Академический Документы

Профессиональный Документы

Культура Документы

Modified Hydraulic System in Bokaro Steel Plant: Outlook

Загружено:

surya325kiran0 оценок0% нашли этот документ полезным (0 голосов)

67 просмотров4 страницыlubricaton

Оригинальное название

Out Look 0212

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документlubricaton

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

67 просмотров4 страницыModified Hydraulic System in Bokaro Steel Plant: Outlook

Загружено:

surya325kiranlubricaton

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 4

Outlook

trip-guide, a servo-hydraulic operated equipment of

a un-coiler of the Double Cold Reduction (DCR) unit

Sat Cold Rolling Mill (CRM), Bokaro Steel Limited

(BSL) maintains a constant processing track of the coils

throughout the processing in the mill to prevent a

staggered profile formation i.e., 'telescopicity' in the

finished coil at the re-coiler end of the unit. In the earlier

system, the mill's centralized hydraulic system caters both

conventional hydraulic equipments and servo-hydraulic

equipments from its common resources. However, at latter

stage, the performance of the servo-hydraulic operated

'strip-guide' has affected severely by poor performance of

the mill's huge centralized hydraulic system, as some of its

hydraulic parameters could not be controlled within the

narrow acceptable range, due to very old hydraulic

equipments, complicated pipeline networks, non-

availability of maintenance spares, etc. However, the

performance of the conventional hydraulic equipments of

mill is not affected much, as comparison to the servo-

hydraulic equipments, as their hydraulic parameters'

acceptable range is very broad. In order to improve the

performance of the servo-hydraulic operated 'strip guide

system', an independent and dedicated hydraulic power

unit was designed, developed and introduced by suitably

modifying the earlier centralized hydraulic circuit of the mill.

It has improved the performance of the strip-guide and

intern increased the availability and productivity of the mill.

Modified Hydraulic

System in Bokaro Steel Plant

- S. Thirumalai Selvam, S. Chaudhuri, I. Sanyal** and A.K.P. Singh*

Research and Development Centre for Iron and Steel (RDCIS)*

Bokaro Steel Plant (BSL)**

Steel Authority of India Limited (SAIL)

February 2012 32

Introduction

For any rolling mill, having servo-

hydraulic operated 'Strip-Guide' at its

both ends i.e., un-coiler and re-coiler

ends, irrespective of its stages of

operation, has become process

necessity, for better coil-profile

formation, i.e., 'zero telescopicity' in its

output coils. The finished coils with

protruded edges got damaged during

further handling for packaging and in

transfers by different material handling

equipments and hence losses its value

to sometimes discard as scraps. The

'telescopicity' in the finished coil is

formed due to lateral movement of the

strip, while processing in the mill. The

servo-hydraulic operated 'strip guide

system' provided in the un-coiler of the

mill, continuously re-adjusts the track

position of the strip immediately, if any

lateral track movement occurs by

controlling the movement of hydraulic

cylinders of the mandrel of the un-

coiler, from which the strip un-wound

for processing. The strip guide system

i s ser vo-hydr aul i c oper at ed

equipment, which needs precious

control and monitoring over its input

hydraulic parameters for its fast and

accurate operations.

The strip guide system of DCR mill

Outlook

February 2012 36

of CRM, BSL was earlier operated

through mill's common hydraulic

system. However at later stage, the

performance of the centralized

hydraulic system of the mill, which

caters both conventional hydraulic

equipments and servo-hydraulic

equipments of the mill, has a trend of

detoriation due to various infeasible

maintenance reasons, such as very old

equipments, complicated pipeline

network, different requirement of

different users etc. The poor

performance of the centralized

hydraulic system has severely affected

the performance of the servo-

hydraulic operated 'strip-guide' more

than the other conventional hydraulic

equipments of the mill, as the

requirement of servo-hydraulic

equipment is very stringent and

precious. Hence, the 'strip-guide' could

not prevent the formati on of

'telescopicity' in its finished coils, due

to its sluggish operation in the system.

