Академический Документы

Профессиональный Документы

Культура Документы

Mill MAX8 PG Emailversion

Загружено:

Maria Jesus TorresИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Mill MAX8 PG Emailversion

Загружено:

Maria Jesus TorresАвторское право:

Доступные форматы

Less down time

Lower power consumption

Patented externally

adjustable suction-side wear

ring

KREBS millMAX

Pumps

2

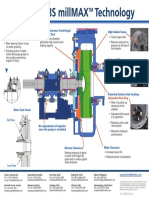

The Heart of the Design

The patented on-line suction side wear

clearance adjustment permits the initial

clearances to be maintained throughout

the life of the pump. This extends the life of

the impeller and suction wear faces to near,

or equal that of, the casing for a one time

maintenance rebuild.

The reduction of solids grinding between

the impeller and suction side reduces power

consumption and wear. The millMAX

Hybrid Suction Sealing System maintains

constant ow and pressure, without

increasing speed or the danger of motor

overload.

KREBS millMAX TECHNOLOGY

The millMAX Pump has a unique

patented design developed exclusively for

mill discharge duties and adapted for other

severe abrasive slurries.

The same wet end components can be

offered as a conversion kit to existing

pumps, without the need to disturb the

foundation or existing bearing frame

assembly.

The millMAX Pump features a patented

on-line wear clearance adjustment, which

minimizes the cost per ton pumped

compared to conventional hard metal and

rubber lined slurry pumps through:

Increased wear life

Even wear life of all wet end parts

Less down time

Lower power consumption

Increased mill throughput

More consistent cyclone separation

Improved gland seal performance

Low-cost no risk wet end

replacement

Wide clearances

at expelling vanes

prevents large

solids from being

crushed.

Tight clearances at

the wear ring pre-

vents suction-side

recirculation.

Tight clearances at

backliner ensures that

shaft sealing system

works well.

millMAX

Hybrid Suction

Sealing System

millMAX

Solves

This Kind of

Problem

millMAX

after 1500 hours

of wear

Competitors suction liner

and impeller - 550 hours

WET END CONVERSIONS

millMAX

PUMPS

20x18 Ghana

Quick-Release

20x18-43 - Australia

Gold

16x14 - Zambia - Copper

10 x 8 - US - Coal

6x4 S. Africa

High Pressure

Krebs millMAX Pumps treat the cause of

pump wear and loss of efciency, whereas

competitive pumps treat the symptoms

through materials or predictive uneven wear

rates.

In most established millMAX installations,

wear life of parts has been even and in

the majority, overall wear life has generally

improved by 50% to 100%. This increase

in wear life is achieved together with a

reduction in power, generally in the 10% to

20% or lower range.

The reduction in power can then be taken

as a cost savings, or through additional

pumping capacity with the same installed

motor.

With the millMAX Hybrid Suction Sealing

System, the front clearance is adjusted

while the pump is running, and takes only

ve minutes to perform. This clearance

is adjusted normally six to eight times

throughout the life of the wet end parts.

20x18-46 - Australia

Gold

14 x 12 - Chile

Copper

The Krebs millMAX

Pump is a new design,

hard metal pump and wet end conversion

kit, designed exclusively for mill discharge

and other abrasive slurries. The Krebs

millMAX

Pump adapts to a variety of power

frames without disturbing the foundation or

bearing frame assemblies.

The millMAX

design can be applied to an

existing pump through a wet end conversion

kit, including impeller, casing, backliner, and

gland seal.

The millMAX

conversion kit is supplied

with an adapter ring, seals, and all hardware

to adapt to a variety of power frames. This

achieves the same results as a complete

pump on a maintenance budget.

2 3

TECHNICAL

High Performance Centrifugal

Dry Gland Seal

Large expeller diameter gener-

ates high suction level sealing

capacity.

Zero leakage while operating.

SPECIFICATIONS

CASING - designed for minimum slurry turbulence and even

wear. Includes (14x12 and smaller) integral wear ring, carrier,

and adjustment screws for on-line adjustment and elimination of

suction side recirculation.

WEAR RING - adjustable wear ring assembly to permit closing

of suction side impeller clearance during operation. This reduces

slurry recirculation and lowers pressure at the suction area,

thereby maintaining fow and reducing wear.

