Академический Документы

Профессиональный Документы

Культура Документы

Techniques in EPC Projects

Загружено:

Santiago PE0 оценок0% нашли этот документ полезным (0 голосов)

195 просмотров11 страницProject management can become the make-it-or-break-it factor for engineering ventures, experts agree. A well managed EPC project in oil and gas industry results in higher efficiency and better productivity. Today managing projects in short periods within tight budgets has become the focus.

Исходное описание:

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документProject management can become the make-it-or-break-it factor for engineering ventures, experts agree. A well managed EPC project in oil and gas industry results in higher efficiency and better productivity. Today managing projects in short periods within tight budgets has become the focus.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

195 просмотров11 страницTechniques in EPC Projects

Загружено:

Santiago PEProject management can become the make-it-or-break-it factor for engineering ventures, experts agree. A well managed EPC project in oil and gas industry results in higher efficiency and better productivity. Today managing projects in short periods within tight budgets has become the focus.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 11

Seite 1 / 11

Efficient Project Management

How to Apply Project Management

Techniques in EPC Projects

06/05/2014 | Autor / Editor: Deepak Makhijani / Dominik Stephan

Project management can become the

makeitorbreakitfactor for

engineering ventures, experts agree.

While tight schedules and limited

budgets put pressure on all EPC

ventures, adapting the right strategy

can help to make your project a

success.

The word Project can be used to

describe an endeavor in which a number

of tasks is performed to accomplish a

particular aim. Projects are usually

undertaken to achieve business

objectives such as engineering,

mechanical/construction services or

research for new product development.

This article talks about Engineering, Procurement and Construction (EPC) Projects in

India and how the organizations are executing these projects using modern techniques

and effective management.

Today managing projects in short periods within tight budgets has become the focus.

Managing a project is quite different from managing a steady state organization: While

projects have a distinct life cycle a beginning and an end a steady state

organization runs continuously. Effective project management therefore requires a clear

concept and an efficient project group within the organization. Most important are

compatibility in interpersonal relations and clarity in mutual understanding and

communication. All involved individuals must clearly know their responsibilities and

what is expected from them. When seamlessly integrated, the collective expertise,

experience and working systems can vastly add to the efficiency.

Transform you Needs into an Actual Project

Transforming the business needs into a physical set requires the effectiveness of a

A well managed EPC project in oil and gas

industry results in higher efficiency and better

productivity. (Picture: Honeywell Process

Solutions)

Seite 2 / 11

series of processes, tools and techniques, and most of all, skills and experience.

Together, these culminate into what is called World Class Project Management

(WCPM). This requirement starts with the early identification of opportunities and

business drivers and evolves into planning and execution. The first step in the process

is to define the situation and determine the desired outcome. Once the situation is

defined, the team leader sets the roles and responsibilities of all involved. Each team

member has an established role and is held accountable for execution, while following

rules and regulations. This takes much of the guesswork out of executing the plan and

establishes efficient and effective method to manage a project regardless of the time

constraints.

GALLERY

Select a picture to open the gallery (4 Pictures)

3D Modelling and Visualization in Project Management

The detailed engineering of the project requires cutting-edge plant simulation and

design systems. Typical 3D model software such as Plant Design Management System

(PDMS) help to design the plant taking into account the bill of material of the

components and orientation of the equipment to prevent fouling or inadequacy of

space. A typical 3D model is shown in figure 1. This reduces cost of re-engineering and

modification costs as the orientation of the equipment in the available plot area can be

visualized online and remedial action can be taken at the time of equipment fabrication.

The relentless push to expand oil and petrochemical plants places even greater

demands on the design and construction of larger, more complex refineries and

facilities worldwide. The importance of bringing new liquefaction plants and crude

crackers online becomes a major challenge to both plant owners and engineering

companies. The latest 3D modeling and visualization applications continue to support

all key aspects of oil and gas projects, from concepts through detailed design and

Seite 3 / 11

construction, into plant operation and maintenance.

How to Use of Integrated IT Systems

Today, one cannot think of project management without using information technology

(IT). The advent of the internet in the 1990s has helped to change the role of IT from a

sole tool for scheduling applications to create project plans for sub-projects and

disciplines, enabling macrolevel planning. Typical software solutions help to save a

copy of the original plan, as well as all later adjustments.