In order to improve the performance of

the 'strip-guide', a dedicated and

improved hydraulic power unit was

designed, developed and installed by

suitably modifying the earlier mill's

centralized hydraulic system to isolate

the 'strip-guide' at DCR unit of Cold

Rolling Mill in Bokaro Steel Limited.

Implementation of the dedicated

hydraulic power unit for the strip-guide

has i mproved i ts performance

significantly, in terms of increased

availability and productivity of the mill.

Strip Guide System (SGS)

Strip guide system is closed loop

proportional hydraulic control system

uses a strip guide detector/sensor that

is located as close to the coil as

possible. The sensor located just after

the un-coiler and before the strip's

entry point into the mill is continuously

senses the edge of the incoming strip

and provides an along output

proportional to the lateral position of

the strip. The signal is processed by an

electronic controller. The electronic

controller compares the detector signal

to the set (guide) point i.e., neutral

point, any difference, results in an

output to the hydraulic servo system

which moves the un-coiler mandrel

along with the coil, repositioning the

strip until the strip edge is centered

in the detector's field of view. This

result in the un-coiler continuously

repositions the lateral deviations of the

guided strip edge to a referenced edge

position through hydraulic cylinders, so

that the strip is fed at a constant tract

and maintains continuously its track.

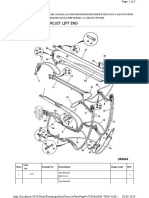

The principle operation of the uncoiler

Strip guide system is shown as

schematic in Fig-1.

Earlier Hydraulic System Of

SGS

The earlier DCR mill's centralized

hydraulic system of 15000 Liters

capacity is catering to almost all the

hydraulic equipments of the mill, such

as walking beam, entry guide car, exit

gui de car, un-coi l er mandrel

operations[1] etc., along with the only

servo hydraulically operated Strip

guide system through various control

val ves syst em f r om a huge

accumulator. There are 9 nos. of vane

type hydraulic pumps operated to cater

the total requirement of the mill. In

which 6 pumps are operated as main

and the remaining were stand-by. A

common hydro-pneumatic accumulator

used as a single storage receiver of the

whole system, from which different

tapping were taken for different

hydraulic equipments. Control valve

station provided for strip guide system

was regulating the hydraulic flow

control at 460 lpm @ 70 bar pressure to

operate the hydraulic cylinders,

provided at both sides of the mandrel of

the uncoiler to re-adjusts its positions,

against the lateral movement of strip

while processing through the mill. The

hydraulic cylinders are designed to

operate at a speed of 150mm/sec i.e.,

'correction speed' to match the

maximum lateral movement of the strip

and the mill speed. The performance of

the strip guide system is wholly

depending upon its correction speed.

Achieving the accurate correction

speed is again depend upon its input

hydraulic parameters, i.e., hydraulic

system's pressure, flow rate and

cleanliness of oil. However due to

numerous operational and maintenance

difficulties in the huge and centralized

hydraulic system such as, older

hydraulic equipments, complicated

pipeline networks, un-noticeable

leakages in the huge system, common

control system for servo-hydraulic

equipments and conventional hydraulic

equipments, etc., maintaining and

Outlook

February 2012 38

control the precisions hydraulic

parameters, needed in the servo-

hydr aul i c oper at ed hydr aul i c

equipment,particularly for the high

speed 'strip guide system' had become

more difficult. These deficiencies of

the centralized hydraulic system had

led to poor performances, such as

frequent failures, slow in operational

speed etc., of the strip guide system,

which ltimately led to huge production

loss and bad profile formation of the

output coils respectively. As the DCR

mill is a finishing type mill and its output

coils are directly dispatched for

packing and forwarding to customer,

the mill is totally depends upon the

functioning of the strip guide system,

which actually controls the quality of

profile formation of its output coils.

