Академический Документы

Профессиональный Документы

Культура Документы

SI3540 User Manual

Загружено:

ramjoceАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

SI3540 User Manual

Загружено:

ramjoceАвторское право:

Доступные форматы

-1-

Hardware Manual

Si3540

Programmable St ep Mot or Driver

mot ors dri ves cont rol s

POWER

M

O

T

O

R

A

C

P

O

W

E

R

A+

A-

B+

B-

G

L

N

P

C

/

M

M

I

INPUT 1

INPUT 2

INPUT 3

INPUT 4

IN 5/JOG CW

IN 6 JOG CCW

INPUT COM

INPUT COM

CCW -

CCW +

CW +

CW -

OUT 1 +

OUT 1 -

OUT 2 +

OUT 2 -

OUT 3 +

OUT 3 -

L

I

M

I

T

S

S

i

3

5

4

0

P

r

o

g

r

a

m

m

a

b

l

e

S

t

e

p

M

o

t

o

r

D

r

i

v

e

r

-2-

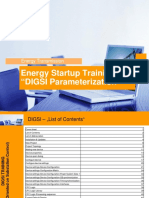

Introducti on - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3

Features - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3

Bl ock Di agram - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3

Getti ng Started - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4

Connecti ng the AC Li ne - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5

Connecti ng the Motor - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7

Connecti ng to the PC- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8

Joggi ng - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9

Li mi t Swi tches - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9

Wi ri ng a Mechani cal Li mi t Swi tch - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10

Wi ri ng a Li mi t Sensor - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10

Wi ri ng Inputs - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 11

Wi ri ng Outputs - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 13

Mi crosteppi ng - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 14

Mounti ng the Dri ve - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 15

Mounti ng the Opti onal MMI - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 15

Recommended Motors - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 17

Mechani cal Outl i ne - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 17

Techni cal Speci fi cati ons - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 18

Mechani cal Outl i ne - Opti onal MMI - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 19

Table of Cont ent s

-3-

MOSFET

3 State

PWM

Power

Amplifier

m

o

t

o

r

p

h

a

s

e

A

m

o

t

o

r

p

h

a

s

e

B

110 or

220 VAC

INPUT1

INPUT2

INPUT3

INPUT4

CW J OG/IN5

CCW J OG/IN6

to PC/MMI

CW LIMIT/IN7

CCW LIMIT/IN8

OUT1

OUT2

OUT3

RS232

Optical

Isolation

Microstepping

Indexer

Sequencer

eeprom

Optical

Isolation

Internal

Power

Supply

power LED

fuse

I ntroduction

Thank you for sel ecti ng an Appl i ed Moti on Products motor control . We hope our

dedi cati on to performance, qual i ty and economy wi l l make your moti on control

proj ect successful . If theres anythi ng we can do to i mprove our products or hel p

you use them better, pl ease cal l or fax. Wed l i ke to hear from you. Our phone

number i s (800) 525- 1609 or you can reach us by fax at (831) 761- 6544.

Features

Powerful , preci se and effi ci ent MOSFET dri ver provi di ng up to 3.5 amps per phase

and mi crosteppi ng to 50,800 steps per revol uti on.

Rel i abl e, effi ci ent, l ow noi se 40 VDC l i near, toroi dal power suppl y.

Powerful , fl exi bl e, easy to use i ndexer.

Connects by a si mpl e cabl e to your PC for programmi ng (cabl e i ncl uded).

Mi crosoft Wi ndows

TM

- based software for easy setup and programmi ng

Ei ght i nputs for i nteracti ng wi th the user and other equi pment.

Three outputs for coordi nati ng external equi pment.

Accepts 110 or 220 vol t AC power (factory preset for 110 vol ts).

External tri gger I/ O i s opti cal l y i sol ated, 5- 24V, si nki ng or sourci ng si gnal s. PC/

MMI port i s RS- 232.

Sturdy 2.25 x 7.8 x 5 i nch metal chassi s.

Pl uggabl e screw termi nal connectors for motor, AC power and I/ O si gnal s.

Opti onal man machi ne i nterface (MMI) al l ows operator to enter di stances, speeds,

cycl e counts and more.

CE and TUV Compl i ant

Block Diagram

Si

TM

-4-

Get t ing St art ed

To use your Si 3540 motor control , you wi l l need the fol l owi ng:

a power cabl e (l i ne cord)

a compati bl e step motor

a smal l fl at bl ade screwdri ver for ti ghteni ng the connectors - an Appl i ed Moti on

Products screwdri ver sui tabl e for thi s purpose i s i ncl uded wi th your dri ve.

a personal computer runni ng Wi ndows 3.1, 95, 98 or NT wi th a 9 pi n seri al port

(486 or better wi th 8 MB ram recommended)

the Si Programmer

TM

software that came wi th your Si 3540

the programmi ng cabl e that came wi th your Si 3540

Si Programmer

TM

software manual

The sketch bel ow shows where to fi nd the i mportant connecti on and adj ustment

poi nts. Pl ease exami ne i t now.

All Mating connectors included.

Al ways use the bl ue & whi te Appl i ed

Moti on screwdri ver wi th the above

I/ O connectors. Larger screwdri vers

may remove the pl asti c di mpl es that

prevent the screws from fal l i ng out.

POWER

M

O

T

O

R

A

C

P

O

W

E

R

A+

A-

B+

B-

G

L

N

P

C

/ M

M

I

INPUT 1

INPUT 2

INPUT 3

INPUT 4

IN 5 / JOG CW

IN 6 / JOG CCW

IN / JOG COM

IN / JOG COM

CCW -

CCW +

CW +

CW -

OUT 1 +

OUT 1 -

OUT 2 +

OUT 2 -

OUT 3 +

OUT 3 -

L

IM

IT

S

S

i

3

5

4

0

P

r

o

g

r

a

m

m

a

b

l

e

S

t

e

p

M

o

t

o

r

D

r

i

v

e

r

AC power

connector

Motor connector

RS232 connector

pc

mmi

I/O connector

outputs 1-3

I/O connector

cw, ccw limits

I/O connector

inputs 1-4

jog cw, ccw

Power LED

-5-

Connect ing t he AC Line

The Si 3540 i s set for 110 VAC operati on at the factory. If you use 110 VAC power,

al l you need to do i s i nstal l a power cord and pl ug i t i n. If you pl an to use 220

VAC power, fol l ow the i nstructi ons bel ow.

