Академический Документы

Профессиональный Документы

Культура Документы

AshPL 1

Загружено:

Peter RhoadsОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

AshPL 1

Загружено:

Peter RhoadsАвторское право:

Доступные форматы

BULLETIN PL-1

PLUS!

Performance

Liquid-filled performance in a dry gauge!

Ashcroft Inc., 250 East Main Street, Stratford, CT 06614 USA

Tel: 203-378-8281 Fax: 203-385-0408

email: info@ashcroft.com www.ashcroft.com

All specifications are subject to change without notice.

All sales subject to standard terms and conditions.

Ashcroft Inc. 2012 05/12

The Problem...

In the past, applications where

heavy vibration and pulsation

were present required the use of

either a conventional dry gauge

with a hard to read pointer and

a limited life span, or, a costly

liquid-filled gauge and all the

headaches that come with them.

The Solution...

An exclusive, breakthrough tech-

nology developed for Ashcroft

pressure gauges providing virtually

liquid-filled performance in a dry

gauge, the Ashcroft

PLUS!

TM

Performance option.

Benefits vs. Dry Gauges...

Dampens vibration and pulsation

Steady pointer Easier to read!

100% longer life

Reduce purchases by 50%!

Benefits vs Liquid-filled...

Dampens vibration and pulsation

without the headaches of liquid-

filled gauges.

No liquid No leaks!

Easier to read...no fill lines!

Easier to recalibrate.

Wider temperature range vs

glycerin-fill.

Eliminates costly specialty fluids.

Patented

Aw

ard W

inning

D

esign!

Howd They Do That?..

The Patented Ashcroft

PLUS!

TM

Performance option utilizes a

unique cartridge to surround the

pinion with an engineered damp-

ening agent to dynamically damp-

en the pointer and movement,

thereby providing a dry gauge

which acts liquid-filled.

IMPROVED PLANT SAFETY

Safety is a critical issue and the

PLUS!

TM

performance option can

improve the safety of your plant.

Industry surveys indicate that

20% to 30% of customers

gauges are misapplied and pre-

maturely fail due to pulsation and

vibration. If a Bourdon tube fails

due to excessive pulsation, the

process media will escape caus-

ing possible environmental dam-

age, process contamination and

more importantly, possible injury,

fire or explosion.

Q. Are PLUS!

TM

Performance gauges

new gauges?

A. No. We simply enhanced the industry lead-

ing Ashcroft products youve grown to trust

with a fluid clutch dampener. The mechani-

cal system is unchanged.

Q. Does PLUS!

TM

Performance affect

accuracy?

A. No. The only difference is that the

response time is similar to liquid-filled

gauges.

Q. Can these gauges be oxygen cleaned?

A. Yes. Our process cleans the system to

meet AMSE B40.1 level IV.

Q. What temperature range is possible?

A. 40

o

F to 200

o

F or 250F depending on

window material.

Q. Can I use PLUS!

TM

Performance instead

of Halocarbon fill

A. Yes!

Q. Can this be used in paint applications or

others requiring no silicone?

A. The standard PLUS!

TM

Performance can-

not be used in silicone-free applications.

However, PLUS!

TM

is available in a sili-

cone-free version. Order as XNZ for sili-

cone-free.

Q. Does the throttle plug do all the work?

A. No. Throttle plugs are designed only to

fight pulsation. Vibration requires either

a liquid-filled gauge or PLUS!

TM

Performance.

Q. Does our competition have

anything similar?

A. No. One competitor evaluated a liquidless

gauge with poor results. Their design uti-

lized a dashpot which caused premature

failures versus even dry gauges. Gauges

with PLUS!

TM

Performance utilize a com-

pletely different approach overcoming their

design problem.

Q. Will this gauge last forever?

A. No gauge will last forever under condi-

tions of severe pulsation and vibration.

The PLUS!

