Академический Документы

Профессиональный Документы

Культура Документы

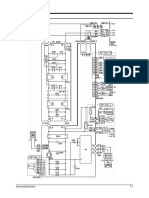

Total Clearing Time-Current Characteristic Curves: Positrol Fuse Links-S&C Standard Speed

Загружено:

faberromeroОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Total Clearing Time-Current Characteristic Curves: Positrol Fuse Links-S&C Standard Speed

Загружено:

faberromeroАвторское право:

Доступные форматы

S&C ELECTRIC COMPANY Chicago

S&C ELECTRIC CANADA LTD. Toronto

TCC NUMBER

123-6-2

Page 1 of 1

January 20, 1986

Supersedes TCC No. 123-6-2 dated 12-17-84

1986

1000

900

800

400

700

600

500

300

200

1000

900

800

400

700

600

500

300

200

T

I

M

E

I

N

S

E

C

O

N

D

S

100

90

80

40

70

60

50

30

20

100

90

80

40

70

60

50

30

20

10

9

8

4

7

6

5

3

2

10

9

8

4

7

6

5

3

2

1

.9

.8

.4

.7

.6

.5

.3

.2

1

.9

.8

.4

.7

.6

.5

.3

.2

.1

.09

.08

.04

.07

.06

.05

.03

.02

.1

.09

.08

.04

.07

.06

.05

.03

.02

1

0

0

0

0

9

0

0

0

8

0

0

0

4

0

0

0

7

0

0

0

6

0

0

0

5

0

0

0

3

0

0

0

2

0

0

0

1

0

0

0

9

0

0

8

0

0

4

0

0

7

0

0

6

0

0

5

0

0

3

0

0

2

0

0

1

0

0

9

0

8

0

4

0

7

0

6

0

5

0

3

0

2

0

1

0

9 8 4 7 6 5 3 2 1 .9 .8 .7 .6 .5

.01 .01

CURRENT IN AMPERES

1

0

0

0

0

9

0

0

0

8

0

0

0

4

0

0

0

7

0

0

0

6

0

0

0

5

0

0

0

3

0

0

0

2

0

0

0

1

0

0

0

9

0

0

8

0

0

4

0

0

7

0

0

6

0

0

5

0

0

3

0

0

2

0

0

1

0

0

9

0

8

0

4

0

7

0

6

0

5

0

3

0

2

0

1

0

9 8 4 7 6 5 3 2 1 .9 .8 .7 .6 .5

T

I

M

E

I

N

S

E

C

O

N

D

S

CURRENT IN AMPERES

BASIS

These fuse links are tested in accordance with the proce-

dures described in ANSI Standard C37.41-1981, to comply with

ANSI Standard C37.42-1981. As required by these standards, the

minimum melting current is not less than 200% of fuse-link ampere

rating, and the minimum melting and total clearing curves are

based on tests starting with the fuse link at an ambient temperature

of 25C and no initial load.

CONSTRUCTION

Fusible elements for fuse links rated 1 through 5

amperes are nickel-chrome; fusible elements for fuse links rated 7

through 100 amperes are silver, helically coiled; fusible elements for

fuse links rated 125 through 200 amperes are silver-tin. All are of

solderless construction.

TOLERANCES

Curves are plotted to maximum test points. All varia-

tions are minus.

APPLICATION

Like all high-voltage fuses, these fuse links are

intended to accommodate overloads, not to interrupt them. Accord-

ingly, they feature fusible elements which are designed with a min-

imum melting current of 200% of the fuse-link ampere rating (for

fuse links rated 100 amperes or less) or 220% of the fuse-link

ampere rating (for fuse links rated over 100 amperes). As a result,

these fuse links have considerable peak-loaad capabilities; how-

ever, they should never be exposed to loading in excess of the

peak-load capabilities listed in S&C Data Bulletin 350-190.

Since fuse links having nickel-chrome or silver element contruc-

tion are not subject to damage by aging or transient overcurrents, it

is unnecessary to replace unblown fuse links of either of these con-

structions in single-phase or three-phase installations when one or

more fuse links have blown. However, it is advisable to replace

unblown silver-tin element fuse links under the same conditions,

sincewhile not subject to agingthey may be damaged by

tranient overcurrents.

COORDINATION

These curves represent the total time required for

a fuse link to melt and interrupt a fault current, and should be fol-

lowed in coordination problems where fuse links are applied as

protecting devices.

