Академический Документы

Профессиональный Документы

Культура Документы

Specif-Dust Extraction System

Загружено:

Christopher LloydОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Specif-Dust Extraction System

Загружено:

Christopher LloydАвторское право:

Доступные форматы

Enquiry No.

:

Due Date :

Supplier Qtn.

No.:

Date :

NOTE:-

SNO

SPECIFIED / TO

BE CONFIRMED

BY OFFERED DEVIATIONS REMARKS

1.0

1.1

Vendor to note

2.0

2.1 Vendor to confirm

Purpose:

DESCRIPTION FOR BHEL REQUIREMENT

FAX NOS.:

SPECIFICATION CUM COMPLIANCE CERTIFICATE OF RENOVATION AND UPGRADATION OF DUST EXTRACTION SYSTEM, ITEM

NAME & ADDRESS OF THE SUPPLIER :

TELEPHONE NOS.: TELEPHONE NOS.:

2. The "Offered" Column and where applicable, the "Deviations" & "Remarks" Column of this format shall be filled in by the Vendor and submitted along

with the offer. Inadequate / incomplete, ambiguous, or unsustainable information against any of the clauses of the specifications/requirements shall be

treated as non-compliance.

3. The offer and all documents enclosed with offer should be in English language only.

NAME & ADDRESS OF THE INDIAN AGENT :

BHARAT HEAVY ELECTRICAL LIMITED

UNIT'S ADDRESS:

CONTACT PERSON'S NAME/DESIGN./PHONE NO./E-MAIL (FROM PURCHASE DEPTT.)

FAX NOS.:

SPECIFICATION:

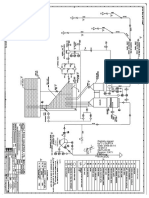

SCOPE:RENOVATION AND UPGRADATION OF 02 Sets OF DUST EXTRACTION SYSTEM, ITEM NO. 19/B/2924 IN INSULATION, TRM BLOCK 3 COMPLYING WITH SPECIFICATIONS

AS BELOW

1. Vendor must submit complete information against clause no. 10 (Qualifying Condition). The offer meeting this clause would only be processed.

Quantity : 02 sets

E-MAIL ADDRESS :

Description of the Dust Extraction Systems

Dust extraction systems shall comprise of on line pulse jet bag filter, supporting structure of bag filter, service platform,

staircase, dust disposal system, centrifugal fan, suction hoods,ducting, flexible joints, duct supports, dampers in duct line

(to adjust suction air quantity), mounted electrics, bag filter control panel, instruments, exhaust duct /stack etc.

E-MAIL ADDRESS :

The insulation shop of transformer manufacturing division comprises of many machines which generates dust in the

form of chips,flakes,dust and fine dust particles.The system envisaged shall collect the dust particles from the near

vicinity of point of generation on the machines shall be conveyed through suitable designed ducting network upto the

dust collecting system,then cyclone installation where chips,flakes and coarser dust particles are separated.The air with

fine dust particles suspended into it shall be conveyed to the bag filters and then the clean air shall be exhausted to

atmosphere through centrifugal exhaust fan and air outlet stack.The existing Two Nos Dust extraction system should be

upgraded for smaller air volumes with limited material contamination and shall include two nos each of the following :-

i) Pre-dust separator Cyclone of capacity of 20000m^3/hr for pre-collection of chips,flakes ,coarser dust particles

complete with bottom dust collecting bin.

ii) Bag-filter of capacity 20000m^3/hr

iii)Single inlet single width Centrifugal Fan of Volume 20000m^3/hr & Pressure 350mmWc or more complete with

motor.

iv)Suitable designed extraction hoods and ducting network.Dust Disposal equipments with standard accessories

This specification outlines the minimum requirement for design, engineering, selection, manufacture, test and

supply/fabrication of Dust Extraction System with all accessories required to be installed to achieve desired performance

in all respect. Specific technical requirement of Dust Extraction System if any shall be mentioned in the job

specification/data sheet as furnished along with the Technical Specification(TS).

PURPOSE & WORKPIECE MATERIAL

Page 1 of 12

SNO

SPECIFIED / TO

BE CONFIRMED

BY OFFERED DEVIATIONS REMARKS

DESCRIPTION FOR BHEL REQUIREMENT

2.2 Vendor to confirm

2.3 Vendor to confirm

2.4 Vendor to confirm

2.5 Vendor to confirm

2.6 Vendor to confirm

2.7 Vendor to confirm

2.8 Vendor to confirm

2.9 Vendor to confirm

2.10 Vendor to confirm

2.11 Vendor to confirm

2.12 Vendor to Confirm

2.13 Vendor to Confirm

2.14 Maximum working temperature: 80C

All stacks for discharge of clean air from dust extraction systems shall have a minimum height of 30m or 3m above top of

roof of the tallest adjacent building / structure whichever is higher or as specified in the job specification. The efflux

velocity from the stacks for dust extraction systems shall be maintained 15m/ sec.(approx.). For rain protection

concentric duct to be provided on the top of stack shall be designed such that it restricts rain water entry into stack but

allows the gases to move vertically upward with the above mentioned efflux velocity.

Horizontal duct shall be avoided as far as possible. Vertical/ inclined ducting shall be

provided.The Successful Tenderer shall include duct supports in their scope as follows:-

a) In-house ducting shall be suitably supported at approx. 3m intervals.

Ducting inside the building shall be supported on the floor or from the column/ civil beam/building

structure/technological structure etc. as applicable. The location and type of supporting arrangement shall be decided by

the Successful Tenderer in consultation with purchaser/or purchasers consultant.

b) Trestle supports shall be provided on ground for the ducting outside the building.

All the rotating parts shall be statically and dynamically balanced. Monitoring ports in ducting

and stack with platforms, approach ladders/ stairs and other requirements shall be strictly as per the latest emission standards

published by Central Pollution Control Board.

Approach, handling and hoisting facilities shall be provided for the equipment. Monitoring port holes of 100mm

diameter with plug, platforms, approach ladders/ stairs, power socket of single phase, 50 Hz,230 V, 15 A and monitoring

equipment lifting facilities shall be provided as per the emission standards published by Central Pollution Control Board.

The dust extraction system shall be designed based on norms specified in the Hand Book of

American Conference of Governmental Industrial Hygienists (ACGIH) with fines factor and to

meet the required fugitive emission standard based on the partys experience. The Successful Tenderer should calculate

and decide the systems capacities of their own using the standard norms. However, in no case, the systems capacities

should be less than as specified in job specification.

The dust extraction systems shall be such that the work zone dust concentration Respirable

Particulate Matter (RPM) less than 10 micron should be limited to 1mg/Nm3 over back

ground level unless otherwise specified in the job specification.

The duct lines shall be designed self-balanced .

Following Indian Standard may please be followed as design guidelines:

i) IS-638-1979: Rubber Gasket sheet jointing

ii) IS-800-1984 (RA 1998): Use of structural steel

iii) IS-822-1970 (RA 1997): Inspection of welds

iv) IS-875-1987 (RA 1997): Structural design

v) IS-1239-1990 (RA 1998) Part I & Part II amendment 2000: Pipe & pipe fittings

vi) IS-1364-1992 (RA 1998) Part I to Part 15 : Hexagonal nuts & bolts

vi) IS-2062-1999 Amendment 2001: Steel for general structure

vii) IS-2309-1989 (RA 1995) : Lighting code practice

viii) IS-2712-1998: CAF gaskets

ix) IS-4894-1957 (RA 1994): Centrifugal fan

x) IS-6392-1971 (RA 1998) Part I & Part II : Design of Steel Chimney

xi) IS-8183-1993 (Amendment1997): Mineral wool insulation

xii) IS-14164-1994 (Amendment2000: Thermal insulation for 80 degC to 750 degC

xiii) IS-11304-1985 (RA 1993): Air Pollution Control in steel plants

Suction hood for the dust extraction systems shall not be less than 5 mm thick MS sheet.