The mistakes committed during a project should be a lesson to learn: Certain type of

software enables a detailed project analysis, providing the ability to forecast trends,

isolate problems and show estimated costs and time for completion. Taking into

account the tough global competition, IT is no longer a luxury but a necessity. It is

possible to measure the ROI in IT, though it may not be as definitive since intangible

capability upgradation and knowledge utilization benefits are involved.

Knowledge Management: Top Trend for Project Engineers

Today, as there is a critical need of knowledge management and information storage,

the design software can directly tunnel into the SAP R/3 transaction system to enable

data storage and retrieval. There is a need to integrate information to generate life cycle

databases for ready reference of all working disciplines to achieve efficiency in all

environments. In absence of readymade solutions to fit their requirement, some EPC

companies such as L&T have invested around US$ 0,87 million per year in the IT.

In large projects, there is a need to design and engineer thousands of items followed by

their procurement from hundreds of suppliers scattered globally. This provides a huge

potential for eprocurement: Most of the EPC companies have launched a web initiative

that enables vendors/suppliers to register their products and services online. On

requirement, the companies could establish contact with the registered vendors and

take offers for their projects. This reduces the cost of floating the enquiry, follow up and

facilitates the EPC companies to have a choice of variety of suppliers/vendors for their

requirements.

The use of technology has enabled suppliers to invoice for products offered online and

payments for the same to be directed to their respective accounts online. This reduces

the paperwork and the processing time for payment significantly and increases the

bond/relationship between the customers and suppliers.

Choosing the Right Software

The different software packages offer varying capabilities and flexibility. However, one

should keep in mind that the latest software will not guarantee success. Instead,

software decisions should be driven by the scope of the indented use, determined by

Seite 4 / 11

the needs or requirements that must be served to satisfy the objective. Microsoft.Net

technology enables unprecedented levels of software integration through use of

extensible language (XML) web services small, discrete building blocks that connect

to each other as well as larger applications through the use of Internet. On the other

hand, Microsoft Project/Primavera Enterprise helps one to manage schedules, resource

project status and project information report. It provides organizations with an

extensible technology platform to securely develop and successfully deploy best

practices for project management across the organization.

The Right Framework to Boost for Industry Projects

Government initiatives to bring in competition and put an end to monopoly would

provide more opportunities for the EPC players. Bandwidth and infrastructure are two

other significant areas which require individual focus in order to further enhance the role

of new technologies. Over the coming years, investment in IT is going to grow three fold

(e-commerce, e-procurement and other such technologies). It is therefore left to the

decision makers to make proper investment in the right software and make the most of

talent as well as the tool (software).

3D modeling helps companies by using latest design codes and standards to prevent

substandard regulatory violations as well as costly and potentially dangerous system

failures. 3D modeling offers a solution to create as quickly as possible from existing

designs or licensors. The solution is rule based and relationship driven to promote

design consistency through the complete process. Of course, integration is a key

element in passing the data in a controlled manner between the engineering tasks,

such as instrument and electrical design as well as physical 3D modeling. Safety,

integrity management, regulatory compliance, time to market, operational uptime all

of these are factors for which the oil and gas market depends on quality information. 3D

modeling offers the longest track record in the industry for delivering integrated

engineering information throughout an assets life cycle.

The my SAP project systems combine industry experience and expertise to provide

number of key capabilities such as managing projects and products throughout their

lifecycles. The my SAP project module is capable of conceptual design/engineering,

product/project estimating, integration with CAD/CAM/CAE and GIS systems and

collaborative planning and engineering that makes it possible to have a single platform

for managing the entire project cycle.

Manage the Supply Chain

The system helps companies to form a supply chain of collaborators and partners to

plan and forecast demand and supply, direct procurement, manufacturing, outsourcing,

order fulfillment and subcontractor performance. These partners share their

inventory/stock and track the status of the orders on a common database of the SAP

Seite 5 / 11

module. The computer can perform all calculations and create planned order releases

and update inventory positions. However, the computers role is only suggestive in

nature; it does not issue purchase or manufacturing orders or reschedule open orders.

SAP is easier to implement in cluster business organization such as engineering and

construction, as the experience with similar companies enables the availability of

proven rapid implementation methods and solution based approaches.

This means the company can be up and running quickly and cost effectively with a

solution that meets the clients specific needs. Larsen & Toubro of India has been

experiencing new challenges ever since the economic liberalization and opening of the

global markets. In order to compete effectively in this scenario, the company felt the

need for computerized management control systems that could be uniformly

implemented across the enterprise. In order to maximize returns of investment, improve

business intelligence and form a value chain of business partners enabling faster

communication and high end integration, the company selected SAP as strategic

partner for implementing the systems.