Design Basis

The following mill data were taken

into consideration for design &

engineering a 'modified' hydraulic

system for the Strip Guide System :

Dedicated Hydraulic Power Unit

of SGS

To improve the performance of the

servo-hydraulic operated SGS, a

dedicated hydraulic power unit for

SGS was designed, developed and

implemented at DCR unit of CRM, BSL,

by isolating the SGS from the earlier

centralized hydraulic system, through

suitably modifying the centralized

hydraulic circuit. The modified

hydraulic circuit of SGS is capable of

controlling and monitoring the

performance of the SGS independently.

This modified and dedicated hydraulic

circuit enables the SGS to operate

smoothly and continuously at its

maximum capacity through precious

Width of strip/coil processed

Weight of the coil processed

Thickness of the strip

Maximum mill speed

System Pressure

Nos. of cylinders

820 1250 mm

15 - 18 tons.

0.15 mm to 0.80mm

30 m/s

70 Kg/cm2

Two

Size of each cylinder

lBore

lStroke

lVelocity

10

1050 mm

150 mm/sec

Flow rate of oil in pressure line 460 lpm

control over various hydraulic

parameters accurately.

The earlier hydraulic valves station

of the SGS was isolated from the main

hydraulic line of the 15000 L capacity

mill's centralized hydraulic system

through suitable circuit modification by

introducing suitable control valves and

isolation valves. Provision of suitable

control and isolation valves in all the

earlier pressure, return, drain lines

etc., of the earlier centralized hydraulic

system facilitates the modified SGS to

be operated also from the earlier

centralized system in case of any

emergency and failure in the modified

and dedicated hydraulic system. The

isolation of the SGS from the mill's main

hydraulic system was carried out by

taking due care of the hydraulic power

requirements for all downstream and

upstream equipments of the centralized

hydraulic system. The earlier hydraulic

'valves station' of the SGS and the

hydraulic cylinders of the un-coiler

mandrel are re-used in the modified

and dedicated hydraulic power system

t h r o u g h a p p r o p r i a t e d e s i g n

modifications. The 'valves station' of

the SGS is directly connected with the

newly implemented hydraulic power

unit of the modified hydraulic system.

The dedicated hydraulic system of

the SGS was designed to cater the

requirement of the existing hydraulic

cylinders to operate at their maximum

speed of 150 mm/sec. The actuation

velocity of the hydraulic cylinders is

very critical parameter for quick and

accurate response to correct the un-

coiler's position. The correcting

velocity of the cylinders is calculated

considering the mill's speed of

operation. The dedicated hydraulic

system was designed to supply the

hydraulic oil at the maximum flow rate

up to 600 LPM at 100 bar pressure. The

oil flow velocity is maintained at 4.4

m/s in the pipelines.

The dedicated hydraulic power

system of the SGS is consists of one

2000 litres capacity storage tank with

all its necessary safety and operational

accessories, 3 nos. of pressure

compensated variable displacement

axial piston pumps with their

independent drive motors assembly,

couplings, strainers, pre-filters,

pressure relieve valves, pressure

reducing valves, check valves,

isolation valves, duplex type pressure

line filters, 2 nos. of diaphragm type

accumulator with its accessories,

return line filters with check valve,

indicators / gauges, off-line plate type

heat exchanger, piping, flexible hoses

etc. The circuit diagram and actual

photograph of the dedicated hydraulic

power unit installed at site is shown

Fig: 2 and Fig: 3 respectively.

The dedicated hydraulic power unit

of the SGS is installed near the un-

coiler in the same level for fast and

accurate response of cylinders'

operation. A dedicated control panel

with various control features to operate

the equipments of the modified

hydraulic system is installed inside the

existing control room of DCR mill. The

three hydraulic pumps are grouped in to

three forms, such as AB, BC, AC for

regular operations, in order to maintain

one pump out of the three pumps kept

as stand-by, while other two pumps are

in operation. Control desk with various

indication lamps is also provided near

Outlook

February 2012 40

Note

1. System Flow Rate .. 460 LPM

2. System Pressure . 100 BAR

3. System Termination ..P.. 2.5NB

4. System Termination ..T.. 4 NB

Fig. 2 : Circuit Diagram of A Dedicated Hydraulic Power Unit

for Strip Guide System

the hydraulic power unit for visual

indication of the health and emergency

operational facility of the system. The

'control panel' of the dedicated

hydraulic system is also inter-

connected with the existing centralized

control system of the DCR mill through

suitable hardware and software

linkages for a centralized monitoring

and control from the mill's main control

room.