Any preloading reduces melting time. With respect to the pro-

tected fuse, the effect of preloading must be determined and

adjustments made to its minimum melting curve:

1. When close coordination is required;

2. When automatic circuit reclosers of three-shot cutouts are

involved;

3. When, regardless of the preciseness of coordination, the pro-

tected fuse is subject to temporary overloads.

If close coordination is to be achieved, overloading must be

avoided since it causes a signicant shift in time-current character-

istics.

The exclusive use of S&C Positrol Fuse Linksbecause of their

inherently narrower tolerance band and because of their nondam-

ageabilitywill expand the scope of coordination as follows:

1. Coordination of adjacent ratings, giving twice as many sec-

tionalizing points. This is true for the sequence operation of

fuse links alone, or for the sequence operation of fuse

links coordinated with automatic circuit reclosers.

2. Coordination of a larger number of fuse-link ratings with a

given automatic circuit recloser between the fast and retarded

curves.

3. Coordination through a greater range, and to higher levels of

fault current, with respect to automatic circuit reclosers.

4. Coordination to higher levels of fault current with respect to

sequence operation of fuse links.

The breadth of coordination described above can be obtained

only by the use of S&C Positrol Fuse Links. No fuse link of low-tem-

perature element construction (tin, lap-joint) can provide similar

performance.

NOTE

A coordination scheme designed to take full advantage of

the nondamageability and the superior coordination capabilities of

S&C Positrol Fuse Links may not function satisfactorily if fuse links

of a similar speed but of other makes are substituted.

REFILL UNITS AVAILABLE

Rell Unit Ampere Ratings

Universal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 through 200

Extra-Performance . . . . . . . . . . . . . . . . . . . . . . . . . . 1 through 100

Indicating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 through 100

Open . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 through 25

TOTAL CLEARING TIME-CURRENT CHARACTERISTIC CURVES

POSITROL

FUSE LINKSS&C STANDARD SPEED

123571

0

1

5

2

0

2

5

3

0

4

0

5

0

6

5

8

0

1

0

0

2

0

0

1

5

0

1

2

5

Вам также может понравиться

- Towards Hydrogen Infrastructure: Advances and Challenges in Preparing for the Hydrogen EconomyОт EverandTowards Hydrogen Infrastructure: Advances and Challenges in Preparing for the Hydrogen EconomyDeepshikha Jaiswal-NagarОценок пока нет

- TCC Number 165 6 2Документ1 страницаTCC Number 165 6 2bertovalenОценок пока нет

- Surface Mount Fuses FundamentalsДокумент28 страницSurface Mount Fuses FundamentalsfwklОценок пока нет

- Machine Learning and Reasoning For Predictive Maintenance in Industry 4.0 - Current Status and ChallengesДокумент15 страницMachine Learning and Reasoning For Predictive Maintenance in Industry 4.0 - Current Status and ChallengesHoa Dinh NguyenОценок пока нет

- SQ-300®i Automatic Voltage Control: Proven Electrostatic Precipitator SolutionsДокумент2 страницыSQ-300®i Automatic Voltage Control: Proven Electrostatic Precipitator SolutionsRafael Paiva100% (1)

- Rect Um 0618 en Rv003phДокумент80 страницRect Um 0618 en Rv003phnikhom_dk1565Оценок пока нет

- Andovercontinuumul 864 Bacnetsmokecontrolsystemdesignguide 101134Документ124 страницыAndovercontinuumul 864 Bacnetsmokecontrolsystemdesignguide 101134Chong CongОценок пока нет

- McQuay Horizontal Water Source Heat Pump - 1/2 To 6 TonДокумент74 страницыMcQuay Horizontal Water Source Heat Pump - 1/2 To 6 Tononewheeldoin200100% (1)

- Wm-E1 2g DB Gsm-Gprs Modem Inst Config v1 2 0 4wДокумент18 страницWm-E1 2g DB Gsm-Gprs Modem Inst Config v1 2 0 4wCristina AntohiОценок пока нет

- CIGRE-Ciclo de Vida de InterruptoresДокумент8 страницCIGRE-Ciclo de Vida de InterruptoresRoland AvlsОценок пока нет

- Circuitpro PM 2.3 Ba v1.0 EngДокумент386 страницCircuitpro PM 2.3 Ba v1.0 Engnuit_claire002Оценок пока нет