Note: If you pl an to hard wi re the Si 3540 to AC power, consul t a qual i fi ed el ectri -

ci an and observe al l bui l di ng and el ectri cal codes. AC power can be dangerous.

220 VAC Instructions

In order to use 220 vol ts, youl l need to change a fuse and a swi tch setti ng i nsi de

the case.

Remove al l mati ng connectors from the dri ve.

Set the dri ve on i ts wi dest si de, so that you can read Si3540 Programmable

St ep Mot or Driver properl y.

Remove the four (4) phi l l i ps head screws that mount the chassi s sheet metal to

the chassi s heat si nk. See page 17 for a mechani cal outl i ne of the dri ve.

The 110/ 220 swi tch i s l ocated near the posi ti on of the AC power connector, next

to the toroi dal transformer (see sketch bel ow).

For 220 VAC operati on sl i de the swi tch towards the bottom of the dri ve, or

towards the transformer end of the dri ve. The posi ti on of the swi tch i s l abel ed on

the PC board al so, 230 bei ng for 200- 240 VAC operati on, and 115 for 100- 120

VAC operati on.

Repl ace the fuse next to the swi tch wi th the 220 VAC fuse that came wi th the

dri ve. See techni cal speci fi cati ons on page 18 to order more fuses.

Repl ace the dri ves cover and assembl y screws.

2

3

0

1

1

5

S

W

1

C

N

1

PC Board

AC Power

Connector

Fuse

110/220 VAC

Switch

Swi tch set for 110 VAC

2

3

0

1

1

5

S

W

1

C

N

1

Swi tch set for 220 VAC

-6-

Installing an AC Line Cord

Remove about 5 mm (3/ 16 i nces) of i nsul ati on from each of the three wi res of your

l i ne cord. (Thats ri ght, three wi res. For safety, al ways use a three wi re power cord

on anythi ng wi th a metal case). dependi ng on where you got your power cord, i t

may have bl ack, whi te and green wi res, or brown, whi te and green wi res.

The AC power pl ug that was shi pped wi th your Si 3540 mi ght be one of two types.

The ol d styl e i s shown bel ow, on the l eft. The new styl e , whi ch comes wi th an

i nsul ati ng rubber boot, i s shown bel ow, on the ri ght.

Make sure you follow the proper sketch for your connector style.

Always unplug the line cord from the wall before attaching

it to the Si3540.

Connect the bl ack or brown wi re to the Si 3540 L termi nal of the AC power

connector. That i s the l i ne, or hot connecti on.

Connect the wi te or bl ue wi re to neutral , the N termi nal .

Fi nal l y, and most i mportantl y, connect the green wi re to the GND termi nal . That

connects the Si 3540 metal encl osure and DC power suppl y ground to earth ground.

!

k c a l b

e t i h w

n e e r g

To Earth Ground

To Neutral

To Li ne (Hot)

To Earth Ground

To Neutral

To Li ne (Hot)

green

bl ack or brown

w

hi t e or bl ue

"Old Style"

AC Power Plug

"New Style"

AC Power Plug

-7-

Connect ing t he Mot or

Never connect or disconnect the motor to the driver when the AC

power is on.

Secure any unused motor leads.

Never disconnect the motor while the AC power is on.

Never connect motor leads to ground or to a power supply.

You must now deci de how to connect your

motor to the dri ve.

Four lead motors can onl y be connected

one way. Pl ease fol l ow the sketch at the

ri ght.

Six lead motors can be connected i n seri es or center tap. In seri es mode, motors

produce more torque at l ow speeds, but cannot run as fast as i n the center tap

confi gurati on. In seri es operati on, the motor shoul d be operated at 30% l ess than

the rated current to prevent overheati ng. Wi ri ng di agrams for both connecti on

methods are shown bel ow.

!

Note: NC means not connected to anythi ng.

A+

A

B+ B

4

lead

motor

Red

Blue

Yellow White

4 Leads

A+

A

NC

B+ B NC

6

lead

motor

Red

Black

Red/

Wht

Green

Grn/Wht

White

A+

A

NC

B+ B NC

6

lead

motor

Grn/Wht

White

Green

Red

Red/

Wht

Black

6 Leads Series Connected 6 Leads Center Tap Connected

-8-

Connect ing t o t he PC

Locate your computer wi thi n 6 feet of the Si 3540.

Your Si 3540 was shi pped wi th a bl ack adapter pl ug. It has a tel ephone styl e j ack

at one end and a l arger 9 pi n connector at the other. Pl ug the l arge end i nto the

COM1 seri al port of your PC. Secure the adapter wi th the screws on the si des. If

the COM1 port on your PC i s al ready used by somethi ng el se, you may use the

COM2 port for the Si 3540. On some PCs, COM2 wi l l have a 25 pi n connector that

does not fi t the bl ack adapter pl ug. If thi s i s the case, and you must use COM2,

you may have to purchase a 25 to 9 pi n seri al adapter at your l ocal computer store.

Your Si 3540 was al so shi pped wi th a 7 foot tel ephone l i ne cord. Pl ug one end

i nto the adapter we j ust attached to your PC, and the other end i nto the PC/ MMI

j ack on your Si 3540.

Never connect the Si3540 to a telephone circuit. It uses the

same connectors and cords as telephones and modems, but the

voltages are not compatible.

Programmi ng Note: Al ways appl y power to the Si 3540 after the Si

TM

Programmer

software i s runni ng on your PC.