Techno-Economics Benefits

The dedicated hydraulic system for

SGS was designed, developed and

installed at a capital cost of ` 35 lakh in

2008 and is in continuous operation

since then. The monetary benefits

accrued around ` 400 lakh till date on

the account of improvement in average

mill availability of 200 hrs/year,

reduction in average generation of bad

profiled coils by 70%, significant

decrease i n mai nt enance and

operational cost of the mill etc. The

'telescopicity' (bad profile formation in

the coil) i.e., lateral displacement

between wrap to wrap of coil has

reduced within the range of +/- 0.5 mm

from the earlier level of +/- 5 mm.

Conclusion

It Is established that no rolling mill

can be operated efficiently without a

Stri p-Gui de i n operati on. The

productivity of the mill is much depends

on the performance of the Strip Guide

System. An independent and a

dedicated hydraulic power unit to the

servo-hydraulic operated 'Strip Guide

System' would certainly improve the

performance of the servo-hydraulic

equipment than if it is operated through

centralized hydraulic power unit.

Introduction of a dedicated hydraulic

power unit to SGS in isolating from the

centralized hydraulic system at DCR

unit, Cold Rolling Mill at Bokaro Steel

Limited, has increased the mill's

availability by around 200 hrs per

annum. The coil's profile formation has

also been improved significantly.

Acknowledgement

The authors express their deepest

gratitude to the management of

Research and Development Centre for

Iron & Steel (RDCIS) and Bokaro Steel

Plant for allowing us to take up this

project and implementing it in DCR unit

of CRM. Co-operation and support

provided by the mechanical, operation,

el ectri cal , and Instrumentati on

personnel of CRM, BSL throughout the

execution of the project is thankfully

acknowledged, without whose support

the execution of this project would

have been impossible. The authors are

gratefully acknowledging the support

provided by the supporting staff of

Design and Engineering Division of

RDCIS, SAIL in Ranchi.

References

1. Operation and maintenance

manual of strip guide system installed

at DCR mill, CRM, BSL.

Вам также может понравиться

- SPE-176811-MS Multinode 8 ZonesДокумент15 страницSPE-176811-MS Multinode 8 ZonesGerman Andres GalloОценок пока нет

- Rig Hill SCRДокумент6 страницRig Hill SCRmadaba723504100% (3)

- Heli Rig-21Документ14 страницHeli Rig-21baanglore345100% (1)

- These Pumps Are Used in Below Given Systems:: Type of PumpДокумент5 страницThese Pumps Are Used in Below Given Systems:: Type of PumpAlex BmxОценок пока нет

- Chapter-6 Hydro-Turbine Governing SystemДокумент27 страницChapter-6 Hydro-Turbine Governing SystemChristian Llanes-de la CruzОценок пока нет

- MINI PROJECT DC Main DrivesДокумент35 страницMINI PROJECT DC Main DrivesSriram MogalapalliОценок пока нет

- Adjustable Speed Asynchronous Machine in Hydro Power Plants and Its Advantages For The Electric Grid StabilityДокумент8 страницAdjustable Speed Asynchronous Machine in Hydro Power Plants and Its Advantages For The Electric Grid StabilitySarah FrazierОценок пока нет

- Canrig Product InfoДокумент71 страницаCanrig Product InfoBabi Lakhdari100% (5)

- Voltage Regulators G225-10-30: Functional Specification GuideДокумент17 страницVoltage Regulators G225-10-30: Functional Specification Guideمصطفى علىОценок пока нет

- Iron Ore Pelletizing Process PresentationДокумент66 страницIron Ore Pelletizing Process Presentationsinghrakes@gmail.com100% (2)

