Академический Документы

Профессиональный Документы

Культура Документы

Behaviour of Glass Fiber Wrapped Concrete

Загружено:

B.r. Anirudh0 оценок0% нашли этот документ полезным (0 голосов)

45 просмотров10 страницThe paper reports the

behaviour of the GFRP wrapped concrete columns under uniaxial compression.

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документThe paper reports the

behaviour of the GFRP wrapped concrete columns under uniaxial compression.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

45 просмотров10 страницBehaviour of Glass Fiber Wrapped Concrete

Загружено:

B.r. AnirudhThe paper reports the

behaviour of the GFRP wrapped concrete columns under uniaxial compression.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 10

International Journal of Advanced Engineering Technology

IJAET/Vol. I/ Issue I/April-June, 2010/74-83

Research Paper

BEHAVIOUR OF GLASS FIBER WRAPPED CONCRETE

COLUMNS UNDER UNIAXIAL COMPRESSION

P.Sangeetha

1

, R.Sumathi

2

Address for Correspondence

1

Lecturer, Department of Civil Engineering ,Sri Venkateswara College of

Engineering, Pennalur, Sriperumbudur-602105 Tamilnadu.

Email id: p_sangeetha77@yahoo.co.in

2

Assistant Professor, Department of Civil Engineering, Arulmugu Meenakshi

Amman College of Engineering, Thiruvanamalai District. Tamilnadu

===============================================================

ABSTRACT

Fiber Wrapping using Fibre Reinforced Plastic (FRP) shells is one of effective methods,

significantly enhances the strength and ductility of concrete columns. The paper reports the

behaviour of the GFRP wrapped concrete columns under uniaxial compression. The cross section

of the concrete columns considered in the work is circular with diameter of 150mm and height

300mm. The Parameters that are varied in the investigation are wrapping shell materials, (which

includes GFRP Materials Surface Mat(SM), Chopped Strand Mat (CSM) and Woven Roving Mat

(WRM)), Number of Plies (1Ply and 3plies) and Period of Curing (7 & 28 Days). Results from a

series of the experimental study were reported and discussed. The study on small scale

specimens showed that confinement increased the strength of the concrete columns loaded

axially.

KEY WORDS

Fiber Reinforcement, Compressive Strength, Curing, Concrete, Glass Fiber.

==============================================================

INTRODUCTION

In recent years, retrofitting of concrete

columns by wrapping and bonding of

fiber reinforced plastic (FRP) sheets,

straps, belts, or precured shells around

the columns has become increasingly

popular. Studies of concrete columns

confined with glass, aramid, or carbon

fibers have been used successfully to

retrofit building columns, bridge or

expressway piers, and chimneys. An

incremental finite element approach [4],

are used to evaluate the response of

fiber-wrapped square columns confined

with carbon and aramid fibers. Many

researchers [1-3 & 5], have proposed

models for concrete cylinders and square

International Journal of Advanced Engineering Technology

IJAET/Vol. I/ Issue I/April-June, 2010/74-83

columns strengthened with FRP sheets.

The axial load behavior of concrete-

filled tubular (CFT) columns with the

width-to-thickness ratios are studied [6]

and stiffening scheme to enhance the

ultimate strength and ductility of square

CFT columns was proposed. The proper

material constitutive models for concrete

filled tube (CFT) columns are

proposed [7] and verified by the

nonlinear finite element program

ABAQUS against experimental data.

This paper, investigates the

characteristics behaviour of reinforced

concrete columns. FRP is used to wrap

the columns circumferentially. All

columns were tested to failure by

applying axial concentric loads. Results

of testing the columns showed that FRP

is effective in producing columns with

high compressive strength.

Experimental Study

Specimen preparation and Testing

A total of forty-two cylindrical columns

of size 150 X 300 mm were prepared

and twenty one specimens were cured

for 7 days and remaining specimens

were cured for 28 days. Out of 21

specimens of 7 days cured and 28 days

cured, eighteen columns were wrapped

circumferentially with glass fiber

reinforced polymer of Surface Mat

type, Chopped Strand Mat and Woven

Roving Mat after 7 and 28days curing of

single and triple plies and three columns

without wrapping respectively. All the

specimens were tested in the

Compression testing machine of capacity

50kN. Ultimate load readings were taken

to study the compression behavior of the

specimens. Table 1 shows the

description of various specimens

prepared for testing. Fig.1 shows the

column specimens without wrapping.

