Академический Документы

Профессиональный Документы

Культура Документы

2013 Product Selection Guide Whole Book

Загружено:

Wallie BillingsleyИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

2013 Product Selection Guide Whole Book

Загружено:

Wallie BillingsleyАвторское право:

Доступные форматы

15th Edition

Programmable

Automation

Controllers

Programmable

Logic

Controllers

Human

Machine

Interfaces

Motion

Controllers

Servomotors

and Ampliers

Variable

Frequency

Drives

Robots

Computerized

Numerical

Controls

Energy

Management

Software

Low Voltage

Switchgear

PRODUCT

SELECTION GUIDE

15th Edition

www.MEAU.com

Mitsubishi Electric Automation, Inc.

500 Corporate Woods Parkway

Vernon Hills, IL 60061

Phn: (847) 478-2100

Fax: (847) 478-2253

www.MEAU.com | Serving the Americas

Printed with soy inks.

L-VH-00029 Effective September, 2013.

Specications subject to change without notice.

2013, Mitsubishi Electric Automation, Inc.

PROGRAMMABLE AUTOMATION CONTROLLERS

PROGRAMMABLE LOGIC CONTROLLERS

HUMAN MACHINE INTERFACES

MOTION CONTROLLERS

SERVOMOTORS AND AMPLIFIERS

VARIABLE FREQUENCY DRIVES

ROBOTS

COMPUTERIZED NUMERICAL CONTROLS

ENERGY MANAGEMENT

SOFTWARE

LOW VOLTAGE SWITCHGEAR

Mitsubishi Electric Automation | Table of Contents I

Stock Product: Stock product is product MEAU makes every effort to have on hand for immediate shipment. There may

be instances when we are out of stock due to unexpected large requirements. All stock product will be indicated in this

book by an S in the Stocked Item columns/rows.

Non-Stock Product: Non-stock product is product supplied on an as-needed basis. Standard lead times of 12 16

weeks apply, product is non-returnable and non-cancelable. Product listed as non-stock may change to stock product

subject to increases in sales and usage. All non-stock product will be indicated in this book by a dash - in the Stocked

Item columns/rows.

Support ................................................................................................ 3

IQ Platform ............................................................................................ 8

QS Safety PAC ....................................................................................... 80

Distributed I/O ....................................................................................... 87

WS Safety Controller ............................................................................. 127

L Series Programmable Logic Controllers .................................................... 131

FX Family .......................................................................................... 149

Human Machine Interfaces ...................................................................... 183

Motion Controllers ................................................................................ 209

Servomotors and Ampliers .................................................................... 233

Variable Frequency Drives ...................................................................... 397

Robots .............................................................................................. 459

Computerized Numerical Controls ............................................................. 477

Energy Products and Solutions ................................................................. 523

Software ............................................................................................ 533

Low Voltage Switchgear ......................................................................... 543

Demonstration Kits ............................................................................... 549

Index ................................................................................................ 551

Mitsubishi Electric Automation | Support and Services 3

Extended Support and Service Programs (ESSP

SM

)

With a sharp focus on the human element, Mitsubishi Electric Automation offers world class training, 24 / 7/ 365 support options, on-site

consultation and application development assistance to ensure profitable manufacturing operation and processes.

Mitsubishi Electric Automation offers three levels of Support & Service Programs, as well as custom support programs to assist you in

maximizing your support, and preserving machine uptime while maintaining your budget.

On-Site Support

Put our experience to work for you! Our engineers have the know-how to understand

your application and provide the critical support your business needs. Whether you

need a single engineer for the day or a staff of engineers stationed at your facility,

Mitsubishi Electric Automation has the solution.

ESSP

SM

Silver ESSP

SM

Gold ESSP

SM

Platinum

Priority Phone Support No hold priority. 7:00 AM - 7:00 PM CST 24/7/365 priority with parts fulfillment* 24/7/365 priority with parts fulfillment*

Application Support On-site - 10 hours On-site - 15 hours On-site - 20 hours

Training*** 2 Seats / 12 days each 2 Seats / 20 days each 2 Seats / Unlimited

Additional Discounts

Up to 10% on Application Support,

Service & Training***

Up to 20% on Application Support,

Service & Training***

Up to 30% on Application Support,

Service & Training**

*After regular business hours, parts fulfillment will be invoiced at standard pricing plus Service Fee. (quoted separately).

**For pricing, quotation, and plan details, please contact the Technical Support Group at (847) 478-2532 or email training@meau.com. All pricing is based on annual charges.

***Regularly scheduled classes per schedule posted on www.meau.com/training

Technical Assistance

USA / Canada Toll Free: 1 (800) 950-7781

Monday-Friday 7:00 AM - 7:00 PM Central

24/7 USA / Canada Toll Free: 1 (888) 701-7999

After 7:00 PM Central time and weekends (P.O. needed if part shipment is required. Fulfillment fee applies. For Non-ESSP customers, this is a

paid service requiring a purchase order or credit card.)

International Support: +1 (847) 478-2100

(Select Option 2 for Technical Support, then Option 2 for Industrial Automation) Monday-Friday 7:00 AM - 7:00 PM Central

Website: www.meau.com/contactus Email: tsg@meau.com

Support

4

n

S

U

P

P

O

R

T

A

N

D

S

E

R

V

I

C

E

S

Standard Product Training

Mitsubishi Electric Automations classes provide practical, hands-on,

product-oriented, customer-paced training which can be used the

moment the student walks out of the class. We offer a wide range

of training over various products. Information about our classes is

on-line at www.meau.com/training. You will find a complete list of

class descriptions, custom training, current training schedules with

pricing, and class registration procedures.

Custom Training

Mitsubishi Electric Automation is one of the few automation product and solution providers worldwide that offers customer-specific

customized training based on your application requirements. Contact one of our professional trainers to discuss your training needs.

Email training@meau.com or call our training coordinator at (847) 478-2532.

Standard Classes Offered

Programmable Logic Controllers Operator Interfaces Motion Control & Servo Robots

PLC Basics (GX Works2) GOT1000 and GT Works3 Motion Basics Robot Basic Programming

FX Series Advanced D75/D77 Positioning Robot Repair Training

Safety Systems Networking MR-MQ100 Controller Robot Basic Maintenance Training

L Series Advanced CC-Link Networking QD77/LD77 Advanced Positioning

A Series Transition CC-Link IE Networking FX Series Pulse Positioning Maintenance & Troubleshooting

A Series PLC Ethernet Networking PLC Maintenance (GX Developer)

MELSECNET/H Networking Variable Frequency Drives PLC Maintenance (GX Works2)

Software MES Introduction D700/E700 Micro Drives GOT1000 Maintenance (GT Works2)

GX Works2 Programming MES Interface F700 Inverters QD75 Maintenance

GX Works2 Structured Programming MES Interface IT

MELSOFT Navigator

MT Works2 Programming

For a complete listing of current courses visit www.meau.com/training/industrial_automation

More detailed course outlines are available at www.meau.com in the Training section.

Mitsubishi University

Mitsubishi University provides many levels of training on different Industrial

Automation products offered by Mitsubishi Electric Automation, Inc. These courses

focus on key needs of each customer category, as listed below.

Mitsubishi Electric Automation | Support and Services 5

Mitsubishi University Classes

Course Name

Length of Class and

Prerequisite

Course Description

A Series PLC

3 Days

Prerequisite None

This course will familiarize the student with the A Series family of PLC products and the software needed to configure, make

changes, and maintain a complete PLC system. This class will be taught using the A1SH PLCs and GX-Developer software.

A Series Hardware; Networks; Programming Equipment; Numbering Systems; System Configuration; Sequence Instructions;

Developing Programs; Timers and Counters; Basic Instructions; Application Instructions; Troubleshooting; Parameters;

Documentation

A Series Transition

1 Day

Prerequisite None

This course is a half-day seminar which will introduce the concepts and issues involved in the transition of the legacy A Series

PLC platform to the Q Series Automation Platform. This class is a half-day instructor-led presentation of the topics and tools, as

well as a discussion of the available resources to assist with the transition process. After lunch is an open question and answer

session for students to discuss specific issues.

Transition Overview; Affected Equipment; Upgrade & Conversion Tools; Converting Systems; Network Conversion

CC-Link Networking

2 Days

Prerequisite GX Works2

Programming

This course will teach the engineer who needs to configure, start up, and troubleshoot CC-Link networks. Issues from network

topology to communication programming are covered. This class will utilize both FX and Q Series network master modules, and

includes remote I/O modules, inverter communication boards, servo amplifiers, and intelligent slave modules.