- Voith Siemens Hydro Power Generation Micro Turbines Harness Water ResourcesДокумент8 страницVoith Siemens Hydro Power Generation Micro Turbines Harness Water ResourcesAshutosh VashishthaОценок пока нет

- Mini ProjectДокумент36 страницMini Projectasif KhanОценок пока нет

- AC TDS 9 36 DriveДокумент375 страницAC TDS 9 36 Drivenobodymagdesign100% (1)

- ABB Medium Voltage SwitchgearДокумент36 страницABB Medium Voltage Switchgearap00100% (1)

- Modular Valves PDFДокумент63 страницыModular Valves PDFMd EliasОценок пока нет

- GIS Switchgear SpecificationДокумент11 страницGIS Switchgear SpecificationbonekbenjeОценок пока нет

- Cat 350-375 TДокумент60 страницCat 350-375 TFernando Sabino100% (1)

- 1996 PRD SPIRAL PIPE MILL SYSTEMSДокумент15 страниц1996 PRD SPIRAL PIPE MILL SYSTEMSMetalacSmzrОценок пока нет

- Training REPORTДокумент14 страницTraining REPORTpk2varmaОценок пока нет

- HgaДокумент24 страницыHgaJenner Volnney Quispe ChataОценок пока нет

- Adjustable candy switch controls timing and dwellДокумент6 страницAdjustable candy switch controls timing and dwellvhrgmar09Оценок пока нет

- Enviando - 1866228934 PDFДокумент451 страницаEnviando - 1866228934 PDFcarlosorizabaОценок пока нет

- Controls: Valve Actuation &Документ4 страницыControls: Valve Actuation &Tg TarroОценок пока нет

- EM 1110-2-2610 12 Dec 03Документ28 страницEM 1110-2-2610 12 Dec 03VictorОценок пока нет

- Electromechanical ActuatorsДокумент4 страницыElectromechanical ActuatorsMohammed Asif NОценок пока нет

- BERMAD IR Engineering 900 MДокумент19 страницBERMAD IR Engineering 900 MRita CaselliОценок пока нет

- SCC9000Документ27 страницSCC9000Geovany RibeiroОценок пока нет

- Installation Guide for Kobelt 7173-KAS Electronic Steering SystemДокумент21 страницаInstallation Guide for Kobelt 7173-KAS Electronic Steering SystemDepil DepikaОценок пока нет

- Auma - Electric ActuatosДокумент44 страницыAuma - Electric ActuatosRakesh Karan Singh100% (1)

- Practical Features - KA/KAX: DC Powered Rotary Paddles Use Long-Life AC MotorДокумент2 страницыPractical Features - KA/KAX: DC Powered Rotary Paddles Use Long-Life AC Motorجمال ابو الفضلОценок пока нет

- Ac - Variable Frequency Drive SystemsДокумент4 страницыAc - Variable Frequency Drive Systemsjyothsna123456Оценок пока нет

- The Megohmmeter For DC-10Документ3 страницыThe Megohmmeter For DC-10Jay CortezОценок пока нет

- 2001 V3 ALR 190 - Data - Sheet 07 01 08 Bs enДокумент6 страниц2001 V3 ALR 190 - Data - Sheet 07 01 08 Bs enSunthron SomchaiОценок пока нет

- D-357557 ManualДокумент65 страницD-357557 ManualAnh NguyenОценок пока нет

- Aft 2010Документ13 страницAft 2010prafullvjОценок пока нет

- Operations and Maintenance Manual SCT 35 10-17SДокумент22 страницыOperations and Maintenance Manual SCT 35 10-17SIgor Grytsenko100% (1)

- Manual Book Coal FeederДокумент22 страницыManual Book Coal Feedermuhlas fabregas100% (1)

- Arc FurnaceДокумент2 страницыArc FurnaceZEAGUIОценок пока нет

- Hydraulic ActuationДокумент10 страницHydraulic ActuationMuh IndrawanОценок пока нет

