Академический Документы

Профессиональный Документы

Культура Документы

HSBEI-1294-0314 Piling Rigs Overturning On Construction Sites

Загружено:

tsuak0 оценок0% нашли этот документ полезным (0 голосов)

124 просмотров4 страницыPiling rigs overturn

Оригинальное название

HSBEI-1294-0314 Piling Rigs Overturning on Construction Sites

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документPiling rigs overturn

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

124 просмотров4 страницыHSBEI-1294-0314 Piling Rigs Overturning On Construction Sites

Загружено:

tsuakPiling rigs overturn

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 4

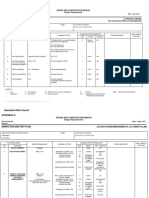

A guide to loss prevention

Piling rigs overturning on construction sites

A guide to loss prevention

The stability of tracked plant depends

on the provision of a well prepared,

inspected and maintained site surface.

Good co-ordination between piling

companies and the principal site

contractors is essential. Details of the

plant to be used and bearing pressures

must be provided, and the site surfaces

must be correctly prepared in advance

of work commencing.

Common terms

Piling rig: A construction machine

mainly used to drill/create piles in soil,

clay, etc. Widely used for cast-in-place

piles, diaphragm walls, and foundation

reinforcement. Max. pile diameter

typically 1.5-4m, max. pile depth from

60-90m. Generally with crawler chassis,

box-type mast, and telescopic drill pipe.

Mainly used in foundation engineering

of elevated roads, bridges, industrial and

civil buildings, slope protection, etc.

Modern piling rigs can weigh as much as 200 tonnes and have a high

centre of gravity. The leader part of a rig can be up to 30 metres high,

thus the high centre of gravity, high static weight, and the forces exerted

while rigs operate or move mean that the ground conditions beneath such

rigs is a critical safety issue.

Each year, piling rigs topple causing signicant property damage and

potential business interruption claims. This is usually due to inadequately

prepared or maintained site surfaces.

Working platform: Temporary

geotechnical structures providing

a stable working surface for piling rigs,

mobile cranes and other heavy

construction equipment. A working

platform is the foundation for a piling

rig which may weigh up to 200 tonnes.

Working Platform Certicate:

A certicate which conrms the working

platform has been properly designed

and constructed in accordance with the

design, and that it will be adequately

maintained to ensure the ongoing

integrity of the platform.

It requires the signature of the main

contractor on the project and must

be handed to the piling contractor

before piling or other foundation work

commences. The certicate introduces

a system for highlighting specic

responsibilities, increasing safety

awareness and highlighting the

importance of maintaining the platform

in good condition.

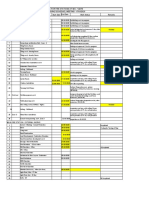

Key components of a safe piling rig

operational plan include:

1. Adequate pre-planning

The following arrangements should

be made prior to arriving on site. Safe

set-down areas need to be established

within reach of the rig; as does an area

accessible to vehicles with suficient

space to unload items up to 20m

in length.

2. Working platform

A working platform is the name given

to the designated area of the site over

which the piling rig will travel during

its delivery to site, piling operations,

and removal.

The design, installation, maintenance

and repair of the working platform

should be the responsibility of the main

contractor. The ground needs to be

checked and its stability conrmed.

This may include load and integrity

testing, investigation of any irregularities

and any necessary remedial works.

The ground must be free-draining to

prevent the build-up of water and

slurry. In certain cases, separation/lter

membranes may need to be installed

beneath the platform material to

prevent damage/weakness of the

ground strength.

3. Working Platform Certicate

The use of Working Platform

Certicates is increasingly being

seen as a way to ensure the following:

the correct procedures have been

followed

the ground is adequate to support

the piling rig

there are no irregularities that could

result in local subsidence and toppling

A visual inspection can only check the

ground surface. It is important to check

the underlying material, the quality

of the ll, its construction and depth

(and the application of any membrane

material if required). The piling

contractor should advise what rigs are to

be used, including the bearing pressures,

dimensions and working space required.