The ducting shall be of circular cross section

The efficiency of the dust cleaning equipment shall be such that the emission from stack

should not be more than 50 mg/Nm3 unless otherwise specified in the job specification. The

average inlet air dust concentration may be taken as 10~15 gm/Nm3 unless otherwise specified in the job specification.

Generally the following air velocities shall be considered for the dust extraction systems.

At hood inlet 1.5 m /sec or suitable.

Ducting 18-25m/ sec

Duct lines shall have cleaning hatches of size 100mm x 75mm with air tight seals for easy

cleaning of accumulated dust near bends & inter connections.

Page 2 of 12

SNO

SPECIFIED / TO

BE CONFIRMED

BY OFFERED DEVIATIONS REMARKS

DESCRIPTION FOR BHEL REQUIREMENT

2.15 Vendor to Confirm

3.0 Vendor to Confirm

3.1 Vendor to confirm

3.2 Vendor to confirm

3.3

3.4 Vendor to confirm

3.5 Vendor to confirm

BAG FILTER

Description of bag filter system

Constructional Features:_The bag filter assembly shall generally consist of the following : -

- Module shell.

- Hopper for each module with manual slide gate & motorized RAVS.

- Storage hopper with rack & pinion gate valves

- Housing and roof panels.

- Tube plate.

- Compressed air distribution system.

- Access doors.

- Filter bags and cages.

- Inlet and outlet manifolds.

- Manual damper at inlet & outlet of each module

- Solenoid operated pulse valves (24 V DC/220 V AC)

- Pulse controller (Sequential timer)

-Bag filter control panel

-Level switch in bag filter hopper & storage hopper

-Pressure switch at compressed air line

- DP switch across bag filter

- Pressure gauge at inlet & outlet of bag filter and at compressed air line

- Weather cowl over bag filter

- Supporting structure of bag filter with service platforms & approach staircases.

Normally bag filter casing thickness shall be 5 mm with sufficient stiffener to withstand design static pressure inside Bag

filter chamber.

The dust extraction system shall be interlocked with the technological equipment/ conveyors.

The sequence of operation shall be such that the dust extraction system shall start 5 minutes

before start of the technological equipment and shall stop 5 minutes after stoppage of the

technological equipment.

Required Air/cloth ratio

The contractor should design the pulse-jet fabric filter dust collector to operate under design flow

conditions with a gas/air to cloth ratio as 1.4 m3/ min/m2 unless otherwise specified in the project specification.

However, the same can vary from 1.0 to 1.8 depending on fabric and dust material to be handled.

The bag filter shall have a plenum chamber, which distributes the incoming gas onto an array of

Fabric filter bags. Dust particles shall be entrapped on the filter fabric, cake lining the bag surface by straining,

impingement, interception and electrostatic attraction. Rotary air lock valves shall be provided at the bottom of bag filter

hopper for dust removal and air sealing.

The inlet air plenum for the fabric filter should feature a tapered feed duct in order to ensure uniform gas flow

distribution to all cells.

Air entry to the cells should be directed uniformly by angles deflection louvers to ensure complete bag usage within the

cell. Cross horizontal flows shall not impinge on the bags in any area.

The bag fixing arrangement shall be such so as to enable easy and quick changing of bags.

Bags shall be hung as near as practicable to vertical so that the bags are not touching anywhere

along their length. The Bag filter shall have antistatic Bags and spark proof design.

Particular attention shall be paid to the layout of the bags. A minimum distance of 75 mm between the bags and the

closest fabric surface such as walls or columns of the casing shall be provided. The spacing between the bags shall be 50

mm (minimum).

Page 3 of 12

SNO

SPECIFIED / TO

BE CONFIRMED

BY OFFERED DEVIATIONS REMARKS

DESCRIPTION FOR BHEL REQUIREMENT

3.6 Vendor to confirm

3.7 Vendor to confirm

3.8 Vendor to confirm

3.9 Vendor to confirm

4.0 Vendor to confirm

5.0 Vendor to confirm

6.0 Vendor to confirm

Antistatic

Filter bags interwoven carbon fiber wire in spiral form should provide higher antistatic properties - both on the surface

and inside than traditional fibers. This should ensure effective purification and reduce the risk of fire and explosion.

Strength and durability

The special shape of filter bags should help to ensure that the high efficiency and effectiveness of the Filter system is

maintained even after long periods of operation. These features should also help to make cleaning of the filter bag very

easy.

Platforms and access stair case

The minimum platform width shall be 1.2 meters. The platforms shall be located at the top of

hoppers, level, at the top of the gas cleaning equipment, and at the different levels required for

maintenance and operation of the equipment and dampers. A safe guard rail should be provided on the platform.

Providing stairways and railing shall provide safe and easy access to the platform.

Intermediate platforms shall be provided for the bag filters. Following minimum structural member shall be considered.

Hand rail: 25 NB IS: 1239-1990

Post: 32 NB IS: 1239-1990

Access grating: 40 depth, 6 thick,

Stair: 40 C/C, 38 slope

Electrics For Bag Filter System of Each DE System

The Electrics for bag filters of D.E. system will consist of pressure switches cum indicator in the

compressed air line, differential pressure switches, solenoid valves, control panel and all other

associated equipment. The brief specification of the major components will be as given below:

Dust hopper/ Holding hopper

A dust storage hopper for each fabric filter module shall be provided. A inverted pyramidal hopper with 65 deg valley

angles shall be installed to collect the settled dust. Vibrator if required in the hopper is to be provided. For hot gas

cleaning system hopper heater with thermal insulation shall be provided to reduce chance of condensation in hopper.

Normally storage hopper thickness shall be 8mm unless defined in the TS .

Bag Cleaning

The bag filters shall be of automatic on line cleaning pulse-jet type as specified in the job specification.The bags

shall be cleaned by means of compressed air pulse jet through solenoid operated pulse valves & programmable sequence

timer. The time interval of cleaning operation & compressed air pulse duration & frequency shall be adjustable.The

sequence timer shall be interlocked with pressure switch (at compressed air line) and DP switch (across bag filter) so

that cleaning operation takes place when there is sufficient compressed air pressure & pressure drop across bag filter is

above the set value. Sequence timer shall be provided for each module separately.

Material of construction of bags shall be selected based on operating temperature, dust quality,Quantity and composition

and air quality. The cleaning of bags shall be carried out in a Predetermined cycle by high-pressure pulse of compressed

air by automatic operation of solenoid valve with timer.

A differential pressure measurement system shall be provided across the bag house. As the dust collects over the bags,

the pressure drop shall be sensed by this system. As this drop exceeds a preset value the differential pressure

measurement system shall send a pulse to start the bag cleaning operation.

Compressed air shall be the cleaning medium and this shall enter the bags in short surges thus

inflating the bags. The dust shall collect in the hoppers provided and shall be transferred by

RAVS to holding hopper.

Efficient and low energy consumption.

It should be polyester filter bag. The filter bag surface which can cope with varying filter loads with all types of wood

dust/ chips. Better filtering efficiency should be achieved with filter medium which provides low pressure drop, giving

low energy consumption.

Page 4 of 12

SNO

SPECIFIED / TO

BE CONFIRMED

BY OFFERED DEVIATIONS REMARKS

DESCRIPTION FOR BHEL REQUIREMENT

6.10 Vendor to confirm

7.00 Vendor to confirm

8.00 Vendor to confirm

9.00 Vendor to confirm

Differential Pressure Switch

i) The differential pressure switch will have two sets of independent micro-switches. The first set will be used for normal

sequential cleaning operation of the bag filters as per lower set value of differential pressure. This set point will be

independently adjustable.

ii) The second set of N.O. contact will close at upper set value of differential pressure representing clogged condition of

bag filter and will be used for signaling and monitoring. This set point will also be independently adjustable. The

contacts will be rated for 5 Amp, 240V AC.

iii) The DP switch will be suitable for outdoor installation. The DP switch casing will be made of

pressure die cast Aluminum with enclosure conforming to IP-66.

iv) One number differential pressure switch with two set points will be provided for each module of the Bag filter.