- MV Industrial VSDДокумент7 страницMV Industrial VSDONILEDA1970Оценок пока нет

- CH Pavan KumarДокумент5 страницCH Pavan KumarPavan KumarОценок пока нет

- Vickers DG4V-3 DG4V-3S 6xДокумент32 страницыVickers DG4V-3 DG4V-3S 6xCarlos Javier Torrico BarreroОценок пока нет

- Tire Machinerry Program NewДокумент8 страницTire Machinerry Program Newmkt mechoceanОценок пока нет

- Caterpillar 320 330 Hydraulic Excavator Electronic Control UnitДокумент9 страницCaterpillar 320 330 Hydraulic Excavator Electronic Control Unitlinda100% (31)

- Variable Shunt ReactorsДокумент8 страницVariable Shunt ReactorsAdeniji OlusegunОценок пока нет

- 6P BSG Us PDFДокумент6 страниц6P BSG Us PDFdocrafiОценок пока нет

- Automatic Gauge Control of Plate Rolling MillДокумент14 страницAutomatic Gauge Control of Plate Rolling MillBenyamin heidariОценок пока нет

- 7000 - Brochure - Paste Slaker PDFДокумент4 страницы7000 - Brochure - Paste Slaker PDFalexituuОценок пока нет

- Selection of Drives and Control Schemes For Mining IndustryДокумент16 страницSelection of Drives and Control Schemes For Mining IndustrySandhya RaghunathОценок пока нет

- DecanterДокумент4 страницыDecanteradalcayde2514Оценок пока нет

- Meter Out Circuit For Speed Control in Hydraulic CircuitsДокумент12 страницMeter Out Circuit For Speed Control in Hydraulic CircuitsThe Information TreeОценок пока нет

- RJ STP BrochureДокумент3 страницыRJ STP Brochurefrancisb65Оценок пока нет

- AGW TrainingДокумент23 страницыAGW TraininglimasmildredОценок пока нет

- SATECH - Eagle Control-Matic - WHC System EH36 Series - Product Brochure (Ed011211 1214Hr) PDFДокумент20 страницSATECH - Eagle Control-Matic - WHC System EH36 Series - Product Brochure (Ed011211 1214Hr) PDFuserscribd2011Оценок пока нет

- HPB Hydraulic Power Braking System: General Comments, Diagrams and Description of ComponentsДокумент46 страницHPB Hydraulic Power Braking System: General Comments, Diagrams and Description of ComponentsDariusz PłazaОценок пока нет

- Stan Shiels on centrifugal pumps: Collected articles from 'World Pumps' magazineОт EverandStan Shiels on centrifugal pumps: Collected articles from 'World Pumps' magazineРейтинг: 5 из 5 звезд5/5 (1)

- Hydraulics and Pneumatics: A Technician's and Engineer's GuideОт EverandHydraulics and Pneumatics: A Technician's and Engineer's GuideРейтинг: 4 из 5 звезд4/5 (8)

- 04 MHA Order Dt. 17.05.2020 To Extend Lockdown Period For 2 Weeks W.E.F. 18.05.2020 With New GuidelinesДокумент9 страниц04 MHA Order Dt. 17.05.2020 To Extend Lockdown Period For 2 Weeks W.E.F. 18.05.2020 With New Guidelinessurya325kiranОценок пока нет

- EPA-occupants Guide PDFДокумент11 страницEPA-occupants Guide PDFUmi PhamОценок пока нет

- CPP ESP DetailsДокумент1 страницаCPP ESP Detailssurya325kiranОценок пока нет

- UV-C Lamp Selection GuideДокумент24 страницыUV-C Lamp Selection GuidetnylОценок пока нет

- Care For Your Air: A Guide To Indoor Air QualityДокумент7 страницCare For Your Air: A Guide To Indoor Air QualitymoshikimОценок пока нет

- Flex Ductwork InstallationДокумент28 страницFlex Ductwork InstallationRenan GonzalezОценок пока нет

- Maintaining Healthy Indoor Air QualityДокумент4 страницыMaintaining Healthy Indoor Air Qualitysurya325kiranОценок пока нет