These details should be summarised on

the Working Platform Certicate.

4. Inspection of piling equipment prior

to the start of piling operations

A review of the general condition should

be supplemented by daily checks using

a checklist form. Equipment should be

inspected at the start of each shift or

during operations; for example, where

the operator suspects that hydraulic

hoses have become snagged during

piling operations.

Safety co-ordination

requires:

Planning: Suficient time must be

spent on planning the safety of the

construction operations.

Space on site: Working schedules

can be tight; foundation

contractors may be asked to arrive

with several piling rigs

simultaneously at a site that is too

small to accommodate them.

Space around the site: Stability of

equipment is crucial due to the

height of the rigs.

5. Inspection of the site during piling

The ground surface can deteriorate over

time. Excavations, trenches, or other

holes dug must be properly backlled

to avoid creating soft spots that might

give way under the tracks of a piling rig.

A 1sq.m soft spot can be suficient to

unbalance a piling rig and cause it

to topple over. The edge of the ground

to be used by the piling rig needs to

be clearly dened (ground preparation

should extend beyond the working

area required) and should be regularly

inspected to identify and correct

any degradation.

6. Risk assessment

A task specic Risk Assessment and

Method Statement should be conducted

to include all hazards and foreseeable

risks relating to the delivery to site,

erection, use, movement, dismantling,

and removal from site of the piling rig.

7. Operator training

All workers involved (e.g. the piling rig

operator; lifting supervisor; rigger and

signalman/banksman) should be trained

and competent in their specic duties.

Both the operator and his supervisor

should be made familiar with the

operational controls and the suppliers

instructions for the specic piling

equipment in use.

8. Permits to Work

The Permit to Work should be prepared

by a person familiar with the piling work

procedures, the hazards involved and the

precautions to be taken. A review of the

Risk Assessment and Working Platform

Certicate should be essential aspects

that are checked prior to sign-of.

9. Qualied banksman

Piling rig movements should be

supervised by a qualied banksman who

must always be in the line of sight of the

operator. The banksman also needs to

have sight of the tracks and the ground it

will be moving over whenever movement

of the rig is planned.

10. Pre-planning for maintenance

and refuelling

Pre-planning should include

consideration of mobile maintenance

and refuelling stations so that such

operations can be brought to the rig

and conducted without tracking the rig

backwards and forwards to xed

maintenance or refuelling points.

Practical considerations

There have been a number of instances

on construction sites of piling rigs

toppling over while operating on

unbound working platforms.

Investigations following such incidents

have often found that inherent, isolated

areas of weakness or ground collapse

have been the actual causes of failure,

which were not indicated by load testing.

For this reason, it is essential that

contractors carefully inspect and check

sub-grades such as old pits or trenches

for evidence of localised weak areas

prior to any work commencing.

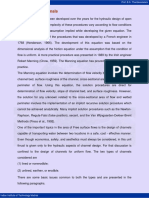

Case study: Piling rig falls across

live passenger/freight railway lines

During piling works on a major

railway infrastructure project, a CFA

piling rig fell across adjacent live

passenger and freight railway lines.

Ground conditions at the piling site

were somewhat marsh-like and a

critical geotextile membrane was

relied upon to prevent the stone

working platform being displaced

into the peat.

To remove an obstruction the

contractor dug a trench in the piling

platform, which damaged the critical

geotextile membrane. The trench was

then poorly backlled. When the rig

crossed the trench, the ground settled

under one side causing the piling rig

to overturn across the live railway

lines; bringing down a 25,000 volt

overhead catenary during rush hour.

A passenger train had passed by just

two minutes earlier - fortunately there

were no injuries; however, the railway

line was closed for three days. A

prosecution and substantial ne

ensued. The subsequent investigation

found that a signicant contributing

factor was the breakdown of

communication between senior and

junior site managers, who were not

aware how critical the piling platform

and design was, or the need to involve

the platform design engineer in

any repairs.