Fig.1: Column Specimens before

wrapping

Fig.2-4 shows 28 days cured column

specimens wrapped with SM, CSM and

WRM of single ply. Fig.5 shows the

compression test carried out on Triple

plies chopped Strand Mat wrapped on

columns cured for 28 days

International Journal of Advanced Engineering Technology

IJAET/Vol. I/ Issue I/April-June, 2010/74-83

Fig.2:Columns with Single ply Surface Mat

Fig.3: Columns with Single ply of Chopped Strand Mat

Fig.4: Columns with single ply of Woven Roving Mat

Fig.5:Compression testing carried out on 28 days cured Triple Plies Chopped

Strand Mat column.

International Journal of Advanced Engineering Technology

IJAET/Vol. I/ Issue I/April-June, 2010/74-83

Fig. 6:Variation in Compressive Strength after 7 and 28 days cured specimens

wrapped with single ply of GFRP.

Fig.7:Variation in Compressive Strength after 7 and 28 days cured specimens

wrapped with Triple plies of GFRP.

0

5

10

15

20

25

30

UC SM CSM WRM

Types of GFRP Material

C

o

m

p

r

e

s

s

i

v

e

S

t

r

e

n

g

t

h

i

n

N

/

m

m

2

7 days cured Columns

Wrapped with Single Ply

28 days cured Columns

Wrapped with Single Ply

0

5

10

15

20

25

30

35

40

45

50

UC SM CSM WRM

Types of GFRP Material

C

o

m

p

r

e

s

s

i

v

e

S

t

r

e

n

g

t

h

i

n

N

/

m

m

2

7 days cured Columns

Wrapped with Triple Plies

28 days cured Columns Wrapped

with Triple Plies

International Journal of Advanced Engineering Technology

IJAET/Vol. I/ Issue I/April-June, 2010/74-83

Fig. 8:(a) and (b)Variation in Compressive Strength of specimens wrapped with

Single and Triple plies of GFRP after 7 and 28 days of curing.

0

5

10

15

20

25

30

35

40

45

50

UC SM CSM WRM

Types of GFRP Material

C

o

m

p

r

e

s

s

i

v

e

S

t

r

e

n

g

t

h

i

n

N

/

m

m

2

7 days Cured columns Wrapped

with Single Ply

7 days cured columns Wrapped

with Triple plies

Series3

0

5

10

15

20

25

30

35

40

45

50

UC SM CSM WRM

Types of GFRP Material

C

o

m

p

r

e

s

s

i

v

e

S

t

r

e

n

g

t

h

i

n

N

/

m

m

2

28 days cured Columns Wrapped

with Single Ply

28 days cured Columns Wrapped

with Triple Plies

Linear (28 days cured Columns

International Journal of Advanced Engineering Technology

IJAET/Vol. I/ Issue I/April-June, 2010/74-83

Fig. 9:Shows the comparison between the compressive strength of 7 & 28 days cured

specimens.

0

5

10

15

20

25

30

35

40

45

Single Ply Triple Plies

No. of Plies

C

o

m

p

r

e

s

s

i

v

e

S

t

r

e

n

g

t

h

i

n

N

/

m

m

2

Un Confined Columns

Columns Wrapped with SM

Columns Wrapped with CSM

Columns Wrapped with WRM

0

5

10

15

20

25

30

35

40

45

50

Single Ply Triple Plies

No. of Plies

C

o

m

p

r

e

s

s

i

v

e

S

t

r

e

n

g

t

h

i

n

N

/

m

m

2

Un Confined Column

Columns Wrapped with SM

Columns Wrapped with CSM

Column Wrapped with WRM

International Journal of Advanced Engineering Technology

IJAET/Vol. I/ Issue I/April-June, 2010/74-83

EXPERIMENTAL RESULTS AND

DISCUSSION

Table 2 shows the results of tested

column specimens. The columns

wrapped with Woven Roving Mat of

Glass fiber exhibited better results than

other type of Glass fiber columns. The

compressive strength of the GFRP

wrapped concrete columns shows better

results when columns are wrapped with

3 plies than single ply.

Effect of FRP Wrapping Materials

The Percentage increase in the

Compressive Strength for change in Ply

from 0 to 1 for specimens wrapped with

Surface Mat, Chopped Strand Mat and

Woven Roving Mat after 7 days curing

were 3.6, 21.46 and 28.97% respectively

and after 28 days curing were 10, 27.17

and 31.46 %. Fig.6. Show the variation

in compressive strength after 7 and 28

days cured specimens wrapped with

single ply of GFRP. The Percentage

increases in the Compressive Strength

for change in Ply from 0 to 3 for

specimen wrapped with Surface Mat,

Chopped Strand Mat and Woven Roving

Mat after 7 days curing were 50, 135.79

and 167.93% respectively and after 28

days curing were 10, 27.17 and 31.46%.