TM

Performance gauges simply

last significantly longer than traditional

dry gauges with the benefits outlined

above. There are a few applications,

chiefly severe high frequency pulsation,

where a liquid-filled gauge or a remote

mounted gauge is necessary. With a few

exceptions, Beta site customers have

found the performance to rival liquid-filled

gauges in life expectancy without any of

the headaches of liquid-filled gauges.

Q. How Do I Order?

A. The product variation XLL designates

PLUS!

TM

Performance in all Duragauge

,

Duralife

, 1008S and 1032 pressure

gauges and Duratran

transmitters.

Ash Bul PL-1 _Layout 11/5/12 9:12 AM Page 1

PLUS!

Performance

Liquid-filled performance in a dry gauge

Ashcroft Inc., 250 East Main Street, Stratford, CT 06614 USA

Tel: 203-378-8281 Fax: 203-385-0408

email: info@ashcroft.com www.ashcroft.com

All specifications are subject to change without notice.

All sales subject to standard terms and conditions.

Ashcroft Inc. 2012 05/12 BULLETIN PL-1

DURAGAUGE

PRESSURE GAUGE

ACCURACY

1

2% full scale

DIAL SIZE

4

1

2, 6, 8

1

2

TUBE MATERIAL

Bronze, 316 SS, Monel, Inconel

SENSING ELEMENT

Bourdon tube

CONNECTION

1

4 NPT,

1

2,NPT, JIS, DIN, BSP,

All lower or back

RANGES

Vac. to 100,000 psi

CASE MATERIAL

Phenolic, aluminum,

polypropylene

MOVEMENT

Stainless steel, rotary design,

Teflon

S coated pinion and

bearings

POINTER

Micrometer adjustable

DIAL

White painted aluminum

TYPE NUMBERS

1279 phenolic (4

1

2, )

1377 aluminum (4

1

2,, 6, 8

1

2, )

1379 aluminum (4

1

2, 6, 8

1

2, )

2462 (6 )

TYPE 2279 DURATRAN

PRESSURE TRANSMITTER

AND GAUGE

ACCURACY

1

2% full scale

OUTPUT

2 wire, 4-20mA

STABILITY

0.25% full scale

SUPPLY VOLTAGE

24 Vdc nominal, 16V min.,

40V max.

DIAL SIZE

4

1

2, analog dial

TUBE MATERIAL

316 SS, Monel

SENSING ELEMENT

Bourdon tube

CONNECTION

1

2 NPT lower

RANGES

Vacuum, 12 to 20,000 psi

CASE MATERIAL

Phenolic

MOVEMENT

Stainless steel

POINTER

Micrometer adjustable

WEATHERPROOF

NEMA 4 Hermetic seal

TYPE 1032

SANITARY GAUGE

ACCURACY

1.5%-2% depending on range

DIAL SIZE

2

1

2, 3

1

2, 4

1

2

TUBE MATERIAL

316 SS

SENSING ELEMENT

316L SS diaphragm

(12-20RA finish)

CONNECTION

Standard: 1

1

2 or 2 Tri-Clamp,

others on request

Location: lower, back,

side or top

RANGES

From 15# to 1000# including

vacuum and compound

CASE & RING MATERIAL

304 stainless steel

MOVEMENT

Stainless steel, PowerFlex

POINTER

Adjustable Pointer (all)

Easy Zero Ext. Adjust (3

1

2)

DIAL

White painted aluminum

WINDOW

Polycarbonate, Polysulfone

(optional)

CLEAN & STEAM IN PLACE

Temperature limits to 300F

(140C)

AUTOCLAVE OR STERILIZE

Temperature limits to 300F

(140C) with polysulfone

window

SYSTEM FILL

Glycerin (Std)

Food Grade Silicone (Opt)

AGENCY APPROVAL

Meets 3A Standard 74-03

TYPE 1008S STAINLESS

STEEL METRIC CASE

ACCURACY

1.6% full scale

DIAL SIZE

63mm, 100mm

TUBE MATERIAL

316 SS

SENSING ELEMENT

Bourdon tube

CONNECTION

1

4 NPT lower or lower back

1

2NPT lower (100mm), JIS,

DIN available

RANGES

Vac. to 15,000 psi including

compound

CASE MATERIAL

304 stainless steel

MOVEMENT

Stainless steel, PowerFlex

POINTER

Fixed

DIAL

White painted aluminum

WINDOW

Polycarbonate

ASME B40.100

EN837.1 compliance available

RO HS compliant

CRN approved

AUTOCLAVABLE!

