Академический Документы

Профессиональный Документы

Культура Документы

SwivelConnectorSteamTraps PDF

Загружено:

tecnidibujosИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

SwivelConnectorSteamTraps PDF

Загружено:

tecnidibujosАвторское право:

Доступные форматы

Swivel Connector

Steam Traps

efficient and cost effective

steam trapping solutions

for steam main drainage,

small process equipment

and steam tracing lines

2

Steam trapping solutions that combine efficient

operation and simplified maintenance

Swivel Connector Steam Trap Overview

Swivel Connector Overview

Model Sizes (inches) Connections Body Material Strainer Options

1

/2

3

/4 1 NPT SW

Standard Stainless Steel Carbon

Connector Steel

Strainer Stainless Steel Carbon Blowdown

Connector Steel

Model Trap Type Body Strainer Options TIS

Material Location Blowdown Valve #

UTD52L/H Thermo-Dynamic

Stainless 2.5161

Disc Steel (Connector Only) (Connector Only)

UTD30L/H Thermo-Dynamic

Stainless 2.517

Disc Steel (Integral)

UBP30 Balanced Pressure Stainless 2.008

Thermostatic Steel (Integral)

UIB30 Inverted Bucket Stainless 2.412

Steel (Integral) (Connector Only)

Spirax Sarcos range of Swivel

Connector steam traps provide optimum

system efficiency through a combination

of these unbeatable factors:

The Swivel Connector design

does just what its name implies.

The trap can be positioned to

give maximum service life

regardless of the piping

configuration.

The Swivel Connector, once

installed, becomes part of the

pipeline. Service of the trap is

made quickly and easily by

the two-bolt connection.

Spirax Sarco has 85 plus years of

experience in providing steam

trapping solutions.

These factors team up to provide the

most flexible, most reliable, and most

respected steam trapping system on the

market today.

Two-bolt connection

makes trap installation

and removal simple.

Optional blowdown

valves available.

Full size integral stainless

steel strainer available.

3

G Compact design reduces installation space.

G Swivel Connector design permits trap to be

oriented for maximum efficiency and service life.

G Two-bolt connection simplifies

maintenance/replacement of steam trap.

G Steam traps automatically discharge air and

non-condensibles to aid rapid warm-up.

G Low cost trap modules reduce inventory

requirements.

G Withstands superheat and waterhammer to

ensure maximum service life.

User benefits

G Choice of traps and connectors to provide

optimum flexibility.

The Swivel Connector Steam Traps are

designed to allow for any piping configuration.

The Swivel Connector is a compact in-line

design that can be easily installed into the

pipeline. Once installed, the Swivel Connector

remains in-line permanently.

The steam traps are assembled to the swivel

connector by the two bolts as shown. The steam

trap can be oriented (or swiveled) to the best

operating position, regardless of the piping,

before the bolts are completely tightened.

Replacement or repair of the steam trap is

now as easy as removing the two bolts, then

installing a new or repaired trap by these same

two bolts.

The Swivel Connector Concept

Trap can always be

positioned to provide

optimum service life.

4

Typical Applications for Swivel Connector Steam Traps

Critical tracing

(Jacketed product lines)

Condensate is removed as it is formed,

ensuring maximum heat transfer to the product,

eliminating the danger of solidification.

Condensate removal

from steam mains

Instant removal of condensate prevents

waterhammer and improves steam quality.

Non-critical tracing

(Product lines)

Simple and robust design, ideal

for harsh outdoor conditions.

Steam Trap Selection and Sizing

Need to Know

1. The steam pressure at the trap after any pressure drop

through the control valve or equipment.

2. The distance the condensate must be lifted after the trap.

Rule of thumb: 2 feet of lift equals 1 psi back pressure

(approximately).

3. Any other possible sources of back pressure in the

condensate return system. For example:

Condensate taken to a pressurized deaerator tank or flash

recovery vessel.

Local back pressure due to discharge of numerous traps

close together into an undersized return.

4. Quantity of condensate handled. Obtained from:

Measurement

Calculation

Manufacturers data

5. Safety Factor that is dependent upon particular application,

typical examples as follows:

Steam Mains 2:1

Tracers 2:1

Non-Modulatng 2:1

Modulating over 30 psi* 3:1

Modulating under 30 psi* Size trap at full load and 1/2 psi

differential

*

TD and Balanced Pressure traps not recommended for modulating service. Refer to TI Sheet

for minimum pressure.

