Академический Документы

Профессиональный Документы

Культура Документы

Pre - Functional Checklist Documentation 9

Загружено:

renjithv_40 оценок0% нашли этот документ полезным (0 голосов)

460 просмотров5 страницPre - Functional Checklist Documentation 9

Авторское право

© © All Rights Reserved

Доступные форматы

DOCX, PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документPre - Functional Checklist Documentation 9

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате DOCX, PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

460 просмотров5 страницPre - Functional Checklist Documentation 9

Загружено:

renjithv_4Pre - Functional Checklist Documentation 9

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате DOCX, PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 5

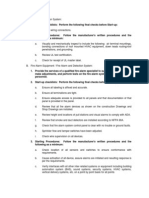

EXAMPLE - PREFUNCTIONAL CHECKLIST

Switchgear, Panelboards, Motor Control Centers, Transformers

Project: _____________________________________ Project #:_____________________

Identification of Equipment or System: _________________________________________

Location of Equipment or System: _______________________________________________

Specification Section: ____________________ Detail/Drawing Number: _______________

Manufacturer / Supplier: ________________________________________________________

This Date: __________________ Inspection Requested for (Date): __________________

Prefunctional Checklist Number: __________________

Components Included: ____Disconnects ____Fuses ____Meters ____Other

__________________________________________________

Associated Prefunctional Checklists: __________________ __________________

1. General:

a. The above systems and components integral to this equipment are complete and ready for

Functional Performance Tests. The Prefunctional Checklist items are complete and have

been checked off only by parties having direct knowledge of the event, as indicted below,

respective to each responsible contractor. This Prefunctional Checklist is submitted for

approval and is subject to the attached list of outstanding items not completed successfully.

Submit a Deficiency Form upon completion of any outstanding or deficient items. None of the

outstanding items preclude safe and reliable functional tests being performed.

b. ___ Deficiency Form attached.

c. This Prefunctional Checklist does not take the place of the manufacturers recommended

checkout and Start-up procedures or report.

d. Contractors assigned responsibility for sections of the Prefunctional Checklist shall be

responsible to ensure that their subcontractors complete and check off their Checklist items.

e. Prefunctional Checklist items shall be completed as part of Start-up and initial checkout,

preparatory to functional testing.

Contractor/Entity Company Abbreviation

MD Anderson Staff MD ANDERSON

Architect/Engineer A/E

General Contractor / Construction

Manager

GC

Mechanical Contractor MC

Electrical Contractor EC

Building Automation System

Provider

BAS

Test, Adjust, and Balance Firm TAB

Commissioning Consultant CA

2. Requested Documentation Submitted:

Specified Requirement Yes No Date to be

Submitted

a) Manufacturers Product Data including Performance Data and

Shop Drawings, as approved by Architect/Engineer

b) Required Test Reports and/or Certifications

c) Installation and Start-up Manual and Plan

d) Wiring Diagrams, Control Schematics and Sequences

e) Operating and Maintenance Manual Content for Applicable

System

f) Equipment Matrix

3. Equipment Verification:

Item Specified Submitted Installed

Manufacturer

Model Number

Serial Number

Service

Equipment Rating (amps)

Voltage/Phase

4. Installation Checks:

a) Unit and General Installation Yes No Comments

1. Permanent labels affixed

2. Physical condition acceptable, no visible damage, cabinets

in place

3. Properly mounted on equipment pad and anchored

4. Maintenance access acceptable

5. Interior clean and dry

6. Meter(s) installed per Contract Documents

7. Disconnects installed and labeled

8. Disconnects are pad lockable in open position

9. Circuit breakers installed and labeled

10. Fuses installed

a) Unit and General Installation Yes No Comments

11. Conduits installed and connected

12. Cable/conduit routing does not obstruct access

13. Equipment room properly ventilated, air-conditioned, heated,

fire/smoke wall separated, fire/smoke dampered, fire

sprinklered, fire alarmed and illuminated (normal, emergency

and battery backed-up fixtures)

14. As-built drawings updated

b) Switchgear (service entrance 1500kVA and above) and

Switchboards (service entrance less than 1500 kVA)