UK Building Research

Establishment - BR 470

Working platforms for

tracked plant

ISBN 1 86081 7009

Provides good practice

guidance on the design,

installation, maintenance

and repair of ground

supported working platforms

constructed of granular

material for the use of tracked

plant. Development of the

BR 470 design method

included a rigorous

benchmarking process,

using a range of types and

sizes of piling rigs, to verify

that the platform thicknesses

calculated would be

economical and safe.

Disclaimer: The guidance in this document refers to

industry best practice loss control advice. Adoption of

the advice contained within this document does not

imply compliance with industry, statutory or HSBEI

guidelines, nor does it guarantee that related losses

will not occur.

HSB-LCE-RGN-007 Rev: 0 Date: 10/03/2014

References:

Federation of Piling Specialists (UK):

www.fps.org.uk

ADSC The International Association of

Foundation Drilling: www.adsc-iafd.com

European Federation of Foundation Contractors:

www.foundationworld.org.uk

Working Platform Certicate: www.fps.org.uk/

fps/guidance/platforms/platforms.php

www.hsbeil.com

For more information contact our

HSB Engineering Insurance ofice:

London

t: 020 7264 7000

Glasgow

t: 0845 345 5514

Manchester

t: 0845 345 5511

Leeds

t: 0113 388 4830

Birmingham

t: 0845 345 5512

Bristol

t: 0844 875 4260

Ipswich

t: 0845 345 5513

Belfast

t: 0845 345 5516

Dublin

t: 01 234 2699

HSB Engineering Insurance Limited registered in England and Wales: 02396114, New London House, 6 London Street, London EC3R 7LP.

Registered as a branch in Ireland: 906020. Authorised by the Prudential Regulation Authority and regulated by the Financial Conduct Authority and

the Prudential Regulation Authority.

HSBEI-1294-0314

NOT IF, BUT HOW

Вам также может понравиться

- Civil specifications for Cut & Bend Processing Building projectДокумент10 страницCivil specifications for Cut & Bend Processing Building projectLuis Gabriel BautistaОценок пока нет

- MCE Newsletter 2013Документ8 страницMCE Newsletter 2013wongey12Оценок пока нет

- Operation and Maintenance: General ConsiderationsДокумент5 страницOperation and Maintenance: General ConsiderationsetienneОценок пока нет

- Design Consultant Guarantee LetterДокумент1 страницаDesign Consultant Guarantee LetterSumantra ChattopadhyayОценок пока нет

- Project Integration Management: Initiation Planning Executing Monitoring and Controlling ClosingДокумент5 страницProject Integration Management: Initiation Planning Executing Monitoring and Controlling Closingvikram122Оценок пока нет

- ReportДокумент21 страницаReportCorniОценок пока нет

- Trenchless Construction TechniquesДокумент26 страницTrenchless Construction TechniquesSimranjitSinghОценок пока нет

- L2 History of Civil EngineeringДокумент22 страницыL2 History of Civil EngineeringELENA MARIE BUYOОценок пока нет

- Green Drop Report 2013: Status and Performance of South African Wastewater SystemsДокумент7 страницGreen Drop Report 2013: Status and Performance of South African Wastewater SystemsrendaninОценок пока нет

- Figure6 2Документ1 страницаFigure6 2api-3705877Оценок пока нет

- Lecture - 01 Introduction To Project ManagementДокумент33 страницыLecture - 01 Introduction To Project ManagementHiếu NguyễnОценок пока нет

- KPI Report For The Minister For ConstructionДокумент34 страницыKPI Report For The Minister For ConstructionEssam Abdelmonem Mohamed PmpОценок пока нет

- Schedule Maintenance WorkДокумент4 страницыSchedule Maintenance WorkbabaОценок пока нет

- Sewerage ReportДокумент13 страницSewerage ReportSelf OperaterОценок пока нет

- Green Drop Requirements - 2021 Requirements - DraftДокумент20 страницGreen Drop Requirements - 2021 Requirements - DraftSkhulie Sque DubeОценок пока нет