How to Size

The difference between the steam pressure at the trap inlet and

the total back pressure, including that due to lift after the trap,

is the differential pressure. The quantity of condensate should

be multiplied by the appropriate safety factor to produce the

sizing load. The trap may now be selected using the differential

pressure and the sizing load.

Note: The inlet pressure to the steam trap should never exceed

the Maximum Operating Pressure (PMO) of the selected trap,

regardless of differential pressure.

Example

A steam trap is required to drain 100 lb/h of condensate from an

8" insulated steam main, which is supplying steam at 100 psig.

There will be a lift after the trap of 20 ft.

Inlet Pressure 100 psig

Lift 20 ft. = 10 psi (approximately)

Therefore,

Differential Pressure 100 psi - 10 psi = 90 psi

Quantity 100 lb/h

Safety Factor 2:1

Sizing Load 200 lb/h

The UTD30L will easily handle the 200 lb/h startup load at a

differential pressure of 90 psi.

UTD52L with Strainer

Connector Shown

UTD30L Shown

UBP30

Shown

5

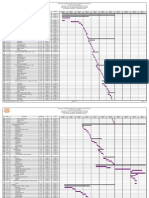

Steam Trap Selection Guide

As the USAs leading provider of steam system solu-

tions, Spirax Sarco recognizes that no two steam trapping

systems are identical. Because of the wide array of steam

trap applications with inherently different characteristics,

choosing the correct steam trap for optimum performance

is difficult. Waterhammer, superheat, corrosive condensate,

or other damaging operating characteristics dramatically

affect performance of a steam trap. With over 85 years of

experience in steam technology, Spirax Sarco is committed

to helping its customers design, operate and maintain an

efficient steam system. You have our word on it!