Alternatively, two numbers of DP switches may be provided for each module one for initiation of bag cleaning operation

and other for signaling and monitoring of clogged

condition.

v) Manometer across filter.

Air Pressure Switch cum indicator

i) One number compressed air pressure switch cum indicator will be provided for each bag filter system in the incoming

compressed air pipeline of the bag filter. The pressure range will match with the operating pressure. The switches will be

snap action type with 1 NO + 1 NC contacts of 5A, 240 V AC. These contacts will be wired up to terminals in the bag

filter control panel. The enclosure of the air pressure switch will be pressure die cast aluminum conforming to IP-65.

Control panel for Bag filter

The control panel will be free standing, floor mounting, fabricated from 2.0 mm thick CRCA sheet steel on a base

channel (ISMC - 75) provided with cable gland plates, having synthetic rubber gasketting, provided with double door &

canopy and enclosure conforming to IPW-55.The control panel will be factory assembled, wired with 1.1 kV grade PVC

flexible wire of copper conductor (minimum size 2.5 sq.mm), factory painted. The control panel will be provided with

following major equipment:

a) Incoming switch (minimum 32A, AC23 duty) with operating handle interlocked with the door,

HRC fuses, contactors, MCBs in the various circuits.

b) Control transformer of required VA rating having +/-5 percent and +/- 2.5 percent tappings in the primary side of the

control transformer with Isolating switches/MCBs in the primary & Secondary sides.

a) 24V DC full wave power pack complete with filter and protective elements and also isolation

cum short circuit protection both at AC and DC sides for power supply to solenoid valves.

b) Auxiliary contactor for control power supply monitoring, interlocking, and controls etc.

e) Auto-manual selector switches, push button switches, indication lamps, various monitoring devices, terminals (with

20 percent spare terminals) and other circuit elements required for control and monitoring.

f) Solid state Bag filter timer.

The bag filter timer will be solid state device suitable for dusty, tropical and specified aggressive environment. The bag

filter timer will be provided with internal semi-conductor fuse protection and will have provision for pulse frequency

setting and pulse duration setting through dependent operating knobs. The number of contacts in the timer will be equal

to number of solenoid operated valves so that the timer will energise only one solenoid valve at a time and shall operate

in sequence.The Bag Filter Timer will provide timed sequential energisation of 24V DC operated solenoid valves of bag

filters. LEDs for each solenoid energisation, power ON in PCB, feedback relay will be provided with potential free

contacts which will close under following conditions :

i) Fault in the PCB.

ii) Open contact in the output side connected to individual solenoid valves. The contact will not close in the event of

Solenoids

i) The solenoid coil will have encapsulated coil ( class`F' insulated with a water proof (IP-65)

plug-on connector. The coil will be suitable for 24V DC /220 V AChaving + 10 % to -15 % voltage

variations. The coil will be made of copper conductor.

Page 5 of 12

SNO

SPECIFIED / TO

BE CONFIRMED

BY OFFERED DEVIATIONS REMARKS

DESCRIPTION FOR BHEL REQUIREMENT

10.00 Vendor to confirm

11.00 Specification of ID Fan

Volume flow: 20000 m3/hr

Volume flow: 4.16 m3/sec

Temperature of Medium: 45 C

Dust load mg/Nm: Clean air

Reference density: 1.293 kg/Nm^3

Density at inlet: 1.058 kg/m^3

Static Pressure at fan inlet: -350 mmwc or more.

Static Pressure at fan outlet: 0 mmwc

Mechanical Design Temperature: 80 C

Fan shaft power at NTP: 28.18 HP

Fan shaft power at operating temperature: 25.3HP

Tip Speed: 81.79 m/s

Impeller: 30.33 GD^2 Kgf.m^2

Rated Torque at Working Condition: 12.83 Kgf.m

Rated Current at Working Condition: 34.53 amp

Sound Level at Design Point: 80.33 db

Max. Sound Level: 88.36 db

Vibration Amplitude (Normal): 1.9900 Mil

Static efficiency: 79.61 %(min)

Total efficiency: 80.5 %( min)

Fan speed: 1440 rpm or suitable.

Minimum recommended motor power with 10 % margin on shaft power at operating condition :30 HP / 4P or more

Type of blade: Backward Inclined

GENERAL ELECTRICAL LOGIC AND OPERATING PRINCIPLE OF THE BAG FILTER SYSTEM

Mainly the differential pressure will govern the Dedusting Bag Filter system across the Dedusting Modules. The total

electrical logic will be controlled by the Devices like Differential Pressure Switch (DPS), solid-state sequential multi-

channel timer, solid-state master card, solenoid operated Diaphragm valves, inlet compressed air line pressure switch

(P.S.) etc. DPS will be connected across the clean and dirty Air Chamber of the Bag Filter Module to measure the

Pressure Differential. As the Filtration process commences, there is a gradual buildup of dust on the Filter Bags which

generates Differential Pressure. When this Differential Pressure attains a Pre-set value based on inlet dust concentration,

type of dust and its particle size distribution, the differential pressure switch will get energized and send signal to the

master card located in the control panel.The master card will actuate the timer whose channels are connected with

solenoid valves mounted on the compressed air header-Air Manifold Tank. Through the timer, the solenoid coil gets

magnetized and makes an opening for the compressed air to flow from air manifold tank to pulse header pipe.The pulse

duration time will be adjustable. During this time the solenoid coil will remain energised allowing pulse air to flow.

Energisation of other solenoid will take place in sequence one after the other. The time gap between the two-solenoid

energisation will also be adjustable.The process continues till the pressure differential drops below the set value. The

D.P.Switch then gets de-energised which in turn cuts off the timer resulting in de-energisation of solenoid valves. The

process will repeat again from the next solenoid valve based on the pressure differential switch and signal from the

master card.A pressure switch mounted on the compressed air line will sense the available pressure and dedusting

system/ centrifugal fan will switched off in case the available pressure falls below

the specified pressure in compressed air line.

Page 6 of 12

SNO

SPECIFIED / TO

BE CONFIRMED

BY OFFERED DEVIATIONS REMARKS

DESCRIPTION FOR BHEL REQUIREMENT

11.1 Vendor to confirm

11.2 Vendor to confirm

11.3 Vendor to confirm

Description of Centrifugal Fan

Dedusting system fans are single width single inlet centrifugal type with inlet box.

Generally the fans shall be of limit load design. Centrifugal Fan design shall conform to IS 4894 1987 (Reaffirmed

1991).The fan shall be of rugged steel construction, industrial duty type and suitable for the proposed project/plant. Fan

housing shall be of welded construction and provided with flanges at inlet and outlet sides for duct connections.Fan

casing, impeller & shaft shall have provision for thermal expansion.Non metallic flexible joint (EPDM quality canvas)

shall be provided at fan inlet & outlet.

The fan unit shall be free from undue noise and vibration during operation; normally the fan speed shall not be more than

1500 RPM, preferably less than 1000 RPM.The fan shall be both statically and dynamically balanced as per ISO:1940. In

general HVAC system application balancing grade shall be of 6.3.

Fan characteristics curve shall be such that the maximum pressure is 15 to 20 % more than the design pressure. The

design point should be chosen at a point located to the right of the optimum efficiency on the fan characteristic curve.

The distance between the design point and the maximum pressure limit shall be

minimum 40%, referred to the volumetric rate.

The fan impeller may be backward curved / backward inclined/forward curve/radial job specification as per

requirement.Drain connection shall be provided at the lowest point of scroll.

Fan bearing shall be of self-aligning, heavy duty type. Bearing shall be selected with ample safety factor for longer life.

Sufficient number of suitable vibration isolators of approved make shall be provided to ensure isolation of vibration from

the equipment to foundation as per requirement.

Fabricated steel bracket of M.S. angles, channels and chequered plates shall be provided to take static and dynamic load

of the fan and motor assembly.The fan shall be suitable for belt/direct coupling operartion.

