Академический Документы

Профессиональный Документы

Культура Документы

Classification of Materials

Загружено:

ABZ007Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Classification of Materials

Загружено:

ABZ007Авторское право:

Доступные форматы

Assignment -1

Classification of Materials

-------------------------------------------------------------------------------------------------------

-------------------------------------------------------------------------------------------------------

Page 1 of 5

An atom is composed of;

i. Nucleus at the centre, made up from Protons (positively charged) and

Neutrons (no charge)

ii. Electrons (negative charge) orbiting around the nucleus

Atom Sketch

The two types of bonding between metals and non-metals atom respectively are;

Ionic bonding, which occurs between metals and non metals.

Covalent bonding, which occurs only between non metals.

i. Mechanical properties

The mechanical behavior of a material reflects the relationship between its

response or deformation to an applied load or force

Assignment -1

Classification of Materials

-------------------------------------------------------------------------------------------------------

-------------------------------------------------------------------------------------------------------

Page 2 of 5

ii. Physical properties

Physical properties are associated to appearance (structure) to the given

material. For example, if one touch a metal at room temperature it feels colder

when compared touching a wood or polymer.

iii. Magnetic and electrical properties

Magnetic properties are related to a material which has a magnetic element (ie

iron).

Electrical properties are related to material which conducts electricity (ie

copper, steel).

iv. Thermal properties

Thermal properties are related to material which has a good resistance to

elevated temperatures and thermal shocks. Insulators are good examples of

materials having thermal properties.

Four mechanical properties to engineering materials are;

Strength

Hardness

Ductility

Stiffness

Some types of test which can be applied on materials in order to determine the

mechanical properties are;

Tensile test

Charpy impact test

Hardness test

a) When a tensile strength is conducted, the data obtained consists of force

applied and the extension of the material. Extension means how the material is

strained during the tensile strength.

b) Stress and strain graphs of a typical ductile material, indicated in diagram

below.

c) Elastic limit and ultimate tensile strength indication, indicated in diagram

below.

Assignment -1

Classification of Materials

-------------------------------------------------------------------------------------------------------

-------------------------------------------------------------------------------------------------------

Page 3 of 5

d) Sketch of a sample of ductile and brittle material after they are fractured using

tensile strength.

Ductile material Brittle material

The following engineering materials are classified according to their properties.

METALS

Brass

Aluminum

Copper

NON METALS

PTFE

Nylon

Iron Nitride

Assignment -1

Classification of Materials

-------------------------------------------------------------------------------------------------------

-------------------------------------------------------------------------------------------------------

Page 4 of 5

Material processing cycle

General Description

Raw materials that are first harvested from the earth and divided into a form that can

be easily transported and stored. These then are processed into semi-finished

materials, which can be the input of a new cycle of production, to create finished

materials, ready for distribution, construction, and consumption, until recycled for

other use.

Each Cycle Description

Extracting raw material

Raw materials coming from nature, that are

found in the earth crust being brought to surface

in an unprocessed state.

Creating raw material

Nature raw material refined into other useful

material

Example

Crude oil is refined into gasoline, fuel, heating

oil, kerosene and gas.

Manufacturing engineering

components

The science and technology by which a material

is converted into a useful shape with a structure

and properties for a particular application.

Fabricating products and

systems

The assembly of different manufactured parts to

form a component.

Servicing of products and

systems

Components need periodic maintenance to keep

them in good condition for its intended purpose.

Recycling / disposing of used

products and systems

The re-use of material coming from waste

during manufacturing process or redundant

fabricated components. Some materials need to

be separated before recycled.

Material processing cycle diagram

Assignment -1

Classification of Materials

-------------------------------------------------------------------------------------------------------

-------------------------------------------------------------------------------------------------------

Page 5 of 5

Вам также может понравиться

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Atom WorksheetsДокумент4 страницыAtom Worksheetsapi-271960049Оценок пока нет

- 429 SampleДокумент40 страниц429 Samplejerrica thomasОценок пока нет

- Astm b571 97 R 13pdfДокумент4 страницыAstm b571 97 R 13pdfkishor150688Оценок пока нет

- Advanced PharmacognosyДокумент13 страницAdvanced PharmacognosyLisa DamayantiОценок пока нет

- Ripening of CheeseДокумент18 страницRipening of CheeseHASVRDОценок пока нет

- Relationships Between The Surface Texture of Flexographic Printing Plates and The Printability of Kraft PaperДокумент11 страницRelationships Between The Surface Texture of Flexographic Printing Plates and The Printability of Kraft PaperQuý Đình Mai MaiОценок пока нет

- AntimonyДокумент72 страницыAntimony沈益Оценок пока нет

- GAP.8.0.1.1. Oil and Chemical Properties Loss Potential Estimation GuideДокумент19 страницGAP.8.0.1.1. Oil and Chemical Properties Loss Potential Estimation Guidemartinnovel100% (1)

- Astm D 388Документ6 страницAstm D 388Julian MonroyОценок пока нет

- Mobile Balance RecordsДокумент2 страницыMobile Balance RecordsABZ007Оценок пока нет

- Abc Company: Order / Contract RegisterДокумент2 страницыAbc Company: Order / Contract RegisterABZ007Оценок пока нет

- Activity Daily PlanДокумент2 страницыActivity Daily PlanABZ007Оценок пока нет

- Lab Report: FffvqfsvanvasnДокумент1 страницаLab Report: FffvqfsvanvasnABZ007Оценок пока нет