- Healty Buildings PDFДокумент108 страницHealty Buildings PDFsurya325kiranОценок пока нет

- Guide To Air Cleaners in The Home 2nd EditionДокумент7 страницGuide To Air Cleaners in The Home 2nd Editionzock01Оценок пока нет

- SINTER Plant ESP DetailsДокумент1 страницаSINTER Plant ESP Detailssurya325kiranОценок пока нет

- Determination of Maximum Span Between Pipe Support Using Bending Stress TheoryДокумент4 страницыDetermination of Maximum Span Between Pipe Support Using Bending Stress TheoryMannattil Krishna KumarОценок пока нет

- Written by Teams of European Experts: How To OrderДокумент4 страницыWritten by Teams of European Experts: How To Ordersurya325kiranОценок пока нет

- Flex Ductwork InstallationДокумент28 страницFlex Ductwork InstallationRenan GonzalezОценок пока нет

- Flex Ductwork InstallationДокумент28 страницFlex Ductwork InstallationRenan GonzalezОценок пока нет

- ICP FEM4X60000b2 Fan Coil Installation InstructionsДокумент17 страницICP FEM4X60000b2 Fan Coil Installation Instructionssurya325kiranОценок пока нет

- ICP NXH560GKA100 Heat Pump Sales BrochureДокумент4 страницыICP NXH560GKA100 Heat Pump Sales Brochuresurya325kiranОценок пока нет

- 10 Good Shortcuts To Good Health For LifeДокумент5 страниц10 Good Shortcuts To Good Health For Lifesurya325kiranОценок пока нет

- ICP Residential Condensed Catalog PDFДокумент151 страницаICP Residential Condensed Catalog PDFsurya325kiran0% (1)

- 02 Chilled Water Piping Pumps PDFДокумент64 страницы02 Chilled Water Piping Pumps PDFbilal almelegyОценок пока нет

- 4 Consumption of Materials 167-174 PDFДокумент8 страниц4 Consumption of Materials 167-174 PDFSheezan KhanОценок пока нет

- Grundfosliterature 1654 PDFДокумент64 страницыGrundfosliterature 1654 PDFkiranОценок пока нет

- Chilled Water Systems Design Issues PDFДокумент6 страницChilled Water Systems Design Issues PDFElmerОценок пока нет

- Dust & Flow RatesДокумент1 страницаDust & Flow Ratessurya325kiranОценок пока нет

- Purpose of LifeДокумент17 страницPurpose of Lifesurya325kiran100% (2)

- ASHRAE Symposis Degrading Delta-T-TaylorДокумент13 страницASHRAE Symposis Degrading Delta-T-TaylormondsbaОценок пока нет

- The Future of Air Conditioning: Lowering Global Warming ImpactsДокумент94 страницыThe Future of Air Conditioning: Lowering Global Warming ImpactsNikesh SinghОценок пока нет

- Do It YourselfДокумент10 страницDo It Yourselfbuggs1152Оценок пока нет

- Condensater DesignДокумент19 страницCondensater Designsurya325kiranОценок пока нет

- I-Package Air Conditioners PDFДокумент10 страницI-Package Air Conditioners PDFsurya325kiranОценок пока нет

- I-Package Air Conditioners PDFДокумент10 страницI-Package Air Conditioners PDFsurya325kiranОценок пока нет

- 7.1. FM Listing Approval of Amipox 2016Документ8 страниц7.1. FM Listing Approval of Amipox 2016minov minovitchОценок пока нет

- Duocheck SBMДокумент1 страницаDuocheck SBMNicolás FriasОценок пока нет

- Rvda 10 - 520 P 030220 enДокумент2 страницыRvda 10 - 520 P 030220 enronald.1978Оценок пока нет

- Abogadie - Single Stage Centrifugal PumpДокумент13 страницAbogadie - Single Stage Centrifugal PumpjohnharveytipozoОценок пока нет

- Mechanical Engineering Department Chapter 2 Compressible FlowДокумент74 страницыMechanical Engineering Department Chapter 2 Compressible FlowWillky FrezerОценок пока нет