- Project Profile On LED Based Lighting System PDFДокумент8 страницProject Profile On LED Based Lighting System PDFsambhudharmadevanОценок пока нет

- EXEMYS - RS232 To TCPДокумент2 страницыEXEMYS - RS232 To TCPJorge_Andril_5370Оценок пока нет

- Installing and Maintaining Panelboards: NECA 407-2009Документ38 страницInstalling and Maintaining Panelboards: NECA 407-2009Ahmed OmarОценок пока нет

- Manual Instalare DR-NKMДокумент10 страницManual Instalare DR-NKMJonathan MolinaОценок пока нет

- PTS 400 3 PLUS Overview EnglishДокумент16 страницPTS 400 3 PLUS Overview EnglisharmansatОценок пока нет

- Pentax Bombas 50hz GC Rev 34Документ520 страницPentax Bombas 50hz GC Rev 34Fabiola barriosОценок пока нет

- Simplex 4100-0031Документ10 страницSimplex 4100-0031vlaya1984Оценок пока нет

- Siemens Modbus and Ion TechnologyДокумент21 страницаSiemens Modbus and Ion TechnologyGabriel SilvaОценок пока нет

- Steam Drum InspectionДокумент3 страницыSteam Drum Inspectionyogacruise100% (1)

- Eco 80 Wind Turbine PlatformДокумент2 страницыEco 80 Wind Turbine PlatformKarthick Velayutham0% (2)

- Analysis of Communication Protocols For Smart MeteringДокумент9 страницAnalysis of Communication Protocols For Smart Meteringedmuarizt7078Оценок пока нет

- A Newton Optimal Power Flow Program For Ontario Hydro EMSДокумент7 страницA Newton Optimal Power Flow Program For Ontario Hydro EMSFlores JesusОценок пока нет

- HarmonicsДокумент3 страницыHarmonicsMiko QuijanoОценок пока нет

- MAN-2004-0001-C - User Guide - Pcorr and Permalog Using WebCorr App PDFДокумент56 страницMAN-2004-0001-C - User Guide - Pcorr and Permalog Using WebCorr App PDFGabiBaciuОценок пока нет

- IEEE 1547 ParametersДокумент24 страницыIEEE 1547 Parametersatrejom123Оценок пока нет

- Ansi Tia 570 AДокумент72 страницыAnsi Tia 570 AInti YacelgaОценок пока нет

- WPM 0119 Digimag PDFДокумент40 страницWPM 0119 Digimag PDFJoeОценок пока нет

- Metercat Data Sheet 1Документ2 страницыMetercat Data Sheet 1Yaju JotosОценок пока нет

- Protective Coating System ISO-12944-5 Pinturas TIKURILLAДокумент2 страницыProtective Coating System ISO-12944-5 Pinturas TIKURILLAmiguel0581Оценок пока нет

- Example GuideДокумент164 страницыExample GuideVincent LiuОценок пока нет

- IEC 60364-5-54-Low Voltage - Earthing Arrangement and Protective ConductorsДокумент43 страницыIEC 60364-5-54-Low Voltage - Earthing Arrangement and Protective Conductorsshazwanshaiful1Оценок пока нет

- 0613CT0001 PDFДокумент180 страниц0613CT0001 PDFhimanshu yadavОценок пока нет

- Info Iec60445 (Ed6.0.RLV) enДокумент17 страницInfo Iec60445 (Ed6.0.RLV) enrioОценок пока нет

- CHAP2Документ101 страницаCHAP2mspd2003Оценок пока нет

- Iom 1202 082013Документ137 страницIom 1202 082013Bianca L. Foliaco100% (1)

- Catalogo He 2004Документ85 страницCatalogo He 2004ferenscribd0% (1)

- Man v32 44crДокумент2 страницыMan v32 44crKeshav Shrivastava KSОценок пока нет

- Instruction Sheet D3208 MANUALДокумент48 страницInstruction Sheet D3208 MANUALscalariОценок пока нет

- Ruggedcom - RX1501Документ13 страницRuggedcom - RX1501kingmonstereОценок пока нет

- Cfgpro01 PDFДокумент10 страницCfgpro01 PDFSalvador FayssalОценок пока нет

- Rittal 7955211 Instrucciones 3 5902Документ68 страницRittal 7955211 Instrucciones 3 5902Elfy PalmaОценок пока нет