A+

A

B+ B

8

lead

motor

8 Leads Series Connected 8 Leads Parallel Connected

A+

A

B+

B

8

lead

motor

Orange

Org/Wht

Blk/Wht

Black

Red Red/

Wht

Yel/

Wht

Yellow

Orange

Org/

Wht

Blk/Wht

Black

Red

Red/Wht

Yel/

Wht

Yel

low

Ei ght l ead mot ors can al so be connected i n two ways: seri es and paral l el . As

wi th si x l ead motors, seri es operati on gi ves you more torque at l ow speeds and l ess

torque at hi gh speeds. In seri es operati on, the motor shoul d be operated at 30%

l ess than the rated current to prevent overheati ng. The wi ri ng di agrams for ei ght

l ead motors are shown bel ow.

!

-9-

Limit Swit ches

The Si 3540 has two l i mi t swi tch i nputs, LIMIT CW and LIMIT CCW. By connect-

i ng swi tches or sensors that are tri ggered by the moti on of the motor or l oad, you

can force the Si 3540 to operate wi thi n certai n l i mi ts. Thi s i s useful i f a program

error coul d cause damage to your system by travel i ng too far.

The l i mi t i nputs are opti cal l y i sol ated. Thi s al l ows you to choose a vol tage for your

l i mi t ci rcui ts of 5 to 24 vol ts DC. Thi s al so al l ows you to have l ong wi res on l i mi t

sensors that may be far from the Si 3540 wi th l ess ri sk of i ntoduci ng noi se to the

Si 3540. The schemati c di agram of the l i mi t swi tch i nput ci rcui t i s shown bel ow.

2200

2200

inside Si3540

COM

CWJOG

CCWJOG

+

5-24

VDC

SUPPLY

-

Si3540

Controller

Chip

2200

10K

+5V +5V

3

4

1

2

CW LIMIT+

CW LIMIT

CCW LIMIT+

CCW LIMIT

TLP621 or

NEC PS2501

inside Si3540

Jogging

Two of the Si 3540 i nput termi nal s are provi ded for j oggi ng the motor. The i nputs

are l abel ed JOG CW and JOG CCW . Acti vati ng one of the i nputs commands the

dri ve to move the motor at a pre- desi gnated speed unti l the contact i s opened. A

rel ay or mechani cal swi tch can be used to acti vate the j og i nputs. 5- 24 vol t ci r-

cui try can be used. The schemati c di agram of the i nput ci rcui t i s shown bel ow.

If youre usi ng a swi tch or rel ay, wi re one end to the JOG i nput and the other to the

power suppl y negati ve (- ) termi nal . Then connect the COM i nput to the power

suppl y posi ti ve (+) termi nal s.

-10-

If the sensor output goes l ow at the l i mi t, sel ect the opti on cl osed . If the output

i s open, or hi gh vol tage, choose open .

Other sensors have sourcing outputs. That means that current can fl ow out of the

sensor output, but not i nto i t. In that case, wi re the sensor thi s way:

If the sensor output goes hi gh at the l i mi t, choose the program opti on cl osed . i f

the output i s l ow at the l i mi t, sel ect open .

Si3540

CCW LIMIT+

CCW LIMIT-

CW LIMIT-

+

5-24

VDC

SUPPLY

-

CW LIMIT+

Si3540

CW LIMIT-

+

DC

Power

Supply

Limit

Sensor

CW LIMIT+

output

+

Si3540

LIMIT-

+

DC

Power

Supply

Proximity

Sensor

LIMIT+

output

+

Wiring a Mechanical Limit Swit ch

You can use normal l y open or normal l y cl osed l i mi t swi tches. Ei ther way, wi re

them as shown here.

Wiring a Limit Sensor

Some systems use acti ve l i mi t sensors that produce a vol tage output rather than a

swi tch or rel ay cl osure. These devi ces must be wi red di fferentl y than swi tches.

If your sensor has an open col l ector output or a si nki ng output, wi re i t l i ke thi s:

Wiring for Sinking or Open Collector Output

Wiring for Sourcing Output

-11-

Wiring I nput s

The Si 3540 i nput ci rcui ts can be used wi th

sourci ng or si nki ng si gnal s, 5 to 24 vol ts.

Thi s al l ows connecti on to TTL ci rcui ts,

PLCs, rel ays and mechani cal swi tches.

Because the i nput ci rcui ts are i sol ated, they

requi re a source of power. If you are con-

necti ng to a TTL ci rcui t or to a PLC, you

shoul d be abl e to get power from the PLC or

TTL power suppl y. If you are usi ng rel ays or

mechani cal swi tches, you wi l l need a 5- 24

power suppl y. Thi s al so appl i es i f you are

connecti ng the Si 3540 i nputs to another Si

product from Appl i ed Moti on, l i ke the Si - 1

and Si - 100 i ndexers or the Si 5580, 7080i

and MC8400 i ndexer- dri ves.

Connecti ng an Input to a Swi tch or Rel ay Connecti ng an Input to a Swi tch or Rel ay Connecti ng an Input to a Swi tch or Rel ay Connecti ng an Input to a Swi tch or Rel ay Connecti ng an Input to a Swi tch or Rel ay

Use normal l y open momentary swi tch to tri gger Si 3540 usi ng Wai t Input i nstructi on.

Use si ngl e throw swi tch for parameter sel ecti on usi ng If Input i nstructi on.

Use normal l y open momentary swi tch for j oggi ng.

2200

2200

2200

2200

2200

2200

inside Si3540

COM

COM

COM

IN1

IN2

IN3

IN4

CWJOG

CCWJOG

Si3540

switch or relay

(closed=logic low)

IN

COM

5-24

VDC

Power

Supply -

+

Note: If current i s fl owi ng i nto or out of an Si 3540 i nput, the l ogi c state of that

i nput i s l ow. If no current i s fl owi ng, or the i nput i s not connected, the l ogi c state

i s hi gh.

The di agrams on the fol l owi ng pages show how to connect Si 3540 i nputs to vari ous

devi ces.

