Академический Документы

Профессиональный Документы

Культура Документы

Materials

Загружено:

api-247243068Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Materials

Загружено:

api-247243068Авторское право:

Доступные форматы

1 of 36 Boardworks Ltd 2009

2 of 34 Boardworks Ltd 2009

3 of 36 Boardworks Ltd 2009

Introduction to materials: density

The study of materials is important to inform decisions about

which materials to use for different things.

density =

mass

volume

r =

m

V

It is important to consider properties of materials such as

density, and how materials react when forces are applied.

The image shows equal

volumes of brass, balsa

wood and polystyrene. How

would their densities and

masses compare? What

could they be used for?

units: kg m

3

4 of 36 Boardworks Ltd 2009

Finding the density

5 of 36 Boardworks Ltd 2009

Calculating the density

6 of 34 Boardworks Ltd 2009

7 of 36 Boardworks Ltd 2009

Introduction to springs

The behaviour of springs is important since they have many

uses, from car and bike suspension to clock-making.

It is important to know how springs will react when forces

are applied.

8 of 36 Boardworks Ltd 2009

Tensile and compressive forces

9 of 36 Boardworks Ltd 2009

Restoring force

10 of 36 Boardworks Ltd 2009

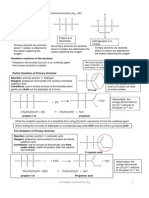

Hookes law and the force constant

Hookes law states that the extension of a spring, x, is

directly proportional to the force applied to it, F.

F x or F = kx where k is a constant.

k is called the force constant or the spring constant, or

sometimes the stiffness constant. The units of k are Nm

-1

.

x original length

F

11 of 36 Boardworks Ltd 2009

Finding the force constant

12 of 36 Boardworks Ltd 2009

Calculating the force constant

13 of 36 Boardworks Ltd 2009

Elastic limit for springs

The elastic limit is a point

beyond which the spring

will no longer return to its

original shape when the

force is removed.

Elasticity is the ability to

regain shape after deforming

forces are removed.

If a spring is stretched far enough, it reaches the limit of

proportionality and then the elastic limit.

extension

f

o

r

c

e

The limit of proportionality is a point beyond which

behaviour no longer conforms to Hookes law.

14 of 34 Boardworks Ltd 2009

15 of 36 Boardworks Ltd 2009

What is elastic potential energy?

EPE is the energy stored in a body

due to a load causing a deformation.

A stretched or compressed material, like

the spring in a jack-in-the-box when the lid

is closed, has elastic potential energy

(EPE) or elastic strain energy stored in it.

According to the principal of conservation of energy, no

energy is created or destroyed when a spring is

compressed. Therefore the work done in compressing the

spring is equal to the EPE stored in it, plus any energy

released as heat and sound.

16 of 36 Boardworks Ltd 2009

Calculating elastic potential energy

Work is done when a

spring is stretched; for

example, in stretching

chest expanders.

EPE = work done

If the conversion of mechanical energy into thermal energy is

ignored, work done is equal to EPE stored in the springs.

= average force extension

For a spring:

= Fd

= average force distance moved

EPE = Fx

EPE = work done

17 of 36 Boardworks Ltd 2009

Work done

18 of 36 Boardworks Ltd 2009

Match up the equations

19 of 34 Boardworks Ltd 2009

20 of 36 Boardworks Ltd 2009

Stretching wires the variables

When using wires and

other materials, it is

important to know how

they will stretch if a

force acts on them.

The following properties

must be considered:

the Young modulus (modulus of elasticity) of the material.

the length (L)

the cross-sectional area (a)

21 of 36 Boardworks Ltd 2009

What is the Young modulus?

22 of 36 Boardworks Ltd 2009

Young modulus calculation: example

23 of 36 Boardworks Ltd 2009

Stressstrain graphs

24 of 36 Boardworks Ltd 2009

Finding the Young modulus from graphs

Which material, A or B, has the larger Young modulus and

how can you tell?

tensile strain

t

e

n

s

i

l

e

s

t

r

e

s

s

(

N

m

2

)

A

B

25 of 36 Boardworks Ltd 2009

Stiffness, strength and toughness

Stiffness, strength and toughness are all different properties

of materials.

Toughness is a measure of the energy needed to

break a material. Toughness is equal to the area

under the stressstrain curve.

Strength refers to the ultimate tensile stress (UTS).

A greater UTS means a stronger material.

Stiffness reflects how difficult it is to change the shape

or size of a material. Greater stiffness means a greater

value for the force constant, k, and a steeper gradient of

stressstrain curve (representing the Young modulus).

26 of 36 Boardworks Ltd 2009

More about properties of materials

A strong material may also be brittle, though at first this

seems counterintuitive.

It is also possible for a plastic material to be tough. How

would such a material behave under tensile testing and what

would its stressstrain curve look like?