Yes No Comments

1. Free standing metal enclosure

2. Cobber buses

3. Penetration to utility service area and equipment per code

c) Distribution Panelboards and other Panelboards Yes No Comments

1. Tin plated copper buses

2. Each circuit identified and labeled

3. Space for additional circuits exist

d) Motor Control Centers Yes No Comments

1. Tin plated copper buses

2. Main breakers installed and labeled

3. Each circuit identified and labeled

e) Transformers Yes No Comments

1. Dry type installed

2. Unit properly labeled and identified

f) Electrical and Controls Yes No Comments

1. Panel devices labeled and wiring tagged per Contract

Documents

2. I/O devices labeled and wiring tagged per Contract

Documents

3. Digital inputs and outputs operational

4. All electrical connections tight

5. Proper grounding installed for the electrical system,

equipment, components, and unit

6. Safeties in place and operable

7. Sensors, transmitters, gages, etc., installed

8. Sensors calibrated (see below)

9. Control system interlocks hooked up and functional

10. All control devices and wiring complete

11. Lightning protection installed

f) Electrical and Controls Yes No Comments

12. Surge protection installed

g) Final Yes No Comments

1. Start-up report completed and attached with this

Prefunctional Checklist

2. Safeties and safe operating ranges for this equipment have

been reviewed and accepted

3. System is ready for Functional Performance Test

5. Operational Checks:

a. These checks supplement the manufacturers list. This is not the Functional Performance

Test.

Operational Checks Yes No Comments

1. Associated Prefunctional Checklists are complete and

accepted

2. Fuses are good

3. Resistance check(s) complete with results attached

4. Disconnect switch operates smoothly with full contact

5. Specified point-to-point checks have been completed and

documentation record submitted for this system

6. Sensor and/or Actuator Calibration:

a. All field-installed temperature sensors, pressure sensors, meters, and gages, and all

actuators and valves on this piece of equipment shall be calibrated. Sensors installed in the

unit at the factory with calibration certification provided are not required to be field calibrated.

b. All test instruments have had a certified calibration within the last 12-months: Y / N

c. Sensor/Actuator Verification Table

Sensor or Actuator Correct

Location

(Y/N)

(1)

Thermometer or

Gage Value

BAS Value

(2)

Instrument

Measured

Value (3)

Pass (Y/N)

1) Thermometer/Gage reading is the reading of the permanently mounted instrument on the

equipment.

2) BAS is the Building Automation System. Instrument = testing instrument.

3) All sensors are calibrated within required tolerances ___ YES ___ NO

FINAL SIGN-OFF

Contractors attest that the above items have been verified and meet the requirements of the

Contract Documents except as noted on the attached Deficiency form.

General Contractor: Print Name:

Signature:

Title:

Date:

Electrical Subcontractor Print Name:

Signature:

Title:

Date:

Other Subcontractor: Print Name:

Signature:

Title:

Date:

Prefunctional Checklist received and reviewed for completeness by MD ANDERSON

representatives. Functional Performance Test can proceed.

MD ANDERSON: Print Name:

Signature:

Title:

Date:

MD ANDERSON: Print Name:

Signature:

Title:

Date:

Вам также может понравиться

- Refrigeration Commissioning ProcedureДокумент12 страницRefrigeration Commissioning ProcedureLmaoОценок пока нет

- Doosan DBC130II Installation ManualДокумент122 страницыDoosan DBC130II Installation ManualDarryl Hardt100% (1)

- Air Cooled Chiller ChecklistДокумент3 страницыAir Cooled Chiller ChecklistDevendra DhumalОценок пока нет

- Cooling Tower Construction ChecklistДокумент6 страницCooling Tower Construction ChecklistGopinath GopiОценок пока нет

- Vesdsa System Method StatementДокумент39 страницVesdsa System Method StatementNideesh RobertОценок пока нет

- Testing & Commissioning Procedure for Ventilation and General Exhaust FansДокумент3 страницыTesting & Commissioning Procedure for Ventilation and General Exhaust FansDong VanraОценок пока нет