The maximum voltage that can be applied to an input terminal is

24 volts DC. Never apply AC voltage to an input terminal. !

-12-

Connecting an Input to the Si-1 Motion Output

(Set Si - 1 moti on si gnal to i n posi ti on . Si - 1 wi l l tri gger Si 3540 at end of each move).

Connecting a 3540i, Si5580, 7080i or MC8400

(When output cl oses, Si 3540 i nput goes l ow).

Connect i ng an NPN Type Proxi mi t y Sensor t o an Si 3540 i nput

(When prox sensor acti vates, Si 3540 i nput goes l ow).

Connecting a PNP Type Proximity Sensor to an Si3540 input

(When prox sensor acti vates, Si 3540 i nput goes l ow).

S

i

3

5

4

0 IN

IN/J OG COM

S

I

-

1

i

n

d

e

x

e

r

MOTION+

MOTION

5-24

VDC

Power

Supply

-

+

S

i

3

5

4

0 IN

COM

S

i

5

5

8

0

,

7

0

8

0

i

o

r

M

C

8

4

0

0

OUT+

OUT

5-24

VDC

Power

Supply

-

+

Si3540

NPN

Proximity

Sensor

IN

COM

output

+

5-24

VDC

Power

Supply

-

+

NPN

Proximity

Sensor

IN

COM

output

+

5-24

VDC

Power

Supply

-

+

Si3540

PNP

Proximity

Sensor

IN

output

+

COM

5-24

VDC

Power

Supply

-

+

PNP

Proximity

Sensor

IN

output

+

COM

5-24

VDC

Power

Supply

-

+

-13-

Wiring Out put s

Before we di scuss the output condi ti ons, we need to tal k about the ci rcui try. Al l

three Si 3540 outputs are opti cal l y i sol ated. That means that there i s no el ectri cal

connecti on between the i ndexer- dri ve and the output termi nal s. The si gnal i s

transmi tted to the output as l i ght. What you see i s a transi stor (NPN type) that

cl oses, or conducts current, when the output i s l ow . When the output i s hi gh, the

transi stor i s open.

Note: At power- up, the Si 3540 sets al l three programmabl e outputs hi gh (open

ci rcui t).

Si nce there i s no el ectri cal conneci ton to the Si 3540, you must provi de the source

of current and vol tage, typi cal l y from a power suppl y. You must al so l i mi t the

current to l ess than 100 mA so that the output transi stor i s not damaged. You

woul d normal l y use a resi stor for thi s, but some l oads (such as PLC i nputs) l i mi t

the current automati cal l y.

The di agram bel ow shows how to connect an Si 3540 output to an opti cal l y i sol ated

PLC i nput.

Schematic Diagram of Si3540 Output Circuit

PLC

COMMON

INPUT

Si3540

OUTPUT-

OUTPUT+

12-24 VDC

Power Supply

+

330

+5V

OUT1

OUT1+

Optoisolator

NEC PS2502

or equiv.

Si3540

Controller Chip

inside Si3540

The maximum voltage between any pair of + and - output

terminals is 24 volts DC. Never connect AC voltages to the

Si3540 output terminals. Maximum current is 100 mA per

output.

!

-14-

Microstepping

Most step motor dri ves offer a choi ce between ful l step and hal f step resol uti ons.

In ful l step mode, both motor phases are used al l the ti me. Hal f steppi ng di vi des

each step i nto two smal l er steps by al ternati ng between both phases on and one

phase on.

Mi crosteppi ng dri ves l i ke the Si 3540 preci sel y control the amount of current i n each

phase at each step posi ti on as a means of el ectroni cal l y subdi vi di ng the steps even

further. The Si 3540 offers a choi ce of 13 step resol uti ons. The hi ghest setti ng

di vi des each ful l step i nto 254 mi crosteps, provi di ng 50,800 steps per revol uti on

when usi ng a 1.8 motor.

In addi ti on to provi di ng preci se posi ti oni ng and smooth moti on, mi crostep dri ves

can be used for moti on conversi on between di fferent uni ts. The 25,400 step/ rev

setti ng i s provded as a means of converti ng moti on from metri c to engl i sh (there are

25.4 mm i n an i nch). Other setti ngs provi de step angl es that are deci mal degrees

(36,000 steps/ rev makes the motor take 0.01 steps). Some setti ngs are used wi th

l ead screws. When the dri ve i s set to 2000 steps/ rev and used wi th a 0.2 pi tch l ead

screw, you get 0.0001 i nches/ step.

The mi crostep resol uti on of the Si 3540 i s set by the Si Programmer

TM

software.

-15-

Mount ing t he Drive.

You can mount your dri ve on the wi de or the narrow si de of the chassi s.

Mount ing t he Opt ional MMI

There are two ways to mount the MMI i n your appl i cati on. No matter whi ch method

you choose, youl l need to connect the MMI to your Si 3540 wi th the programmi ng

cabl e. You wi l l not, however, need the adapter pl ug. The MMI has the same

tel ephone styl e connector as the Si 3540.

Dependi ng on how you mount the MMI and cabl e i n your appl i cati on, you may fi nd

that i t i s di ffi cul t to remove the cabl e from the back of the MMI. If thi s i s the case,

and you need to reprogram the Si 3540, you can use any tel ephone l i ne cord as a

programmi ng cabl e. They are avai l abl e at most supermarkets and di scount stores.

Pl eae be careful not to l ose the adapter pl ug that connects the tel ephone cord to the

COM port of your PC. The adapter i s a custom made part and i s onl y avai l abl e

from Appl i ed Moti on.

Use for NARROW-SIDE

mounting.

Use for WIDE-SIDE

mounting.

Never use your drive in a space where there is no air flow or

where the ambient temperature exceeds 50C (120F).

Never put the drive where it can get wet.

Never allow metal particles near the drive.

!

-16-

Flush Mounting

When you remove the MMI from the shi ppi ng carton, you wi l l noti ce that i t has two

parts. The fi rst i s a fai rl y thi n secti on that contai ns the keypad, di spl ay and some

ci rcui t boards. The other part i s thi cker and contai ns the tel ephone j ack and a cabl e

that connects to the keypad assembl y.