- Xmas Daily Plan01Документ2 страницыXmas Daily Plan01ABZ007Оценок пока нет

- Quality Management GurusДокумент5 страницQuality Management GurusABZ007Оценок пока нет

- Assignment ChemicalsДокумент5 страницAssignment ChemicalsABZ007Оценок пока нет

- Leave PlanningДокумент2 страницыLeave PlanningABZ007Оценок пока нет

- Work Ethics Principles - PPT PDFДокумент11 страницWork Ethics Principles - PPT PDFABZ007100% (1)

- Classification of MaterialsДокумент5 страницClassification of MaterialsABZ007Оценок пока нет

- Classification of Basic Materials PDFДокумент5 страницClassification of Basic Materials PDFABZ007Оценок пока нет

- Terminology of Materials: ST ND RDДокумент2 страницыTerminology of Materials: ST ND RDABZ007Оценок пока нет

- Definitions: 1. Quality 2. Quality AssuranceДокумент3 страницыDefinitions: 1. Quality 2. Quality AssuranceABZ007Оценок пока нет

- Dept Leave PlannerДокумент1 страницаDept Leave PlannerABZ007Оценок пока нет

- Show-Hide File ExtensionДокумент1 страницаShow-Hide File ExtensionForza JuveОценок пока нет

- PPT-Template SchoolPaperДокумент3 страницыPPT-Template SchoolPaperABZ007Оценок пока нет

- Customer Expectations DefinedДокумент2 страницыCustomer Expectations DefinedABZ007Оценок пока нет

- All Pictures From Web NatureДокумент43 страницыAll Pictures From Web NatureABZ007Оценок пока нет

- Chapter Two: What Is Quality?Документ11 страницChapter Two: What Is Quality?ABZ007Оценок пока нет

- Eng TQM Ch03Документ14 страницEng TQM Ch03ABZ007Оценок пока нет

- SY 2022-2023 Updated Chem 301 Biochem Lec Synch and AsynchДокумент3 страницыSY 2022-2023 Updated Chem 301 Biochem Lec Synch and AsynchLYKA ANTONETTE ABREGANAОценок пока нет

- Ekatalog 2023 Sulsel RajawaliДокумент50 страницEkatalog 2023 Sulsel RajawaliSafria HamzaОценок пока нет

- Philippine Coconut Authority: Coconut Methyl Ester (Cme) As Petrodiesel Quality EnhancerДокумент37 страницPhilippine Coconut Authority: Coconut Methyl Ester (Cme) As Petrodiesel Quality EnhancerAnthony MoraОценок пока нет

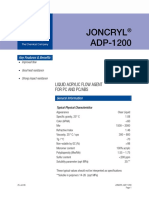

- 1200 TDSДокумент2 страницы1200 TDSRoxana LencinaОценок пока нет

- Chapter 2-The Column in GCДокумент92 страницыChapter 2-The Column in GCkhanhvan2105Оценок пока нет

- BASF Pharma Solutions - Main Product Catalog - WebДокумент44 страницыBASF Pharma Solutions - Main Product Catalog - WebŽeljko StanojkovskiОценок пока нет

- Characterizing Synthetic Dyes by 2D LC-MSДокумент18 страницCharacterizing Synthetic Dyes by 2D LC-MSM BustamanteОценок пока нет

- 14 CH242 Conjugated & UVДокумент72 страницы14 CH242 Conjugated & UVrizqiaОценок пока нет

- Non Renewable EnergyДокумент28 страницNon Renewable EnergyTariq KhanОценок пока нет

- Lab Report Chemist 3Документ3 страницыLab Report Chemist 3Aiman Athirah Binti Hasbullah E21A0446Оценок пока нет

- Evolution of Atomic Structure PDFДокумент1 страницаEvolution of Atomic Structure PDFAnonymous VI4gZ25FbaОценок пока нет

- Tandem Dyes For Flow Cytometry, Quality Concerns, Beckman CoДокумент2 страницыTandem Dyes For Flow Cytometry, Quality Concerns, Beckman CocandiddreamsОценок пока нет

- Puresilk Salt ChlorinatorДокумент10 страницPuresilk Salt Chlorinatornike_y2kОценок пока нет

- Company Profile 4 April - CompressedДокумент10 страницCompany Profile 4 April - CompressedPhilip PhilipsОценок пока нет

- Lecture - 3 Dosimetric Quantities and Biological EffectsДокумент33 страницыLecture - 3 Dosimetric Quantities and Biological Effectsmz2v8rs7srОценок пока нет

- 0926p5richard-Lee2 Good Slids For Composite Wrap RepairДокумент37 страниц0926p5richard-Lee2 Good Slids For Composite Wrap RepairVignesh VelОценок пока нет

- Lactose ProfileДокумент3 страницыLactose ProfileKK90441Оценок пока нет

- Booster in Sunscreen INOLEX PDFДокумент18 страницBooster in Sunscreen INOLEX PDFrenatoporangaОценок пока нет

- Brochure TDS RedicoteE 11Документ1 страницаBrochure TDS RedicoteE 11Rabin BeraОценок пока нет

- Effect of Acids and Bases On The Browning of ApplesДокумент2 страницыEffect of Acids and Bases On The Browning of ApplesAnkur Agarwall0% (1)

- Kinetics of The Selective Hydrogenation of Phenol To Cyclohexanone Over A Pd-Alumina CatalystДокумент8 страницKinetics of The Selective Hydrogenation of Phenol To Cyclohexanone Over A Pd-Alumina CatalystTaylor PennaОценок пока нет