Application

Steam Mains to 30 psig

30-400 psig

to 600 psig

to 900 psig

to 2000 psig

with Superheat

Separators

Steam Tracers Critical

Non-Critical

Heating Equipment

Shell & Tube Heat Exchangers

Heating Coils

Unit Heaters

Plate & Frame Heat Exchangers

Radiators

General Process Equipment to 30 psig

to 200 psig

to 465 psig

to 600 psig

to 900 psig

to 2000 psig

Hospital Equipment Autoclaves

Sterilizers

Fuel Oil Heating Bulk Storage Tanks

Line Heaters

Tanks & Vats Bulk Storage Tanks

Process Vats

Vulcanizers

Evaporators

Reboilers

Rotating Cylinders

Freeze Protection

1st Choice 2nd Choice

D i m e n s i o n s (nominal) in inches

Size A B(L) B(H) C(L) C(H) D E F(L) F(H) J(L) J(H) K(L) K(H) Weight

UTD52L/H with Standard Swivel Connector

1/2 2.4 2.7 3.0 2.0 2.1 0.7 2.6 3.3 3.8 2.3 2.7 0.4 0.5 3.3 lb

3/4" 2.9 2.7 3.0 2.0 2.1 0.7 2.6 3.3 3.8 2.3 2.7 0.4 0.5 3.3 lb

1" 3.6 2.7 3.0 2.0 2.1 0.7 2.6 3.4 3.8 2.3 2.7 0.4 0.5 3.7 lb

UTD52L/H with Strainer Swivel Connector

1/2" 3.2 2.7 3.0 1.6 1.7 2.9 2.3 3.3 3.8 2.3 2.7 0.4 0.5 3.8 lb

3/4" 3.5 2.7 3.0 1.4 1.5 3.0 2.5 3.3 3.8 2.3 2.7 0.4 0.5 4.2 lb

1" 3.9 2.7 3.0 1.2 1.3 3.1 2.7 3.4 3.8 2.3 2.7 0.4 0.5 4.5 lb

6

Swivel Connectors

Dimensions (nominal) in inches

Size A B B1 C* C1* E Weight

1/2" 3.2 2.9 3.9 4.0 4.4 1.1 1.8 lb

3/4" 3.5 3.0 4.0 4.1 4.5 1.0 2.1 lb

1" 3.9 3.1 4.2 4.2 4.6 0.9 2.4 lb

UTD52L/H

B

A

B1 C1

Body Stainless Steel

Optional Carbon Steel

Strainer Screen Stainless Steel

Strainer Cap Stainless Steel

Blowdown Plug Forged Steel

Blowdown Cap Stainless Steel

Blowdown Screw Stainless Steel

Blowdown Valve Stainless Steel

Strainer Connector

C

Body Stainless Steel

Optional Carbon Steel

Standard Connector

Dimensions (nominal) in inches

Size A Weight

1/2" 2.4 1.3 lb

3/4" 2.8 1.5 lb

1" 3.5 1.6 lb

Strainer Connector Strainer Connector

with optional blowdown

E

* Withdrawal distance

UTD52L/H

with

Strainer

Swivel

Connector

UTD52L/H

with

Standard

Swivel

Connector

The UTD52L/H combines the rugged TD52 with Spirax

Sarcos swivel connector. The result is a Thermo-

Dynamic

steam trap that can be installed in vertical or

horizontal piping. This is ideal for steam main drainage

and steam tracing applications where space may be limit-

ed. The use of Spirax Sarcos Strainer Connector provides

the UTD52 with a permanent, in-line strainer for added

protection against dirt and pipe scale. Blowdown valve

available.

UTD30L/H

L - Insulcap

withdrawal

distance

D

C

B

A

A

with optional

blowdown

valve

Dimension

D=2.8"

K

C

D

E

A

B

F

K

J

D

C

B

A

F

E

K

A

A

J

7

UTD30L/H

UBP30

Sizes

1

/2",

3

/4", 1"

Body Material Stainless Steel

Connections NPT

Piping Configuration In-Line, Swivel Connector

Options SW and BSP connections,

subcooling capsule

TIS# 2.008

Maximum Operating Pressure (PMO): 435 psig

UBP30

Differential Pressure, psi

UBP30 Capacities

2000

1000

800

600

500

400

300

400 300 150 200 100 40 50 60 80 30 20

Dimensions (nominal) in inches

Size A B C D Weight

1/2" 2.4 3.2 2.2 2.5 3.5 lb

3/4" 2.8 3.1 2.2 2.5 3.8 lb

1" 3.5 3.2 2.2 2.5 4.2 lb

C

B

D

A

A

Sizes 1/2", 3/4", 1"

Body Material Stainless Steel

Connections NPT

Piping Configuration In-Line/Swivel

Carbon Steel Connector

Options SW Connections

Insulcap, Blowdown Valve

TIS# 2.517 & 2.5161

Maximum

Operating 450 psig

Pressure (PMO)

UTD30L/H and UTD52L/H

The UTD30L/H combines a Thermo-Dynamic

steam trap

with Spirax Sarcos swivel connector to provide a compact

and versatile trap that can be installed in either vertical or

horizontal piping. The UTD30s built in strainer provides

added protection against dirt and pipe scale, plus the

strainer can be renewed as quickly as the trap resulting in

less downtime.

Dimensions (nominal) in inches

Size A B C D J K L Weight

UTD30L/H

1/2" 2.4 2.7 1.6 2.1 2.3 2.3 1.5 3.7 lb

3/4" 2.8 2.6 1.6 2.1 2.3 2.3 1.5 3.9 lb

1" 3.5 2.8 1.6 2.1 2.3 2.3 1.5 4.0 lb

The UBP30 joins the sealed thermostatic steam trap with

Spirax Sarcos popular swivel connector. The result is a

balanced pressure thermostatic steam trap with the flexi-

bility of being installed in either a vertical or horizontal line.

The convenience in piping and repair make it ideal for low

capacity process systems as well as steam tracing sys-

tems and steam main drips.

4,000

3,000

2,000

10 20 30 40 50 100 200 300 450

Differential Pressure, psi

1,000

UTD30L/H, UTD52L/H Capacities

500

400

300

200

100

70

Dimensions (nominal) in inches

Size A B C D E Weight

1/2" 2.4 3.4 4.9 1.3 3.1 4.8 lb

3/4" 2.9 3.3 4.9 1.3 3.1 4.9 lb

1" 3.5 3.4 4.9 1.3 3.1 5.2 lb

UIB30 / UIB30H UIB30 / UIB30H

The UIB30

is a sealed

i n v e r t e d

b u c k e t

steam trap

complete with

Spirax Sarcos

versatile swivel

connector for

i n s t a l l a t i o n s

requiring horizontal or vertical

flow. The swivel connector is

ideal for maintaining the proper

trap operation. The two-bolt

connector design simplifies

maintenance and reduces downtime.