When you fl ush mount the MMI i n a

panel , onl y the thi n secti on wi l l sti ck out

from your panel - the l arge porti on mounts

behi nd your panel . Youl l need to cut a

preci se secti on from your panel . There i s

a cardboard templ ate i n the MMIs

shi ppi ng box for thi s purpose.

If you want the MMI to be dust proof and

waterti ght, you must pl ace the bl ack

rubber gasket between the thi n part of the

MMI and your panel . Assembl e the two

hal ves usi ng the ei ght smal l screws

provi ded.

Surface Mounting

An easi er way to mount the MMI i s to bol t the two hal ves together ahead of ti me,

usi ng the ei ght smal l screws. If you want the MMI to be dust proof and waterti ght,

put the bl ack rubber gasket between the two hal ves before screwi ng them together.

Then cut a hol e i n your panel for the cabl e

that runs between the MMI and the

Si 3540. The hol e must be at l east 5/ 8 i n

di ameter for the connector to fi t thorugh.

You wi l l al so need two hol es that l i ne up

wi th the bi g mounti ng hol es i n the MMI.

The mechani cal outl i ne on page 19 shows

the l ocati on of the bi g mounti ng hol es.

When you mount the MMI to your panel ,

you wi l l need to use some ki nd of seal ant

to keep dust and l i qui d out. Si l i cone or

l atex caul ki ng i s okay, or you can make

your own gasket from a sheet of compl i ant

materi al l i ke rubber or RTV.

1

2

3

4

5

6

7

8

9

YES

NO

.

0

SPACE

BKSP

ENTER

panel

MMI

(front section

and gasket)

MMI

(rear section)

1

2

3

4

5

6

7

8

9

YES

NO

.

0

SPACE

BKSP

ENTER

panel

sealant (not included)

MMI

gasket

(included)

-17-

Motor Size Winding Max Torque Current

Number inches Connection oz-in Amps

5014- 842 1.38 x 1.38 x 1.57 4 l ead 19 1.0

HT17- 068 1.65 x 1.65 x 1.30 paral l el 23 1.0

HT17- 071 1.65 x 1.65 x 1.54 paral l el 30 1.25

HT17- 075 1.65 x 1.65 x 1.85 paral l el 40 1.7

5023- 122 2.22 x 2.22 x 2.0 paral l el 60 2.0

5023- 123 2.22 x 2.22 x 3.0 paral l el 100 2.5

5023- 124 2.22 x 2.22 x 4.0 paral l el 150 3.5

HT23- 394 2.22 x 2.22 x 1.54 paral l el 60 2.8

HT23- 397 2.22 x 2.22 x 2.13 paral l el 140 2.8

HT23- 400 2.22 x 2.22 x 2.99 paral l el 180 2.0

5034- 348 3.38 x 3.38 x 2.50 paral l el 130 3.5

Recommended Motors

Mechanical Outline

7.80"

2.25"

1.125" 0.750" 0.750"

5.00"

5.40"

POWER

M

O

T

O

R

A

C

P

O

W

E

R

A+

A-

B+

B-

G

L

N

P

C

/ M

M

I

INPUT 1

INPUT 2

INPUT 3

INPUT 4

IN 5 / JOG CW

IN 6 / JOG CCW

IN / JOG COM

IN / JOG COM

CCW -

CCW +

CW +

CW -

OUT 1 +

OUT 1 -

OUT 2 +

OUT 2 -

OUT 3 +

OUT 3 -

L

IM

IT

S

S

i

3

5

4

0

P

r

o

g

r

a

m

m

a

b

l

e

S

t

e

p

M

o

t

o

r

D

r

i

v

e

r

-18-

Ampl i f i ers

Power Suppl y

I nput s

Out put s

Mi crost eppi ng

Mot i on Updat e

Physi cal

Connect ors

Agency

Approval s

Fuses

Dual , MOSFET H- bri dge, 3 state, pul se wi dth modul ated (PWM)

swi tchi ng at 20 kHz. 0.2 - 3.5 amps/ phase output current, software

sel ectabl e. 122 watts maxi mum output power. Automati c i dl e current

reducti on (software programmabl e) reduces current to motor when

i dl e. Mi ni mum motor i nductance i s 0.8 mH.

Li near, toroi dal transformer based for hi gh rel i abi l i ty and l ow noi se.

100- 120 or 200- 240 VAC i nput, swi tch sel ectabl e. 50/ 60 Hz. DC

vol tage at nomi nal l i ne vol tage: 35 VDC ful l l oad, 40 VDC no l oad.

5 - 24 VDC, opti cal l y i sol ated. 2200 ohms i nternal resi stance. Can be

confi gured for si nki ng (NPN) or sourci ng (PNP) si gnal s.

Opti cal l y i sol ated. 12- 24 VDC, 100 mA max.

13 software sel ectabl e resol uti ons. Steps per revol uti on wi th 1.8

motor: 2000, 5000, 10000, 12800, 18000, 20000, 21600, 25000,

25400, 25600, 36000, 50000, 50800. Waveform: pure si ne.

12800 Hz.

Constructed wi th bl ack anodi zed al umi num heat si nk and heavy

gauge steel housi ng. 2.25 x 5.40 x 7.80 i nches overal l . 4.0 l bs. 0 to

50C ambi ent operati ng temperature. See page 17 for detai l ed

drawi ng.

European styl e, pl uggabl e screw termi nal bl ocks. Motor: 4 posi ti on

(A+, A- , B+, B- ). Si gnal Input/ Output: 18 posi ti on (8 i nput, 6 output,

4 l i mi t). AC i nput: 3 posi ti on (L, N, G).

CE (compl i es wi th EN55011A, EN50082- 1(1997), EN50178(1997))

and TUV.

Wi ckman TR- 5 styl e. Order from Di gi key (1- 800- DIGIKEY).