- Tender Notice and Invitation To TenderДокумент1 страницаTender Notice and Invitation To TenderWina George Muyunda100% (1)

- Project KPIs track safety, cost, scheduleДокумент2 страницыProject KPIs track safety, cost, schedulejdadha100% (2)

- Contract Change Order No. 13 RedactedДокумент7 страницContract Change Order No. 13 RedactedL. A. PatersonОценок пока нет

- Glenfield Road Corridor Management PlanДокумент225 страницGlenfield Road Corridor Management PlanJohn GillonОценок пока нет

- !!!chlorate Cell PDFДокумент20 страниц!!!chlorate Cell PDFSlava75Оценок пока нет

- Fuel Dispensing Pump TestingДокумент4 страницыFuel Dispensing Pump TestingAnonymous FW5PVUp50% (2)

- MKC McCormick 2018 CAGNYДокумент77 страницMKC McCormick 2018 CAGNYAla BasterОценок пока нет

- Site Works Scheduel Meeting - 17/10/2020: Epic For Fire Stations at Mic - 143/18Документ2 страницыSite Works Scheduel Meeting - 17/10/2020: Epic For Fire Stations at Mic - 143/18HariKumar PОценок пока нет

- Lecture Arch 513 Construction ManagementДокумент45 страницLecture Arch 513 Construction ManagementJanine Abuyan ObligadoОценок пока нет

- PROGRESS REPORT For Month EndingДокумент13 страницPROGRESS REPORT For Month EndingShahid AliОценок пока нет

- Standard System 2015 7th EditДокумент130 страницStandard System 2015 7th EditLisa Shenton100% (2)

- Request For Information (Rfi) : Company (Contractor) Contract/ Purchase NoДокумент2 страницыRequest For Information (Rfi) : Company (Contractor) Contract/ Purchase NoResearcherОценок пока нет

- GPR Survey Short ReportДокумент4 страницыGPR Survey Short ReportGalihprasetya89Оценок пока нет

- Curtain Wall ProblemsДокумент4 страницыCurtain Wall ProblemsMohammad Reza NateghОценок пока нет

- CE511-Topic-1a Introduction Project Managment-352Документ25 страницCE511-Topic-1a Introduction Project Managment-352leena samuelОценок пока нет

- NHA CSR 2014 Rates for Sindh ProjectsДокумент262 страницыNHA CSR 2014 Rates for Sindh ProjectsSohail Ahmed Khilji100% (1)

- Types of ManholesДокумент6 страницTypes of ManholesEvonYongОценок пока нет

- Owner Design-Build Entity Sub-ConsultantsДокумент2 страницыOwner Design-Build Entity Sub-ConsultantsAnas Bin ShamsudinОценок пока нет

- Pricing PreamblesДокумент15 страницPricing PreamblesSabeoОценок пока нет

- STANDARD SYSTEM OF MEASURING BUILDING WORKДокумент71 страницаSTANDARD SYSTEM OF MEASURING BUILDING WORKmutyoka100% (1)

- ConstruxdelayanalysisДокумент33 страницыConstruxdelayanalysisrajkamal_eОценок пока нет

- Community Development ProgramsДокумент2 страницыCommunity Development ProgramsAnonymous iScW9lОценок пока нет

- 02 - Project Scope ManagementДокумент51 страница02 - Project Scope Managementabdallah391Оценок пока нет

- Cold Milling SpecificationДокумент3 страницыCold Milling SpecificationSunil BoseОценок пока нет

- Role of consulting engineersДокумент2 страницыRole of consulting engineersSuvarnaОценок пока нет

- DC PT Contractors Role Responsibilities PTIA IEAust NewcastleДокумент30 страницDC PT Contractors Role Responsibilities PTIA IEAust NewcastleSree NivasОценок пока нет