TYPE 1009

PRESSURE GAUGE

ACCURACY

1% full scale

DIAL SIZE

2

1

2, 3

1

2, 4

1

2, 6

TUBE MATERIAL

316 SS (2

1

2, 3

1

2)

Bronze, 316 SS, monel,

steel (4

1

2 6)

SENSING ELEMENT

Bourdon tube, Helium leak test

to 1 x 10

-6

ATM

cc

/sec

CONNECTION

1

8 NPT,

1

4 NPT,

1

2 NPT,

7

16 x 20 SAE lower or lower

back, other threads on

application

RANGES

Vac. to 30,000 psi including

compound

CASE & RING MATERIAL

304 Stainless steel with ventable

relief plug

MOVEMENT

Stainless steel, PowerFlex

(2

1

2, 3

1

2)

Stainless steel (4

1

2, 6)

POINTER

Adjustable

DIAL

White painted aluminum

WINDOW

Polycarbonate (2

1

2, 3

1

2)

Glass (4

1

2 6), safety glass

optional

ASME B40.100

EN837.1 compliance available

RO HS compliant

CRN approved

Ash Bul PL-1 _Layout 11/5/12 9:12 AM Page 2

Вам также может понравиться

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (894)

- Health Information System Developmen T (Medical Records)Документ21 страницаHealth Information System Developmen T (Medical Records)skidz137217100% (10)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Wsi PSDДокумент18 страницWsi PSDДрагиша Небитни ТрифуновићОценок пока нет

- Production Chokes Flow Line Accessories and Manifold Skid Packages PDFДокумент16 страницProduction Chokes Flow Line Accessories and Manifold Skid Packages PDFRicardo Paz SoldanОценок пока нет

- Oracle Fusion Financials Book Set Home Page SummaryДокумент274 страницыOracle Fusion Financials Book Set Home Page SummaryAbhishek Agrawal100% (1)

- Nature and Scope of Marketing Marketing ManagementДокумент51 страницаNature and Scope of Marketing Marketing ManagementFeker H. MariamОценок пока нет

- Using Snapchat For OSINT - Save Videos Without OverlaysДокумент12 страницUsing Snapchat For OSINT - Save Videos Without OverlaysVo TinhОценок пока нет

- Module 4-Answer KeyДокумент100 страницModule 4-Answer KeyAna Marie Suganob82% (22)

- Consumer Behaviour Towards AppleДокумент47 страницConsumer Behaviour Towards AppleAdnan Yusufzai69% (62)

- No.6 Role-Of-Child-Health-NurseДокумент8 страницNo.6 Role-Of-Child-Health-NursePawan BatthОценок пока нет

- Customized Seals and Critical Components For Completion and Production SystemsДокумент4 страницыCustomized Seals and Critical Components For Completion and Production SystemsPeter RhoadsОценок пока нет

- Regulator Type 92Документ1 страницаRegulator Type 92Peter RhoadsОценок пока нет

- 08 - FPS01 Subsea Series (Issue 4 Feb 05)Документ4 страницы08 - FPS01 Subsea Series (Issue 4 Feb 05)Peter RhoadsОценок пока нет

- G-Series Pneumatic Performance Data MetricДокумент5 страницG-Series Pneumatic Performance Data MetricPeter RhoadsОценок пока нет

- BILIT Module 10.2 10-12Документ156 страницBILIT Module 10.2 10-12Peter RhoadsОценок пока нет