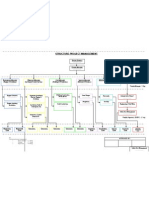

Figure 2 shows the business model of project information systems using SAP project

systems in the organization: The company was linked to its customer and contractor via

Internet server link. A common database was updated with information from the

relevant source, like the project status or site progress details. The Internet link enabled

online updating of project information and seamless integration of the information

availability, enabling prompt action on critical activities.

The my SAP supply chain management is a supply chain solution that provides the

tools to implement the above philosophy to real business value, by dramatically

improving the ability to plan, respond and execute. My SAP SCM enables the

organization to adapt to the inevitable exceptions that occur in the race to meet the

market demands.

Modular Design & Construction

Today, global players and technological advancements have significantly changed the

way in which projects are being implemented. These include use of 3D design software,

extensive use of enterprise resource planning systems, e-commerce and

advancements in information technology. The harnessing of these techniques has

given rise to innovative approaches like modularization.

EPC contractors are increasingly resorting to the advantages of modularization where

applicable, especially in terms of feasibility and required capabilities. Modularization is a

design, fabrication and construction technique of breaking up a plant into sub-sections

(called modules) and fabricating these modules at a remote location. As these modules

come with all equipment, piping, structurals, electrical, insulation, painting, etc. they can

Seite 6 / 11

be readily assembled along with adjacent modules at the installation site. Modular

plants are particularly well suited for remote and difficult site locations.

Modular fabrication requires minimal site work and lesser mobilization of labor at site in

terms of duration. Further, foundation requirements are also simplified and module

erection at site requires minimum space, minizing the effefect of harsh site conditions

such as heavy rains, freezing cold or scorching heat.

Since modular fabrication is carried in controlled shop environment, labor productivity is

high. It is possible to maintain very high standards of quality and safety at the shop floor

compared to project site. It allows for very low tolerances for ensuring smooth

interaction during erection at site. Ensuring minimal disruptions to the operating plant is

of paramount importance. Construction at site is often governed by restrictions imposed

due to safety regulations in operating plants. Modular construction lowers the need for

hot work permits and planned shutdowns of existing operations. Module fabrication can

commence at the fabricators shop even before regulatory or environment approvals

are obtained for clients work site. The time saving bonus with modular approach

provides for greater scope for concurrent engineering due to higher extent of

standardization. It is possible to utilize existing module layouts, P&I diagrams, 3D-

Models, etc. for new facilities that result in shorter schedules.

Reduction in Capital Costs

Modularization offers reduced capital costs, depending on the project size, location and

scope. The total number of man hours is reduced on account of better productivity,

lesser supervision requirement and efficient material handling. Further, delays on

account of labor relations issues often encountered at site are also minimized.

Modular plants are more amenable to retrofitting and revamp. As the modules are

readily movable, the complete plant can be moved to a new location. Thus, the project

management of EPC projects requires a broad understanding and planning, use of

technology, modularization of the packages and above all, effective management of the

resources to provide a best fit for the project needs. It is only with seamless integration

of effective management along with the use of technology, that projects can be

executed in a faster track domain.

* Courteously of PROCESS India

Copyright 2014 - Vogel Business Media

Seite 7 / 11

Dieser Beitrag ist urheberrechtlich geschtzt.

Sie wollen ihn fr Ihre Zwecke verwenden?

Infos finden Sie unter www.mycontentfactory.de.

Dieses PDF wurde Ihnen bereitgestellt von http://www.bulk-solids-handling.com

FIG 1: Project management schedule (Picture: Deepak Makhijani)

Seite 8 / 11

FIG 2: Project information systems implemented using SAP project systems (Picture: Deepak Makhijani)

Seite 9 / 11

A well managed EPC project in oil and gas industry results in higher efficiency and better productivity.

(Picture: Honeywell Process Solutions)

Seite 10 / 11

A well managed EPC project in oil and gas industry results in higher efficiency and better productivity.