Network Introduction, CC-Link Network, Hardware Introduction, Configuring FX Series Master, Inverter Communications,

Servo Communications, Configuring Q Series Master, Intelligent Devices, Standby Master

CC-Link IE Networking

2 Days

Prerequisite GX Works2

Programming

This course demonstrates the setup, operation, and troubleshooting of the CC-Link IE networks. This includes CC-Link IE

Control and CC-Link IE Field.

Network Overview; CC-Link IE Overview; CC-Link IE Modules; CC-Link IE Control; CC-Link IE Field; Standby Master;

Troubleshooting

D75/D77 Positioning

2 Days

Prerequisite GX Works2

Programming

This course will familiarize the attendee with the QD75, QD77, LD75 and LD77 families of motion control modules and the

software needed to configure, make changes and maintain a motion system.

Module Introduction; GX Works2 Configuration; Module Configuration; Module Control; Diagnostics; Origin Point; Positioning

Tables; Positioning Profiles; Speed Control Profiles; Dedicated Commands; Advanced Positioning

D700/E700 Micro Drives

2 Days

Prerequisite None

This course will introduce the FR-D700 and FR-E700 series of variable frequency drives. It will give the student a

thorough knowledge of the hardware, parameters and troubleshooting of the D700 and E700. This class is taught using

both inverter models.

AC Motor Theory; VFD Theory; Braking, Loads; Hardware Review; Parameters; Troubleshooting; Stand Alone Options;

Harmonics, Noise and Microsurges; Key Features

Ethernet Networking

2 Days

Prerequisite GX Works2

Programming

This class is solely focused on Ethernet within Mitsubishis structure. This class is for the advanced user and we will learn

Networking, system configuration, protocols, modeling, and advanced applications.

Topologies, O S I modeling, Hardware, Practical Lessons, Practice Applications

F700 Inverter

2 Days

Prerequisite None

This course will introduce the FR-F700 Series of variable frequency drives. It will give the student a thorough knowledge of the

hardware, parameters and troubleshooting of the F700. This class is taught using the F720.

Inverter Product Lineup; Installation; Wiring Connections; Keypad; Parameter Settings; Troubleshooting; Built-in PLC;

FR-Configurator Setup Software

FX Series Advanced

2 Days

Prerequisite None

This class will explain and demonstrate some of the higher end functionality of the FX Series controllers. This class is taught

with the FX3U and FX3UC controllers and GX Developer programming software.

High Speed Counters; File Registers; Data Tables; ASCII Text; Serial Communications; Parallel Link; N:N Networking;

Inverter Communications

FX Series Pulse

Positioning

2 Days

Prerequisite None

This course will familiarize the student with the motion control capabilities of the FX Series family of PLC products and the

software needed to configure, make changes to, and troubleshoot a motion control system based on the FX Series controllers.

This class will be taught using the FX3U PLCs, MR-J3-A servos, and GX Developer and MR Configurator software packages.

FX Series Hardware Review; Pulse Control Addresses; Connections; Basic Servo Configuration; Zero Return (Homing);

Positioning Commands; Table Positioning

GOT1000 and GT Works3

3 Days

Prerequisite GX Works2

Programming

This course is designed to introduce the various hardware platforms within the GOT1000 family, the programming software

GT Designer3, and the special functions of the GOT1000 products.

Introduction to GOTs; GOT1000 Family Overview; Communication Options; GT Designer3 Basics; Screen Design Basics;

Switches and Lamps; Basic Screen Objects; Graphs; Alarms; Recipes; Monitoring Functions

GOT1000 Maintenance

(GT Works2)

1 Day

Prerequisite None

This course will instruct the attendee on identifying the GOT1000 Series hardware. Using software tool GT Designer2 to install/

upgrade Boot OS, Communication Driver and Extended Function OS. Understand basic modification and troubleshooting of

GOT projects.

Introduction to GOTs; GOT1000 Family Overview; Communications Options; GT Designer2 Basics; Screen Design Basics; Basic

Screen Objects; Alarms; Monitoring Functions

GX Works2 Programming

3 Days

Prerequisite PLC Basics

(GX Works2)

This course will guide the student through the operation of GX Works2 and the programming of Mitsubishi PLCs using ladder

logic. It includes programming, diagnostics, and software features.

iQ Works Introduction; GX Works2 Introduction; Creating a Project, Online Operations; Program Documentation; PLC

Parameters; Timers & Counters; Basic Instructions; Special Addresses; Mathematics; GX Works2 Utilities; Intelligent Modules;

Additional Commands; Multiple Programs; Project Revision Tracking; Project Security

GX Works2 Structured

Programming

3 Days

Prerequisite GX Works2

Programming

This course demonstrates and explains advanced programming topics related to structured programming. This class covers the

additional programming languages of Structured Ladder, Structured Text, and Sequential Function Chart.

Label Programming; Structured Projects; Structured Ladder; Structured Text; Sequential Function Chart; Function Blocks;

Libraries; Arrays and Structured Data Types

L Series Advanced

2 Days

Prerequisite GX Works2

Programming

This course demonstrates the advanced features of the L Series CPU, including built-in I/O, positioning, counting,

and data logging.

Built-In Inputs and Outputs; Pulse Positioning; High Speed Counters; Display Module, Data Logging

6

n

S

U

P

P

O

R

T

A

N

D

S

E

R

V

I

C

E

S

Mitsubishi University Classes

Course Name

Length of Class and

Prerequisite

Course Description

MES Introduction

1 Day

Prerequisite GX Works2

Programming

This course is designed to introduce the user to the systems that the MES Interface and the MES Interface IT modules use

and operate within. The basics of the eco system, OPC, enterprise computing are covered.

Product Introduction, MES Eco System, MES Interface IT Introduction, Demonstration Equipment, OPC Introduction,

Support Overview, Application Examples, Enterprise Computing, Quick Start Guide

MES Interface

1 Day

Prerequisite MES

Introduction

This course builds on what is learned in the MES Interface Introduction course. This course is designed for people who have

working knowledge of OPC and Eco systems and have limited knowledge of the Mitsubishi MES Interface module.

QJ71MES96 Installation, Basic Troubleshooting, Diagnostics, Programming, Configuration

MES Interface (IT)

2 Days

Prerequisite MES

Interface (Intermediate)

This course is designed for the advanced IT and MES module knowledge user. The Student will learn commissioning the

MES module and the GOT operator Interface along with system diagnostics.

Advanced Applications, Advanced Troubleshooting, Diagnostics, Security, Commissioning, GOT Connectivity

Motion Basics

1 Day

Prerequisite None

This course will introduce the basic concepts required to understand servo based motion and motion controllers. Servo and

motor theory are discussed, as well as applications and control theory.

Motor and Servo Theory, Applications and Sizing, Motion Controllers, Programming Basics

MR-MQ100 Controller

3 Days

Prerequisite Motion

Basics

This course will introduce the MR-MQ100 1.5 axis motion controller and the programming methods. The student will learn

the controller architecture, programming, and create sample applications using the MR-MQ100 controller and the

MT Developer2-MQ programming software.

MR-MQ100 Introduction, MT Developer2 Basics, Memory Structure, Motion SFC Introduction, Motion SFC Programming,

Virtual Mode Introduction, Virtual Mode Programming, Registration Function, Cam Function, Application Examples,

GOT1000 Connection

MELSECNET/H Networking

2 Days

Prerequisite GX Works2

Programming

This course demonstrates the setup, operation, and troubleshooting of the MELSECNET/H network.

Network Overview; MELSECNET/H Overview; Parameters; Routing; Cyclic Communication; Transient Communication;

Remote I/O; Additional Functions; Troubleshooting

MELSOFT Navigator

1 Day

Prerequisite GX Works2

Programming

This course is designed to teach the usage of MELSOFT Navigator and system labels.

Introduction; MELSOFT Navigator; System Labels

MT Works2 Programming

4 Days

Prerequisite Motion

Basics, GX Works2

Programming

This course will familiarize the attendee with the motion controllers and MT Works2 software. This course focuses on the

Motion Control CPU and programming.

Hardware Introduction; Getting Started; MT Developer2 Introduction; Sequence Processor; Memory Structure; Origin Point;

Motion SFC Introduction; MT Works2 Tools; Positioning Profiles; Motion SFC Examples; Virtual Mode Introduction; Virtual

Mode Programming; Cam Programming; CPU Integration; Dedicated Instructions; Advanced Concepts

PLC Basics (GX Works2)

1 Day

Prerequisite None

This course will introduce the concepts of PLCs, as well as provide an introduction to the components of the various

Mitsubishi PLC families. Basics of PLC design, assembly, and addressing are covered. This course also includes an

introduction to the ladder logic programming language.