- Domestic Water and Hot Water Testing and Commissioning ChecklistsДокумент6 страницDomestic Water and Hot Water Testing and Commissioning ChecklistsIwan Tristiawan100% (1)

- Lighting Control System Testing & Commissioning ProcedureДокумент4 страницыLighting Control System Testing & Commissioning Procedurevin ss0% (1)

- Testing & Commissioning ExampleДокумент12 страницTesting & Commissioning Examplemikeo2Оценок пока нет

- Testing and Commissioning Procedure For Air-Conditioning, Refrigeration, VentilationДокумент247 страницTesting and Commissioning Procedure For Air-Conditioning, Refrigeration, VentilationPraveen KasrottaranОценок пока нет

- Method Statement For Testing & Commissioning of Fresh Air Handling Units FAHUs With Heat Recovery Wheel SystemДокумент4 страницыMethod Statement For Testing & Commissioning of Fresh Air Handling Units FAHUs With Heat Recovery Wheel Systemvin ssОценок пока нет

- Testing & Commissioning of Fan Coil Units FCU'sДокумент3 страницыTesting & Commissioning of Fan Coil Units FCU'svin ssОценок пока нет

- Method of Statement For Testing & Commissioning of Fire Alarm SystemДокумент4 страницыMethod of Statement For Testing & Commissioning of Fire Alarm Systemvin ssОценок пока нет

- Commissioning Test Procedure Overhead LinesДокумент10 страницCommissioning Test Procedure Overhead LineshusnikhalilОценок пока нет

- Commissioning Test Procedure Overhead LinesДокумент10 страницCommissioning Test Procedure Overhead LineshusnikhalilОценок пока нет

- SoftX3000 Technical Manual-System DescriptionДокумент115 страницSoftX3000 Technical Manual-System DescriptionSoma ArunОценок пока нет

- (SAPPHIRE NOW and SASUG Annual ConferenceДокумент321 страница(SAPPHIRE NOW and SASUG Annual ConferenceProj100% (1)

- PC - Packaged DX Air Conditioning or Heat Pump, IdДокумент7 страницPC - Packaged DX Air Conditioning or Heat Pump, Idsushilalway4uОценок пока нет

- Pre - Functional Checklist Documentation 10Документ4 страницыPre - Functional Checklist Documentation 10renjithv_4Оценок пока нет

- LAWA Basic Commissioning Forms - CompleteДокумент53 страницыLAWA Basic Commissioning Forms - Completemohammed_hatem0% (1)

- Testing & Commissioning of CCUДокумент2 страницыTesting & Commissioning of CCUamg007100% (1)

- Testing and Commissioning Split ACДокумент2 страницыTesting and Commissioning Split ACNuratiqah SharifahОценок пока нет

- AV SystemsCommissioningTestsChecklistДокумент17 страницAV SystemsCommissioningTestsChecklistKhaja Muqeem UddinОценок пока нет

- Method Statement For Testing & Commissioning of AHUДокумент4 страницыMethod Statement For Testing & Commissioning of AHUsamsul maarif100% (1)

- Method Statement For Precommissioning & Commissioning of Close Control Units CCU'sДокумент3 страницыMethod Statement For Precommissioning & Commissioning of Close Control Units CCU'svin ssОценок пока нет

- Air Handling Unit QC Checklist: AHU InformationДокумент5 страницAir Handling Unit QC Checklist: AHU InformationRaheel AhmedОценок пока нет

- Testing and Commissioning For Fire Alarm SystemДокумент2 страницыTesting and Commissioning For Fire Alarm SystemDong VanraОценок пока нет

- Testing and Commissioning Catering EquipmentДокумент27 страницTesting and Commissioning Catering EquipmentTrần ChâuОценок пока нет

- Testing and commissioning fire alarm systemsДокумент10 страницTesting and commissioning fire alarm systemsRobin Oidem CaniedoОценок пока нет

- Aerosol System Test ReportДокумент3 страницыAerosol System Test ReportMahmoud HassanОценок пока нет

- Fire Alarm Commissioning ChecklistДокумент2 страницыFire Alarm Commissioning ChecklistSavy PhanethОценок пока нет