(Picture: Honeywell Process Solutions)

Seite 11 / 11

Fig. 2: Enterprise-wide project management through extranet from anywhere and at any time linking

company, customer and contractor (Picture: Deepak Makhijani)

Вам также может понравиться

- Florida Motor Fuel Tax Relief Act of 2022Документ9 страницFlorida Motor Fuel Tax Relief Act of 2022ABC Action NewsОценок пока нет

- Piping Erection Estimating NormsДокумент60 страницPiping Erection Estimating NormsmehdiОценок пока нет

- EPC Project Management PDFДокумент28 страницEPC Project Management PDFRuna Jully100% (1)

- Detailed Process of Project Execution & Progress Measurement and TrackingДокумент22 страницыDetailed Process of Project Execution & Progress Measurement and Trackingzhangj5100% (1)

- EPC Job DescriptionsДокумент31 страницаEPC Job Descriptionsacalerom3625Оценок пока нет

- EPC 4.0 - Engineering Procurement ConstructionДокумент38 страницEPC 4.0 - Engineering Procurement ConstructionManoj Kumar Singh50% (2)

- EPC Projects BasicsДокумент2 страницыEPC Projects Basicsmahmood75080% (5)

- Air SysДокумент11 страницAir Syspbhat83Оценок пока нет

- Projects Control FEEDДокумент12 страницProjects Control FEEDRic S. MalongaОценок пока нет

- EPC Schedule Levels ExplanationДокумент1 страницаEPC Schedule Levels ExplanationJoe_Average0% (1)

- Managing Risk in EPC ContractsДокумент20 страницManaging Risk in EPC ContractspoundingОценок пока нет

- EPC Structure Project ManagementДокумент1 страницаEPC Structure Project ManagementArif Rachman100% (3)

- How To Get Costing of Labor?: Preparing Detailed EstimateДокумент21 страницаHow To Get Costing of Labor?: Preparing Detailed Estimatecass0608Оценок пока нет

- Cost Premise - 2011Документ17 страницCost Premise - 2011Olusegun OyebanjiОценок пока нет

- PT Borneo Mitra Sinergi: Project Close Out PlanДокумент4 страницыPT Borneo Mitra Sinergi: Project Close Out PlanaswarОценок пока нет

- EPC PlantsДокумент12 страницEPC PlantsLuis Fernando Gonzales MedinaОценок пока нет

- SAEP-14 Project ProposalДокумент53 страницыSAEP-14 Project ProposalRaad AbwiniОценок пока нет

- EPC Hyundai Project Structure - Fertilizer PlanДокумент51 страницаEPC Hyundai Project Structure - Fertilizer PlanZairus Fadzli Dzulkifli100% (4)

- FEED or No FEEDДокумент15 страницFEED or No FEEDjohndagheОценок пока нет

- Design of Steel Free StackДокумент37 страницDesign of Steel Free StackSantiago PEОценок пока нет

- EPC PracticeДокумент4 страницыEPC PracticeSaid Ahmed SalemОценок пока нет

- EPC V EPCM TableДокумент8 страницEPC V EPCM TableChris Eggleton100% (1)

- Engineering Procurement and ConstructionДокумент84 страницыEngineering Procurement and ConstructionAayushi Arora75% (4)

- Dokumen - Tips - Epcprojectinterdepency and Work Flow 1pdfДокумент103 страницыDokumen - Tips - Epcprojectinterdepency and Work Flow 1pdfAhmed AggourОценок пока нет

- Best Practice Project Definition Rating Index PDFДокумент49 страницBest Practice Project Definition Rating Index PDFAryan Khairmem KhanОценок пока нет

- Fluent 14.5 TutorialДокумент1 146 страницFluent 14.5 TutorialBruno Morabito100% (2)

- Oil & Gas Project Phases Instrumentation Civil Electrical Mechanical ProcessДокумент1 страницаOil & Gas Project Phases Instrumentation Civil Electrical Mechanical ProcessfloredaОценок пока нет

- Aspen Plus User ModelsДокумент339 страницAspen Plus User Modelskiny81100% (1)

- Research FEED, EPC and Engineering Contract in Oil, Gas and Petrochemicals - July 2013 Contract AwardsДокумент2 страницыResearch FEED, EPC and Engineering Contract in Oil, Gas and Petrochemicals - July 2013 Contract AwardsSarwarzadEnergyPRОценок пока нет

- Eng Ineering Definit Ion Project EngineeringДокумент18 страницEng Ineering Definit Ion Project EngineeringLeman IbishovaОценок пока нет