- Palash Das: (PMP - Trained) Lead Planner/Senior Planning EngineerДокумент3 страницыPalash Das: (PMP - Trained) Lead Planner/Senior Planning EngineerPalash DasОценок пока нет

- Terminal 5 Update June 2019Документ10 страницTerminal 5 Update June 2019WestSeattleBlogОценок пока нет

- FTC Tech Design GuideДокумент383 страницыFTC Tech Design GuideSharon Lambert100% (1)

- Construction MethodsДокумент3 страницыConstruction MethodsIngeniero EstructuralОценок пока нет

- 1978 Effect of Sequence of Construction in Analysis of Multistoreyed Building - S.C.chakrabarti G. C. Nayak and S.K. AgarwalaДокумент6 страниц1978 Effect of Sequence of Construction in Analysis of Multistoreyed Building - S.C.chakrabarti G. C. Nayak and S.K. AgarwalaAnonymous UXWnUJqhОценок пока нет

- Construction Project Planning and ManagementДокумент32 страницыConstruction Project Planning and Managementሽታ ዓለሜ100% (1)

- Building Construction CAP 123B PDFДокумент28 страницBuilding Construction CAP 123B PDFJustin NgОценок пока нет

- 3 BConstruction Stormwater Erosion Control PlansДокумент4 страницы3 BConstruction Stormwater Erosion Control Plans许爱文Оценок пока нет

- Upgrade of Muldersdrift Sports Complex Project Charter 23.09.2014Документ14 страницUpgrade of Muldersdrift Sports Complex Project Charter 23.09.2014Michael BenhuraОценок пока нет

- KBrown Course Project Week 1Документ3 страницыKBrown Course Project Week 1Kyle BrownОценок пока нет

- Agenda For Contract Award MeetingДокумент3 страницыAgenda For Contract Award MeetingAbdelmuneimОценок пока нет

- Specification for Siphonic Rainwater Drainage SystemsДокумент5 страницSpecification for Siphonic Rainwater Drainage SystemsAsoka Kumarasiri JayawardanaОценок пока нет

- Concrete in High-Rise BuildingsДокумент6 страницConcrete in High-Rise BuildingsxeryhoneyОценок пока нет

- Emerging Technologies A Suggested Design Method For Curved Jacked Steel PipeДокумент11 страницEmerging Technologies A Suggested Design Method For Curved Jacked Steel PipefalokunОценок пока нет

- Interface Mangement: Formalize Contractor Collaboration To Mitigate Interface-Related Cost & Schedule RiskДокумент2 страницыInterface Mangement: Formalize Contractor Collaboration To Mitigate Interface-Related Cost & Schedule RiskJonathen Hormen100% (2)

- FIDIC Lecture - EOT & Related Costs in ConstructionДокумент39 страницFIDIC Lecture - EOT & Related Costs in Constructionsomapala88Оценок пока нет

- Independent Power Producers Face Risks Under New Power Purchase RegulationДокумент7 страницIndependent Power Producers Face Risks Under New Power Purchase RegulationtsuakОценок пока нет

- 2013 IPP Procedure PDFДокумент10 страниц2013 IPP Procedure PDFtsuakОценок пока нет

- 21 - 1 Concrete Lining PDFДокумент46 страниц21 - 1 Concrete Lining PDFtsuakОценок пока нет

- Construction Specification Cs-Ut-243, Concrete Canal LiningДокумент4 страницыConstruction Specification Cs-Ut-243, Concrete Canal LiningtsuakОценок пока нет

- An Update On New and Future Earthworks Standards in The UK and EuropeДокумент6 страницAn Update On New and Future Earthworks Standards in The UK and EuropetsuakОценок пока нет

- Study On Karai Mini-Hydro Power Project PDFДокумент280 страницStudy On Karai Mini-Hydro Power Project PDFtsuakОценок пока нет

- Indonesia PPP Book 2017 Provides Latest Infrastructure Project UpdatesДокумент112 страницIndonesia PPP Book 2017 Provides Latest Infrastructure Project UpdatesHilda IsfanoviОценок пока нет