Electrically operated / manually operated inlet vane damper shall be provided as a regulating device for control of fan flow volume

as per TS requirement. The air stream shall be caused to rotate through alteration of the pitch of guide vanes.

Manually/electrically operated fan outlet damper shall be provided as per TS requirement. Fan inlet and outlet flexible connections

shall be provided as per TS requirement. Guide plate shall be provided to prevent direct contact of flexible fabric with air flow.

Anchor bolts, nuts, foundation plates etc. as required shall be supplied with the equipment. The equipment shall be designed to

permit ease of access during inspection, maintenance and repair.

The first critical speed of the rotating assembly shall be at least 25% above the operating speed.

The housing shall be provided with lifting eye for ease of handling and bolted type access door.

The noise level of fan shall not exceed 85dB(A) at a distance of 1 m when running at full load. Material of construction, capacity

and static pressure of fan shall be as per requirement.

The fan shall have following minimum thickness of materials for different parts unless otherwise specified in TS for HVAC

application

Impeller :

Backward curved blades (non overloading type) shall be provided. The blades shall be welded between the impeller

discs. The impeller connection shall be flanged on the shaft for an adequate torque protection and centring to take care of

thermal expansion. Post weld heat treatment shall be done for stress relieve of

welds.The impeller shall be balanced dynamically complying with a balancing grade of at least Grade 6.3 according to

ISO 1940 Part 1. The quiet running of the fan shall be within the range "good" in conformity with VDI 2056 machine

group "G" or "T".Fan impeller blade shall have composite liner (6mm base plate & 3 mm hard facing) of hardness 650

BHN (minimum)

The fan shall be provided with Casing with inspection door & drain plug ,drive motor, Variable Frequency drive unit ,

drive coupling/V-belt, belt pulley, belt guard, variable inlet vane, fan outlet damper, slide rails, foundation plates,

gaskets, base frame, vibration isolators, fan inlet protection screen, Impeller, Hub, Inlet Cone, Flexible type coupling

with guards, Long pedestal with Common base frame,Std. Inlet & Outlet Non-Metallic flexible connection with C/F,

Foundation bolts & fixing hardware and Insulation, Fire arrestor, Fire Detectors and other standard accessories unless

otherwise specified in the TS.All these items/materials and accessories shall be supplied with the fan.

Painting Parrot Green

Page 7 of 12

SNO

SPECIFIED / TO

BE CONFIRMED

BY OFFERED DEVIATIONS REMARKS

DESCRIPTION FOR BHEL REQUIREMENT

Vendor to confirm

Vendor to confirm

13.0 Vendor to confirm

14.0 Vendor to confirm

15.0 Vendor to confirm Duct line dampers

a) Hand operated damper (Geared hand wheel)

The hand operated damper shall be multileaf opposite acting aerofoil blade type damper with external operating links

provided at the outlet of the fan for controlling air flow. The damper shall be made of GI sheet with MS frame unless

otherwise specified in the TS. The fully close/ open/ partial closing position shall be marked on

the damper casing.

b) Electrically operated/pneumatic damper

The electrically operated damper shall be provided as a regulating device for control of air flow through duct as per TS

requirement. Provisions shall be kept for interlocking the damper with fire protection system. The fully closed / open /

partial closing position shall be marked on the damper casing.

c) Solenoid operated fire proof damper

This damper shall be provided in supply air duct. It shall be operated by solenoid which is to be interlocked with the fire

detection system of the served premises. In case of fire in the premises the fire detection system shall activate the

solenoid and the solenoid in turn shall close the damper to stop air flow in the duct line. The fully close/open position of

the damper shall be marked on damper casing.

Shaft :

Shaft dimensioning shall be such that the first critical speed for bending, taking into consideration the bearing elasticity,

is at least 25% above the working speed of the fan. The fan shaft has to be balanced dynamically, individually, or

together with the impeller. The balancing grade must be at least Grade 6.3 according to

ISO 1940 Part 1.

Shaft Seal :

The sealing between shaft and casing shall be designed as a set collar or a carbon ring seal, preferably to be fastened to

the bearing or bearing pedestal and flexibly connected with the casing. The same shall be replaceable from outside fan

casing without disturbing shaft/ bearing.

Bearings :

The impeller shaft shall be supported on grease lubricated antifriction bearings.The locating bearing at the drive end

must be able to absorb axial forces in either direction.Bearing pedestal & sole plate shall be suitable for rigid concrete

foundation.

Casing :

The volute casing together with the inlet boxes shall have a horizontal split for removing the impeller. Splitting lines

shall be flanged & supplied with gaskets.For reinforcement of the casing continuously welded ribs shall be provided. Fan

casing shall be with insulation anchors. Acoustic insulation shall be provided to limit the noise level within 85 dB (A) at

1 m distance.Hinged inspection doors shall be provided on casing & inlet boxes.

Provision for fixed points and guides must ensure casing expansion.

Pre-Collector

The collector shall be used as a preliminary dust catcher and a common header for different incoming ducts fromvarious

suction hoods. The collector shall comprise cylindrical casing with service doors of quickly clamped type, incoming and

exhaust manifold connected to collector, rotary air lock / double flap valve at the bottom. The dust accumulated at the

bottom of collector shall be disposed off through rotary air lock / double flap valve to the conveyor. The velocity of air

inside the collector shall be around 4-5 m/s. The Tenderer shall compute the diameter of the collectors to achieve this

velocity. The length of the collector shall depend on the convenience of connecting various ducts to it. Duct connections

should not be bunched in a particular area and shall be evenly distributed on the cylindrical surface of the collector. The

mode of connecting incoming ducts with collector body shall be of flanged type. The air shall enter the collector

tangentially and not radially. The exhaust duct shall be fitted to the exhaust manifold by flanged connection. The body

and support of the collector shall be designed to withstand its self weight along with the weight of water and dust

considering worst conditions.

Descriptions of the dampers

Wall mounted dampers

a) Self acting damper (Gravity damper)

Self acting dampers are provided to maintain pressurisation inside the premises.

The damper shall be multiblade type made of Aluminium flaps of not less than 24G thickness and MS frame. These shall

be designed to operate when the positive pressure inside the premises exceeds 2-3 mm WC. It can operate in fully open

or partial open positions.

b) Fusible link fire damper

Fusible link fire dampers are provided to stop the flow of air through the exhaust opening when fire breaks out in the

premises. This damper shall be provided at the inside face of wall opening to be provided for outlet/exhaust of air from

the premises.This damper shall essentially consist of multi-leaf blades. MS frame, fusible link with spring/gravity

arrangement of auto closing of the damper. The fusible link shall be made of low melting alloy which can fuse at a

temperature of about 70/80oC. The damper shall be normally in open position; it shall close on melting of the fusible link

caused by temperature rise due to fire etc. in the premises.

Page 8 of 12

SNO

SPECIFIED / TO

BE CONFIRMED

BY OFFERED DEVIATIONS REMARKS

DESCRIPTION FOR BHEL REQUIREMENT

16.0 Vendor to confirm

16.1 Vendor to confirm

16.2 Vendor to confirm

16.3 Vendor to confirm

16.4 Vendor to confirm

16.5 Vendor to confirm

16.6 Vendor to confirm

16.7 Vendor to confirm

16.8 Vendor to confirm

JOINTS

Matching flanges are to be bolted together with asbestos rope gasket or rubber gaskets. All bolts and gaskets for jointing

shall be included in the successful tenderer scope of work. All duct joints are to be air tight to minimise air leakage

2) Conveying velocity

A conveying velocity of 18-25 m/Sec shall be maintained at all points in the ductwork between dust collection hood and

dust collection plant to ensure flow of air without settling of dust.Hinged cleaning hatches shall be provided on the

ducting near the bends & interconnection of ducts. Measuring ports shall be provided on the ducting near each suction

point and on ducting before & after the centrifugal fan to measure the flow rate and pressure. Platform with ladder shall

be provided for approach to cleaning hatches & measuring ports.