- How To Prepare Planning Deliverables For LNG Project?: Sapto Hari WibowoДокумент17 страницHow To Prepare Planning Deliverables For LNG Project?: Sapto Hari WibowoSalman Syafar RamzyОценок пока нет

- EPC4A HUC Estimating Methodology Rev 0Документ21 страницаEPC4A HUC Estimating Methodology Rev 0Amine DabbabiОценок пока нет

- Ways To Improve Bid and FEED Phases of Capital ProjectsДокумент13 страницWays To Improve Bid and FEED Phases of Capital Projectsdinu69inОценок пока нет

- Cost EstimationДокумент29 страницCost Estimationgeorgiadisg100% (4)

- Pursuit of Performance Findings From The 2014 Miller Heiman Sales Best Practices StudyДокумент37 страницPursuit of Performance Findings From The 2014 Miller Heiman Sales Best Practices StudyLoredanaОценок пока нет

- 4th Annual Global EPC Project Management Summit September 2017.Документ6 страниц4th Annual Global EPC Project Management Summit September 2017.radiciptaОценок пока нет

- 03 Epc Contract ManagementДокумент37 страниц03 Epc Contract Managementzhangj5100% (4)

- Epc PresentationДокумент41 страницаEpc PresentationJayadevDamodaran100% (3)

- FeedДокумент4 страницыFeedHafsa JalalОценок пока нет

- EPC ProcessesДокумент37 страницEPC ProcessesSagar Garg100% (3)

- Best Practices in Delivery of EPC ProjectsДокумент13 страницBest Practices in Delivery of EPC ProjectsDaniel WismanОценок пока нет

- Introduction To EPC ContractДокумент4 страницыIntroduction To EPC ContractEslam AshourОценок пока нет

- 01 - Developing A Contracting StrategyДокумент67 страниц01 - Developing A Contracting Strategyali deveboynuОценок пока нет

- Concept Definition (Pre-FEED)Документ3 страницыConcept Definition (Pre-FEED)icq4joyОценок пока нет

- Epc Contracts Process Plant SectorДокумент30 страницEpc Contracts Process Plant Sectorlimpama100% (2)

- Il Processo EPCДокумент103 страницыIl Processo EPCAtha APОценок пока нет

- Appropriate Contracting Strategy For Fast TrackДокумент7 страницAppropriate Contracting Strategy For Fast TrackAsebaho BadrОценок пока нет

- E-Book - Journeymap To Project Risk AnalysisДокумент19 страницE-Book - Journeymap To Project Risk Analysisjorge pla100% (2)

- 3 - Stephen - Mulva-Project Definition Rating IndexДокумент27 страниц3 - Stephen - Mulva-Project Definition Rating Indexinitiative1972100% (1)

- EPC & EPCM Definition and ComparisonДокумент4 страницыEPC & EPCM Definition and Comparisonconstp1Оценок пока нет

- Conveying Bends Article Paul SoltДокумент8 страницConveying Bends Article Paul SoltJoel Olson100% (1)

- Phase DiagramДокумент3 страницыPhase DiagramTing TCОценок пока нет

- EPC AnalysisДокумент46 страницEPC AnalysisVinaya NayakОценок пока нет

- The Role of Needs Analysis in Adult ESL Programme Design: Geoffrey BrindleyДокумент16 страницThe Role of Needs Analysis in Adult ESL Programme Design: Geoffrey Brindleydeise krieser100% (2)

- Tourism PlanningДокумент36 страницTourism PlanningAvegael Tonido Rotugal100% (1)

- Bases Feed Epc Parte 2vi LibreДокумент404 страницыBases Feed Epc Parte 2vi LibreJavier100% (1)

- A Guide Line To Perform: EPC Project Contract Cost EstimationДокумент60 страницA Guide Line To Perform: EPC Project Contract Cost EstimationieltsabadanОценок пока нет

- Introduction and EPC Business Don McKenzie - Janaka RuwanpuraДокумент39 страницIntroduction and EPC Business Don McKenzie - Janaka RuwanpuraRehana MalikОценок пока нет

- Fidic - Condictions of Contract For Epc-Turnkey ProjectsДокумент49 страницFidic - Condictions of Contract For Epc-Turnkey Projectssharon gradosОценок пока нет

- White Paper PDRIДокумент10 страницWhite Paper PDRIhumberto zuletaОценок пока нет