- 2015 TCF SectorPropositions HydroEnergyДокумент36 страниц2015 TCF SectorPropositions HydroEnergytsuakОценок пока нет

- 2014 Jica - The Preparatory Survey On SHP Sulawesi SumateraДокумент56 страниц2014 Jica - The Preparatory Survey On SHP Sulawesi SumateratsuakОценок пока нет

- Construction Specification Cs-Ut-243, Concrete Canal LiningДокумент4 страницыConstruction Specification Cs-Ut-243, Concrete Canal LiningtsuakОценок пока нет

- Project Standards and Specifications Piping Systems Rev01Документ20 страницProject Standards and Specifications Piping Systems Rev01viktor_gligorovОценок пока нет

- Designstandards3 PDFДокумент254 страницыDesignstandards3 PDFErik GelvezОценок пока нет

- Construction Specification 52-Steel Pipe: 1. ScopeДокумент6 страницConstruction Specification 52-Steel Pipe: 1. ScopetsuakОценок пока нет

- Geo Tech Term SymbolsДокумент8 страницGeo Tech Term SymbolsMark Gerald Prades RegalaОценок пока нет

- FEM in Geotech EngineeringДокумент21 страницаFEM in Geotech Engineeringtsuak100% (1)

- Geotechnical Assesment For Weir Foundation RMRДокумент4 страницыGeotechnical Assesment For Weir Foundation RMRtsuakОценок пока нет

- RanceforContracted Power Generation Agrmts Final 2012-c1Документ42 страницыRanceforContracted Power Generation Agrmts Final 2012-c1tsuakОценок пока нет

- CEA Manual-TD PlanningДокумент50 страницCEA Manual-TD PlanningSaravanan Elumalai0% (1)

- MANUAL ON CONSTRUCTION, TESTING, COMMISSIONING AND MAINTENANCE OF TRANSMISSION PROJECTSДокумент381 страницаMANUAL ON CONSTRUCTION, TESTING, COMMISSIONING AND MAINTENANCE OF TRANSMISSION PROJECTSKrish Arumuru100% (1)

- Gravity Retaining Walls Subject To Seismic LoadingДокумент64 страницыGravity Retaining Walls Subject To Seismic Loadingbennorth84Оценок пока нет

- Manual For Transmission Lines and SubstationДокумент77 страницManual For Transmission Lines and Substationnancypapa625100% (1)

- Colorado Small Hydropower GuideДокумент100 страницColorado Small Hydropower GuidevthiseasОценок пока нет

- Sample Project 2016 Foundation ManualДокумент102 страницыSample Project 2016 Foundation ManualJOSE OSCAR ZAMBRANO CANCHALAОценок пока нет

- Cavitation ReviewДокумент8 страницCavitation ReviewtsuakОценок пока нет

- HydДокумент502 страницыHydtsuakОценок пока нет

- AppendixH ITPДокумент17 страницAppendixH ITPtsuakОценок пока нет

- Medtech OriginalДокумент12 страницMedtech OriginaltsuakОценок пока нет

- Ubc - 1968 - A7 W45Документ59 страницUbc - 1968 - A7 W45tsuakОценок пока нет

- 2 - 1 - Civil Works - Guidelines For Layout of Small Hydro PlantsДокумент24 страницы2 - 1 - Civil Works - Guidelines For Layout of Small Hydro PlantsjmiguelmenaОценок пока нет

- Air Pak SCBA Ordering Specifications (HS 6701)Документ8 страницAir Pak SCBA Ordering Specifications (HS 6701)QHSE ManagerОценок пока нет

- OceanPixel Abundo Marine Renewable Energy An Emerging OptionДокумент96 страницOceanPixel Abundo Marine Renewable Energy An Emerging OptionjopaypagasОценок пока нет

- Aesculap: F E S SДокумент28 страницAesculap: F E S SEcole AcharafОценок пока нет