IMPELLER - designed for high slurry efciency and hydraulic

performance. Machined surface at the eye for wear ring adjust-

ment and high expelling vanes.

BACKLINER - designed for close clearance at the back (14x12

and smaller), or SUCTION LINER with integral wear ring

(16x14 and larger). Matching full impeller diameter and profle

for close operating clearance.

High Radial Vanes

Clears large solids.

Prevents solids from being crushed.

Reduces casing slurry pressure at the eye

of the impeller.

External Wear Adjustment

Screw

Four screws for on-line wear

clearance adjustment.

Adjusted while the pump is

operating.

Adjusted six to eight times

during the life of the pump.

Adjustable Wear Ring

Wear ring takes up clear-

ance at the impeller.

Adjusted during operation.

Reduces suction side recir-

culation.

Maintains hydraulic per-

formance.

WEAR PARTS - designed hydraulically to wear evenly. Construct-

ed of high chrome at 680/720 Brinell hardness.

POWER FRAME - heavy duty cast iron pedestal with external

bearing assembly adjustment mechanism. Drilled for overhead

motor mounting assembly.

FLANGES - loose intake and discharge fanges drilled to suit vari-

ous pipe requirements.

BEARING ASSEMBLY - heavy duty shaft and indirect tted

taper roller bearings rated at 100,000 hrs B-10 life minimum.

Bearing arrangement designed to prevent over greasing and ingress

of slurry.

Slurry pumps are Krebs millMAX

design and include the following:

No adjustment of impeller once

the pump is installed.

Narrow Clearance

Reduces pressure at gland to

assist centrifugal dry gland seal or

reduce gland water pressure.

Wide Clearance

Dramatic reduction in crushing of

solids.

Increased wear life.

Reduced power consumption.

SHAFT SEAL OPTIONS

Max Gland Water Required

GPM

FRAME FULL LOW

CMC 8 0.15

MMA 14 0.2

MMB 19 0.3

MMC 24 0.5

MMD 30 1.0

MME 55 --

MMF 85 --

driMAX

Mechanical Seal

Operates in extreme abrasive environment.

Individual seal wear parts are easily replaced

on-site without special tools.

Ability to adjust for wear if required.

Impeller suction wear clearance adjustment

without touching seal.

millMAX

Power Frame

Heavy duty cast pedestal.

External bearing assembly adjustment.

Wide bearing centers.

Heavy duty shaft and bearings.

Double clamp.

Reverse Taper Roller Bearings

Increases effective load span to improve life.

Main bearing failure is due to over greasing.

Pumping action of taper rollers discharges grease to the

outside, preventing ingress of slurry or over greasing of

bearing cartridge.

FULL FLOW

LOW FLOW

WATER FLUSH GLAND

4 5

Standard millMAX

Discharge Positions

*NOTE: CONSULT FACTORY FOR OTHER DISCHARGE POSITIONS.