110V: P/ N WK4250BK- ND (T 1.25 A IEC)

220V: P/ N WK4243BK- ND (T O.63 A IEC).

Technical Specifications

-19-

Mechanical Out line - Opt ional MMI

4

.

9

0

4

.

9

0

1

.

3

8

0

.

1

3

3

.

8

7

5

C

E

N

T

E

R

E

D

3

.

8

7

5

C

E

N

T

E

R

E

D

1

2

3

4

5

6

7

8

9

Y

E

S

N

O

.

0

S

P

A

C

E

B

K

S

P

E

N

T

E

R

2

.

9

8

8

1

.

9

7

5

0

.

4

2

5

0

.

9

6

3

0

.

9

6

0

-20-

Applied Mot ion Product s, I nc.

404 Westri dge Dri ve Watsonvi l l e, CA 95076

Tel (831) 761- 6555 (800) 525- 1609 Fax (831)- 761- 6544

http:/ / www.appl i ed- moti on.com

Copyri ght 1999

11/2/99

Вам также может понравиться

- Cardinal 205 y 210 ManualДокумент56 страницCardinal 205 y 210 ManualOmar Glez100% (3)

- ST330 Stepper Motor Driver Board User ManualДокумент13 страницST330 Stepper Motor Driver Board User ManualEsteban CarrilloОценок пока нет

- Protex-Max Pd8-154 & 158 Annunciators: Instruction ManualДокумент40 страницProtex-Max Pd8-154 & 158 Annunciators: Instruction ManualWilmer Andres Sanchez RinconОценок пока нет

- GF8100 A eДокумент54 страницыGF8100 A eZOTACОценок пока нет

- ENODE Distributed IO Controller Operations Manual 1000003483 RevRДокумент83 страницыENODE Distributed IO Controller Operations Manual 1000003483 RevRMUzair5100% (1)

- Olefins-All Product CatalogДокумент28 страницOlefins-All Product Catalogayon_hossen242Оценок пока нет

- Sa Max700 PDFДокумент124 страницыSa Max700 PDFAngeler Jp100% (1)

- CFAF320480C5 035T TS - Datasheet - Release - 2016 09 15Документ22 страницыCFAF320480C5 035T TS - Datasheet - Release - 2016 09 15Kristine GonzalezОценок пока нет

- Panasonic+SA-MAX5000PN MAX5000PSДокумент85 страницPanasonic+SA-MAX5000PN MAX5000PSMario MotaОценок пока нет

- Panasonic Sa Akx56gn Psg1304028ce Printdb PDFДокумент99 страницPanasonic Sa Akx56gn Psg1304028ce Printdb PDFRoberoОценок пока нет

- Brainchild VR18 ManualДокумент96 страницBrainchild VR18 ManualKerwin GrapaОценок пока нет

- SC Akx8Документ70 страницSC Akx8Maximiliano rodriguezОценок пока нет

- DCD300 ServoamplifierДокумент31 страницаDCD300 ServoamplifierPaun Al100% (1)

- Senstar100 Product Guide Installation - J2DA0102 ENДокумент128 страницSenstar100 Product Guide Installation - J2DA0102 ENjeanyoperОценок пока нет

- Saakx 18 PHДокумент68 страницSaakx 18 PHKarina GonzalezОценок пока нет

- Beginner - Guide PLC ControllerДокумент255 страницBeginner - Guide PLC ControllerLuís Ki-llahОценок пока нет

- Quick Setup Guide Weight Indicator InstrumentДокумент40 страницQuick Setup Guide Weight Indicator InstrumentKhurram Shahzad100% (3)

- Paperless Recorder Model VR-18 ManualДокумент91 страницаPaperless Recorder Model VR-18 Manualata03003993360Оценок пока нет

- Panasonic Sa-Pt470Документ154 страницыPanasonic Sa-Pt470videoson100% (5)

- Manual ZotacДокумент50 страницManual ZotacJose Patricio Torres ContrerasОценок пока нет

- WK 2402Документ16 страницWK 2402spagmonstaОценок пока нет

- 205 Weight Indicator Installation ManualДокумент58 страниц205 Weight Indicator Installation ManualaswinraveendranОценок пока нет

- Yokogawa YPP6210 ManualДокумент104 страницыYokogawa YPP6210 ManualAhmadrazatahirОценок пока нет

- (01-04-2014-TM-5402HD M3 CI Super+ - Manual - English+franch - UK - Rev1.0 PDFДокумент132 страницы(01-04-2014-TM-5402HD M3 CI Super+ - Manual - English+franch - UK - Rev1.0 PDFJohnWilliamsОценок пока нет

- (Ebook) PLC Beginner Guide (OMRON CPM1A)Документ306 страниц(Ebook) PLC Beginner Guide (OMRON CPM1A)Vicente Tan100% (1)

- Arcsin: 3-Axis Bipolar Micro-Stepping Motor Driver With Integrated Digital Joystick ControlДокумент27 страницArcsin: 3-Axis Bipolar Micro-Stepping Motor Driver With Integrated Digital Joystick ControlNugraha IndrawanОценок пока нет

- Manual of Jupiter Drive V.01Документ137 страницManual of Jupiter Drive V.01Tee Kok ShengОценок пока нет

- Chinese Instruction For SERVO DRIVERДокумент58 страницChinese Instruction For SERVO DRIVERhassems100% (1)

- Jupiter DriveДокумент138 страницJupiter DriveTee Kok ShengОценок пока нет

- 3540i Hardware ManualДокумент14 страниц3540i Hardware ManualRicardo PossebonОценок пока нет

- Panasonic SC-AKX36Документ90 страницPanasonic SC-AKX36Nan NanОценок пока нет

- Welch Allyn Sloartec 100 Sevice Manual GSCE03622Документ56 страницWelch Allyn Sloartec 100 Sevice Manual GSCE03622Carlos Noe Livia PomaОценок пока нет

- Panasonic SAPM-24-EB Service ManualДокумент99 страницPanasonic SAPM-24-EB Service ManualTibor NagyОценок пока нет