Provision for Slide Gates/ Dampers

All extraction points shall have slide gates (single leaf inclined plate type) /dampers provisions for flow balancing during

commissioning if required. These gates/dampers shall be bolted by the successful tenderer in position after

commissioning to prevent inadvertent operation and consequent un-balancing of flow of the dedusting system.

DUCTING NETWORK OF DUST EXTRACTION SYSTEM

01 DUCTING NETWORK

Ducting Network shall comprise of suction hood, ducting, duct support, measuring hatch,cleaning hatch and duct line

dampers as required.

Details of collecting enclosure and suction hoods

The suction hoods and enclosures shall be constructed of 5 mm MS plate unless otherwise specified in the job

specification with necessary external stiffeners, flanges, counter flanges,fasteners, gaskets and other accessories for

fixing with technological equipment and duct line.

Dust collection hoods and enclosures shall be fitted with conveniently placed hinged access doors (top hinged type) to

enable internal access to the equipment for maintenance as required. The air velocity at hood inlet shall be 1.5m/Sec or

suitable.

Straight Duct Runs

Interconnecting duct work shall be circular in cross section. The duct work shall be fabricated from mild steel plate,

IS:2062-1999 or be seam welded spiral wound duct work as per job specification requirement.

Branches

Branch connections should be oriented to the top or side of the main with no two branches entering at opposite sides.

Duct Cleanout Doors

Clean-out doors will be provided on horizontal runs, before elbows and junctions. The spacing between cleanout doors

should not exceed 6 meters. Clean out doors will be constructed to have a length of 600 mm or the duct diameter which

ever is less for ducts upto 1 meter diameter. Larger diameter ducts will have clean out doors sized 600 mm high by 600

mm wide.

Provision of Flow Testing Points

All extraction branch ducts shall have two 50mmdiameter capped sockets installed at 90 to one another at least 6D away

fromflow disturbance (bends, hood inlets) for insertion of pitot tubes for flow measurement and system balancing during

commissioning. Test points are to be located in a readily accessible position in the duct. However in any suction hood if

flow appears to be on the lower then necessary flow measurement and correcting device shall be made by the successful

tenderer to suit site.

Duct work details shall have following minimum features :

1) Construction

The duct sizing shall be so selected to maintain proper conveying velocity throughout the system. Man holes/hand holes

and dust outlets shall be provided at intervals to facilitate cleaning of dusts and for disposal of dust. The successful

tenderer shall design the dedusting system ductwork connecting the dust collection hoods, to the dust collector, fans and

stack. The ducting shall be fabricated from M.S.(IS : 2062- 1999 ) having

thickness as follows unless otherwise specified in the job specification.

Duct diameter Straight line duct thickness Bend Thickness

Upto 500 mm 3.15 mm 4 mm

Upto f 900mm 4 mm 6 mm

f 900mm to f 1500mm 6 mm 8 mm

f1500mm to f 2000 mm 8 mm 10 mm

above f 2000mm 10 mm 10 mm

Approx 250 M2 of duct work has to be fabricated.

Suitable ceramic rope/ rubber packing shall be provided at the flanged joint to make the system leak- proof.

Page 9 of 12

SNO

SPECIFIED / TO

BE CONFIRMED

BY OFFERED DEVIATIONS REMARKS

DESCRIPTION FOR BHEL REQUIREMENT

16.9 Vendor to confirm

16.10 Vendor to confirm

16.11 Vendor to confirm

16.12 Vendor to confirm

16.13 Vendor to confirm

16.14 Vendor to confirm

16.15 Vendor to confirm

16.16 Vendor to confirm

17.0 Vendor to confirm

Fire /spark arrestor and detectors placed in all ducting network at the inlet of suction side of bag filter.

To protect both the duct system and dust collector from ignition, a QUENCHER in-line spark arrestor/cooler shall be

installed in the ductwork .Automatic fire quencher system with suitable quenching madium/arrangement for WOODEN

DUST PARTICLES

The duct work will be pressure balance type. However, during testing and commissioning if any throttle piece is required

for adjustment of flow in any duct branch same will be carried out by the successful tenderer without any commercial

implication.

Flexible connection at inlet & outlet of fan and in the ducting network will be provided by the

successful tenderer as required.

Self-supported stack shall be provided to discharge the cleaned air to atmosphere.Exhaust ducting upto the roofing and

outside the block shall be provided.

TECHNICAL SPECIFICATIONS FOR SPARK ARRESTOR

1. Type of Spark Arrestor Type Baffle Type

2. Air handling Capacity M3/hr 20000

3. Type of Dust Fine wood chips

4. Dust concentration at Suction g/Nm3 30

5. Dust concentration at Exhaust g/Nm3 25

6. Inlet temperature Deg C 50

7. Maximum Design Temperature Deg C 130

8. Pressure drop spark arrestor Mm WG 50

9. Number of baffle in housing Qty 3

10. Velocity at inlet and outlet of Spark Arrestor m/s 16

11 Velocity inside Spark Arrestor m/s 5

B CONSTRUCTIONAL DETAILS

C HOUSING

1. Material MS

2. Thickness mm 5

D HOPPER

1. Material MS

2. Thickness mm 5

3. Hopper Valley Angle Deg 61

E INLET TRASITION

1. Material mm MS

2. Thickness mm 5

3. Number of Housing No. 1

4. No. of Hopper No. 1

F SAND BLASTING Excluded

G PAINTING Enamel

Following safety features in addition to other standard safety features should be provided on the system:

Duct system hangers and support

The ductwork support spacing and hangers will be designed for the weight of settled dust plus a 25% design margin.

Following dust load will be considered for designing duct and duct support and duct stiffeners.

Duct dia % Cross section of duct filled up with dust.

Less than 500 mm 35%

500 mm to 1400 mm 30%

1400 mm and more 25%

Bulk density of dust will be considered 1.7 t/m3 unless otherwise specified in job specification.

All inside building duct and duct along main structural building will be supported from plant building structure. Duct

supporting member's length height section will be decided during detail engineering. To suit site condition supporting

members may have to be modified by the successful tenderer without any commercial implication to the purchaser. All

outside ducting network shall have independent duct supporting trestles.

Ductwork Layout

Ductwork will not interfere with fixed or mobile crane access to the plant. Horizontal run of the ducting will be avoided

to prevent settling of dust.

Minimum horizontal clearance from road center line is 5 meters. It is the successful tenderers responsibility to effect the

dedusting system ductwork arrangement in accordance with the design requirements set down in the specification and to

the satisfaction of the purchaser/consultant.

Ductwork integrity

The successful tenderers ductwork design must ensure that the ductwork will not collapse at any point, should it be

subject to the maximum suction capacity of the fan system. The design will accommodate any variation in ambient

temperature.

Page 10 of 12

SNO

SPECIFIED / TO

BE CONFIRMED

BY OFFERED DEVIATIONS REMARKS

DESCRIPTION FOR BHEL REQUIREMENT

Vendor to confirm

Vendor to confirm

Vendor to confirm

19.0

19.1 Vendor to Confirm

19.2 Vendor to Confirm

19.3 Vendor to Confirm

19.4 Vendor to Confirm

20.0

20.1 Vendor to Confirm

20.2 Vendor to specify &

confirm

20.3 Vendor to Confirm

21.0

21.1 Vendor to Confirm

22.0 START-UP & COMMISSIONING

22.1 Vendor to confirm

22.2 Vendor to confirm

22.3 Vendor to confirm

22.4 Vendor to confirm

22.5 Vendor to confirm

22.6 Vendor to confirm

22.7 Vendor to confirm

23.0

Schedule of Commissioning shall be submitted with the offer.

Charges, duration, terms & conditions for Installation & Commissioning should be furnished in detail separately by

vendor along with offer.

Civil foundation and foundation material will be in BHEL scope of supply. While the Foundation and other requirements

for civil work will be specified by the supplier. BHEL will be provide chequer plates for trench& pit

covering.Dismantling of existing dust master and any Civil work shall be in BHEL scope of work. However drawings

duly approved has to be furnished by supplier for foundation etc.