Top 45 degree

Bottom 45 degree

Top vertical

Top horizontal

Bottom horizontal

millMAX

Engineering Dimensions - BARE SHAFT PUMP

Pump Model Size Frame Key Pump Model

MM080AA4 3X2-9 MMAA 794 403 138 185 185 200 31 150 150 314 370 42 114 8X12X100 30 293 235 210 19 189 MM080AA4

MM100AA4 4X3-12 MMAA 870 514 185 234 262 200 35 188 148 314 370 42 115 8X12X100 30 293 235 247 19 311 MM100AA4

MM100A4 4X3-12 MMA 974 514 185 234 262 230 5 188 148 375 431 65 150 11X18X100 40 323 265 278 22 369 MM100A4

MM100A5 HP 4X3-17 MMA 1047 730 230 365 378 230 135 248 53 431 375 65 150 11X18X100 40 323 265 291 22 685 MM100A5 HP

MM100B5 HP 4X3-17 MMB 1266 730 230 365 378 300 65 248 53 475 548 80 215 14X22X150 50 410 335 337 29 839 MM100B5 HP

MM150A4 6X4-16 MMA 1005 629 229 286 326 230 55 219 190 375 431 65 145 11X18X100 40 323 265 279 22 537 MM150A4

MM150B4 6X4-16 MMB 1233 629 229 286 326 300 15 219 190 475 548 80 215 14X22X150 50 410 335 339 29 682 MM150B4

MM150B4 QR 6X4-16 MMB 1292 629 229 286 326 300 15 219 190 475 548 80 215 14X22X150 50 410 335 390 29 702 MM150B4 QR

MM150B5 HP 6X4-21 MMB 1302 856 283 422 470 300 128 260 71 475 548 80 215 14X22X150 50 410 335 361 29 1177 MM150B5 HP

MM200B4-20 8X6-20 MMB 1334 843 318 371 460 300 90 288 230 475 548 80 215 14X22X150 50 410 335 370 35 1035 MM200B4-20

MM200C4-20 8X6-20 MMC 1493 843 318 371 460 400 10 288 230 666 766 100 370 16X28X180 75 555 455 370 35 1424 MM200C4-20

MM200B4-24 8X6-24 MMB 1335 998 419 434 480 300 169 290 277 475 548 80 215 14X22X150 50 410 335 370 29 1504 MM200B4-24

MM200C4-24 8X6-24 MMC 1491 998 419 434 480 400 70 290 277 666 766 100 228 16X28X180 75 555 455 370 35 1886 MM200C4-24

MM250C4 10X8-24 MMC 1540 1032 419 441 480 400 60 325 290 666 766 100 228 16X28X180 75 555 455 384 35 1952 MM250C4

MM300C4 12X10-30 MMC 1585 1235 462 570 610 400 199 342 348 666 766 100 228 16X28X180 75 555 455 413 35 2715 MM300C4

MM300C4 QR 12X10-30 MMC 1656 1235 462 570 610 400 196 342 348 666 766 100 227 16X28X180 75 555 455 483 35 2750 MM300C4 QR

MM300D4 12X10-30 MMD 1933 1235 462 570 610 500 98 342 348 863 963 150 349 36X20X280 78 693 593 487 41 3495 MM300D4

MM350C4 14X12-36 MMC 1751 1569 629 700 674 400 365 402 405 666 766 100 264 16X28X180 75 555 455 493 35 4083 MM350C4

MM350D4 14X12-36 MMD 2030 1569 629 712 674 500 278 402 405 863 963 150 349 36X20X280 78 693 593 515 41 4813 MM350D4

MM350D4 QR 14X12-36 MMD 2074 1569 629 700 674 500 265 402 405 863 963 150 349 36X20X265 78 693 593 558 41 4850 MM350D4 QR

MM400D4 16X14-39 MMD 2112 1738 666 804 893 500 326 441 229 863 963 150 349 36X20X280 78 693 593 567 41 5776 MM400D4

MM500D4 20X18-46 MMD 2224 1986 703 965 1054 500 473 506 251 863 963 150 349 36X20X280 78 693 593 619 41 10025 MM500D4

MM500E4 20X18-46 MME 2370 1986 703 965 1054 850 124 506 251 1010 1111 150 320 36X20X280 38 1048 700 545 32 10757 MM500E4

MM500E4 QR 20X18-46 MME 2485 1986 703 965 1054 850 124 506 251 1010 1111 150 320 36X20X280 38 1048 700 653 32 11633 MM500E4 QR

MM600E5 24X20-54 MME 2440 2208 791 1030 1226 850 218 565 236 1022 1111 150 320 36X20X280 38 1048 700 555 32 12640 MM600E5

MM600E5 QR 24X20-54 MME 2554 2208 791 1030 1226 850 218 565 236 1022 1111 150 322 36X20X280 38 1048 700 663 32 13373 MM600E5 QR

MM700F5 28X26-64 MMF 3008 2748 1060 1253 1300 1092 235 648 304 1422 1549 190 293 45X25X254 38 1451 1219 583 38 22236 MM700F5

MM700F5 QR 28X26-64 MMF 3027 2748 1060 1253 1300 1092 403 648 304 1422 1549 190 291 45X25X254 38 1451 1219 602 38 22546 MM700F5 QR