- NT-Series UPS Installation and Commissioning Check ListДокумент20 страницNT-Series UPS Installation and Commissioning Check ListWalter AchayaОценок пока нет

- Pre - Functional Checklist Documentation 7Документ2 страницыPre - Functional Checklist Documentation 7renjithv_4Оценок пока нет

- Method of Statement For Conduit InstallationДокумент15 страницMethod of Statement For Conduit InstallationMohd MuksinОценок пока нет

- AHU ChecklistДокумент11 страницAHU ChecklistHeltonОценок пока нет

- MEPF-Testing and Commissioning ChecklistДокумент90 страницMEPF-Testing and Commissioning ChecklistADEN LIUОценок пока нет

- Learning Guid For Elecrical CommisioningДокумент9 страницLearning Guid For Elecrical CommisioningAbela DrrsОценок пока нет

- Testing & Commissioning Procedure For Staircase Pressurisation SystemДокумент3 страницыTesting & Commissioning Procedure For Staircase Pressurisation Systemvin ssОценок пока нет

- Method Statement For Precommissioning & Commissioning of Extract FansДокумент3 страницыMethod Statement For Precommissioning & Commissioning of Extract Fansvin ssОценок пока нет

- T&C Method StatementДокумент16 страницT&C Method StatementMohd Salleh Zainal79% (24)

- Safe Work Method Statement For Testing & Commissioning of DX Split UnitsДокумент5 страницSafe Work Method Statement For Testing & Commissioning of DX Split Unitsvin ssОценок пока нет

- Building Services Branch Testing and Commissioning ProcedureДокумент211 страницBuilding Services Branch Testing and Commissioning ProcedurePHYRAK100% (1)

- Plumbing Systems - CommissioningДокумент4 страницыPlumbing Systems - CommissioningLouie MirandaОценок пока нет

- Internal Approval of Method StatementsДокумент12 страницInternal Approval of Method Statementsmidhun muraliОценок пока нет

- Grundfos Chilled Water Pumps Testing & Commissioning Method StatementДокумент10 страницGrundfos Chilled Water Pumps Testing & Commissioning Method Statementshanu YahiyaОценок пока нет

- Testing & Commissioning of Fire Suppression SystemДокумент5 страницTesting & Commissioning of Fire Suppression Systemmyanmarfire100% (2)

- Visual and Technical Checking of I&C SystemsДокумент13 страницVisual and Technical Checking of I&C SystemszhangyiliОценок пока нет

- Air handling unit startup log templateДокумент4 страницыAir handling unit startup log templateAhmed SofaОценок пока нет

- Testing & Commissioning of Fan Coil Units FCU'sДокумент2 страницыTesting & Commissioning of Fan Coil Units FCU'sDong VanraОценок пока нет

- Testing & Commissioning of Split Air Conditioning AC UnitsДокумент3 страницыTesting & Commissioning of Split Air Conditioning AC Unitsvin ssОценок пока нет

- Hvac Testing Adjusting BalancingДокумент7 страницHvac Testing Adjusting Balancingarour.mokraneОценок пока нет

- T&C of Pressurization UnitДокумент6 страницT&C of Pressurization UnitMohamed YousufОценок пока нет

- FDAS Testing & Commissioning MethodologyДокумент5 страницFDAS Testing & Commissioning MethodologyDean Matthew GinsonОценок пока нет

- HVAC System: Exhaust FanДокумент4 страницыHVAC System: Exhaust FanAnsari1918Оценок пока нет

- AHU - Pre-Commissioning Checklist FormДокумент5 страницAHU - Pre-Commissioning Checklist FormMarvin ArinueloОценок пока нет

- MST Installation of Pressurization UnitДокумент10 страницMST Installation of Pressurization Unitvictor100% (1)

- Testing Commissioning of HVAC SystemДокумент53 страницыTesting Commissioning of HVAC SystemAnandu Ashokan100% (4)

- The Central Business District: New Administrative CapitalДокумент18 страницThe Central Business District: New Administrative CapitalAbanoub HakeemОценок пока нет

- Plumbing CommissioningДокумент5 страницPlumbing CommissioningZineddine ALICHEОценок пока нет