A

B

C

UIB30 / UIB30H

A

D

1,000

700

8 10 20 30 40 3 0 0

Differential Pressure, psi

600

UIB30 / UIB30H Capacities

500

400

300

100

60

800

900

200

58 80 2 0 0 1 7 5 1 2 5 1 0 0 2 9 0 4 0 0

E

Size 1/2", 3/4", 1"

Body Material Stainless Steel

Connections NPT, SW

Piping Configuration In-Line , Swivel Conector

TIS# 2.412

Model 30/8 30/7 30/6 30/5 30/4

Maximum

58 123 174 290 435

Operating

psig psig psig psig psig

Pressure (PMO)

Model 30H/10 30H/8 30H/6 30H/5

Maximum

58 123 290 435

Operating

psig psig psig psig

Pressure (PMO)

Regional Hub Offices

1150 Northpoint Blvd.

Blythewood, SC 29016

1-800-883-4411

Fax: (803) 714-2200

www.spiraxsarco-usa.com

Printed in USA 3/99. Copyright 1999 Spirax Sarco, Inc.

Northeast

Spirax Sarco, Inc.

209 W. Central Street,

Suite 228

Natick, MA 01760

Phone: (508) 651-3200

Fax: (508) 655-9434

Mid-Atlantic

Spirax Sarco, Inc.

1125 S. Cedar Crest Blvd.

Allentown, PA 18103

Phone: (800) 251-7676

Fax: (800) 996-3232

Southeast

Spirax Sarco, Inc.

1304 Rockbridge Road

Suite 2

Stone Mountain, GA 30087

Phone: (770) 209-0999

Fax: (770) 209-0777

Mideast

Spirax Sarco, Inc.

7760 Olentangy River Rd,

Suite 120

Columbus, OH 43235

Phone: (614) 436-8055

Fax: (614) 436-8479

Midwest

Spirax Sarco, Inc.

2806 Centre Circle Drive

Downers Grove, IL 60515

Phone: (630) 268-0330

Fax: (630) 268-0336

Southwest

Spirax Sarco, Inc.

203 Georgia Ave.

Deer Park, TX 77536

Phone: (281) 478-4002

Fax: (281) 478-4615

Mountain States

Spirax Sarco, Inc.

15375 Holbein Drive

Colorado Springs, CO 80921

Phone: (719) 488-5765

Fax: (719) 488-5754

West

Spirax Sarco, Inc.

1930 East Carson Street

Suite 102

Long Beach, CA 90810

Phone: (310) 549-9962

Fax: (310) 829-1712

Midsouth

Spirax Sarco, Inc.

200 Centre Port Drive, Suite 170

Greensboro, NC 27409

Phone: (336) 605-0221

Fax: (336) 605-5758

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5795)

- High-Rise Buildings enДокумент88 страницHigh-Rise Buildings entecnidibujosОценок пока нет

- Corrosion Protection: Arcelormittal Europe - Long Products Sections and Merchant BarsДокумент48 страницCorrosion Protection: Arcelormittal Europe - Long Products Sections and Merchant BarstecnidibujosОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- C E C T Steel Penstocks PDFДокумент80 страницC E C T Steel Penstocks PDFtecnidibujosОценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Relax, Spirax Sarco Is in ControlДокумент2 страницыRelax, Spirax Sarco Is in ControltecnidibujosОценок пока нет

- 2017 EIBN Sector Report Food and BeverageДокумент47 страниц2017 EIBN Sector Report Food and BeverageRizky PriantamaОценок пока нет

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Production II Composite IPR Multilatral TPRДокумент32 страницыProduction II Composite IPR Multilatral TPRUsamaОценок пока нет

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Catalogo Transair Aluminio 8pg 168mm 2015 Ing JDSДокумент8 страницCatalogo Transair Aluminio 8pg 168mm 2015 Ing JDSNahbi Emilio PerezОценок пока нет

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Confi Dence: Bond Bond BondДокумент16 страницConfi Dence: Bond Bond Bonderickcastillo1Оценок пока нет