- P3 NRJCAT17764EN v16 072019 PDFДокумент122 страницыP3 NRJCAT17764EN v16 072019 PDFHoang Bao ThaiОценок пока нет

- Mettler Toledo POWERCELL Load Cell Brochure J.A. KingДокумент12 страницMettler Toledo POWERCELL Load Cell Brochure J.A. Kinghaidar ismailОценок пока нет

- IOP Report 2015 3 PDFДокумент488 страницIOP Report 2015 3 PDFCusco PardoОценок пока нет

- FREJA300-306-Win5 4 UG en V03Документ204 страницыFREJA300-306-Win5 4 UG en V03apofviewОценок пока нет

- Catalogo Sediver Hvac 1 16Документ16 страницCatalogo Sediver Hvac 1 16glenysyaОценок пока нет

- DGS-5 Documentation v003Документ38 страницDGS-5 Documentation v003nando_nando_Оценок пока нет

- Catalogo INGESCO ENGДокумент32 страницыCatalogo INGESCO ENGBogdan MondocОценок пока нет

- Ansi c80.5-2005 American National Standard For Electrical Rigid Aluminium Conduit (Erac)Документ16 страницAnsi c80.5-2005 American National Standard For Electrical Rigid Aluminium Conduit (Erac)Chike NwachukwuОценок пока нет

- Diagrama Unifilar ModelДокумент1 страницаDiagrama Unifilar Modelgian93100% (1)

- PDFДокумент10 страницPDFajit aryanОценок пока нет

- KTH EI2436 20142 1 enДокумент2 страницыKTH EI2436 20142 1 enGIngaaОценок пока нет

- Ekor - RPS: Multifunctional Protection Unit Volume 1 of 3Документ144 страницыEkor - RPS: Multifunctional Protection Unit Volume 1 of 3Mayrita M Rojas100% (1)

- SSE 2227 Archivo Ingecon Sun Catalogue 2016 v2 EnglishДокумент160 страницSSE 2227 Archivo Ingecon Sun Catalogue 2016 v2 EnglishVitor Olivetti0% (1)

- Wiring Diagram: Samsung Electronics 7-1Документ2 страницыWiring Diagram: Samsung Electronics 7-1Jose Antonio Mellado DiazОценок пока нет

- PGT006 Centrifugal Pumps Intro Training PDFДокумент14 страницPGT006 Centrifugal Pumps Intro Training PDFWiesen LimОценок пока нет

- SIP5 6MD85-86 V04.00 Manual C015-3 EsДокумент880 страницSIP5 6MD85-86 V04.00 Manual C015-3 Esgusfaj100% (1)

- Abb RcboДокумент8 страницAbb RcbojaniankoОценок пока нет

- Buss MannДокумент73 страницыBuss ManncocacolapepsiОценок пока нет

- Ampacity Chart For Copper Bus Bar DesignДокумент2 страницыAmpacity Chart For Copper Bus Bar DesignfaberromeroОценок пока нет

- Acometida FullДокумент4 страницыAcometida FullfaberromeroОценок пока нет

- Joint ENTSO-E Europacable FINAL 17 Dec 2010 SignedДокумент26 страницJoint ENTSO-E Europacable FINAL 17 Dec 2010 SignedfaberromeroОценок пока нет

- Ampacity Chart For Copper Bus Bar DesignДокумент2 страницыAmpacity Chart For Copper Bus Bar DesignfaberromeroОценок пока нет

- Copper Busbar Ampacity TablesДокумент2 страницыCopper Busbar Ampacity TablesfaberromeroОценок пока нет

- Copper Busbar Ampacity TablesДокумент2 страницыCopper Busbar Ampacity TablesfaberromeroОценок пока нет

- Buss Bar Ampacities - Ampacity TablesДокумент1 страницаBuss Bar Ampacities - Ampacity TablesfaberromeroОценок пока нет

- Buss Bar Ampacities - Ampacity TablesДокумент1 страницаBuss Bar Ampacities - Ampacity TablesfaberromeroОценок пока нет

- Storm Copper Busbar BrochureДокумент6 страницStorm Copper Busbar BrochurefaberromeroОценок пока нет

