: Norhayati Binti Ahmad Department of Mechanical EngineeringДокумент4 страницыJJ205 Engineering Mechanics: Prepared By: Norhayati Binti Ahmad Department of Mechanical EngineeringIjal HaizalОценок пока нет

- Adtec MelakaДокумент5 страницAdtec MelakaIjal HaizalОценок пока нет

- Group Assignment 1Документ1 страницаGroup Assignment 1Ijal HaizalОценок пока нет

- Chapter Summary: Prepared By: Amry.m.sДокумент6 страницChapter Summary: Prepared By: Amry.m.sIjal HaizalОценок пока нет

- Linear Angular RelationshipsДокумент9 страницLinear Angular Relationshipsfaris_sami7431Оценок пока нет

- S Chapter 06Документ64 страницыS Chapter 06alhanunОценок пока нет

- DynamicsДокумент16 страницDynamicsIjal HaizalОценок пока нет

- 1D Kinematics Notebook - Scoring RubricДокумент3 страницы1D Kinematics Notebook - Scoring RubricIjal HaizalОценок пока нет

- Work & EnergyДокумент25 страницWork & EnergyIjal HaizalОценок пока нет

- Work and EnergyДокумент112 страницWork and EnergyIjal HaizalОценок пока нет

- First LE Exam Reviewer Answer KeyДокумент2 страницыFirst LE Exam Reviewer Answer KeyLeah Ann Mari BongcoОценок пока нет

- Chemistry Investigatory Project On AntacidsДокумент13 страницChemistry Investigatory Project On AntacidsJoderick Sherwin100% (1)

- Litesse IДокумент1 страницаLitesse IAnthonyPonceParedesОценок пока нет

- Aldehydes and KetonesДокумент19 страницAldehydes and KetonesVaibhav TarkasbandОценок пока нет

- P-Block Elements GuideДокумент83 страницыP-Block Elements GuidePriyansh MishraОценок пока нет

- Intergranular Corrosion - An Overview - ScienceDirect TopicsДокумент14 страницIntergranular Corrosion - An Overview - ScienceDirect TopicsRex RusselОценок пока нет

- Liquid SolutionДокумент8 страницLiquid SolutionAyush KumarОценок пока нет

- Hollow Fiber MenbranesДокумент15 страницHollow Fiber MenbranespikipelukiОценок пока нет

- PDS Technofoam PT 01 - Hfc.Документ2 страницыPDS Technofoam PT 01 - Hfc.Ahmed FoudaОценок пока нет

- Dental Cement Types and PropertiesДокумент17 страницDental Cement Types and PropertiesMella Bella WilsonОценок пока нет

- Section 12 - Welding Consumables - HardfacingДокумент69 страницSection 12 - Welding Consumables - HardfacingFriedrich SchwimОценок пока нет

- Viskrings Seals SDSДокумент6 страницViskrings Seals SDSTarik ConceptОценок пока нет

- Experiment 2: Water of HydrationДокумент10 страницExperiment 2: Water of HydrationNur Faizatul AtiqahОценок пока нет

- Youngs Modulus For Different MaterialsДокумент3 страницыYoungs Modulus For Different Materialschaitanya kulkarniОценок пока нет

- Cast Irons - Engineering Materials & Metallurgy Questions and Answers - SanfoundryДокумент6 страницCast Irons - Engineering Materials & Metallurgy Questions and Answers - SanfoundrySample UseОценок пока нет

- Flame Resistant Cable LSZHДокумент2 страницыFlame Resistant Cable LSZHshinojbaby4148Оценок пока нет

- 1.molecules of Life PDFДокумент47 страниц1.molecules of Life PDFaeylynnОценок пока нет

- 157 - Omc Introduction and ExamplesДокумент9 страниц157 - Omc Introduction and Examplessamer alassadОценок пока нет

- 1.2.4 HDG - Painting Issues PDFДокумент2 страницы1.2.4 HDG - Painting Issues PDFAnonymous 1AAjd0Оценок пока нет

- Year 12 IAL Biology Week 1Документ34 страницыYear 12 IAL Biology Week 1MNSB Year 04Оценок пока нет

- Feedwater System 2Документ45 страницFeedwater System 2ika yuliyani murtiharjonoОценок пока нет

- Datasheet For Stainless Steel Super Duplex 2507Документ10 страницDatasheet For Stainless Steel Super Duplex 2507Prem EditsОценок пока нет

- Fibres PPT 1Документ19 страницFibres PPT 1rajesh duaОценок пока нет