Maintenance manual

BHEL testing engineer and maintenance person should be trained at supplier's Works for mutually agreed period in the

area of

(a) Use of all system Features, programming for Measuring Systems & supplied accessories etc.

(b) Electrical, Electronic & maintenance for system & other supplied equipments

Demonstration of all features of the Dust extraction system & all accessories to the satisfaction of BHEL for their

efficient and effective use.

Demostration by actual use of all supplied components and accessories to their full capacity.

Commissioning spares, required for commissioning of the system within stipulated time, shall be brought by the supplier

on returnable basis.

Supplier to take full responsibility for carrying out the start up and commissoning.Complete erection and commissioning

of the system and proving of process parameters will be in suppliers scope of work. Any modification in the existing

system has to be done by supplier.. Minimum two job trial will be taken as per BHEL process specifications. Successful

proving of BHEL components by the supplier shall be considered as part of commissioning. Operational Tests deemed

necessary for system acceptance shall form part of the commissioning activity.

Test & Guarantee Certificate.

DOCUMENTATION :

4 copies of each of the following in English language shall be supplied along with the system

Instruction manual

TRAINING:

SYSTEM INSPECTION:

Calibration certificate

Inspection at suppliers works before dispatch

Demonstration of all features of test plant transformer and all Accessories.

The Instrument shall conform to following factors related to environment :

ENVIRONMENTAL PERFORMANCE OF THE SYSTEM: 18.0

(a) If any safety / environmental protection enclosure is required it should be built in the system by the vendor.

2. All electronics parts are housed in shielded enclosures.

AMBIENT CONDITIONS & THERMAL STABILITY :

All routine type tests should be carried out at suppliers works on the system before dispatch in presence of BHEL

representatives

1.System should have adequate and reliable safety interlocks / devices to avoid damage to the system, workpiece and the

operator due to the malfunctioning or mistakes.

Page 11 of 12

SNO

SPECIFIED / TO

BE CONFIRMED

BY OFFERED DEVIATIONS REMARKS

DESCRIPTION FOR BHEL REQUIREMENT

23.1 Vendor to Confirm

23.2 Vendor to Confirm

24.0

24.1 Vendor to Confirm

25.0

25.1 Vendor to Confirm

26.0

26.1 Vendor to Confirm

26.2 Vendor to Confirm

26.3 Vendor to submit

26.4 Vendor to submit

27.0

27.1 Vendor to confirm

27.1.1 Vendor to confirm

27.1.2 Vendor to confirm

27.1.3 Vendor to confirm

27.1.4 Vendor to confirm

27.1.5 Vendor to confirm

27.1.6 Vendor to confirm

27.1.7 Vendor to confirm

27.1.8 Vendor to confirm

27.1.9 Vendor to confirm

Equipment Model

Total weight of the system

Name of the customer / company where similar system is installed. (Copy of Purchase order should be furnished)

Only those vendors should quote, who or their principal have supplied and commissioned (either directly or their

autorised vendor) at least one No of dust extraction system of Air flow 20000 m3/hr or higher capacity in the past ten

years and such system is presently working satisfactorily

i) For more than one year after commissioning and and

ii) The issuing date of such Performance Certificate should not be more than 1 year old from the tender opening date.

Phone, FAX no. and email address of the contact person of the customer.

Performance certificate (in English language only) regarding satisfactory performance of the equipment AND of Spark

Arrestor mentioned in clause 27.1 from any one customer (issued within 1 year of tender opening).

BHEL reserves the right to verify information submitted by vendor. In case the information is found to be false /

incorrect , the offer shall be rejected.

Authorization Letter from Original Equipment Manufacturer( in case of not directly quoted by OEM) for quoting of

their system and provide support for commissioning and after sales services.

GENERAL : The vendor should submit the following information:

Complete postal address of the customer.

Year of commissioning.

Name and designation of the contact person of the customer.

Application for which the system is supplied with details of accuracies achieved on the job.

Vendor to submit, along with offer, the reference list of customers where similar systems have been supplied mentioning

the customer, Machine Model, major specifications of the supplied system, Year of Supply etc

Detailed catalogues , sketch/ photographs of the m/c and accessories/ attachments should be submitted with the offer.

12 months from the date of commissioning of the system.

QUALIFYING CONDITIONS :

GUARANTEE :

Thermal Stability of the complete system keeping in view specified Ambient Conditions and accuracy requirements of

BHEL components and trouble free operation of the system should be ensured by vendor.

(Vendor to confirm that system is suitable for above and details of provisions on the system for the same should be

furnished by Vendor)

Air worthy/Sea worthy & rigid packing for all items of complete system, all Accessories and other supplied items to

avoid any damage/loss in transit. When system is dispatched in containers, all small loose items shall be suitably packed

in boxes

PACKING:

Total System and all supplied items should work trouble free and efficiently under following operating conditions and

should give specified accuracies. power supply : Frequency: 50 Hz

1.5 Hz Operating Humidity : 10% to 90% Operating Temperature : 0C to 45C

(Vendor to confirm that system is suitable for above and details of provisions on the system for the same are to be

furnished by Vendor. The ambient conditions mentioned above for control system will be made available with suitable

air-conditioning at works.)

Page 12 of 12

Вам также может понравиться

- CH Fume Extraction System RSP BF#1Документ7 страницCH Fume Extraction System RSP BF#1bappabatliboi100% (1)

- 803 Service ManualДокумент196 страниц803 Service Manualвася рогов100% (1)

- Air Washer UnitДокумент19 страницAir Washer UnitAnonymous BbZceWkVn100% (1)

- FAT Form Winch UnitДокумент7 страницFAT Form Winch UnitYadi KusmayadiОценок пока нет

- Uma Cement Bag FilterДокумент11 страницUma Cement Bag FilterSUNIL TVОценок пока нет

- Calculate pump discharge pressure from total headДокумент8 страницCalculate pump discharge pressure from total headMansuri Tausif AhmedОценок пока нет

- Truck and Rail Unloading SystemДокумент6 страницTruck and Rail Unloading SystembalavenguОценок пока нет

- TAC Hydrant Manual PDFДокумент113 страницTAC Hydrant Manual PDFVaibhav SawantОценок пока нет

- Practical Guide to Dust SuppressionДокумент20 страницPractical Guide to Dust SuppressionSeshupower09100% (1)

- Wet Scrubber Application Guide: Impingement Plate Scrubbers Venturi Scrubbers Eductor Venturi ScrubbersДокумент11 страницWet Scrubber Application Guide: Impingement Plate Scrubbers Venturi Scrubbers Eductor Venturi ScrubberssilahganОценок пока нет

- Ash Handling Piping Systems: Chapter C14Документ28 страницAsh Handling Piping Systems: Chapter C14abhilash nairОценок пока нет

- Aterial Andling Lassics: Achieving High Reliability From Gravity Flow Hoppers and Bins and Pneumatic Conveying SystemsДокумент33 страницыAterial Andling Lassics: Achieving High Reliability From Gravity Flow Hoppers and Bins and Pneumatic Conveying SystemsShrikant Jadhav100% (1)

- Digitally signed wet dust extraction system design reportДокумент17 страницDigitally signed wet dust extraction system design reportmathan_aeОценок пока нет

- Damper TorqueДокумент3 страницыDamper TorqueNguyễn LinhОценок пока нет

- Arch Environmental Equipment Dust HandbookДокумент19 страницArch Environmental Equipment Dust Handbookshanmars100% (2)

- Magnetic Separators and Metal DetectorsДокумент31 страницаMagnetic Separators and Metal Detectorstrung2iОценок пока нет

- Mecawber DenseveyorДокумент4 страницыMecawber DenseveyorkanthmekalaОценок пока нет

- Tender For Dust ExtractionДокумент73 страницыTender For Dust ExtractionMohsinShaikh100% (1)

- TS of Travelling TripperДокумент10 страницTS of Travelling TripperShashank HegdeОценок пока нет

- Understanding and Preventing Hazards of Metal DustДокумент9 страницUnderstanding and Preventing Hazards of Metal DustBobKatОценок пока нет