PLC Hardware; Numeric Data Handling; System Addressing; Programming Software; Ladder Logic Basics

PLC Maintenance

(GX Developer)

2 Days

Prerequisite None

This course will familiarize the attendee with the components of a PLC. Identify the memory addresses for inputs and

outputs. Understand the basics of ladder logic. Use of the troubleshooting tools in GX Developer. How to make basic

program changes. Identify and replace modules in the PLC.

PLC Hardware; Numeric Data Handling; System Addressing; Basic Ladder Logic; GX Developer Basics; Online Operations;

Intelligent Modules; Special Addresses; PLC Parameters; GX Developer Utilities; Hardware Maintenance

PLC Maintenance

(GX Works2)

2 Days

Prerequisite None

This course will familiarize the attendee with the components of a PLC. Identify the memory addresses for inputs and

outputs. Understand the basics of ladder logic. Use of the troubleshooting tools in GX Works2. How to make basic program

changes. Identify and replace modules in the PLC.

PLC Hardware; Numeric Data Handling; System Addressing; Basic Ladder Logic; GX Works2 Basics; Online Operations;

Intelligent Modules; Special Addresses; PLC Parameters; GX Works2 Utilities; Hardware Maintenance

QD75 Maintenance

1 Day

Prerequisite None

This course will familiarize the attendee on how to configure a motion module and the servo parameters. Build motion

control tasks and downloading of motion tables. Execute motion control tasks. Diagnose and troubleshoot systems using the

motion module.

Module Introduction; Software Configuration; Module Configuration; Module Control; Diagnostics; Origin Point;

Positioning Profiles

QD77/LD77 Advanced

Positioning

1 Day

Prerequisite D75/D77

Positioning

This course will familiarize the student with the synchronous control functions of the QD77 and LD77 families of motion

control modules.

Synchronous Control; Synchronous Configuration: Synchronous Operation; Cams

Robot Basic Programming

3 Days

Prerequisite None

This course will familiarize the student with the Mitsubishi robot products and the software needed to configure, make

changes, and maintain a robot system. This class will be taught using the RV-3S robot and RT Toolbox software.

Robot Operation, Robot Construction and Maintenance, Controller Functions, Teach Box Menus, Offline and Online

Programming, Basic Troubleshooting

Robot Basic Maintenance

Training

1 Day

Prerequisite None

This course has been designed to explain the basic maintenance structure of the Mitsubishi Robots through lecture and

hands on practice. Upon completion of this course, operative employees will have a fundamental understanding of the

Mitsubishi Robot system. They will be able to perform routine maintenance and basic troubleshooting on the Mitsubishi

robot system.

Robot Repair Training

3 Days

Prerequisite None

This course is an in depth look at the maintenance structure of the Mitsubishi Robot. It includes complete removal and

reinstallation of multiple joints on the robot. This will give the individual a greater understanding of the internal workings of

the Mitsubishi robot and allow them to have the ability to properly troubleshoot any issue that may arise on the robot. Upon

completion of this course, operative employees will have a fundamental understanding of the Mitsubishi robot system and

should be able to troubleshoot and maintain a complete robot system.

Safety Systems

2 Days

Prerequisite PLC Basics

(GX Works2)

This course will introduce the Q Safety Controller, Safety Relays, CC-Link Safety, and WS Safety Controller.

MELSEC QS Component Overview; Safety I/O Connectivity; CC-Link Safety; System Status and Monitoring; Safety Control;

Safety Relay Modules; Safety Addition to Servo and VFD; Safety Application Examples; WS Controller

Mitsubishi Electric Automation | Programmable Automation Controller / PAC 7

Programmable Automation Controller

16-4096 iQ Platform

12-1024 QS Safety PLC

P

E

R

F

O

R

M

A

N

C

E

I/ O

Stock Product: Stock product is product MEAU makes every effort to have on hand for immediate shipment. There may be instances when we are out

of stock due to unexpected large requirements. All stock product will be indicated in this book by an S in the Stocked Item columns/rows.

Non-Stock Product: Non-stock product is product supplied on an as-needed basis. Standard lead times of 12 - 16 weeks apply, product is

non-returnable and non-cancelable. Product listed as non-stock may change to stock product subject to increases in sales and usage. All non-stock

product will be indicated in this book by a dash - in the Stocked Item columns/rows.

iQ Platform ............................................................................................................................................................................ 8

MELSEC QS Safety ............................................................................................................................................................... 80

8

n

P

R

O

G

R

A

M

M

A

B

L

E

A

U

T

O

M

A

T

I

O

N

C

O

N

T

R

O

L

L

E

R

/

P

A

C

Power supply module

Battery for

QCPU (Q6BAT)

Extension cable

Extension base unit

*Minimum Requirements

Main base unit

Sequence

CPU

Robot

CPU

CNC

CPU

Motion

CPU

WINCPU

I/O, Intelligent function modules

Memory card

PC card adapter Memory card

RS-232 cable

USB cable

(customer supplied)

Ethernet cable

(customer supplied)

PC (GX Works2)

A

D

B

C

C

C

E

F

F

F

MPG

RIO

BAT

ACFAIL

FRONT

MPG

RIO

BAT

ACFAIL

FRONT

MPG

RIO

BAT

ACFAIL

FRONT

*

*

*

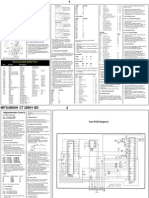

Multiple CPU System Configuration

iQ Platform

IQ Platform

Modular CPUs ............................................................................................................................................................................. 9

Base Units ................................................................................................................................................................................... 20

iQ Platform Base Units .......................................................................................................................................................... 20

Q Series Base Units ............................................................................................................................................................... 20

DIN Rail Adapters .................................................................................................................................................................. 20

Extension Base Units and Connection Cables ............................................................................................................................. 21

Power Supply Modules ............................................................................................................................................................... 21

I/O and Intelligent Function Modules .......................................................................................................................................... 23

Digital Input Modules ............................................................................................................................................................ 23

Combination I/O Modules ...................................................................................................................................................... 24

Digital Output Modules .......................................................................................................................................................... 25

Analog Input Modules ........................................................................................................................................................... 27

High Speed Analog Input Modules ........................................................................................................................................ 28

Combination Analog Modules................................................................................................................................................ 33

Analog Output Modules ......................................................................................................................................................... 34

HART Interface Module ......................................................................................................................................................... 38

Temperature Control Modules ............................................................................................................................................... 40

High Speed Counter Modules ................................................................................................................................................ 45

Interrupt Modules .................................................................................................................................................................. 48

Positioning Modules .............................................................................................................................................................. 49

Serial Communication Modules ............................................................................................................................................. 52

Network Modules ........................................................................................................................................................................ 55

e-F@ctory ................................................................................................................................................................................... 72

MES Solution .............................................................................................................................................................................. 74

Accessories ................................................................................................................................................................................. 76

Mitsubishi Electric Automation | Programmable Automation Controller / PAC 9

iQ Platform CPU Configuration

iQ Base Units: Q35DB, Q38DB or Q312DB

The iQ Platform unifies all of the Mitsubishi Electric automation

disciplines into a one-of-a-kind modular Programmable Automation

Controller (PAC). Based on the multi-CPU architecture of the

renowned Q Series Automation Platform, the iQ ultra high-speed

dual-bus back plane allows the iQ to be the only PAC to integrate

individual Sequence, Motion, CNC, and Robot control onto a single

rack. The iQ Platform is ideal for multi-discipline systems, requiring

at least one sequence CPU. Users can expand their configuration

with existing Q Series I/O and intelligent modules, providing the iQ

Platform customized flexibility without the cost of new development

or double-stock.