A strong but brittle material

would have a linear stressstrain

curve, i.e. would break without

any plastic deformation taking

place. However, it would only

break under high stress, so the

end-point of the line would be at

a high y-value on the graph.

tensile strain

t

e

n

s

i

l

e

s

t

r

e

s

s

(

N

m

2

)

high UTS

breaking

point

27 of 36 Boardworks Ltd 2009

Investigating stressstrain graphs

28 of 36 Boardworks Ltd 2009

Different types of material

29 of 36 Boardworks Ltd 2009

Measuring the Young modulus

The Young modulus of a wire can be measured in the

classroom without a tensile testing machine, using the set-up

below.

Young modulus =

stress

strain

=

FL

Ax

marker on wire

ruler

length of wire under test

How could the equipment could be used to find the

Young modulus? Remember the equation:

30 of 36 Boardworks Ltd 2009

Young modulus calculations

31 of 34 Boardworks Ltd 2009

32 of 36 Boardworks Ltd 2009

Glossary

33 of 36 Boardworks Ltd 2009

Whats the keyword?

34 of 34 Boardworks Ltd 2009

Multiple-choice quiz

Вам также может понравиться

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Resistance and ResistivityДокумент31 страницаResistance and Resistivityapi-247243068Оценок пока нет

- Bio Unit 1 and Unit 2 Revision Posters - ComprehensiveДокумент70 страницBio Unit 1 and Unit 2 Revision Posters - Comprehensiveapi-247243068Оценок пока нет

- Bio Unit 1 and Unit 2 Revision Posters - ComprehensiveДокумент70 страницBio Unit 1 and Unit 2 Revision Posters - Comprehensiveapi-247243068Оценок пока нет

- Chem1 2 - Calculations 1Документ8 страницChem1 2 - Calculations 1api-247243068Оценок пока нет

- Cross-Hole Sonic Logging Test For PilesДокумент11 страницCross-Hole Sonic Logging Test For PilesbatteekhОценок пока нет

- Solution Manual For Engineering Fluid Mechanics 11th Ed - Donald F. Elger, Barbara A. LeBret, Clayton T. Crowe, John A. RobertsonДокумент30 страницSolution Manual For Engineering Fluid Mechanics 11th Ed - Donald F. Elger, Barbara A. LeBret, Clayton T. Crowe, John A. RobertsonAfshar Arabi0% (4)

- IS 800-2007 Example 002w321321weДокумент6 страницIS 800-2007 Example 002w321321weputra wiraОценок пока нет

- Aisi 4140 Alloy Steel (Uns g41400)Документ4 страницыAisi 4140 Alloy Steel (Uns g41400)adil_farooq_6Оценок пока нет

- Psychology Revision - Research Methods A2Документ5 страницPsychology Revision - Research Methods A2api-247243068Оценок пока нет

- c2 SpectrosДокумент2 страницыc2 Spectrosapi-247243068Оценок пока нет

- Sophisticated Living - Travel Costs ExplainedДокумент1 страницаSophisticated Living - Travel Costs Explainedapi-247243068Оценок пока нет

- Sophisticated Living - Travel Costs ExplainedДокумент1 страницаSophisticated Living - Travel Costs Explainedapi-247243068Оценок пока нет

- c2 HalogensДокумент3 страницыc2 Halogensapi-247243068Оценок пока нет

- Moments and Centre of GravityДокумент26 страницMoments and Centre of Gravityapi-247243068Оценок пока нет

- Muscle Contraction and Anaerobic RespДокумент2 страницыMuscle Contraction and Anaerobic Respapi-247243068Оценок пока нет

- 3 Faces of Eve Results TableДокумент2 страницы3 Faces of Eve Results Tableapi-247243068Оценок пока нет

- Particle PhysicsДокумент26 страницParticle Physicsapi-247243068Оценок пока нет

- c2 AlcoholsДокумент3 страницыc2 Alcoholsapi-247243068Оценок пока нет

- KinematicsДокумент22 страницыKinematicsdiane hoyles100% (1)

- Mod 2 Revision Guide 2 Reaction KineticsДокумент3 страницыMod 2 Revision Guide 2 Reaction Kineticsapi-247243068Оценок пока нет

- c2 Group-2Документ2 страницыc2 Group-2api-247243068Оценок пока нет

- c2 EnergeticsДокумент7 страницc2 Energeticsapi-247243068Оценок пока нет

- c2 AlkenesДокумент4 страницыc2 Alkenesapi-247243068Оценок пока нет

- c2 EquilibriaДокумент2 страницыc2 Equilibriaapi-247243068Оценок пока нет

- Chem1 5 1 6 - OrganicДокумент6 страницChem1 5 1 6 - Organicapi-247243068Оценок пока нет

- c2 Metal-ExtractionДокумент2 страницыc2 Metal-Extractionapi-247243068Оценок пока нет

- c2 - RedoxДокумент2 страницыc2 - Redoxapi-247243068Оценок пока нет

- Equations Amount of SubstanceДокумент11 страницEquations Amount of Substanceapi-247243068Оценок пока нет

- Chem1 4 - PeriodicityДокумент1 страницаChem1 4 - Periodicityapi-247243068Оценок пока нет