- Write Like An Academic: Designing An Online Advanced Writing Course For Postgraduate Students and ResearchersДокумент9 страницWrite Like An Academic: Designing An Online Advanced Writing Course For Postgraduate Students and ResearchersLexi TronicsОценок пока нет

- Method of MomentsДокумент114 страницMethod of MomentsankladhaОценок пока нет

- Rob Thomas Digital Booklet - Cradle SongДокумент15 страницRob Thomas Digital Booklet - Cradle SongAgnieszka ŁukowskaОценок пока нет

- SANY SSR180C 8 OM EN PreviewДокумент31 страницаSANY SSR180C 8 OM EN Previewzaploc.admОценок пока нет

- Tutorial Ip 2 Win EnglishДокумент25 страницTutorial Ip 2 Win EnglishGarry Zein0% (1)

- InductorsДокумент13 страницInductorsManish AnandОценок пока нет

- XHB CommFuncДокумент10 страницXHB CommFuncPalatОценок пока нет

- Applying The Haar Wavelet Transform To Time Series InformationДокумент27 страницApplying The Haar Wavelet Transform To Time Series InformationJohn LemonОценок пока нет

- Auto Temp II Heat Pump: Programmable Thermostat For Single and Multistage Heat Pump SystemsДокумент22 страницыAuto Temp II Heat Pump: Programmable Thermostat For Single and Multistage Heat Pump Systemswideband76Оценок пока нет

- SE01 SE04 SE03 SE02 E14 E13: As BuiltДокумент1 страницаSE01 SE04 SE03 SE02 E14 E13: As BuiltgenricОценок пока нет

- Designing The Marketing Channels 13Документ13 страницDesigning The Marketing Channels 13Gajender SinghОценок пока нет

- Advanced Excel FormulasДокумент25 страницAdvanced Excel Formulasskmohit singhalОценок пока нет

- RCE Unpacking Ebook (Translated by LithiumLi) - UnprotectedДокумент2 342 страницыRCE Unpacking Ebook (Translated by LithiumLi) - Unprotecteddryten7507Оценок пока нет

- Sanju MT 799 PT Swi 100kДокумент2 страницыSanju MT 799 PT Swi 100kSumantri On LineОценок пока нет

- UCID Number Request FormДокумент1 страницаUCID Number Request FormOmar AwaleОценок пока нет

- TN 46Документ23 страницыTN 46Khalil AhmadОценок пока нет

- BSC Prospectus 2019-20Документ37 страницBSC Prospectus 2019-20Gaurav VamjaОценок пока нет

- Mechanical Engineer Resume - Digambar BhangeДокумент3 страницыMechanical Engineer Resume - Digambar BhangeTOP DHAMAKAОценок пока нет

- Gsxp07er Opera1tion Manual PDFДокумент94 страницыGsxp07er Opera1tion Manual PDFMohamed SaadAllahОценок пока нет

- Advances in Remediation-eBookДокумент88 страницAdvances in Remediation-eBookalinerlfОценок пока нет

- Basicline BL 21t9stДокумент28 страницBasicline BL 21t9stgabriel6276Оценок пока нет

- Excel Dashboard WidgetsДокумент47 страницExcel Dashboard WidgetskhincowОценок пока нет

- Geometric Design of Highways for EngineersДокумент39 страницGeometric Design of Highways for EngineersZeleke TaimuОценок пока нет

- LTE Advanced - Leading in Chipsets and Evolution: August 2013Документ33 страницыLTE Advanced - Leading in Chipsets and Evolution: August 2013Muneeb JavedОценок пока нет

- Tech Rider For ShaanДокумент7 страницTech Rider For ShaanSagar Shirole100% (1)

- GPT 1-15 LineBackerДокумент4 страницыGPT 1-15 LineBackerazadeazОценок пока нет

- Needle System Guide For Old Industrial Singer Sewing MachinesДокумент4 страницыNeedle System Guide For Old Industrial Singer Sewing MachinesWilberth FrancoОценок пока нет