Key Features:

Up to 4 CPUs total, including one sequence CPU; Motion, CNC,

and Robot CPUs available

Large 4096 I/O capacity and as low as 9.5ns instruction

processing, with selectable CPU program size

Selectable built-in Ethernet sequence CPUs, enabling program

upload/download, monitoring, debugging, SNTP, and FTP

functionality via Ethernet

System configuration and PLC/Motion/HMI programming using

iQ Works

Backward compatibility with Q Series programs and parameters

Multiple program processing

Selectable 8 or 32-axis high-speed fiber optic motion

controller CPUs

Selectable 16-axis C70 CNC controller CPU

Selectable vertical or horizontal type robot controller CPUs

Infinite I/O and intelligent function module customization

possibilities

Minimal hardware footprint

Certified by UL, cUL, CE (as indicated), as well as DNV, ABS,

RINA, BV, LR and NK shipping approvals for all Q Series products

A. Modular CPUs

CON0

30

25

20

15

10

5

1

A B

CON0

30

25

20

15

10

5

1

A B

CON0

30

25

20

15

10

5

1

A B

CON0

30

25

20

15

10

5

1

A B

CON0

30

25

20

15

10

5

1

A B

CON0

30

25

20

15

10

5

1

A B

CON0

30

25

20

15

10

5

1

A B

CON0

30

25

20

15

10

5

1

A B

CON0

30

25

20

15

10

5

1

A B

20

15

10

15

1

Q03UDCPU

RS-232

MODE

RUN

ERR.

USER

BAT.

BOOT

USB

PULL

Power

Supply

CPU 0 1 2 3 4 5 6 7

1st CPU

QnU Sequence CPU

Q03UDECPU

Q04UDEHCPU

Q06UDEHCPU

Q10UDEHCPU

Q13UDEHCPU

Q20UDEHCPU

Q26UDEHCPU

Q50UDEHCPU

Q100UDEHCPU

2nd 4th CPU

QnU Sequence CPU; 3 Max.

Q03UDECPU

Q04UDEHCPU

Q06UDEHCPU

Q10UDEHCPU

Q13UDEHCPU

Q20UDEHCPU

Q26UDEHCPU

Q50UDEHCPU

Q100UDEHCPU

QD Motion CPU; 3 Max.

Q172DCPU

Q173DCPU

SQ Robot CPU; 3 Max.

Q172DRCPU

C70 CNC CPU; 2 Max.

Q173NCCPU-S01

C CPU, MES IT, or WinCPU; 3 Max.

Q12DCCPU-V

QJ71MES96IT

Q10WCPU-W1-E

Q10WCPU-W1-CFE

Process CPU

Q02PHCPU

Q06PHCPU

Q12PHCPU

Q25PHCPU

Process CPU

Q02PHCPU

Q06PHCPU

Q12PHCPU

Q25PHCPU

10

n

P

R

O

G

R

A

M

M

A

B

L

E

A

U

T

O

M

A

T

I

O

N

C

O

N

T

R

O

L

L

E

R

/

P

A

C

Notes:

1. The unit of the file size stored in the memory area varies depending on the CPU module. For more details, refer to the QCPU Users Manual (Function Explanation, Program Fundamentals)

2. The maximum number of executable sequence steps is shown. (Program capacity) - (File header size (default: 34 steps)). For details, refer to the QCPU Users Manual (Function Explanation, Program Fundamentals).

3. The CPU module can only execute up to 124 programs, though more may be stored.

4. Applies to QnU CPUs with built-in Ethernet ports only.

5. Indicates the total number of TCP/IP and UDP/IP protocols.

6. The current value consumption of the built-in Ethernet part version is 0.46A

7. The current consumption of the built-in Ethernet port version is 0.46A.

Model Number

Built-In

Ethernet

Q03UDECPU Q04UDEHCPU Q06UDEHCPU Q10UDEHCPU Q13UDEHCPU Q20UDEHCPU Q26UDEHCPU Q50UDEHCPU Q100UDEHCPU

Stocked Item S S S - S - S - -

Processing

Speed

(Sequence

Instruction)

LD X0 20ns 9.5ns

MOV D0 D1 40ns 19ns

Program Capacity (*1, *2) 30k steps 40k steps 60k steps 100k steps 130k steps 200k steps 260k steps 500k steps 1000k steps

Memory

Capacity

(*1)

Program Memory (Drive 0) 120 kB 160 kB 240 kB 400 kB 520 kB 800 kB 1040 kB 2000 kB 4000 kB

Standard RAM (Drive 3) 192 kB 256 kB 768 kB 1024 kB 1280 kB 1536 kB 1792 kB

Standard ROM (Drive 4) 1024 kB 2048 kB 4096 kB 8192 kB 16384 kB

Max.

Number

of Files

Stored

Program Memory 124 252 (*3)

Standard RAM 4 files

Standard ROM 256 512

Memory Card Interface Yes

Max. I/O Device Points 8192 points (X/Y0 to 1FFF)

Max. Physical I/O Points 4096 points (X/Y0 to FFF)

No. of Device Points Set in PLC parameters

File Registers Available

Specs. of

Built-In

Ethernet

Port CPU

Module

(*4)

Data Transmission Speed 100/10Mbps

Communication Mode Full-duplex / Half duplex

Ethernet Functions Program upload/download, remote monitor/maintenance, HMI connection, FTP server, SNTP

Max. Distance Between Hub

and Node

100m (328.08 feet)

Max. No. of

Connectable

Nodes

10BASE-T Cascade connection: Four stages maximum

100BASE-TX Cascade connection: Two stages maximum

Number of Connections (*5) 16 for MELSOFT connection and MC protocol, 1 for FTP

Communication Ports USB (Mini-B), RS-232 / Ethernet USB (Mini-B), Ethernet

5VDC Internal Current Consumption 0.33A (*6) 0.39A (*7) 0.50A

Base Unit Slots Occupied 1

Weight (kg) 0.22 0.24

The QnU CPUs bring high-end sequence control to the Mitsubishi

PAC lineup and are required in every iQ system. These CPUs are most

effective when used in conjunction with other iQ Platform CPUs such

as Motion, Robot, CNC, PC and C Language controllers. However, they

can also be used in Q Series configurations to increase performance

and functionality.

Key Features:

World-leading processor execution speeds as low as 9.5ns

per instruction

Significantly enhanced arithmetic and data processing (sorting,

floating point, etc.)

Vastly increased data storage and non-volatile program memory

Utilizes dedicated high-speed CPU-only communication bus with

other iQ CPUs

Backward compatibility with Q Series CPUs, I/O and Intelligent

Modules; QnU CPUs can be configured in single-CPU and / or

standard Q Series CPUs

Built-in Ethernet port for increased accessibility and ease-of-use

USB (Mini-B) connection to CPU for rapid program

upload/download

iQ Platform QnU Universal Sequence CPUs

Required Manuals

Note: Many of these manuals are available by free download from our website, www.meau.com

Model Number Description Included with CPU? Stocked Item

SH(NA)080483 QCPU Users Manual No -

SH(NA)080485-ENG QCPU Users Manual (Multiple CPU Systems) No -

SH(NA)080807-ENG QnUCPU Users Manual No -

SH(NA)080809-ENG QCPU Programming No -

SH(NA)080811-ENG QnUCPU Users Manual (Ethernet Communication) No -

iQ Platform CPUs

Mitsubishi Electric Automation | Programmable Automation Controller / PAC 11

Model Number Built-In Ethernet Q03UDVCPU Q04UDVCPU Q06UDVCPU Q13UDVCPU Q26UDVCPU

Stocked Item S - S - S

Processing

Speed

(Sequence

Instruction)

LD X0 1.9ns

MOV D0 D1 3.9ns

Program Capacity (*1, *2, *3) 30k steps 40k steps 60K steps 130k steps 260k steps

Memory

Capacity

(*1)

Program Memory (Drive 0) 120 kB 160 kB 240 kB 520 kB 1040 kB

Memory Card RAM (Drive 1) -

Memory Card SD (Drive 2) Depends on the SD memory card (SD or SDHC type) used. (Max. 32GB)

Standard RAM (Drive 3) Without

Extended SRAM Cassette

192 kB 256 kB 768 kB 1024 kB 1280 kB

Standard RAM (Drive 3) With

Extended SRAM Cassette

Capacities of the memory in the module and extended SRAM cassette. (The maximum capacity of an extended SRAM casette is 8MB)

Standard ROM (Drive 4) 1025.5 kB 2051 kB 4102 kB

CPU Shared Memory 32 kB

Max.