- Chem1 3 - BondingДокумент6 страницChem1 3 - Bondingapi-247243068Оценок пока нет

- Chem1 1 - Atomic StructureДокумент5 страницChem1 1 - Atomic Structureapi-247243068Оценок пока нет

- Membrane Transport RevisionДокумент14 страницMembrane Transport Revisionapi-247243068Оценок пока нет

- The Journey of Boo PowerpointДокумент11 страницThe Journey of Boo Powerpointapi-247243068Оценок пока нет

- Welding Defects PraДокумент2 страницыWelding Defects PraEzhil Vendhan PalanisamyОценок пока нет

- Rollcage MaterialДокумент10 страницRollcage Materialhimanshu AroraОценок пока нет

- Durability Analysis Methodology Engine Valve 14Документ12 страницDurability Analysis Methodology Engine Valve 14myusernameatscribd100% (1)

- Rheed & Leed: Presented By-Mohammad Rameez Devika LaishramДокумент42 страницыRheed & Leed: Presented By-Mohammad Rameez Devika LaishramMohammad RameezОценок пока нет

- Lec 1 Stresses in Solid BodyДокумент36 страницLec 1 Stresses in Solid Bodyumair100% (1)

- Thermodynamics 8th TablesДокумент19 страницThermodynamics 8th Tablesusama.mОценок пока нет

- 9A01403 Structural Analysis - IДокумент4 страницы9A01403 Structural Analysis - IsivabharathamurthyОценок пока нет

- DCC 20053-Assignment 2 Set 1 Jun 2021Документ4 страницыDCC 20053-Assignment 2 Set 1 Jun 2021MUHAMMAD ANAS BIN MHD JELANIОценок пока нет

- Review On Jominy Test and Determination of Effect of Alloying On Hardenability of Steel Using Jominy End Quench Test Copyright Ijaet1Документ8 страницReview On Jominy Test and Determination of Effect of Alloying On Hardenability of Steel Using Jominy End Quench Test Copyright Ijaet1enrico susantoОценок пока нет

- E0018 - 08 - 21 HRCДокумент36 страницE0018 - 08 - 21 HRCServando LozanoОценок пока нет

- Axial Short Column DesignДокумент22 страницыAxial Short Column DesignNikhilОценок пока нет

- 7th International Conference on Materials Science and Engineering – BRAMAT 2011 ProgramДокумент27 страниц7th International Conference on Materials Science and Engineering – BRAMAT 2011 ProgramBarbinta Constantin100% (1)

- PA2200 Polyamide White PDFДокумент11 страницPA2200 Polyamide White PDFМихаилЖелтышевОценок пока нет

- Civ100 M5Документ80 страницCiv100 M5Anonymous WmMP8H6JGОценок пока нет

- Vehicle Crash Can FEA Model Simulation and Validation With Experiment Data NLENG.2014.0030.R1Документ19 страницVehicle Crash Can FEA Model Simulation and Validation With Experiment Data NLENG.2014.0030.R1rrmerlin_2Оценок пока нет

- Master in Nanoscience - High Electron Mobility Transistor (HEMT) Structure and Working PrincipleДокумент17 страницMaster in Nanoscience - High Electron Mobility Transistor (HEMT) Structure and Working PrincipleBhaswati ChakrabortyОценок пока нет

- 1 s2.0 S2288430016300343 MainДокумент7 страниц1 s2.0 S2288430016300343 MainArif KurniawanОценок пока нет

- Machine Design Problems SolvedДокумент5 страницMachine Design Problems SolvedNguyễn Thái Phương ThảoОценок пока нет

- Fracture in Fiber Reinforced Composite Material:Mathematical Models and Experimental MethodsДокумент54 страницыFracture in Fiber Reinforced Composite Material:Mathematical Models and Experimental MethodsSubayyal IlyasОценок пока нет

- Formulating Constitutive Stress-Strain Relations For Flexural Design of Ultra-High-Performance Fiber-Reinforced ConcreteДокумент9 страницFormulating Constitutive Stress-Strain Relations For Flexural Design of Ultra-High-Performance Fiber-Reinforced ConcreteShah Zaib FarooqОценок пока нет

- Rotary Friction Welding of Aluminium Using Lathe: Keywords: AbstractДокумент8 страницRotary Friction Welding of Aluminium Using Lathe: Keywords: AbstractAditya UОценок пока нет

- Dws Info Plain Carbon Steel SlicklineДокумент1 страницаDws Info Plain Carbon Steel Slicklineerwin atmadjaОценок пока нет

- In 738 Alloy Strain CharacteristicsДокумент7 страницIn 738 Alloy Strain CharacteristicsJJОценок пока нет

- BTD Module 2 Work and Heat PDFДокумент16 страницBTD Module 2 Work and Heat PDFAkshay ShettyОценок пока нет

- Nano TPFДокумент3 страницыNano TPFnithyanrajОценок пока нет

- Diagarama de Fase de Los CupratosДокумент97 страницDiagarama de Fase de Los CupratosjamesОценок пока нет