- GL-Huyett-Retaining-Rings-Catalog Vários PDFДокумент240 страницGL-Huyett-Retaining-Rings-Catalog Vários PDFPoliana PolyОценок пока нет

- Model Ninety Degree: Cavity: T-33AДокумент7 страницModel Ninety Degree: Cavity: T-33APeter RhoadsОценок пока нет

- Module4E Comp Guide v3Документ92 страницыModule4E Comp Guide v3Peter RhoadsОценок пока нет

- Micropulse® BTL7 TA12 Explosion Proof Linear Position SensorsДокумент2 страницыMicropulse® BTL7 TA12 Explosion Proof Linear Position SensorsPeter RhoadsОценок пока нет

- Fluoroloy A19: Material Data SheetДокумент1 страницаFluoroloy A19: Material Data SheetPeter RhoadsОценок пока нет

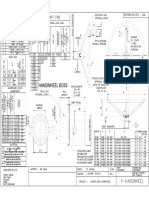

- Hand!Wheel!Dimensions:! Measurement!Guide!Документ4 страницыHand!Wheel!Dimensions:! Measurement!Guide!Peter RhoadsОценок пока нет

- F14/FA14 INPUTF14/FA14 OUTPUT Ib5 Gearbox: Drawing NoДокумент1 страницаF14/FA14 INPUTF14/FA14 OUTPUT Ib5 Gearbox: Drawing NoPeter RhoadsОценок пока нет

- Precision Key S: C U T, F IL E, & F ITДокумент188 страницPrecision Key S: C U T, F IL E, & F ITLuis ReyesОценок пока нет

- F Handwheelr9Документ1 страницаF Handwheelr9Peter RhoadsОценок пока нет

- ICoT 5200 - 5300 - 5400 Ordering GuideДокумент1 страницаICoT 5200 - 5300 - 5400 Ordering GuidePeter RhoadsОценок пока нет

- Belzona 5111 Product Data SheetДокумент2 страницыBelzona 5111 Product Data SheetPeter RhoadsОценок пока нет

- Rotork Gears Gearbox Ab1250N-Pr4: Torque: Mounting Holes: DescriptionДокумент1 страницаRotork Gears Gearbox Ab1250N-Pr4: Torque: Mounting Holes: DescriptionPeter RhoadsОценок пока нет

- Cat BeanieДокумент12 страницCat BeaniePeter RhoadsОценок пока нет

- Series 61 Booster RelaysДокумент2 страницыSeries 61 Booster RelaysPeter RhoadsОценок пока нет

- Application Conditions and Bill of MaterialsДокумент1 страницаApplication Conditions and Bill of MaterialsPeter Rhoads100% (1)

- Filter-Regulator Introduction & SpecificationsДокумент2 страницыFilter-Regulator Introduction & SpecificationsPeter RhoadsОценок пока нет

- IQMK3 Size 2 Cover Tube Adapter DrawingДокумент1 страницаIQMK3 Size 2 Cover Tube Adapter DrawingPeter RhoadsОценок пока нет

- TYPE 330/340 Series Air Filter Regulator & Air Regulator: Installation, Operation, and Maintenance InstructionsДокумент4 страницыTYPE 330/340 Series Air Filter Regulator & Air Regulator: Installation, Operation, and Maintenance InstructionsPeter RhoadsОценок пока нет

- IQMK3 Size 2 Cover Tube Adapter DrawingДокумент1 страницаIQMK3 Size 2 Cover Tube Adapter DrawingPeter RhoadsОценок пока нет

- Critical service choke valve solutionДокумент4 страницыCritical service choke valve solutionPeter RhoadsОценок пока нет

- Floppy Hop FlipbookДокумент3 страницыFloppy Hop FlipbookPeter RhoadsОценок пока нет