- Three-Dimensional Cavity Flow Fields at Subsonic and Transonic SpeedsДокумент83 страницыThree-Dimensional Cavity Flow Fields at Subsonic and Transonic SpeedsMonitering EyeОценок пока нет

- Elgi Air Compressor Parts Catalogue - Google SearchДокумент2 страницыElgi Air Compressor Parts Catalogue - Google SearchSharad KokateОценок пока нет

- GE Gas Turbine PG9171E: Comprehensive Guide to Components and OperationДокумент77 страницGE Gas Turbine PG9171E: Comprehensive Guide to Components and Operationsiva prasad100% (1)

- Valve Seat Leakage TestДокумент3 страницыValve Seat Leakage Testtaeyun hwngОценок пока нет

- Iiche Online Internship - 2020 Petroleum Refinery Engineering - Batch 1 Assignment 1 - White Paper 1Документ3 страницыIiche Online Internship - 2020 Petroleum Refinery Engineering - Batch 1 Assignment 1 - White Paper 1Shivam Kumar RaiОценок пока нет

- Excelon Filter - Regulators - B72, 73, 74Документ3 страницыExcelon Filter - Regulators - B72, 73, 74Sreevathsa GururajОценок пока нет

- Line List (Ibr)Документ3 страницыLine List (Ibr)vtbkОценок пока нет

- SP1206 39 D4C Cartridge High Pressure PumpДокумент2 страницыSP1206 39 D4C Cartridge High Pressure PumpMarcin WersockiОценок пока нет

- Better Reciprocating Compressor Capacity ControlДокумент5 страницBetter Reciprocating Compressor Capacity ControlFranklin Santiago Suclla PodestaОценок пока нет

- Journal of Engineering For Gas Turbines and Power 2005.Vol.127.N2Документ226 страницJournal of Engineering For Gas Turbines and Power 2005.Vol.127.N2Ivan YurkoОценок пока нет

- Valvula Check AlarmДокумент20 страницValvula Check AlarmCarlos Amaya CuevaОценок пока нет

- GD675-5 Fuel Filter Assembly Parts ListДокумент2 страницыGD675-5 Fuel Filter Assembly Parts ListJuan MendozaОценок пока нет

- Smith Nozzles PDFДокумент2 страницыSmith Nozzles PDFrangga1000Оценок пока нет

- Wallchart PDFДокумент1 страницаWallchart PDFJee SelvaОценок пока нет

- Thermo-Dynamic Steam Trap TD52-Installation Maintenance ManualДокумент2 страницыThermo-Dynamic Steam Trap TD52-Installation Maintenance ManualMasroor GhouriОценок пока нет

- MG-880 Specification PDFДокумент3 страницыMG-880 Specification PDFMartin HasskelОценок пока нет

- Commodity ListДокумент1 страницаCommodity Listmahalakshmi muruganОценок пока нет

- 06 Final Drive & Tandem PDFДокумент4 страницы06 Final Drive & Tandem PDFYerson Genovez RamosОценок пока нет

- Valve Types and SymbolsДокумент164 страницыValve Types and Symbolssantos ayala100% (3)

- ME Yichang Man B&W 6S 35 MC Spare Parts - BLG-A-1077 - 19.09.2023Документ2 страницыME Yichang Man B&W 6S 35 MC Spare Parts - BLG-A-1077 - 19.09.2023Mohamed KiwanОценок пока нет

- Stationary Two-Stage Air Compressor: Description SpecificationsДокумент12 страницStationary Two-Stage Air Compressor: Description SpecificationsMireya Linares MoriОценок пока нет

- 9802/7860 E1-2-1 Circuit Lift EndДокумент3 страницы9802/7860 E1-2-1 Circuit Lift EndAnonymous japNfeОценок пока нет

- Codes and StandardsДокумент6 страницCodes and StandardsZaid ImranОценок пока нет

- Qsi Series CompressorДокумент142 страницыQsi Series CompressorJayОценок пока нет