- Tech Specs For Nitrogen GeneratorДокумент5 страницTech Specs For Nitrogen Generatordhanu_lagwankarОценок пока нет

- BV-P2103GB Pneumatic Conveying For The Cement and Gypsum Industries Sept 12Документ20 страницBV-P2103GB Pneumatic Conveying For The Cement and Gypsum Industries Sept 12Kenny RuizОценок пока нет

- Konseling Kreatif Dan Jarak JauhДокумент66 страницKonseling Kreatif Dan Jarak JauhNindyani BudiОценок пока нет

- Dust Extraction Design ReportДокумент13 страницDust Extraction Design ReportKartik Mendiratta100% (1)

- General Indications: AnticoagulantsДокумент15 страницGeneral Indications: AnticoagulantswahidОценок пока нет

- Pneumatic Conveying: Technology You Can TrustДокумент16 страницPneumatic Conveying: Technology You Can TrustSyed Rameez MohiuddinОценок пока нет

- Axial Fan SpecificationДокумент9 страницAxial Fan SpecificationRamakrishnan100% (1)

- Confined Space Ventilation TechniquesДокумент16 страницConfined Space Ventilation TechniquesTerry A. WaldropОценок пока нет

- Ash Handling SystemДокумент4 страницыAsh Handling Systemrmm99rmm99Оценок пока нет

- Pneumatic Conveying Systems and Components For Bulk Material HandlingДокумент8 страницPneumatic Conveying Systems and Components For Bulk Material HandlingmseifОценок пока нет

- B652 Dust ControlДокумент20 страницB652 Dust ControlSiva Kumar MathanОценок пока нет

- Dust Extraction SystemДокумент13 страницDust Extraction SystemEng Tennyson SigaukeОценок пока нет

- Dedusting SystemДокумент4 страницыDedusting SystemdanmertzОценок пока нет

- Dust extraction system bag filter detailsДокумент6 страницDust extraction system bag filter detailsAnonymous W9VINoTzaОценок пока нет

- Pneumatic TechnikДокумент16 страницPneumatic TechnikFarid AhmedОценок пока нет

- Technical Specification DuctДокумент13 страницTechnical Specification DuctramamoorthyОценок пока нет

- Tech Specification VSDДокумент9 страницTech Specification VSDDony SaputraОценок пока нет

- 9.0 Dust Collection SystemsДокумент15 страниц9.0 Dust Collection SystemsNol BarandonОценок пока нет

- Underground Facilities for Better Environment and Safety - India Ventilation of long tunnelsДокумент13 страницUnderground Facilities for Better Environment and Safety - India Ventilation of long tunnelsClifford Allen CooperОценок пока нет

- Chapter 11 Blood Specimen Handling: Phlebotomy, 5e (Booth)Документ35 страницChapter 11 Blood Specimen Handling: Phlebotomy, 5e (Booth)Carol Reed100% (2)

- 6 Conveyor PneumaticДокумент35 страниц6 Conveyor PneumaticRahmat RN100% (1)

- Normal To Real Flow Rate and FAD Flow RateДокумент25 страницNormal To Real Flow Rate and FAD Flow RateChristopher LloydОценок пока нет

- IBC CODE - International Code For The Construction and Equipment of Ships CarryiДокумент9 страницIBC CODE - International Code For The Construction and Equipment of Ships CarryiLuka KriletićОценок пока нет

- Data Sheet AgitatorДокумент10 страницData Sheet AgitatorEdi KurniawanОценок пока нет

- Belt CONVEYOR ProcedureДокумент8 страницBelt CONVEYOR ProcedureNovan RosyandyОценок пока нет

- Dust Collector Specification - Pilani - 1Документ11 страницDust Collector Specification - Pilani - 1pilanienviroОценок пока нет

- Venturi Scrubber Design Project for Air Pollution ControlДокумент1 страницаVenturi Scrubber Design Project for Air Pollution ControlChristopher LloydОценок пока нет

- Pulley System - CalculationsДокумент3 страницыPulley System - CalculationsSIL PROJECTSОценок пока нет

- GTS 2Документ730 страницGTS 2Aveek SenguptaОценок пока нет

- Water Mist Systems in Tunnels: Some Unanswered QuestionsДокумент10 страницWater Mist Systems in Tunnels: Some Unanswered QuestionsChristopher LloydОценок пока нет

- Ultrasonic Gas Metering Skid SpecificationДокумент38 страницUltrasonic Gas Metering Skid Specificationer_bhavin3119100% (1)

- Indian Standard - Code of Practice For Installation and Maintenance of Internal Fire Hydrants and Hose Reels On PremisesДокумент33 страницыIndian Standard - Code of Practice For Installation and Maintenance of Internal Fire Hydrants and Hose Reels On PremisesDilip VemulaОценок пока нет

- Atex ExplainedДокумент3 страницыAtex ExplainedErica LindseyОценок пока нет

- Tandem lifting method at ACC siteДокумент7 страницTandem lifting method at ACC siteHsebepl NkОценок пока нет

- Beumer - Pipeconveyor TechnologyДокумент51 страницаBeumer - Pipeconveyor TechnologyAli AlatasОценок пока нет

- Aptech Advances in Pneumatic Conveying EditorialДокумент17 страницAptech Advances in Pneumatic Conveying EditorialMinh Tú PhạmОценок пока нет

- Flow Assessment of Powders in Pneumatic Conveying - A Bench Top A PDFДокумент385 страницFlow Assessment of Powders in Pneumatic Conveying - A Bench Top A PDFwijaya adidarmaОценок пока нет

- Secondary Dedusting System - Manual AДокумент144 страницыSecondary Dedusting System - Manual AAlberto BragaОценок пока нет

- Eziduct Ducting CatalogueДокумент32 страницыEziduct Ducting CataloguethecrowdedhouseОценок пока нет

- Space Requirements For Electrical RoomsДокумент2 страницыSpace Requirements For Electrical Roomsnetsavy71100% (1)

- Sugar Dust Explosion and FireДокумент13 страницSugar Dust Explosion and FireBestKanlayaprasitОценок пока нет

- Carbon Dioxide Fire Fighting System DesignДокумент28 страницCarbon Dioxide Fire Fighting System DesignMohamed Abdel BasitОценок пока нет

- Aero Belt ConveyorДокумент8 страницAero Belt ConveyorsrinivasakumarОценок пока нет

- Bin vent selection for pneumatic conveying systemsДокумент7 страницBin vent selection for pneumatic conveying systemsĐặng Trung AnhОценок пока нет

- Papers - Pipe Conveyors - Development and AdvantagesДокумент8 страницPapers - Pipe Conveyors - Development and AdvantagesJulie WillisОценок пока нет

- 02 12 Solving Closed Loop Pneumatic Conveying System ProblemsДокумент4 страницы02 12 Solving Closed Loop Pneumatic Conveying System Problemsleekiangyen100% (1)

- Tech Specs For Nitrogen GeneratorДокумент5 страницTech Specs For Nitrogen Generatorn.hartonoОценок пока нет

- GEP Stack Height Rule ExplainedДокумент3 страницыGEP Stack Height Rule ExplainedGui Bruno BackhamОценок пока нет

- Sro Government of Pakistan Oil and Gas Regulatory Authority Notificat IonДокумент54 страницыSro Government of Pakistan Oil and Gas Regulatory Authority Notificat Ionashraf2904Оценок пока нет

- 3472 Vol 2b-Pac Tech.-Spec.Документ123 страницы3472 Vol 2b-Pac Tech.-Spec.Satadal LahiriОценок пока нет

- زندگی پنهان مادر ترزاДокумент10 страницزندگی پنهان مادر ترزاChristopher LloydОценок пока нет

- Energy and Efficiency Characteristics of The Ejector Venturi ScrubberДокумент5 страницEnergy and Efficiency Characteristics of The Ejector Venturi ScrubberChristopher LloydОценок пока нет