Number

of Files

Stored

Program Memory 124 (*4) 252 (*4)

Memory Card SD Root directory: 512 files (maximum); Subdirectory: 65534 files (maximum)

Memory Card SDHC Root directory: 65535 files (maximum); Subdirectory: 65534 files (maximum)

Standard RAM With or Without

an Extended SRAM Cassette

323

Standard ROM 256

Max. I/O Device Points 8192 points (X/Y0 to 1FFF)

Max. Physical I/O Points 4096 points (X/Y0 to FFF)

Specs. of

Built-In

Ethernet

Port CPU

Module

(*4)

Data Transmission Speed 100/10Mbps

Communication Mode Full-duplex/Half-duplex

Max. Distance Between Hub

and Node

100m

Max. No. of

Connectable

Nodes

10BASE-T Cascade connection: Up to four bases (*5)

100BASE-TX Cascade connection: Up to two bases (*5)

Number of Connections (*6) 16 for a total of socket communication, MELSOFT connection, and MC protocol, and 1 for FTP

5VDC Internal Current Consumption 0.58A (only CPU module), 0.6A (with an extended SRAM cassette)

Base Unit Slots Occupied 1

Weight (kg) 20

Notes:

1. The maximum number of executable sequence steps is obtained by the following formula.

2. Program size file header size (default: 34 steps)

3. When the QnUD(H)CPU or QnUDE(H)CPU is replaced with the QnUDVCPU, the number of steps in the program may change (increase or decrease)

4. Data in the CPU shard memory cannot be latched. Data in the CPU shared memory is cleared when the programmable controller is powered on or the CPU module is reset.

5. This is the number of connectable modes when a repeater hub is used. For the number of connectable nodes when a switching hub is used, contact the manufacturer of the switching hub used.

6. The number is a total of TCP/IP and UDP/IP.

12

n

P

R

O

G

R

A

M

M

A

B

L

E

A

U

T

O

M

A

T

I

O

N

C

O

N

T

R

O

L

L

E

R

/

P

A

C

Model Number Q173DCPU Q172DCPU

Stocked Item S S

Number of Control Axes Up to 32 axes Up to 8 axes

Operation Cycle (Default)

SV13

0.44ms / 1 to 6 axes; 0.88ms / 7 to 18 axes

1.77ms / 19 to 32 axes

0.44ms / 1 to 6 axes; 0.88ms / 7 to 8 axes

SV22

0.44ms / 1 to 4 axes; 0.88ms / 5 to 12 axes

1.77ms / 13 to 28 axes; 3.55ms / 29 to 32 axes

0.44ms / 1 to 4 axes; 0.88ms / 5 to 8 axes

Manual Pulse Generator Operation

Function

Possible to connect 3 modules

Synchronous Encoder Operation Function 12 modules max. 8 modules max.

Number of SSCNET III Systems (*1) 2 systems 1 system

Motion Related Interface Module

Q172DLX: 4 modules usable; Q172DEX: 6 modules usable

Q173DPX: 4 modules usable (*2)

Q172DLX: 1 module usable; Q172DEX: 4 modules usable

Q173DPX: 3 modules usable (*2)

Internal Current Consumption (5VDC) [A] 1.25 1.14

Mass (kg) 0.33 0.33

Base Unit Slots Occupied 1

Notes:

1. The servo amplifiers for SSCNET cannot be used.

2. When using the incremental synchronous encoder (SV22 use), you can use above number of modules. When connecting the manual pulse generator, you can use only 1 module.

Synchronous Encoder

Type

Synchronous Encoder

Manual Pulse Generator

Serial Absolute Incremental

Model Number Q172DEX Q173DPX

Stocked Item S S

Q173DCPU 12 modules 12 modules 3 modules

Q172DCPU 8 modules 8 modules 3 modules

Base Unit Slots Occupied 1

iQ Platform Motion CPUs

The iQ Platform unifies four key fields of automation, one being

servo motion. The iQ Motion CPUs combined with MR-J3 servos

deliver the highest level of speed and precision with tight integration

to interdisciplinary automation control. Exploiting the high-speed

inter-CPU communication bus, servo movement can be scattered

seamlessly throughout Sequence, Robot, and CNC operations.

For more details on associated Motion products, please see the

Motion Controllers product section.

Key Features:

Accelerated communication speed over a freely designated

expanded range of inter-CPU shared memory

Additional clutch control functionality

Faster processing for improved multi-axis support

Up to 32 axes per CPU, 96 axes per system

MR-J3-B Servo and SSCNETIII benefits, including noise free,

50Mbps, fiber optic communication, and active auto-tuning

Required Manuals

Note: Many of these manuals are available by free download from our website, www.meau.com

Model Number Description Included with CPU? Stocked Item

IB(NA)0300133-A QD Users Manual No S

IB(NA)0300134-A QD Common Manual No S

IB(NA)0300136-A QD Real Mode Manual No S

IB(NA)0300137-A QD Virtual Mode Manual No S

IB(NA)0300135-A QD SFC Programming Manual No S

Mitsubishi Electric Automation | Programmable Automation Controller / PAC 13

iQ Platform CNC CPU

The Q173NCCPU enables entry level CNC Control to be integrated

with Sequence, Motion, and Robot automation systems. Also known

as the C70 Series CNC Controller, an iQ CNC CPU system uses multi-

purpose GOT1000 HMIs and on-rack I/O cards to minimize TCO on

CNC line solutions.

For more details on associated CNC products, please see the CNC

product section.

Key Features:

Accelerated communication speed over the inter-CPU

shared memory

Up to 16 axes with 4 simultaneously controlled axes per CPU,

2 CPUs per system

16.8k Block/min processing speed

Streamlined production with reduced Tact Time and host

information system linkage

Uses GOT1000 HMI and iQ rack-based I/O card interfaces

SSCNETIII benefits, including noise free, 50Mbps, fiber optic

communication

Required Manuals

CNC CPU Specifications

Q173NCCPU-S01

Machining Center Type Lathe Type

Stocked Item S S

Number of Control Axes 16

Maximum Number of Simultaneous Control Axes 4

Maximum Number of Spindles 7 4

Maximum Number of PLC Axes 7

Maximum Number of Part Systems 7 3

Control Unit 1m / 0.1m

Interpolation Processing Performance 16.8k Block/min

Max Feed Rate 1000m/min

Base Unit Slots Occupied 1

Model Number Description Contents Included with CPU? Stocked Item

IB1500261 C70 Connection Manual Covers Q173NCCPU installation and connections Yes (PDF format) -

IB1500267 C70 Instruction Manual Covers screen operation for C70 Yes (PDF format) -

IB1500263 C70 PLC Interface Manual

Describes the various signal interfaces and functions

required when creating sequence program of PLC CPU to

operate C70

Yes (PDF format) -

IB1500269 C70 Programming Manual (Machining Center System) Covers programming for machining centers Yes (PDF format) -

IB1500275 C70 Programming Manual (Lathe System) Covers programming for lathe systems Yes (PDF format) -

IB1500265 C70 Setup Manual Covers setup Yes (PDF format) -

IB1500259 C70 CPU Module Q173NCCPU Specifications Manual General and functional specifications Yes (PDF format) -

iQ Platform Robot CPU

The new Q172DRCPU Robot controller combines faster processing

speed and enhanced motion control, providing superior flexibility and

performance when designing robotic work cells.

For more details on associated Robot products, please see the Robot

product section.

Model

Number

(*1, *2)

Axes /

Degrees of

Freedom

Max.

Payload

(kg)

Max.

Reach

Radius

(mm)

Position

Repeatability

(mm)

Stocked

Item

RV-2SQ-_ 6 2 504 .02 -

RV-3SQJ-_ 5 3.5 641 .02 -

RV-3SQ-_ 6 3.5 642 .02 -

RV-6SQ-_ 6 6 695 .02 -

RV-6SQL-_ 6 6 902 .02 -

RV-12SQ-_ 6 12 1086 .05 -

RV-12SQL-_ 6 12 1385 .05 -

Notes:

1. Includes arm, drive unit, CPU, arm to drive unit cable set, and CPU to drive unit cable set.

2. -_ Indicates additional specifications for UL, clean, and oil mist types. Please contact MEAU.

Notes:

1. Includes arm, drive unit, CPU, arm to drive unit cable set, and CPU to drive unit cable set.

2. -_ Indicates additional specifications for UL, clean, and oil mist types. Please consult with MEAU

Vertically Articulated Robots for iQ

SCARA Robots for iQ

Model Number

(*1, *2)

Axes /

Degrees

of

Freedom

Max.

Payload

(kg)

Max.

Reach

Radius

(mm)

Z Axis

Stroke

(mm)

Position Repeatability

Stk

Item

X-Y

Composite

(mm)

Z

(mm)

J4

(deg.)