Fig.7. Show the variation in compressive

strength after 7 and 28 days cured

specimens wrapped with Triple plies of

GFRP.

Effect of Plies

The percentage increase in the

Compressive Strength for 7 days & 28

days cured column wrapped with

Surface Mat for Single Ply and Triple

Plies is 3.6 and 50% respectively. The

percentage increase in the Compressive

Strength for column wrapped with

Chopped Strand Mat for Single Ply and

Triple Plies is 21.46 and 136%

respectively. The percentage increase in

the Compressive Strength for column

wrapped with Woven Roving Mat for

Single Ply and Triple Plies is 29 and

168% respectively .Fig. 8 (a) and (b)

show the variation in compressive

strength of specimens wrapped with

Single and Triple plies of GFRP after 7

and 28 days of curing.

Effect of Curing

The percentage increases in the

Compressive Strength for column

wrapped with Single ply of Surface Mat,

Chopped Strand Mat and Woven Roving

Mat from 7 to 28 days cured are 32.72,

30.87 and 27.4% respectively and with

Triple Plies are 21.46, 6.05 and 6.66%

respectively.

International Journal of Advanced Engineering Technology

IJAET/Vol. I/ Issue I/April-June, 2010/74-83

Table.1:.Descripition of various specimens prepared for testing

S. No. Specimen Descriptions No. of

Casted

columns

taken

Period

of curing

(days)

Number

of plies

3 7 0 1 Unconfined Column (UC)

3 28 0

3 7 1

3 28 1

3 7 3

2 Surface Mat Column (SMC)

3 28 3

3 7 1

3 28 3

3 7 3

3 Chopped Strand Mat Column (CSMC)

3 28 3

3 7 1

3 28 1

3 7 1

4 Woven Roving Mat Column (WRMC)

3 28 1

Table.2.Results of tested column specimens under Compressive loading condition

S.

No.

Specimen Descriptions Period

of curing

(days)

Number of

plies

Compressive

Strength

(N/mm

2

)

7 0 15.84 1 Unconfined Column (UC)

28 0 19.81

7 1 16.41

28 1 21.78

7 3 23.76

2 Surface Mat Column (SMC)

28 3 28.86

7 1 19.24

28 1 25.18

7 3 37.35

3

Chopped Strand Mat Column (CSMC)

28 3 39.61

7 1 20.43

28 1 26.03

7 3 42.44

4

Woven Roving Mat Column (WRMC)

28 3 45.27

International Journal of Advanced Engineering Technology

IJAET/Vol. I/ Issue I/April-June, 2010/74-83

The over all Percentage increase in

Compressive Strength for different

materials is 30% for single ply from 7

days to 28days of curing and 20% for

Triple Plies .

.

Fig.10.Tested Columns

CONCLUSIONS

The present study used forty-two

columns, wrapped with GFRP of types

Surface Mat(SM), Chopped Strand Mat

(CSM) and Woven Roving Mat (WRM).

Based on the results from a series of the

experimental work the following

Conclusions are made.

The confinement of columns

with GFRP wrap increased the

strength and ductility of the

concrete Column.

Different types of glass fiber are

Surface Mat, Chopped Stand Mat

and Woven Roving Mat also

increasing the compressive

strength of the columns.

Compressive Strength of the

Concrete Columns increases with

increase in the number of plies of

GFRP.

Period of Curing also increases

the load carrying capacity of

columns.

REFERENCES

1. Amir Mirmiran and Mohsen

Shahawy, Behavior of concrete

columns confined by fiber

composites, J of Struct Engg 123

(1997) (5), pp. 583 590.

2. M.Samaan, A .Mirmiran and M.

Shahawy, Model of concrete

confined by fiber composites, J

of Struct Engg 124 (1998) (9),

pp.1025-1031.

3. R. Marijn, Spoelstra and Giorgio

Monti, FRP-confined concrete

model, J of Compos for

Construction 3 (1999) (3), pp. 143

150.

4. P.Rochettee and P. Labossiere,

Axial testing of rectangular column

model confined with composites, J

of compos for construction 4 (2000)

(3), pp.129-136.

5. A.Parvin and W. Wang, Behavior of

FRP jacketed concrete columns

under eccentric loading, J of compos

International Journal of Advanced Engineering Technology

IJAET/Vol. I/ Issue I/April-June, 2010/74-83

for construction 4 (2000) (3),

pp.146 152.