- SA-BTT350P SA-BTT750P: Blu-Ray Disc Home Theater Sound SystemДокумент149 страницSA-BTT350P SA-BTT750P: Blu-Ray Disc Home Theater Sound SystemValentin SivrievОценок пока нет

- Precision Digital pd6000 ManualДокумент50 страницPrecision Digital pd6000 ManualOlumide OyetokeОценок пока нет

- Quick Setup Guide for Weight Indicating InstrumentДокумент32 страницыQuick Setup Guide for Weight Indicating InstrumentCeleynes RTОценок пока нет

- Panasonic Sa-Pm500dbebДокумент121 страницаPanasonic Sa-Pm500dbebDavidОценок пока нет

- SA-PMX100EG: CD Stereo SystemДокумент74 страницыSA-PMX100EG: CD Stereo SystemTại TâmОценок пока нет

- NN-ST342 PanasonicДокумент40 страницNN-ST342 PanasonicBaloncesto Usuluteco100% (1)

- Vfd150c43a ManualДокумент458 страницVfd150c43a Manualhau100% (2)

- AVIN Android 4.1.1 Operating Manual - 01!07!2015Документ25 страницAVIN Android 4.1.1 Operating Manual - 01!07!2015ETRIОценок пока нет

- S4000 NetworkInstallationДокумент45 страницS4000 NetworkInstallationArtan MucaОценок пока нет

- Panasonic Sa Akx600pn Sa Akx800psДокумент79 страницPanasonic Sa Akx600pn Sa Akx800psLucas CarrizoОценок пока нет

- PLC 1SXU127010C0202-Section A PDFДокумент114 страницPLC 1SXU127010C0202-Section A PDFAng RicardoОценок пока нет

- Installation & Operating Instructions: Remote Monitoring GSM/SMS Communicating Wireless Alarm SystemДокумент29 страницInstallation & Operating Instructions: Remote Monitoring GSM/SMS Communicating Wireless Alarm SystemAldo BusuttilОценок пока нет

- Sa Max750phДокумент121 страницаSa Max750phMaria de Guerrero100% (1)

- Sa-Akx12Ph Sa-Akx12Pn: CD Stereo SystemДокумент110 страницSa-Akx12Ph Sa-Akx12Pn: CD Stereo SystemGerardo RodriguezОценок пока нет

- MS - SC Akx12lb KДокумент121 страницаMS - SC Akx12lb KCarlos ZavarceОценок пока нет

- Usrman002401 Leotrak User Manual LowresДокумент56 страницUsrman002401 Leotrak User Manual LowresDave OMОценок пока нет

- Sa-Akx36Ph Sa-Akx36Pn: CD Stereo SystemДокумент90 страницSa-Akx36Ph Sa-Akx36Pn: CD Stereo SystemEdwin BerruetaОценок пока нет

- 4188 856 PDFДокумент186 страниц4188 856 PDFshahbazalam4a550% (2)

- MA7200 Installation ManualДокумент169 страницMA7200 Installation ManualWilmer AlegriaОценок пока нет

- Ka 100Документ46 страницKa 100sindaelОценок пока нет

- Sky 301vsДокумент4 страницыSky 301vsSazzad Hossan RaselОценок пока нет

- Omron PLC Beginner GuideДокумент254 страницыOmron PLC Beginner GuideTrịnh Quang100% (6)

- Radio Shack TRS-80 Expansion Interface: Operator's Manual: Catalog Numbers: 26-1140, 26-1141, 26-1142От EverandRadio Shack TRS-80 Expansion Interface: Operator's Manual: Catalog Numbers: 26-1140, 26-1141, 26-1142Оценок пока нет

- WAN TECHNOLOGY FRAME-RELAY: An Expert's Handbook of Navigating Frame Relay NetworksОт EverandWAN TECHNOLOGY FRAME-RELAY: An Expert's Handbook of Navigating Frame Relay NetworksОценок пока нет

- 1A Low Dropout Voltage Regulator DatasheetДокумент8 страниц1A Low Dropout Voltage Regulator DatasheetMauricio Raul RotmanОценок пока нет

- CNCProДокумент94 страницыCNCProramjoceОценок пока нет

- Keyence LKДокумент20 страницKeyence LKramjoceОценок пока нет

- Bending ShapesДокумент4 страницыBending ShapesramjoceОценок пока нет

- MP40 Rubber Band Gun PDFДокумент16 страницMP40 Rubber Band Gun PDFramjoce80% (56)

- L96A1 Sniper Rifle PDFДокумент44 страницыL96A1 Sniper Rifle PDFramjoce33% (3)

- RBguns YouTube Channel HomepageДокумент17 страницRBguns YouTube Channel HomepageDavid ExfannyОценок пока нет

- DeerДокумент2 страницыDeerramjoceОценок пока нет

- Rapid 2010 Presentation - Automated Low Cost 3D ScanningДокумент34 страницыRapid 2010 Presentation - Automated Low Cost 3D Scanning3D3 SolutionsОценок пока нет

- Press Brake PlansДокумент4 страницыPress Brake PlansMeme Here100% (1)

- Sheet Metal BenderДокумент11 страницSheet Metal BenderramjoceОценок пока нет

- Daves Brake PlansДокумент11 страницDaves Brake PlansramjoceОценок пока нет

- Press Brake PlansДокумент4 страницыPress Brake PlansMeme Here100% (1)

- How to Calculate Bend Allowance for Press BrakeДокумент3 страницыHow to Calculate Bend Allowance for Press BrakedarkomaОценок пока нет

- Add On Stepper Board TextДокумент2 страницыAdd On Stepper Board TextramjoceОценок пока нет

- Strictlyic IndexДокумент27 страницStrictlyic IndexramjoceОценок пока нет

- Amplifier Clss DДокумент169 страницAmplifier Clss DJuan Carlos ItriagoОценок пока нет