- Operation Instructions - Multi-Turn - Actuators - SAEx - 07.2-SAEx - 16.2 - SAREx - 07.2-SAREx - 16.2 - Control - HART - enДокумент108 страницOperation Instructions - Multi-Turn - Actuators - SAEx - 07.2-SAEx - 16.2 - SAREx - 07.2-SAREx - 16.2 - Control - HART - enPeter RhoadsОценок пока нет

- Series 500 - 550 CatalogДокумент8 страницSeries 500 - 550 CatalogPeter RhoadsОценок пока нет

- Cortec FlyerДокумент3 страницыCortec FlyerPeter RhoadsОценок пока нет

- Linguistics: Chapter 1 - 10Документ41 страницаLinguistics: Chapter 1 - 10Ahmad A. JawadОценок пока нет

- Donny UfoaksesДокумент27 страницDonny UfoaksesKang Bowo D'wizardОценок пока нет

- Hastrof Si Cantril. 1954. The Saw A Game. A Case StudyДокумент6 страницHastrof Si Cantril. 1954. The Saw A Game. A Case Studylandreea21Оценок пока нет

- W1inse6220 PDFДокумент11 страницW1inse6220 PDFpicalaОценок пока нет

- Mole Concept - DPP 09 (Of Lec 13) - Yakeen 2.0 2024 (Legend)Документ3 страницыMole Concept - DPP 09 (Of Lec 13) - Yakeen 2.0 2024 (Legend)Romeshchandra Class X-CОценок пока нет

- CH - 3Документ3 страницыCH - 3Phantom GamingОценок пока нет

- Nqs PLP E-Newsletter No68Документ5 страницNqs PLP E-Newsletter No68api-243291083Оценок пока нет

- Form 1 AДокумент2 страницыForm 1 ARohit Jain100% (1)

- Believer - Imagine Dragons - CIFRA CLUBДокумент9 страницBeliever - Imagine Dragons - CIFRA CLUBSilvio Augusto Comercial 01Оценок пока нет

- CV Abdalla Ali Hashish-Nursing Specialist.Документ3 страницыCV Abdalla Ali Hashish-Nursing Specialist.Abdalla Ali HashishОценок пока нет

- OLA CAB MARKET ANALYSIS AND TRENDSДокумент55 страницOLA CAB MARKET ANALYSIS AND TRENDSnitin gadkariОценок пока нет

- A Systematic Scoping Review of Sustainable Tourism Indicators in Relation To The Sustainable Development GoalsДокумент22 страницыA Systematic Scoping Review of Sustainable Tourism Indicators in Relation To The Sustainable Development GoalsNathy Slq AstudilloОценок пока нет

- Principles of SamplingДокумент15 страницPrinciples of SamplingziggerzagОценок пока нет

- 9 - NCP Computer Science PGДокумент19 страниц9 - NCP Computer Science PGM AmbreenОценок пока нет

- Call SANROCCO 11 HappybirthdayBramanteДокумент8 страницCall SANROCCO 11 HappybirthdayBramanterod57Оценок пока нет

- VARCДокумент52 страницыVARCCharlie GoyalОценок пока нет

- Medical filter performance specificationsДокумент1 страницаMedical filter performance specificationsPT.Intidaya Dinamika SejatiОценок пока нет

- (App Note) How To Design A Programmable Gain Instrumentation AmplifierДокумент7 страниц(App Note) How To Design A Programmable Gain Instrumentation AmplifierIoan TudosaОценок пока нет

- Main Hoon Na - WikipediaДокумент8 страницMain Hoon Na - WikipediaHusain ChandОценок пока нет

- Plant Air Centrifugal Compressors: Turbo-Air Series Featuring Oil-Free AirДокумент20 страницPlant Air Centrifugal Compressors: Turbo-Air Series Featuring Oil-Free AirSharad KokateОценок пока нет

- Fiery Training 1Документ346 страницFiery Training 1shamilbasayevОценок пока нет

- Brooks Instrument FlowmeterДокумент8 страницBrooks Instrument FlowmeterRicardo VillalongaОценок пока нет