- Road Map Update for Carbon Capture, Utilization, and Storage Demonstration and Deployment in the People’s Republic of ChinaОт EverandRoad Map Update for Carbon Capture, Utilization, and Storage Demonstration and Deployment in the People’s Republic of ChinaОценок пока нет

- Overview of Construction Industry and Project PlanningДокумент50 страницOverview of Construction Industry and Project PlanningNilesh GadgeОценок пока нет

- EPC - EPC Contract - EPC Companies - EPC Engineering - Ador Welding LTDДокумент4 страницыEPC - EPC Contract - EPC Companies - EPC Engineering - Ador Welding LTDchinmayОценок пока нет

- Ramel Ornales Construction SuperintendentДокумент6 страницRamel Ornales Construction SuperintendentIndustrial WeldersОценок пока нет

- EPC ScheduleДокумент81 страницаEPC ScheduleSatyajit MondalОценок пока нет

- PQ Doc For Ammonia - Urea II Project Final (2 Indonesia's Petrokimia Gresik,.Документ29 страницPQ Doc For Ammonia - Urea II Project Final (2 Indonesia's Petrokimia Gresik,.George Van BommelОценок пока нет

- Catalogue Engineering ENG-exДокумент16 страницCatalogue Engineering ENG-exMus ChrifiОценок пока нет

- Powercore Filter Packs - CP SeriesДокумент2 страницыPowercore Filter Packs - CP SeriesSantiago PEОценок пока нет

- CampanaДокумент1 страницаCampanaSantiago PEОценок пока нет

- ToritBinVentProductManual r2Документ5 страницToritBinVentProductManual r2Santiago PEОценок пока нет

- FT BaghouseДокумент4 страницыFT BaghouseSantiago PEОценок пока нет

- Solar EnergyДокумент36 страницSolar EnergySantiago PEОценок пока нет

- Iom 7541701 Modular Baghouse MBTДокумент44 страницыIom 7541701 Modular Baghouse MBTSantiago PEОценок пока нет

- m3156 Series P NeunaticosДокумент30 страницm3156 Series P NeunaticosSantiago PEОценок пока нет

- Bin VentДокумент2 страницыBin VentSantiago PEОценок пока нет

- Materialhandlingsolutions Grainindustry 08.13 WebДокумент4 страницыMaterialhandlingsolutions Grainindustry 08.13 WebSantiago PEОценок пока нет

- Maintaining Discharge Devices - Staskiewicz - WebДокумент2 страницыMaintaining Discharge Devices - Staskiewicz - WebSantiago PEОценок пока нет

- Tetratex PTFE Membrane: Filter Bag Media For Torit Baghouse Dust CollectorsДокумент2 страницыTetratex PTFE Membrane: Filter Bag Media For Torit Baghouse Dust CollectorsSantiago PEОценок пока нет

- Minerals DonaldsonДокумент4 страницыMinerals DonaldsonSantiago PEОценок пока нет

- Tetratex PTFE Membrane: Filter Bag Media For Torit Baghouse Dust CollectorsДокумент2 страницыTetratex PTFE Membrane: Filter Bag Media For Torit Baghouse Dust CollectorsSantiago PEОценок пока нет

- Designed To Exceed Your Expectations: Gas Turbine SystemsДокумент4 страницыDesigned To Exceed Your Expectations: Gas Turbine SystemsSantiago PEОценок пока нет

- Dal Am A TicДокумент12 страницDal Am A TicMiguelAngelDavilaОценок пока нет

- FT BaghouseДокумент4 страницыFT BaghouseSantiago PEОценок пока нет

- Louvers Selection Design Considerations and DetailsДокумент8 страницLouvers Selection Design Considerations and Detailsamit2131923Оценок пока нет

- New York BlowerДокумент12 страницNew York BlowerSantiago PEОценок пока нет

- The Practical Resource For Cleaner, Safer, More Productive Dust & Material ControlДокумент575 страницThe Practical Resource For Cleaner, Safer, More Productive Dust & Material ControljgguiaОценок пока нет

- Dry Fog Dust SuppressionДокумент4 страницыDry Fog Dust SuppressionSantiago PEОценок пока нет

- ANSYS CFX Introduction 14.5Документ70 страницANSYS CFX Introduction 14.5gebrefikruОценок пока нет

- Secad - Disec 18-3-225 - 2nd - 11-05Документ8 страницSecad - Disec 18-3-225 - 2nd - 11-05Santiago PEОценок пока нет