- 1.method of Statement - BMS - R0Документ2 страницы1.method of Statement - BMS - R0JaveedMdJaveedОценок пока нет

- Method Statement For Testing & Commissioning of Smoke Extract FansДокумент3 страницыMethod Statement For Testing & Commissioning of Smoke Extract Fansvin ssОценок пока нет

- Fire Alarm and Detection System ProcedureДокумент7 страницFire Alarm and Detection System ProcedureProjects aissol100% (1)

- Electrical ChecklistДокумент12 страницElectrical ChecklistAdhyartha KerafОценок пока нет

- Rmprtbiddoc PREFUNCTIONALCHECKLISTSДокумент37 страницRmprtbiddoc PREFUNCTIONALCHECKLISTSDani HambalinaОценок пока нет

- Check ListДокумент6 страницCheck Listiman2222Оценок пока нет

- Section 16900 Systems Integration: Summary - This Section IncludesДокумент6 страницSection 16900 Systems Integration: Summary - This Section Includesrenjithv_4Оценок пока нет

- New LV Cable ScheduleДокумент13 страницNew LV Cable Schedulerenjithv_4Оценок пока нет

- General Plant Cost EstimatingДокумент27 страницGeneral Plant Cost EstimatingAnand Gupta73% (11)

- Business Plan For The Small Construction FirmДокумент31 страницаBusiness Plan For The Small Construction FirmAlvie Borromeo Valiente100% (1)

- Self-Assessment Guide: ELCICS306-0510 1 Instrumentation and Control Servicing NC IIIДокумент2 страницыSelf-Assessment Guide: ELCICS306-0510 1 Instrumentation and Control Servicing NC IIIrenjithv_4Оценок пока нет

- Supplier's Documentation of EquipmentДокумент32 страницыSupplier's Documentation of Equipmentrenjithv_4Оценок пока нет

- 9556 - CM-707 - Supplement 5.6 - InstrumentationДокумент19 страниц9556 - CM-707 - Supplement 5.6 - Instrumentationrenjithv_4Оценок пока нет

- Process Industries Data Handover Procedure 1Документ2 страницыProcess Industries Data Handover Procedure 1renjithv_4Оценок пока нет

- Procurment Process Manual 1Документ1 страницаProcurment Process Manual 1renjithv_4Оценок пока нет

- Ball Valves vs Gate Valves: Which is Best for Your ApplicationДокумент4 страницыBall Valves vs Gate Valves: Which is Best for Your Applicationrenjithv_4Оценок пока нет

- 2 Pneumatic Systems Part 1 of 3Документ32 страницы2 Pneumatic Systems Part 1 of 3ashunitkОценок пока нет

- Understanding CalibrationДокумент1 страницаUnderstanding Calibrationrenjithv_4Оценок пока нет

- QA&QC - Installation of Field InstrumentationДокумент4 страницыQA&QC - Installation of Field InstrumentationMuhammadZahirKhan100% (1)

- Geothermal Pipe Line DesignДокумент15 страницGeothermal Pipe Line DesignjohnjuantamadОценок пока нет

- How To Conquer MountainДокумент11 страницHow To Conquer Mountainrenjithv_4Оценок пока нет

- MOS For InstrumentationДокумент6 страницMOS For Instrumentationrenjithv_4100% (1)

- Process Industries Data Handover Procedure 8Документ2 страницыProcess Industries Data Handover Procedure 8renjithv_4Оценок пока нет

- Process Industries Data Handover Procedure 9Документ2 страницыProcess Industries Data Handover Procedure 9renjithv_4Оценок пока нет

- Instrumentation and ControlДокумент37 страницInstrumentation and ControlMukesh Raghuvanshi100% (2)

- HZ WriteUpДокумент20 страницHZ WriteUprenjithv_4Оценок пока нет

- QA Protocols for Equipment ConstructionДокумент1 страницаQA Protocols for Equipment Constructionrenjithv_4Оценок пока нет

- QA&QC - Installation of Field InstrumentationДокумент4 страницыQA&QC - Installation of Field InstrumentationMuhammadZahirKhan100% (1)