RH-3SQHR3515-_ 4 3 350 150 .01 .01 .01 -

RH-6SQH3520-_ 4 6 350 200 .02 .01 .02 -

RH-6SQH4520-_ 4 6 450 200 .02 .01 .02 -

RH-6SQH5520-_ 4 6 550 200 .02 .01 .02 -

RH-12SQH5535-_ 4 12 550 350 .02 .01 .03 -

RH-12SQH7035-_ 4 12 700 350 .025 .01 .03 -

RH-12SQH8535-_ 4 12 850 350 .025 .01 .03 -

RH-18SQH8535-_ 4 18 850 350 .025 .01 .03 -

RH-20SQH8535-_ 4 20 850 350 .025 .025 .025 -

RH-20SQH8545-_ 4 20 850 450 .025 .025 .025 -

RH-20SQH10035-_ 4 20 1000 350 .025 .025 .025 -

RH-20SQH10045-_ 4 20 1000 450 .025 .025 .025 -

Note: Many of these manuals are available by free download from our website, www.meau.com

Note: If used, the Q173SXY CNC Safety I/O module requires programming by GX Developer (unavailable with GX Works2).

Key Features:

Capable of controlling up to 3 robots per system

Base Unit (one slot per CPU)

Both vertically articulated and SCARA robots can be

configured on a single platform

Single programming software package for all robot types

Versatility through shared iQ networking, I/O, and intelligent

modules

Improved cycle times through inter-CPU shared memory bus

14

n

P

R

O

G

R

A

M

M

A

B

L

E

A

U

T

O

M

A

T

I

O

N

C

O

N

T

R

O

L

L

E

R

/

P

A

C

Note 1: _ = number of valves (1-4)

Options for iQ Robots

Model Number Description Notes Stocked Item

Teach Pendants

R32TB Standard Teach Pendant, 7m Cable Basic Teaching and Operation S

R32TB-15 Standard Teach Pendant 15m Cable Basic Teaching and Operation -

R56TB Enhanced Teach Pendant 7m Cable Advanced Function Pendant S

R56TB-15 Enhanced Teach Pendant 15m Cable Advanced Function Pendant S

Software

RT-TOOLBOX 2 C1 Robot Programming and Setup SW-Light Version Without Simulation Tool S

RT-TOOLBOX 2 LT-C1 Robot Programming and Setup SW With Simulation Tool S

MELFA-VISION-C1 Vision Interface and Setup SW Tool Compatible with Cognex In-Sight sensors S

MELFA-WORKS-C1 Advanced Design and Integration SW Tool Add on to Solid Works Required S

Hand Interface Card

2A-RZ365 Pneumatic Hand Interface Sink Type S

2A-RZ375 Pneumatic Hand Interface Source Type S

Solenoid Valve Sets

(*1)

1E-VD01 1 Valve Set with Connection Cable (Sink) RV-2 -

1E-VD01E 1 Valve Set with Connection Cable (Source) RV-2 S

1E-VD02 2 Valve Set with Connection Cable (Sink) RV-2 -

1E-VD02E 2 Valve Set with Connection Cable (Source) RV-2 S

1S-VD0_-02 Valve Set with Connection Cable (Sink) RV-3, 6 S

1S-VD0_E-02 Valve Set with Connection Cable (Source) RV-3, 6 S

1S-VD0_-01 Valve Set with Connection Cable (Sink) RV-12 S

1S-VD0_E-01 Valve Set with Connection Cable (Source) RV-12 S

1S-VD0_M-04 Valve Set with Connection Cable (Sink) RH-6 S

1S-VD0_ME-04 Valve Set with Connection Cable (Source) RH-6 S

1S-VD0_M-03 Valve Set with Connection Cable (Sink) RH-12, 20 S

1S-VD0_ME-03 Valve Set with Connection Cable (Source) RH-12, 20 S

Hand I/O Cables

1E-GR35S Hand Output Cable 8-Connection, RV-2 S

1S-HC30C-11 Hand Input Cable 12-Connection, RV-2 S

1S-GR35S-01 Hand Output Cable 4-Connection, RV-3, 6, 12 S

1S-HC25C-01 Hand Input Cable 8-Connection, RV-3, 6, 12 S

1S-GR35S-02 Hand Output Cable 4-Connection, RH S

1S-HC35C-02 Hand Input Cable 8-Connection, RH S

Hand Curl Tube

1N-ST0602C 6 - 1 Connection RV-12 S

1N-ST0604C 6 - 2 Connections RV-12 S

1N-ST0606C 6 - 3 Connections RV-12 S

1N-ST0608C 6 - 4 Connections RV-12, RH-6, 12, 20 S

1E-ST0402C 4 - 1 Connection RV-2, 3, 6 S

1E-ST0404C 4 - 2 Connections RV-2, 3 S

1E-ST0406C 4 - 3 Connections RV-3, 6 S

1E-ST0408C 4 - 4 Connections RV-3, 6 S

1E-ST0408C-300 4 - 4 Connections, 300 mm RH-6 S

Mitsubishi Electric Automation | Programmable Automation Controller / PAC 15

Model Number Q10WCPU-W1-E Q10WCPU-W1-CFE

Stock S S

Number of Slots Occupied 2 slots

CPU Intel

Atom Processor N450 1.66GHz

Chipset Intel

ICH8M

Memory

L1 Cache Instruction 32KB + Data 24KB

L2 Cache 512KB

Main Memory 1GB (3.3V 200-pin DDR2 SO-DIMM DDR667Socket x 1)

Video

Controller N450 built-in

Video RAM Main memory shared

CRT I/F Analog-RGB 15-pin HD-SUB connector

Resolution 1,400 x 1,050 @60Hz (16 million colors)

Serial I/F RS-232C-compliant: 1ch (9-pin D-SUB connector) baudrate: 50 - 115200bps

LAN

I/F 1000BASE-T/100BASE-TX/10BASE-TRJ-45 connector 2

Controller Intel 82574L

CF Card Slot CF CARD Type I (Only for the memory card of IDE connection) Indication: access LED (green) 1 (*1, *2)

CF Card - 4GB CF Card included

Built-in SSD (*3) Built-in flash drive 4GB

USB I/F USB2.0-complicant 5ch (front 3ch, bottom 2ch) Transfer rate: 480Mbps Supply power: +5V each channel 0.5A max. (*4)

Watch Dog Timer 2ch Time-up period: system WDT 20msec - 2sec, user WDT 10msec - 10sec

General I/O

Terminal block [1, 2] Input for shutdown (current drive input) Terminal block [3] Output to notify shutdown completion (open

collector output) Terminal block [4] Output to nofity the start of watch dog timer (open collector output)

RTC/CMOS

Lithium battery backup life: 10 years or more (when no power input, at 25C) The real-time clock is accurate within

3 minutes (at 25C) per month

Indication RDY (green), B.RUN (green), ERR. (red), USER (red), BAT. (orange), EXIT (green), CF/SSD (green)

Control Reset PUSH switch, DIP switch 4-pole, DIP switch 6-pole, 3-position toggle switch

Supported OS Windows Embedded Standard 2009

DC5V Internal Current Consumption 3.0A (Max.) (This does not include the current consumption by any peripheral devices (such as the CF Card and USB device))

Dimensions (W X D x H) [mm] 55.2 x 115.0 x 98.0 (Excluding protrusions)

Weight (g) 440 450 (Including CF card, Fittings and screws to fix a CF card)

iQ Platform PC Controller (WinCPU)

The iQ Platform combines several key automation disciplines

including the ability to integrate an industrial PC and its environment

on this hardware platform. The iQ PC (WinCPU) is design to

compress your hardware architecture and manage your automation

system while taking full advantage of benefits of a PC. This flexible

solution is ideal for a wide range of applications including many

nontraditional machine designs. Users can leverage all the benefits of

each discipline and merge them into a seamless control system that

far exceeds any control expectation

Key Features:

Integration of multiple technologies in a single platform

High-speed communication and data sharing over the backplane

Embedded Windows software architecture

Solid State PC hardware architecture

Notes:

1. When power is on, you can not push in / pull out a CF card. Memory card is supported but other purposes are not supported.

2. Access LED shows the access of both a CF card and built-in SSD.

3. Built-in SSD is used as OS space. SSD has rewritable life (1 million times). For details, refer to Built-in SSD of Chapter 5 Each Component Function

4. Current capacity shows the maximum value the connector supports. But the actual value is limited because the total current cannot exceed the capacity of the power supply module. Therefore the actual

available value may be less than 0.5A.