- Troubleshooting MicrowaveДокумент96 страницTroubleshooting Microwaveramjoce0% (1)

- Fr5 300 ManualДокумент18 страницFr5 300 ManualramjoceОценок пока нет

- Fr5 300 ManualДокумент18 страницFr5 300 ManualramjoceОценок пока нет

- B00009oyh5 ManualДокумент72 страницыB00009oyh5 ManualramjoceОценок пока нет

- Fender BassmanДокумент2 страницыFender BassmanramjoceОценок пока нет

- Design A Radial EngineДокумент88 страницDesign A Radial Engineİsmet SezerОценок пока нет

- SpeakerДокумент4 страницыSpeakerramjoceОценок пока нет

- Yamaha P2250Документ44 страницыYamaha P2250ramjoceОценок пока нет

- 9412Документ31 страница9412ramjoceОценок пока нет

- TFM 15cb ServiceДокумент19 страницTFM 15cb ServiceramjoceОценок пока нет

- Basic 40 ManualДокумент4 страницыBasic 40 ManualramjoceОценок пока нет

- 2205 Elwood N-Series Cut SheetДокумент2 страницы2205 Elwood N-Series Cut SheetramjoceОценок пока нет

- Edge Slayer Series ShredderДокумент16 страницEdge Slayer Series ShredderKshitiz MittalОценок пока нет

- DIGSI ParameterizationДокумент46 страницDIGSI ParameterizationДмитрОценок пока нет

- Fujifilm VP 7000 BRДокумент8 страницFujifilm VP 7000 BRMoosa QamarОценок пока нет

- IOT Early Flood Detection & AvoidanceДокумент3 страницыIOT Early Flood Detection & AvoidancesanjayshelarОценок пока нет

- V81-AG RACK Controller ManualДокумент116 страницV81-AG RACK Controller ManualsinytellsОценок пока нет

- Operating Guide: DCR-DVD106E/DVD108E/ DVD109E/DVD306E/DVD308E/ DVD608E/DVD708EДокумент123 страницыOperating Guide: DCR-DVD106E/DVD108E/ DVD109E/DVD306E/DVD308E/ DVD608E/DVD708ELuis AlbertoОценок пока нет

- Epson R220-R230 ServiceДокумент117 страницEpson R220-R230 ServiceJack Aillon50% (2)

- QA Engineer Naresh Kumar resumeДокумент4 страницыQA Engineer Naresh Kumar resumeVarma DuvvaОценок пока нет

- m161 PDFДокумент260 страницm161 PDFMihai PopescuОценок пока нет

- Academy - Rewa.tech: Abbrev. MeaningДокумент2 страницыAcademy - Rewa.tech: Abbrev. MeaningАзери ПрограммистОценок пока нет

- Fluke 1650B Series: Multifunction Installation TestersДокумент10 страницFluke 1650B Series: Multifunction Installation TestersWasinchai KanjanapanОценок пока нет

- TG 389 AcДокумент74 страницыTG 389 Acsean_goh_8Оценок пока нет

- Noren Products BrochureДокумент2 страницыNoren Products BrochureQuantumAutomationОценок пока нет

- Secureusa Product Brochure Perimeter Defence BarriersДокумент20 страницSecureusa Product Brochure Perimeter Defence BarriersRedОценок пока нет

- EXM Serie Installation Guide Rev M Ver 1 34Документ60 страницEXM Serie Installation Guide Rev M Ver 1 34mcabreraОценок пока нет

- FM-8700 Sme 56170-A PDFДокумент102 страницыFM-8700 Sme 56170-A PDFHikmat RahimovОценок пока нет

- Diferencia Entre SB y SLДокумент1 страницаDiferencia Entre SB y SLAnonymous cxl3kOJ5Оценок пока нет

- Daftar Buku S2 (2018)Документ43 страницыDaftar Buku S2 (2018)MADE WIDYA JAYANTARI 03111850050002Оценок пока нет

- Technical specifications for dock levelerДокумент1 страницаTechnical specifications for dock levelerBalgo BalgobinОценок пока нет

- Log File Host ErrorsДокумент26 страницLog File Host ErrorsAli Hamjah DeztroyerОценок пока нет

- Report On Porters 5 ForcesДокумент19 страницReport On Porters 5 Forcesblue_devil8132409100% (1)

- Production Engineering Strategies and Metalworking at Toyota Motor CorporationДокумент13 страницProduction Engineering Strategies and Metalworking at Toyota Motor CorporationCesar de la LuzОценок пока нет

- Beechcraft Raytheon 1900D 1998Документ4 страницыBeechcraft Raytheon 1900D 1998Ridzuan MohammadОценок пока нет

- Prysmian Medium Voltage CatalogueДокумент144 страницыPrysmian Medium Voltage CatalogueGeorgios PourtsidisОценок пока нет

- VolvoaudioДокумент12 страницVolvoaudioapi-3718946100% (1)

- Colour Veil View: A Unique Feature For Sharp's SmartphonesДокумент5 страницColour Veil View: A Unique Feature For Sharp's SmartphonesShahzain QadirОценок пока нет

- STRAIL Installation InstructionsДокумент7 страницSTRAIL Installation InstructionsBrooke TrevinoОценок пока нет

- 500-02845V3-A - All in One IPC Realse Note V1.000.HW01.3.20200326Документ8 страниц500-02845V3-A - All in One IPC Realse Note V1.000.HW01.3.20200326carlos0217Оценок пока нет

- Fisa Tehnica Centrala Adresabila de Alarmare La Incendiu UTC Fire Security FP1216C-45 2-4 Bucle 128 Adrese-Bucla 16 ZoneДокумент2 страницыFisa Tehnica Centrala Adresabila de Alarmare La Incendiu UTC Fire Security FP1216C-45 2-4 Bucle 128 Adrese-Bucla 16 ZoneMariusОценок пока нет

- So-It-Chapter-3-Computer Architecture PDFДокумент35 страницSo-It-Chapter-3-Computer Architecture PDFSumit SoniОценок пока нет