- Angewandte Chemie International Edition Volume 55 Issue 2 2016 (Doi 10.1002/anie.201504971) Osada, Irene de Vries, Henrik Scrosati, Bruno Passerini, ST - Ionic-Liquid-Based Polymer ElectrolytesДокумент14 страницAngewandte Chemie International Edition Volume 55 Issue 2 2016 (Doi 10.1002/anie.201504971) Osada, Irene de Vries, Henrik Scrosati, Bruno Passerini, ST - Ionic-Liquid-Based Polymer ElectrolytesNoriko MedorumaОценок пока нет

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- Is 14268 - 2022-1Документ16 страницIs 14268 - 2022-1Ramudu Kodur100% (18)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- CW Pump Station Rev01Документ3 страницыCW Pump Station Rev01karna@Оценок пока нет

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- No199 (1999 Eurosteel Conference)Документ719 страницNo199 (1999 Eurosteel Conference)FourHorsemenОценок пока нет

- Process Pumps For Chemical and Industrial Application: Standards: Iso 2858 / Din en 22858Документ22 страницыProcess Pumps For Chemical and Industrial Application: Standards: Iso 2858 / Din en 22858kztro066Оценок пока нет

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Seminar Report (Roll No. 143040044) - Structural Health Monitoring of Concrete StructuresДокумент30 страницSeminar Report (Roll No. 143040044) - Structural Health Monitoring of Concrete StructuresSouradeep Sen86% (7)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- LSS PartsДокумент21 страницаLSS PartsAndreK HantzОценок пока нет

- Upply INE Anitization: Operation & Maintenance Manual Demineralization Water Treatment SystemДокумент11 страницUpply INE Anitization: Operation & Maintenance Manual Demineralization Water Treatment SystemHedi Ben MohamedОценок пока нет

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Hoch Span Nung S TeilerДокумент4 страницыHoch Span Nung S TeilerRahul YadavОценок пока нет

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1091)

- Instruction Manual: CT 159 Internal Combustion Engine Basic ModuleДокумент25 страницInstruction Manual: CT 159 Internal Combustion Engine Basic Modules_nimalanОценок пока нет

- Manual Elc ElectronicДокумент23 страницыManual Elc ElectronicRavi Dhamange100% (1)

- The Magazine For Our Customers and Friends: PM 3582 GBДокумент13 страницThe Magazine For Our Customers and Friends: PM 3582 GBAna RadzicОценок пока нет

- Concept Paper On Solid Waste ManagementДокумент1 страницаConcept Paper On Solid Waste ManagementYashimera Laid Maape60% (5)

- قيمت ماسه و مصالح ساختماني اماراتДокумент11 страницقيمت ماسه و مصالح ساختماني اماراتgharavii2063Оценок пока нет

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Pioneer Pro Water Tite 102 Technical Spec SheetДокумент2 страницыPioneer Pro Water Tite 102 Technical Spec SheetGerald Ordoñez Delos ReyesОценок пока нет

- Instrument Calibration ProcedureДокумент10 страницInstrument Calibration ProcedureMohammad Nurayzat JohariОценок пока нет

- CUTTING, WELDING Boiler AreaДокумент1 страницаCUTTING, WELDING Boiler Areaadil khanОценок пока нет

- 5S Audit FormДокумент2 страницы5S Audit FormNavnath Tamhane100% (2)

- PQR Acero Al CarbonoДокумент2 страницыPQR Acero Al CarbonoROBERTO QUESADAОценок пока нет

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- CPD AssignmentДокумент2 страницыCPD AssignmentHemant0% (1)

- BS en 13657-2002Документ30 страницBS en 13657-2002ASESORIAS SOLDADURASОценок пока нет

- 3kg 3 ENGДокумент47 страниц3kg 3 ENGRuben TecorralcoОценок пока нет

- Torsion Spring Design InfoДокумент3 страницыTorsion Spring Design Infoashish19851Оценок пока нет

- EVS3020 B50 060142 02 InglêsДокумент20 страницEVS3020 B50 060142 02 InglêsPaulo RodriguesОценок пока нет

- t70 1050gbДокумент3 страницыt70 1050gbSani PoulouОценок пока нет

- 74.00.02.000 (Stainless Steel)Документ8 страниц74.00.02.000 (Stainless Steel)Andres Romero PinedaОценок пока нет