Weight A B C D E F G F1 K L M G1 H I J O Hole Dia. N

Side-by-Side

Direct Inline

Reverse Overhead

Pump Model Size Frame Key Pump Model

MM080AA4 3X2-9 MMAA 794 403 138 185 185 200 31 150 150 314 370 42 114 8X12X100 30 293 235 210 19 189 MM080AA4

MM100AA4 4X3-12 MMAA 870 514 185 234 262 200 35 188 148 314 370 42 115 8X12X100 30 293 235 247 19 311 MM100AA4

MM100A4 4X3-12 MMA 974 514 185 234 262 230 5 188 148 375 431 65 150 11X18X100 40 323 265 278 22 369 MM100A4

MM100A5 HP 4X3-17 MMA 1047 730 230 365 378 230 135 248 53 431 375 65 150 11X18X100 40 323 265 291 22 685 MM100A5 HP

MM100B5 HP 4X3-17 MMB 1266 730 230 365 378 300 65 248 53 475 548 80 215 14X22X150 50 410 335 337 29 839 MM100B5 HP

MM150A4 6X4-16 MMA 1005 629 229 286 326 230 55 219 190 375 431 65 145 11X18X100 40 323 265 279 22 537 MM150A4

MM150B4 6X4-16 MMB 1233 629 229 286 326 300 15 219 190 475 548 80 215 14X22X150 50 410 335 339 29 682 MM150B4

MM150B4 QR 6X4-16 MMB 1292 629 229 286 326 300 15 219 190 475 548 80 215 14X22X150 50 410 335 390 29 702 MM150B4 QR

MM150B5 HP 6X4-21 MMB 1302 856 283 422 470 300 128 260 71 475 548 80 215 14X22X150 50 410 335 361 29 1177 MM150B5 HP

MM200B4-20 8X6-20 MMB 1334 843 318 371 460 300 90 288 230 475 548 80 215 14X22X150 50 410 335 370 35 1035 MM200B4-20

MM200C4-20 8X6-20 MMC 1493 843 318 371 460 400 10 288 230 666 766 100 370 16X28X180 75 555 455 370 35 1424 MM200C4-20

MM200B4-24 8X6-24 MMB 1335 998 419 434 480 300 169 290 277 475 548 80 215 14X22X150 50 410 335 370 29 1504 MM200B4-24

MM200C4-24 8X6-24 MMC 1491 998 419 434 480 400 70 290 277 666 766 100 228 16X28X180 75 555 455 370 35 1886 MM200C4-24

MM250C4 10X8-24 MMC 1540 1032 419 441 480 400 60 325 290 666 766 100 228 16X28X180 75 555 455 384 35 1952 MM250C4

MM300C4 12X10-30 MMC 1585 1235 462 570 610 400 199 342 348 666 766 100 228 16X28X180 75 555 455 413 35 2715 MM300C4

MM300C4 QR 12X10-30 MMC 1656 1235 462 570 610 400 196 342 348 666 766 100 227 16X28X180 75 555 455 483 35 2750 MM300C4 QR

MM300D4 12X10-30 MMD 1933 1235 462 570 610 500 98 342 348 863 963 150 349 36X20X280 78 693 593 487 41 3495 MM300D4

MM350C4 14X12-36 MMC 1751 1569 629 700 674 400 365 402 405 666 766 100 264 16X28X180 75 555 455 493 35 4083 MM350C4

MM350D4 14X12-36 MMD 2030 1569 629 712 674 500 278 402 405 863 963 150 349 36X20X280 78 693 593 515 41 4813 MM350D4

MM350D4 QR 14X12-36 MMD 2074 1569 629 700 674 500 265 402 405 863 963 150 349 36X20X265 78 693 593 558 41 4850 MM350D4 QR

MM400D4 16X14-39 MMD 2112 1738 666 804 893 500 326 441 229 863 963 150 349 36X20X280 78 693 593 567 41 5776 MM400D4

MM500D4 20X18-46 MMD 2224 1986 703 965 1054 500 473 506 251 863 963 150 349 36X20X280 78 693 593 619 41 10025 MM500D4

MM500E4 20X18-46 MME 2370 1986 703 965 1054 850 124 506 251 1010 1111 150 320 36X20X280 38 1048 700 545 32 10757 MM500E4

MM500E4 QR 20X18-46 MME 2485 1986 703 965 1054 850 124 506 251 1010 1111 150 320 36X20X280 38 1048 700 653 32 11633 MM500E4 QR

MM600E5 24X20-54 MME 2440 2208 791 1030 1226 850 218 565 236 1022 1111 150 320 36X20X280 38 1048 700 555 32 12640 MM600E5

MM600E5 QR 24X20-54 MME 2554 2208 791 1030 1226 850 218 565 236 1022 1111 150 322 36X20X280 38 1048 700 663 32 13373 MM600E5 QR