- FILTROS 18-5-205 - 2nd - 8-06Документ8 страницFILTROS 18-5-205 - 2nd - 8-06Santiago PEОценок пока нет

- Abrasion Resistant Pipeline FittingsДокумент4 страницыAbrasion Resistant Pipeline FittingsSantiago PEОценок пока нет

- Xii - STD - Iit - B1 - QP (19-12-2022) - 221221 - 102558Документ13 страницXii - STD - Iit - B1 - QP (19-12-2022) - 221221 - 102558Stephen SatwikОценок пока нет

- Electric PotentialДокумент26 страницElectric PotentialGlitchОценок пока нет

- Num Sheet 1Документ1 страницаNum Sheet 1Abinash MohantyОценок пока нет

- Disney - QMДокумент14 страницDisney - QMSyarifuddin Zulkifli0% (1)

- Graduate Macro Theory II: The Real Business Cycle Model: Eric Sims University of Notre Dame Spring 2017Документ25 страницGraduate Macro Theory II: The Real Business Cycle Model: Eric Sims University of Notre Dame Spring 2017Joab Dan Valdivia CoriaОценок пока нет

- Riveted JointsДокумент28 страницRiveted Jointsgnbabuiitg0% (1)

- PLASSON UK July 2022 Price Catalogue v1Документ74 страницыPLASSON UK July 2022 Price Catalogue v1Jonathan Ninapaytan SanchezОценок пока нет

- Electromechani Cal System: Chapter 2: Motor Control ComponentsДокумент35 страницElectromechani Cal System: Chapter 2: Motor Control ComponentsReynalene PanaliganОценок пока нет

- AE HM6L-72 Series 430W-450W: Half Large CellДокумент2 страницыAE HM6L-72 Series 430W-450W: Half Large CellTaso GegiaОценок пока нет

- Effect of IctДокумент10 страницEffect of IctRVID PhОценок пока нет

- DICKSON KT800/802/803/804/856: Getting StartedДокумент6 страницDICKSON KT800/802/803/804/856: Getting StartedkmpoulosОценок пока нет

- FmatterДокумент12 страницFmatterNabilAlshawish0% (2)

- Help SIMARIS Project 3.1 enДокумент61 страницаHelp SIMARIS Project 3.1 enVictor VignolaОценок пока нет

- BS 07533-3-1997Документ21 страницаBS 07533-3-1997Ali RayyaОценок пока нет

- Experion Legacy IO Link Module Parameter Reference Dictionary LIOM-300Документ404 страницыExperion Legacy IO Link Module Parameter Reference Dictionary LIOM-300BouazzaОценок пока нет

- Content Analysis of Studies On Cpec Coverage: A Comparative Study of Pakistani and Chinese NewspapersДокумент18 страницContent Analysis of Studies On Cpec Coverage: A Comparative Study of Pakistani and Chinese NewspapersfarhanОценок пока нет

- Logarithms Functions: Background Information Subject: Grade Band: DurationДокумент16 страницLogarithms Functions: Background Information Subject: Grade Band: DurationJamaica PondaraОценок пока нет

- Gauss' Law: F A FAДокумент14 страницGauss' Law: F A FAValentina DuarteОценок пока нет

- A12 CanSat Technlology Forclimate Monitoring PDFДокумент10 страницA12 CanSat Technlology Forclimate Monitoring PDFDany PABON VILLAMIZARОценок пока нет

- Classroom Debate Rubric Criteria 5 Points 4 Points 3 Points 2 Points 1 Point Total PointsДокумент1 страницаClassroom Debate Rubric Criteria 5 Points 4 Points 3 Points 2 Points 1 Point Total PointsKael PenalesОценок пока нет

- TMS320C67x Reference GuideДокумент465 страницTMS320C67x Reference Guideclenx0% (1)

- Burn Tests On FibresДокумент2 страницыBurn Tests On Fibresapi-32133818100% (1)

- USB-to - Serial RS-232 Hub USB-to - Serial RS-422/485 Hub: UC2322/UC2324/UC4852/UC4854Документ1 страницаUSB-to - Serial RS-232 Hub USB-to - Serial RS-422/485 Hub: UC2322/UC2324/UC4852/UC4854sitrakiniavoОценок пока нет

- 2021 Bookmatter BasicSciencesOfNuclearMedicineДокумент12 страниц2021 Bookmatter BasicSciencesOfNuclearMedicineBeatriz MartinhoОценок пока нет