16

n

P

R

O

G

R

A

M

M

A

B

L

E

A

U

T

O

M

A

T

I

O

N

C

O

N

T

R

O

L

L

E

R

/

P

A

C

C Language CPU

Model Number Q12DCCPU-V

Stocked Item S

Certication UL cUL CE

Endian Format (Memory Layout) Little endian

User File

Capacity (For

User File

Storage

Standard RAM 3Mb

CompactFlash Card Up to 8 Gb

Work RAM (for OS, Driver, User Program Execution) 128 Mb

Battery Backed-up RAM 128 kB

Software

Operating System (*1) VxWorks Version 6.4

Programming Language C language (C/C++)

Ethernet

10BASE-T/

100BASE-TX

Number of Channels 2 channels (same specication for CH1 and CH2 )

Interface (*2) 10BASE-T/100BASE-TX

Number of Cascaded Stages Up to 4 (10BASE-T)/Up to 2 (100BASE-TX)

Maximum Segment Length (Distance

Between Hub and Node)

100m (328.08 feet)

Supported Function

Auto negotiation function (automatically recognizes 10BASE-T or 100BASE-TX); Auto-MDIX function

(automatically recognizes straight or crossing cable)

RS-232

Transmission Speed 9600, 14400, 19200, 28800, 38400, 57600, 115200 bps

Transmission Distance Up to 15m (49.21 feet)

Recommended Cable

7/0.127_P HRV-SV outside diameter: 8.5mm (0.33 inches) or larger

(Oki Electric Cable Company, Limited Specify the number of pairs in_.)

Connector Applicable to External

Wiring

Round connector (10-pin)

USB

Transmission Speed 12Mbps (Full Speed Mode: FS)

Connector Mini-B

Other Electric Characteristics USB 2.0

CompactFlash

Card

Supply Power Voltage 3.3V 5%

Supply Power Capacity Up to 150mA

Card Size TYPE I card TYPE II card is not allowed. I/O cards, such as a modem card are not allowed.

Number of Card Slots 1

Number of I/O Points (Number of Points Accessible to

Actual I/O Modules)

4096 points (X/Y 0 to FFF)

5VDC Internal Current Consumption 0.93A

Weight (kg) 0.24

Base Unit Slots Occupied 1

Notes:

1. For the development environment (personal computer), refer to the following manual. C Controller Module Users Manual (Utility Operation, Programming)

2. The C Controller module differentiates 10BASE-T and 100BASE-TX according to the target device.

The C Language CPU can be added to an iQ Platform or Q Series conguration and allows experienced C programmers to create custom

control programs using VxWorks (sold separately). This product is only meant for the advanced user. The Q12DCCPU-V is the hardware

base for the MES Interface IT e-F@ctory solution, and is included within the QJ71MES96IT Model Number. It is also the hardware base for

the iQ Platforms Ethernet/IP scanner, EIP4CCPU.

Mitsubishi Electric Automation | Programmable Automation Controller / PAC 17

These CPUs include a wide variety of process control functions

optimized to the task of controlling large scale, complex continuous

processes where downtime is not an option. This allows a Q Series

system to fully address the needs of users outside of the scope of

traditional discrete control applications.

Key Features:

52 process control instructions added to standard instruction set

Floating point math coprocessor dedicated to floating point and

process control operations

Autotuning PID with 2 degrees of freedom (responds to both set

value and disturbance)

Compensation functions to allow loop modeling closer to the

actual process

Process alarm functions related to high, low and deviation process

and manipulated variable values

Tracking functions to allow smooth transfer between manual and

automated control

Hot swappable modules

Increased functionality in Version C or later (S/N 07032x)

- SFC active step comment readout instruction

- Increased multiple CPU shared memory flexibility

- 1/1000 second resolution timestamp capability

- Store sampling trace data in Standard RAM

- Power supply error detection function

Model Number Q02PHCPU Q06PHCPU Q12PHCPU Q25PHCPU

Stocked Item S S S -

Programming

Language

Sequence Control

Dedicated Language

Relay symbol language, logic symbolic language, MELSAP3 (SFC), MELSAP-L, Function block and structured text (ST)

Process Control

Language

FBD for process control (*1)

Processing

Speed (Sequence

Instruction)

LD X0 34ns

MOV D0 D1 102ns

Program Capacity (*2, *3) 28k steps 60 kB 124k steps 252k steps

Memory Capacity

Item

Program Memory

(Drive 0)

112 kB 240 kB 496 kB 1008 kB

Standard RAM (Drive 3) 128 kB 256 kB (*4)

Standard ROM (Drive 4) 112 kB 240 kB 496 kB 1008 kB

CPU Shared Memory 8 kB

Maximum No. of

Stored Files

Program Memory 28 60 124 252 (*5)

Standard RAM 3 (*6)

Standard ROM 28 60 124 252

Memory Card Interface Yes

Max. I/O Device Points 8192 points (X/Y0 to 1 FFF)

Max. Physical I/O Points 4096 points (X/Y0 to FFF)

Communication Ports USB (Type-B), RS-232

5VDC Internal Current Consumption 0.64A

Weight (kg) 0.20

Base Unit Slots Occupied 1

Required Manuals

Process Control CPUs

Model Number Description Contents Included with CPU? Stk Item

SH(NA)080316

QnPHCPU/QnPRHCPU (Process

Control Instructions) Programming

Manual

Overview, structure and combinations of process control, instructions,

data used for process control instructions, how to execute PCI, execution

condition switching and functions, instruction list, how to read instruction

list, I/O control instructions, control operator instructions, compensation

operator instructions, arithmetic operation instructions, comparison

operation instructions, auto tuning, error codes, appendices

No (purchase separately) -

Note: Many of these manuals are available by free download from our website, www.meau.com

Notes:

1. PX Developer is required for programming by FBD.

2. The unit of the file size stored in the memory area varies depending on the CPU module. For details, refer to the QCPU Users Manual (Function Explanation, Program Fundamentals)

3. The maximum number of executable sequence steps is as shown. (Program capacity) - (File header size (default 34 steps)). Refer to the QCPU Users Manual (Function Explanation, Program Fundamentals)

4. CPU shared memory is not latched.

5. The CPU module can only execute up to 124 programs.

6. Extended by the upgraded functions of the CPU module.

Q Series Process Control CPUs

Process and Redundant CPUs

18

n

P

R

O

G

R

A

M

M

A

B

L

E

A

U

T

O

M

A

T

I

O

N

C

O

N

T

R

O

L

L

E

R

/

P

A

C

These CPUs take the process control capabilities of the Q Series

process CPUs and add full hot-backup capability by using dual

redundant CPUs. Use this system in applications where downtime

cannot be tolerated for reasons of safety, equipment damage, financial

loss, interruption of service, or regulatory compliance.

Key Features:

Prevent controller downtime with dual redundant CPUs (control and

back-up). Any failure of the control CPU causes immediate transfer

of control to the back-up, preventing system failure or interruption.

Synchronize up to 100,000 words of process data between CPUs

per scan

Switchover time typically around 40ms, insuring

bumpless transfer

CPUs reside on physically separate racks, allowing control CPU to

be replaced while back-up maintains system operation

Low cost of ownership; most parts are interchangeable with

standard Q Series systems

Redundant power supply option

Redundant MELSECNET/H control level network provides link to I/O

stations at up to 25Mbit/s

Over 50 process control related instructions (same as Q Process CPUs)

Most I/O may be hot swapped

Increased functionality in Version D or later (S/N 07032x)

- SFC active step comment readout instruction

- Increased multiple CPU shared memory flexibility

- 1/1000 second resolution timestamp capability

- Store sampling trace data in standard RAM

- Power supply error detection function

Required Manuals

Model Number Description Contents Included? Stocked Item

SH(NA)080486

QnPRHCPU Users Manual

(Redundant System)

Overview, System Configuration, Tracking cable, Procedure for starting

up a redundant system, Redundant system functions, Redundant system

networks, Programming cautions, Troubleshooting, Processing time for

redundant systems

No (purchase separately) -

Note: Many of these manuals are available by free download from our website, www.meau.com

Use same manual set as shown for Q Series Process CPUs, plus the manual listed below.

Redundant CPUs

Model Number Q12PRHCPU Q25PRHCPU

Stocked Item S -

Programming

Language

Sequence Control Dedicated

Language

Relay symbol language, logic symbolic language, MELSAP3 (SFC), MELSAP-L, function block and structured text (ST)

Process Control Language FBD for process control (Programming by PX Developer)

Processing

Speed (Sequence

Instruction)

LD X0 34ns

MOV D0 D1 102ns

Processing Speed

(Redundant

Function)

Tracking Execution Time

(Increased Scan Time)

Device memory 48k words: 10ms; Device memory 100k words: 15ms; QnPRHCPU Users Manual (Redundant System)

Program Size 124 steps 252 steps

Program Memory (Drive 0) 496 kB 1008 kB

Memory Size

Standard RAM (Drive 3) Size of the installed memory card (2MB max.)