- ConversionДокумент1 страницаConversionCosmin CinciОценок пока нет

- FortДокумент3 страницыFortjohn buahОценок пока нет

- 06 Reference For ConstructionДокумент46 страниц06 Reference For ConstructionRamil S. ArtatesОценок пока нет

- Furnace Rectifier Trafos ABBДокумент8 страницFurnace Rectifier Trafos ABBvakilianmeОценок пока нет

- Thyristor Bridge, SCR, Bridge: Disc DiodeДокумент4 страницыThyristor Bridge, SCR, Bridge: Disc DiodeKátia OliveiraОценок пока нет

- SM Series: Aluminium Electrolytic CapacitorДокумент2 страницыSM Series: Aluminium Electrolytic CapacitorStuxnetОценок пока нет

- Lalt 1151 - Installation ManualДокумент36 страницLalt 1151 - Installation ManualJuan Carlos Chaparro100% (1)

- Buzzaround Extreme Service Guide REVA 062916Документ30 страницBuzzaround Extreme Service Guide REVA 062916Parker EastmanОценок пока нет

- Forklift Drive MotorsДокумент1 страницаForklift Drive MotorsahmadОценок пока нет

- Calculate Size of Main ELCB & Brach MCBДокумент6 страницCalculate Size of Main ELCB & Brach MCBHamid Khan0% (1)

- Osti Ia G Interlocks Hinge Pin v032113Документ13 страницOsti Ia G Interlocks Hinge Pin v032113EvaldoGualbertoОценок пока нет

- Column Schedule: Column Footing Typical Section ThroughДокумент1 страницаColumn Schedule: Column Footing Typical Section ThroughAlucardОценок пока нет

- Arduino DC MotorДокумент12 страницArduino DC MotorJohn Clifford Ambaic JayomaОценок пока нет

- Fieldstar Led Floodlight: Division Digital SolutionsДокумент9 страницFieldstar Led Floodlight: Division Digital SolutionsAkash PanigrahiОценок пока нет

- Study ExpДокумент41 страницаStudy ExpNishant Nagle100% (1)

- IC-201 Restoration DL7MAJ 2018Документ9 страницIC-201 Restoration DL7MAJ 2018A KОценок пока нет

- ABB OTM ATS Auto Transfer Switch Instruction ManualДокумент104 страницыABB OTM ATS Auto Transfer Switch Instruction ManualPhuong Do83% (6)

- 555 Delay OFF Timer Circuit For Delay Before Turn OFF Circuit PDFДокумент11 страниц555 Delay OFF Timer Circuit For Delay Before Turn OFF Circuit PDFdhanysiregar100% (1)

- DW13261207 PDFДокумент136 страницDW13261207 PDFp_janko100% (1)

- DOT DOT9100 Performance Series 2 DatasheetДокумент4 страницыDOT DOT9100 Performance Series 2 DatasheetErvin SmithОценок пока нет

- Ex 1872 FMДокумент10 страницEx 1872 FMAaron BaconОценок пока нет

- Manhole EstimateДокумент5 страницManhole EstimateEngr TahseenОценок пока нет

- Sizing The DOL Motor Starter PartsДокумент4 страницыSizing The DOL Motor Starter Partsat35Оценок пока нет

- HVX-O India - 36Kv MANUALДокумент30 страницHVX-O India - 36Kv MANUALAction GamesОценок пока нет

- Balustrade System: cATALOG 2019Документ93 страницыBalustrade System: cATALOG 2019Riadh Ben SmidaОценок пока нет

- Ex-Linear LED Light Fitting LL48Документ4 страницыEx-Linear LED Light Fitting LL48Ahmed GhreebОценок пока нет

- 2tak Vs 4takДокумент3 страницы2tak Vs 4takTaufiq AlhakimОценок пока нет

- Dahlander WindingДокумент1 страницаDahlander WindingSreekanth Raveendran50% (2)

- RCC Foundation PlanДокумент1 страницаRCC Foundation Plandgupta1987Оценок пока нет

- Lab 4: TITLE: Inspection and Maintenance The Air Circuit Breaker (ACB) ObjectivesДокумент4 страницыLab 4: TITLE: Inspection and Maintenance The Air Circuit Breaker (ACB) ObjectivesAslam SdОценок пока нет

- Speed Control Motor (pg.139 271)Документ135 страницSpeed Control Motor (pg.139 271)durmazmedikalОценок пока нет