MM700F5 28X26-64 MMF 3008 2748 1060 1253 1300 1092 235 648 304 1422 1549 190 293 45X25X254 38 1451 1219 583 38 22236 MM700F5

MM700F5 QR 28X26-64 MMF 3027 2748 1060 1253 1300 1092 403 648 304 1422 1549 190 291 45X25X254 38 1451 1219 602 38 22546 MM700F5 QR

Weight A B C D E F G F1 K L M G1 H I J O Hole Dia. N

DRIVE

ARRANGEMENTS

6 7

FLSmidth Krebs expertise in the process industries spans

more than five decades. Our innovative technologies meet the

high-performance demands of today and in some of the most

challenging process environments. FLSmidth Krebs is the leading

provider of hydrocyclone technology and is quickly becoming the

leader in severe duty slurry pumps worldwide.

With the main office in Tucson, Arizona, FLSmidth Krebs has

worldwide offices in Australia, Austria, Brasil, Chile, China, the

Philippines, and South Africa.

www.Krebs.com or

www.FLSmidthMinerals.com

8

FLSmidth Group 2008. All rights reserved. This brochure makes no offers, representations or warranties (express or implied), and information and data contained in this

brochure are for general reference only and may change at any time. Please contact FLSmidth Mineral for specic information or data that may relate to your interests

Вам также может понравиться

- Komatsu 930E-3 DUMP TRUCK Service ManualДокумент904 страницыKomatsu 930E-3 DUMP TRUCK Service Manualatommota100% (2)

- Warman Pumps: Assembly, Operating and Maintenance InstructionsДокумент19 страницWarman Pumps: Assembly, Operating and Maintenance InstructionsMamiherintsoa Issaia RanaivoarimananaОценок пока нет

- Product Bulletin N 6: Bearing Assemblies - Shaft VariationsДокумент1 страницаProduct Bulletin N 6: Bearing Assemblies - Shaft VariationsRANAIVOARIMANANAОценок пока нет

- Technical Bulletin 3Документ17 страницTechnical Bulletin 3RANAIVOARIMANANAОценок пока нет

- TC Pump: The Total Slurry SolutionДокумент4 страницыTC Pump: The Total Slurry SolutionDiego Mejia100% (1)

- Slurrymax Camur Pompasi 3 PDFДокумент8 страницSlurrymax Camur Pompasi 3 PDFTecnologia Fabricación MetalmecanicaОценок пока нет

- Krebs Mill Max Centrifugal Slurry Pump We BXДокумент8 страницKrebs Mill Max Centrifugal Slurry Pump We BXPhaniОценок пока нет

- Krebs Products For The Coal IndustryДокумент20 страницKrebs Products For The Coal IndustryAОценок пока нет

- 10-400FLSmidthKrebs SlurryMAX Brochure EmailДокумент8 страниц10-400FLSmidthKrebs SlurryMAX Brochure EmailpacodmxОценок пока нет

- Krebs Millmax-E Pump: The New High-Efficiency Slurry Pump Designed For Abrasive Slurry ApplicationsДокумент4 страницыKrebs Millmax-E Pump: The New High-Efficiency Slurry Pump Designed For Abrasive Slurry ApplicationsPhaniОценок пока нет

- Slurrymax Pump: Split Casing Design For Multiple ApplicationsДокумент8 страницSlurrymax Pump: Split Casing Design For Multiple Applicationssergio.manuel ovandoОценок пока нет

- ManualДокумент8 страницManualSherif AdelОценок пока нет

- Warman VerticalДокумент4 страницыWarman VerticalCristobal JM CreativОценок пока нет

- KREBS slurryMAX Pump BrochureДокумент12 страницKREBS slurryMAX Pump Brochuredavidgaro12Оценок пока нет

- Shadeco Excellence Pump ManualДокумент34 страницыShadeco Excellence Pump ManualRichard Reyes romeroОценок пока нет

- 00 Mill MAXSlurry Pump July 2016 CutawayДокумент1 страница00 Mill MAXSlurry Pump July 2016 CutawayPatricio Acuña100% (1)

- B.5 MillMAX 3x2-14x12 IOM (July 2015)Документ67 страницB.5 MillMAX 3x2-14x12 IOM (July 2015)Alief FadilОценок пока нет