- WO2017037540A1Документ29 страницWO2017037540A1Christopher LloydОценок пока нет

- CyclonesДокумент11 страницCyclonesMisdi HabibiОценок пока нет

- All-Round Ceramic Protection: by Tim Connors, Blasch Precision Ceramics, USAДокумент3 страницыAll-Round Ceramic Protection: by Tim Connors, Blasch Precision Ceramics, USAChristopher LloydОценок пока нет

- کنترل آشوبДокумент41 страницаکنترل آشوبmshahОценок пока нет

- Comparison of Jet Aeration Systems vs. Diffused Aeration SystemsДокумент8 страницComparison of Jet Aeration Systems vs. Diffused Aeration SystemsChristopher LloydОценок пока нет

- Modelling of The Pressure Drop in Tangential Inlet Cyclone SeparatorsДокумент10 страницModelling of The Pressure Drop in Tangential Inlet Cyclone SeparatorsChristopher LloydОценок пока нет

- Funk, Baker - Dust Cyclone Technology - A Literature Review PDFДокумент12 страницFunk, Baker - Dust Cyclone Technology - A Literature Review PDFJorge VeraОценок пока нет

- Balancing of Industrial Ventilation SystemsДокумент4 страницыBalancing of Industrial Ventilation SystemsChristopher LloydОценок пока нет

- EVE 402 Air Pollution Generation and Control: Wet CollectorsДокумент8 страницEVE 402 Air Pollution Generation and Control: Wet CollectorsChristopher LloydОценок пока нет

- Pressure Independent Control Valves (PICV) : Principle of OperationДокумент2 страницыPressure Independent Control Valves (PICV) : Principle of OperationChristopher LloydОценок пока нет

- Experimental Evaluation of Ball Bar Standard ThermДокумент12 страницExperimental Evaluation of Ball Bar Standard ThermChristopher LloydОценок пока нет

- Thermodynamic Analysis of EAF Electrical Energy deДокумент17 страницThermodynamic Analysis of EAF Electrical Energy demshahОценок пока нет

- Description of Thermal Oxidizers PDFДокумент5 страницDescription of Thermal Oxidizers PDFChristopher LloydОценок пока нет

- Fire Evacuation Analysis of an AuditoriumДокумент8 страницFire Evacuation Analysis of an AuditoriumChristopher LloydОценок пока нет

- Description of Thermal Oxidizers PDFДокумент5 страницDescription of Thermal Oxidizers PDFChristopher LloydОценок пока нет

- Description of Thermal Oxidizers PDFДокумент5 страницDescription of Thermal Oxidizers PDFChristopher LloydОценок пока нет

- Energy and Exergy of Electric Arc Furnace PDFДокумент26 страницEnergy and Exergy of Electric Arc Furnace PDFChristopher LloydОценок пока нет

- (1647) PDFДокумент114 страниц(1647) PDFChristopher LloydОценок пока нет

- Fire Evacuation Analysis of an AuditoriumДокумент8 страницFire Evacuation Analysis of an AuditoriumChristopher LloydОценок пока нет

- Fire Evacuation Analysis of an AuditoriumДокумент8 страницFire Evacuation Analysis of an AuditoriumChristopher LloydОценок пока нет

- Capture and Purify Gas Arc Steel-Smelting FurnacesДокумент4 страницыCapture and Purify Gas Arc Steel-Smelting FurnacesChristopher LloydОценок пока нет

- Modelling of Flows in A Ladle With Gas Stirred Liquid Wood's Metal PDFДокумент6 страницModelling of Flows in A Ladle With Gas Stirred Liquid Wood's Metal PDFRasul BzОценок пока нет

- Notes On Sizing of Horizontal Ceiling Vents With Traditional Flow ModelДокумент7 страницNotes On Sizing of Horizontal Ceiling Vents With Traditional Flow ModelChristopher LloydОценок пока нет

- CSHP Template For Small Construction Projects Residential Project/S (2 Storey and Below) or Minor Repair WorksДокумент5 страницCSHP Template For Small Construction Projects Residential Project/S (2 Storey and Below) or Minor Repair WorksZeny BocadОценок пока нет

- Badhabits 2022Документ53 страницыBadhabits 2022Sajad KhaldounОценок пока нет

- Vitamin D DeficinyДокумент11 страницVitamin D DeficinyسالمОценок пока нет

- Evonik-BREAK THRU Brochure Microbials EN Asset 2214205Документ5 страницEvonik-BREAK THRU Brochure Microbials EN Asset 2214205李雷Оценок пока нет

- Respiratory Epithelium: Human Histology Lecture Chapter 17 Ï The Respiratory SystemДокумент16 страницRespiratory Epithelium: Human Histology Lecture Chapter 17 Ï The Respiratory SystemEvandie OngОценок пока нет

- Deck Damage and Penetrations: Prepared by Richard B. Heagler, P.EДокумент9 страницDeck Damage and Penetrations: Prepared by Richard B. Heagler, P.ENelzon MamaniОценок пока нет

- Deped Memo No. 165, S 2010: WastedДокумент6 страницDeped Memo No. 165, S 2010: WastedJayne InoferioОценок пока нет

- RC14001® & RCMS®: Your Guide To Implementing A Responsible Care® Management SystemДокумент4 страницыRC14001® & RCMS®: Your Guide To Implementing A Responsible Care® Management SystemMohammed MehranОценок пока нет

- Isoflurane, Sevoflurane and AnestesiДокумент124 страницыIsoflurane, Sevoflurane and Anestesizidni fatayanОценок пока нет

- SKY BUILDER SILICON CITY QuotationДокумент10 страницSKY BUILDER SILICON CITY QuotationVikram SolankiОценок пока нет

- Developmental Psychology - Socioemotional Development in Middle & Late ChildhoodДокумент56 страницDevelopmental Psychology - Socioemotional Development in Middle & Late ChildhoodAlyОценок пока нет

- 631 500seriesvalves PDFДокумент2 страницы631 500seriesvalves PDFsaiful_tavipОценок пока нет

- 4th QUARTER EXAMINATION IN TLE 8Документ3 страницы4th QUARTER EXAMINATION IN TLE 8judy ann sottoОценок пока нет

- HVDCProjectsListingMarch2012 ExistingДокумент2 страницыHVDCProjectsListingMarch2012 ExistingHARLEY SANDERSОценок пока нет

- HPAD 201 Sat Days 2 and 3Документ11 страницHPAD 201 Sat Days 2 and 3Arianne A ZamoraОценок пока нет

- Apraxia of Speech and Grammatical Language Impairment in Children With Autism Procedural Deficit HypothesisДокумент6 страницApraxia of Speech and Grammatical Language Impairment in Children With Autism Procedural Deficit HypothesisEditor IJTSRDОценок пока нет

- The Payment of Bonus Act 1965 PDFДокумент30 страницThe Payment of Bonus Act 1965 PDFappu kunda100% (1)

- Metals and Metallurgy: Theodore L. Brown H. Eugene Lemay, Jr. and Bruce E. BurstenДокумент43 страницыMetals and Metallurgy: Theodore L. Brown H. Eugene Lemay, Jr. and Bruce E. BurstenDheeraj KumarОценок пока нет

- Chloe Kho - Assignment 5 - MTT PracticeДокумент5 страницChloe Kho - Assignment 5 - MTT PracticeanthonyОценок пока нет

- Everything You Want To Know in ChennaiДокумент428 страницEverything You Want To Know in ChennaiBalamuruganОценок пока нет

- NPD High Level Status: Concept Development FeasibilityДокумент22 страницыNPD High Level Status: Concept Development FeasibilityRaviОценок пока нет

- Vodafone Idea Limited: PrintДокумент2 страницыVodafone Idea Limited: PrintPrakhar KapoorОценок пока нет

- INTUSSUSCEPTIONДокумент1 страницаINTUSSUSCEPTIONMaecy PasionОценок пока нет

- PR GL Fragmentiser Best PracticeДокумент51 страницаPR GL Fragmentiser Best PracticeMohamedSaidОценок пока нет