- Boiler AnnexДокумент66 страницBoiler Annexrenjithv_4Оценок пока нет

- QapДокумент9 страницQaprenjithv_4Оценок пока нет

- Final - CFR CqappДокумент134 страницыFinal - CFR CqappPatricia JacksonОценок пока нет

- Quality Assurance Protocol-4Документ2 страницыQuality Assurance Protocol-4renjithv_4Оценок пока нет

- Quality Assurance Protocol-2Документ1 страницаQuality Assurance Protocol-2renjithv_4Оценок пока нет

- Quality Assurance Protocol-1Документ1 страницаQuality Assurance Protocol-1renjithv_4Оценок пока нет

- VMware VSphere Data ProtectionДокумент53 страницыVMware VSphere Data ProtectionHaiОценок пока нет

- Jadual Kelas Kafa Tahap 1 2021Документ9 страницJadual Kelas Kafa Tahap 1 2021Wira B. RamliОценок пока нет

- Canal Trough DesignДокумент18 страницCanal Trough DesignGarg Tj100% (1)

- TOA 2: Schedule of ReportsДокумент1 страницаTOA 2: Schedule of Reportsapi-26464523Оценок пока нет

- Asana TutorialДокумент39 страницAsana TutorialAlice CabreraОценок пока нет

- Fire Safety Executive ManualДокумент8 страницFire Safety Executive ManualFaisal MehmoodОценок пока нет

- DB13 FixДокумент5 страницDB13 FixanupamОценок пока нет

- GSM Events OverviewДокумент6 страницGSM Events OverviewTayyabIjaz87Оценок пока нет

- Ethernet Cable Color Coding Diagram PDFДокумент2 страницыEthernet Cable Color Coding Diagram PDFFabiolaОценок пока нет

- COBIT5 OverviewДокумент6 страницCOBIT5 Overviewjussamary4100% (1)

- Mt. Laurel - 0520 PDFДокумент20 страницMt. Laurel - 0520 PDFelauwitОценок пока нет

- (Riba Stage 5) 31600000 - SHOP DRAWING: Triple Bay Construction Village Workers Village Kitchen & DiningДокумент1 страница(Riba Stage 5) 31600000 - SHOP DRAWING: Triple Bay Construction Village Workers Village Kitchen & Diningabou bakarОценок пока нет

- Trenching Shoring SafetyДокумент29 страницTrenching Shoring SafetyMullapudi Satish KumarОценок пока нет

- Cell Algorithm SwitchДокумент12 страницCell Algorithm Switchsandy_arisandy100% (2)

- Fail OldДокумент18 320 страницFail OldHarold Gallardo MamitagОценок пока нет

- AITT-IAM SDD Siteminder+FedMgr v1.0Документ60 страницAITT-IAM SDD Siteminder+FedMgr v1.0Santosh AgrawalОценок пока нет

- 12 Maya LinДокумент6 страниц12 Maya LinVidishaОценок пока нет

- Concrete Division 3Документ9 страницConcrete Division 3Ma Monica M. MuncadaОценок пока нет

- Desain Pondasi PileДокумент9 страницDesain Pondasi PilegembulflowОценок пока нет

- Manual Funciones Alternantes stm32f7Документ227 страницManual Funciones Alternantes stm32f7erika salinasОценок пока нет

- BRKRST-3114 The Art of Network ArchitectureДокумент60 страницBRKRST-3114 The Art of Network ArchitectureTimucin DIKMEN100% (1)

- New Text DocumentДокумент4 страницыNew Text DocumentSFWОценок пока нет

- Damp Proofing-1 PDFДокумент6 страницDamp Proofing-1 PDFmaneeshaОценок пока нет

- Urban Design: The BeginningsДокумент13 страницUrban Design: The BeginningsjohnzenlukeОценок пока нет

- Formwork Support DesignДокумент71 страницаFormwork Support DesignMurugesan Elaiyappan100% (5)

- SWIMMING POOL HYDRAULIC ANALYSISДокумент6 страницSWIMMING POOL HYDRAULIC ANALYSISdcoveОценок пока нет

- MPI Lab Manual PDFДокумент25 страницMPI Lab Manual PDFAbhishek KapadneОценок пока нет