- CertifiedДокумент1 страницаCertifiedIta BarreraОценок пока нет

- Product Bulletin 22Документ2 страницыProduct Bulletin 22RANAIVOARIMANANAОценок пока нет

- 005056B6021E1ED4AEFF0B99E4B424D3Документ8 страниц005056B6021E1ED4AEFF0B99E4B424D3Cristhian Niño MartinezОценок пока нет

- A7 PumpДокумент14 страницA7 PumpIr Go JarОценок пока нет

- GX Catalogue2013Документ32 страницыGX Catalogue2013Leobardo DiazОценок пока нет

- Technical Bulletin 4Документ8 страницTechnical Bulletin 4RANAIVOARIMANANAОценок пока нет

- 34g KSBДокумент1 страница34g KSBGut BeerliОценок пока нет

- Warman International LTD: Intake FlangeДокумент3 страницыWarman International LTD: Intake FlangerickОценок пока нет

- Sump Pump Critical Speeds WDS 101Документ3 страницыSump Pump Critical Speeds WDS 101RANAIVOARIMANANA0% (1)

- Manual Horizontal IOM Envirotech ESPДокумент67 страницManual Horizontal IOM Envirotech ESPOmar RodriguezОценок пока нет

- R05323 P 001a X009 0042 PDFДокумент464 страницыR05323 P 001a X009 0042 PDFcquibajoОценок пока нет

- Product Bulletin 20Документ5 страницProduct Bulletin 20RANAIVOARIMANANAОценок пока нет

- PDF 5000 Series Vertical Pumps Elastomer Lined or All Metal Abrasion Corrosion Resistant - CompressДокумент4 страницыPDF 5000 Series Vertical Pumps Elastomer Lined or All Metal Abrasion Corrosion Resistant - CompressPepe CarrОценок пока нет

- Installation, Operation and Maintenance Manual: JANUARY 31, 2018Документ31 страницаInstallation, Operation and Maintenance Manual: JANUARY 31, 2018DANIEL NICOLAS GONZALEZ SANCHEZОценок пока нет

- WPG 151AH31: 14 MM 14 MMДокумент24 страницыWPG 151AH31: 14 MM 14 MMMamiherintsoa Issaia RanaivoarimananaОценок пока нет

- Eaton AirflexДокумент12 страницEaton AirflexagusОценок пока нет

- Product Bulletin 35Документ2 страницыProduct Bulletin 35RANAIVOARIMANANAОценок пока нет

- Bombas Galigher Serie VRAДокумент7 страницBombas Galigher Serie VRARAUL PEREZ NEGREIROSОценок пока нет

- Giw Conversion Slurry PumpsДокумент2 страницыGiw Conversion Slurry Pumpsmarcosandia1974Оценок пока нет

- Material Data Sheet: Ferralium 255Документ3 страницыMaterial Data Sheet: Ferralium 255fendix67% (3)

- ST Ives 16x14 UMD Case Study UpdateДокумент11 страницST Ives 16x14 UMD Case Study Updatesinter-musicОценок пока нет

- 1345 John CraneДокумент2 страницы1345 John CraneseptixОценок пока нет

- LCC M150 500 3 LCCPump Metal PDFДокумент8 страницLCC M150 500 3 LCCPump Metal PDFFrancisco Loyola CarrascoОценок пока нет

- Bombas Hidrociclones ResumenДокумент289 страницBombas Hidrociclones ResumenJesus vera alvarado100% (1)

- Product Bulletin 15Документ2 страницыProduct Bulletin 15RANAIVOARIMANANAОценок пока нет

- Wear Reduction Technology: Centrifugal Slurry PumpsДокумент12 страницWear Reduction Technology: Centrifugal Slurry PumpstinoОценок пока нет

- 086EAHPPPGM Listado de PartesДокумент1 страница086EAHPPPGM Listado de PartesJavier Alejandro Rodriguez Melgoza100% (1)

- Pump Performance Curve Index: 1.5/1 AH 2/1.5 AHДокумент9 страницPump Performance Curve Index: 1.5/1 AH 2/1.5 AHMamiherintsoa Issaia RanaivoarimananaОценок пока нет

- MANUAL Slurry MAX PUMP RM150 KM04579Документ61 страницаMANUAL Slurry MAX PUMP RM150 KM04579Rimbert100% (1)