Standard ROM (Drive 4) 496 kB 1008 kB

Max. Number of

Files Stored

Program Memory 124 252

Standard ROM 124 252

Max. I/O Device Points (*1) 8192 points (X/Y0 to 1FFF)

Max. Physical I/O Points (*2) 4096 points (X/Y0 to FFF)

Max. CPUs Mounted 1 (multiple-CPU configuration is not available)

Max. Extension Base

0 (All non-redundant modules are mounted on the remote I/O station (the maximum number of modules that can be mounted

on a remote station is 64))

Max. Remote I/O Points 8192 points (up to 2048 points per station)

Program Capacity

Number of Steps 124 ksteps 252 ksteps

Number of Programs 124 252 (*3)

Functions Compatible With Redundant System

Redundant configuration of the entire system, including the CPU, the power supply, and the base unit. Hot standby system for

the control and standby systems online module change both backup and separate mode available. Large-capacity data tracking:

Large-capacity device data transfer (100 kwords) from the control system to the standby system. Network system compatible

with redundant system: Switchover in case of MELSECNET/H or Ethernet module malfunction or network wire disconnection.

Loop Control

Specs.

Control Cycle 10 ms -/control loop (Can be set for each loop)

Number of Control Loops No limit (*4)

Main Functions 2-degree-of-freedom PID control, cascade control, automatic tuning function, feed forward control

RAS

Online Module Replacement The I/O, analog, temperature input, temperature control, and pulse input modules can be replaced (on a remote I/O station)

Output In Case Of Error Stop Clear or output retention can be designated for each module

Communication Ports USB (Type-B), RS-232

Modules Mountable On Main Base Unit Network modules for the Q series can be mounted (Ethernet, MELSECNET/H, and CC-Link only)

Programming Software GX Developer, PX Developer

5VDC Internal Current Consumption 0.89

Weight (kg) 0.30

Base Unit Slots Occupied 2

Notes:

1. Total number of the I/O points on the main base unit, which are directly controlled from the CPU module, and the I/O points controlled as remote I/O by the remote I/O network.

2. The number of I/O points on the main base unit, which are directly controlled from the CPU module.

3. The max. number of files that can be executed is 124. Two SFC/MELSAP-Ls are available, one of which is a program execution control SFC.

4. The number of control loops is restricted by the combination of the device memory capacity (128 kwords/loop used) and the control cycle.

Q Series Redundant CPUs

Mitsubishi Electric Automation | Programmable Automation Controller / PAC 19

Q Redundant CPU Parts

Communication and Networking Module Version Information For Compatibility With Redundant Systems

Note:

1. The boards must be used in combination with the attached driver package SW0DNC-MNETH-B[90K] or later version.

Product Name Model Overview

Stock

Item

Redundant CPU Module

Q12PRHCPU Max. I/O device points: 8192 (physical I/O points: 4096), program capacity: 124 ksteps S

Q25PRHCPU Max. I/O device points: 8192 (physical I/O points: 4096), program capacity: 252 ksteps -

Tracking Cable

QC10TR 1m cable for tracking S

QC30TR 3m cable for tracking -

Base Unit For Redundant

Power Supply Systems

Q38RB Q series I/O mounting main base: Number of power supply slots: 2, number of CPU slots: 1, number of I/O slots: 8 S

Q68RB Q series I/O mounting extension base: Number of power supply slots: 2, number of I/O slots: 8 -

Q65WRB Q series I/O mounting extension base: Dual Q Bus Inputs, Number of power supply slots: 2, number of I/O slots: 5 S

Power Supply Module For Redundant

Power Supply Systems

Q64RP 100 to 120/200 to 240VAC input, 5VDC, 8.5 A output -

Product Name Model Number Overview Version Stock Item

MELSECNET/H

Master Module

QJ71LP21-25

For MELSECNET/H dual optical loop interface module (compatible with SI and QSI)

control / normal / master stations

Function version D

or later

S

QJ71LP21S-25

For MELSECNET/H dual optical loop interface module (compatible with SI and QSI)

control / normal / master stations, equipped with an external power supply

-

QJ71LP21GE

For MELSECNET/H dual optical loop interface module (compatible with GI) control /

normal / master stations

-

QJ71BR11 For MELSECNET/H coaxial single bus interface module control / normal / master stations S

MELSECNET/H

Remote I/O Module

QJ72LP25-25

For MELSECNET/H dual optical loop interface module (compatible with SI and QSI)

remote I/O stations (*1)

S

QJ72LP25GE

For MELSECNET/H dual optical loop interface module (compatible with GI) remote I/O

stations

-

QJ72BR15 For MELSECNET/H coaxial single bus interface module remote I/O stations S

Ethernet

Interface Module

QJ71E71-B2 Ethernet interface module (10BASE2) -

QJ71E71-B5 Ethernet interface module (10BASE5) -

QJ71E71-100 Ethernet interface module (100BASE-TX/10BASE-T) S

MELSECNET / H Board

For Personal Computers

Q81BD-J71LP21-25

For dual optical loop interface board (compatible with SI and QSI) control / normal

stations (*1)

-

Q80BD-J71LP21G For dual optical loop interface board (compatible with GI) control / normal stations (*1) -

Q81BD-J71BR11 For coaxial single bus interface board control / normal stations (*1) S

CC-Link IE Control

QJ71GP21-SX For CC-Link IE Control, dual-loop fiber control stations S

QJ71GP21S-SX For CC-Link IE Control, dual-loop fiber with redundant power control stations -

Tracking cable

Q38RB Q38RB

System A -

Control System

System B - Standby

System

Make Redundant Power

supply module redundant

Make Redundant Power

supply module redundant

Q63RP/Q64RP

(Two modules mounted

on Q38RB)

Q63RP/Q64RP

(Two modules mounted on Q38RB)

Redundant power supply configuration

Sample Configurations

Non-redundant power supply configuration

Tracking cable

QJ71E71

QJ61BT11

QJ71LP21

Q12PRHCPU

Q61P

B 5 3 Q B 5 3 Q

System A -

Control System

System B -

Standby System

Install a module with the

same module name into

the same slot.

20

n

P

R

O

G

R

A

M

M

A

B

L

E

A

U

T

O

M

A

T

I

O

N

C

O

N

T

R

O

L

L

E

R

/

P

A

C

Required Manuals

Required Manuals

Q Series Base Units

The base unit (sometimes called a base rack) is the foundation of Q Series systems. All CPU modules are installed on it, along with a power

supply, I/O and special function modules. Besides providing physical support to the component modules, the base unit enables communication

and power distribution between modules. The base unit can either be directly bolted to a panel, or mounted via DIN rail. In the case of DIN rail

mounting, the DIN rail Adapters must be used. Base units accommodate between 3 and 12 modules. For systems that require more modules

than be accommodated on the base unit, an extension base unit is required. These connect to the base unit via extension cables.

Use these Adapters in situations where mounting of a base or extension unit on a DIN rail is required.

Note: DIN rail mounting is not recommended in locations where high vibration or mechanical shock exists.

Note: Many of these manuals are available by free download from our website, www.meau.com

DIN Rail Mounting Adapters

Model Number Q33B Q35B Q38B Q38RB Q312B

Stocked Item S S S - S

Certification UL cUL CE

Number of Expansion Slots

(Excluding 1st CPU Slot)

3 5 8 8 12

Applicable I/O and Intelligent

Function Modules

Q Series/iQ Platform

Redundant Power Supply Slot No No No Yes No

Dimension (W x H) mm (in) 189 x 98 (7.45 x 3.86) 245 x 98 (9.65 x 3.86) 328 x 98 (12.92 x 3.86) 439 x 98 (17.30 x 3.86)

Weight (kg) 0.21 0.27 0.36 0.47 0.47

Accessories 4- M4 x 14 base unit mounting screws

Model Number Description Contents Included? Stocked Item

IB(NA)0800061

QCPU(Q mode) CPU Module Users

Manual (Hardware)

General specs

CE compliance information

Installation

Safety requirements

Power supply wiring

Overview of system parts

No (included with base units) -

SH(NA)080483

QCPU (Q Mode) Users Manual

(Hardware Design, Maintenance and

Inspection)

PSU specs

CPU H/W specs

Base Unit specs

Memory Card specs

CE compliance information

Installation

Maintenance and inspection

Troubleshooting

No (purchase separately) -

Model Number Description Contents Included? Stocked Item