- Curva de Performance 4 Bombas - Recomendação WEIRДокумент1 страницаCurva de Performance 4 Bombas - Recomendação WEIRJoão Paulo Augusto MacedoОценок пока нет

- Bomba Galigher Horizontal - InglésДокумент7 страницBomba Galigher Horizontal - Ingléslilium2816100% (1)

- WPG 2020D20: 170 MM 170 MMДокумент1 страницаWPG 2020D20: 170 MM 170 MMMamiherintsoa Issaia RanaivoarimananaОценок пока нет

- Warman WRT BrochureДокумент8 страницWarman WRT BrochurePaul Ticla PuenteОценок пока нет

- 11.1.06 Warman Pump Shaft SealsДокумент12 страниц11.1.06 Warman Pump Shaft SealsMartin Calderon100% (1)

- General Conditions of Sale: 1. ApplicationДокумент3 страницыGeneral Conditions of Sale: 1. ApplicationsyamimialifahОценок пока нет

- 0-WD745-EJ610-00001 - Rev.1 - Operation and Maintenance Manuals For Control ValveДокумент100 страниц0-WD745-EJ610-00001 - Rev.1 - Operation and Maintenance Manuals For Control Valveraul gonzalezОценок пока нет

- EHM Series Slurry Pump: Excellence Pump Industry Co., LTDДокумент6 страницEHM Series Slurry Pump: Excellence Pump Industry Co., LTDAgung Bakdo TriyonoОценок пока нет

- Model 3196 ANSI B73.1M Process Pump: Engineered Performance For Increased Plant ReliabilityДокумент74 страницыModel 3196 ANSI B73.1M Process Pump: Engineered Performance For Increased Plant Reliabilityscottt_84Оценок пока нет

- A New Large Pump For Oil SandsДокумент62 страницыA New Large Pump For Oil SandsAdam BartonОценок пока нет

- VC vcr1.5pДокумент8 страницVC vcr1.5pfaundesОценок пока нет

- Bomba Warman 3x2Документ44 страницыBomba Warman 3x2Alex ContrerasОценок пока нет

- Product Bulletin N 5: New Materials W410, W411 AND W106Документ3 страницыProduct Bulletin N 5: New Materials W410, W411 AND W106RANAIVOARIMANANAОценок пока нет

- 10 001 Krebs millMAX Centrifugal Slurry Pumps 2017 PDFДокумент8 страниц10 001 Krebs millMAX Centrifugal Slurry Pumps 2017 PDFNicolas BaquedanoОценок пока нет

- KREBS millMAX Slurry Pump BrochureДокумент12 страницKREBS millMAX Slurry Pump BrochureEloize OliveiraОценок пока нет

- ALS Santiago Mineral Services Centre - MetallurgyДокумент8 страницALS Santiago Mineral Services Centre - MetallurgyPrimitivo GonzálezОценок пока нет

- Cleansource - Cleansolv HF EP Technical BulletinДокумент1 страницаCleansource - Cleansolv HF EP Technical BulletinPrimitivo GonzálezОценок пока нет

- Guided Waves For Stress Corrosion Crack Detection in Pipelines - Feature Selection and ClassificationДокумент33 страницыGuided Waves For Stress Corrosion Crack Detection in Pipelines - Feature Selection and ClassificationPrimitivo GonzálezОценок пока нет

- Failure AnalysisДокумент16 страницFailure AnalysisPrimitivo GonzálezОценок пока нет

- Monitoring Acoustic Emission (AE) Energy of Abrasive Particle Impacts in A Slurry Impingement Flow LoopДокумент8 страницMonitoring Acoustic Emission (AE) Energy of Abrasive Particle Impacts in A Slurry Impingement Flow LoopPrimitivo GonzálezОценок пока нет

- 14 YanДокумент9 страниц14 YanPrimitivo GonzálezОценок пока нет

- Industrial Scanners Catalog en 201311Документ30 страницIndustrial Scanners Catalog en 201311Primitivo GonzálezОценок пока нет

- Paper Electronics ET009 SozopolДокумент4 страницыPaper Electronics ET009 SozopolPrimitivo GonzálezОценок пока нет

- Minalliance 100 Innovations enДокумент0 страницMinalliance 100 Innovations enPrimitivo GonzálezОценок пока нет

- Duratray Steve HallДокумент0 страницDuratray Steve HallPrimitivo GonzálezОценок пока нет