6. C.S.Huang , Y.K.Yeh , G.Y.Liu ,

H.T. Hu , K.C.Tsai , Y.T.Weng ,

S.H.Wang and M.H.Wu , Axial

load behaviour of stiffened

concrete- filled steel columns, J of

Struct Engg. 128 (2002) (9),

pp.1222 1230.

7. A.Ghobarah ,M.N. Ghorbel ,S.E.

Chidiac , Upgrading torsional

resistance of reinforced concrete

beams using fiber reinforced

polymer, J of compos for

construction, (2002),pp. 257 263.

8. Hsuan-Teh Hu, Chiung Shiann

Huang, Ming- Hsien Wu & Yih-Min

Wu, Nonlinear analysis of axially

loaded concrete- filled tube columns

with confinement effect, J of struct

Engg. 129 (2003) (10), pp.1322-

1329.

Вам также может понравиться

- The Fatigue Strength of Transverse Fillet Welded Joints: A Study of the Influence of Joint GeometryОт EverandThe Fatigue Strength of Transverse Fillet Welded Joints: A Study of the Influence of Joint GeometryОценок пока нет

- Load-Bearing Fibre Composites: International Series on the Strength and Fracture of Materials and StructuresОт EverandLoad-Bearing Fibre Composites: International Series on the Strength and Fracture of Materials and StructuresОценок пока нет

- FIBRE REINFORCED CONCRETE USING DOMESTIC WASTE PLASTICS AS FIBRES by R. Kandasamy and R. MurugesanДокумент8 страницFIBRE REINFORCED CONCRETE USING DOMESTIC WASTE PLASTICS AS FIBRES by R. Kandasamy and R. MurugesanIvan KotОценок пока нет

- Nitinol-Shape Memory AlloyДокумент12 страницNitinol-Shape Memory AlloyIsraa NizzarОценок пока нет

- Prediction of Shear Strength of PPFRC Moderate Deep Beams Using Strut-and-Tie ModelsДокумент4 страницыPrediction of Shear Strength of PPFRC Moderate Deep Beams Using Strut-and-Tie Modelschetan2042Оценок пока нет

- Final Tesile Testing ReportДокумент12 страницFinal Tesile Testing Reportismael hashiОценок пока нет

- J Korean Acad Conserv DentДокумент22 страницыJ Korean Acad Conserv Dentsweet_apple921587Оценок пока нет

- Test Methods For Textile Reinforced ConcreteДокумент12 страницTest Methods For Textile Reinforced ConcreteSHEIKH MUHAMMAD FAHADОценок пока нет

- Ferrocement PaperДокумент8 страницFerrocement PaperClassic11Оценок пока нет

- Strengthening of Concrete Beams Using Fiber-Reinforced PlasticsДокумент7 страницStrengthening of Concrete Beams Using Fiber-Reinforced PlasticsOttawa CanadaОценок пока нет

- Shear Behaviour of Steel Fibre Reinforced Self-Compacting ConcreteДокумент8 страницShear Behaviour of Steel Fibre Reinforced Self-Compacting Concretejack21abОценок пока нет

- BFRPConfinedCylinders AK ERTДокумент4 страницыBFRPConfinedCylinders AK ERTMahmoud HamadaОценок пока нет

- Performance of Steel Fiber Reinforced Self Compacting ConcreteДокумент5 страницPerformance of Steel Fiber Reinforced Self Compacting ConcreteInternational Journal of computational Engineering research (IJCER)Оценок пока нет

- 8venkata Subba Reddy Dandu Et AlДокумент5 страниц8venkata Subba Reddy Dandu Et AlAnu AmruthОценок пока нет

- Comparison of Core and Cube Compressive Strength of Hardened ConcreteДокумент5 страницComparison of Core and Cube Compressive Strength of Hardened ConcreteRajmonda RamaОценок пока нет

- Fracture Properties of Glass Fiber Composite Laminates and Size Effect EGYPTДокумент14 страницFracture Properties of Glass Fiber Composite Laminates and Size Effect EGYPTRajaneesh AnantharajuОценок пока нет

- T01 07 Ivanic - Kravanja - Lubej - GNP2020Документ7 страницT01 07 Ivanic - Kravanja - Lubej - GNP2020Kenan KajosevicОценок пока нет

- Data Full Papers 112 DelДокумент8 страницData Full Papers 112 DelDBW Quality Control JVACCОценок пока нет

- Evaluation of The Tensile Strength of SFRC As Derived From Inverse Analysis of Notched Bending TestsДокумент9 страницEvaluation of The Tensile Strength of SFRC As Derived From Inverse Analysis of Notched Bending TestsJakob FiskerОценок пока нет

- Efficiency SFR 2003Документ10 страницEfficiency SFR 2003Kemal Tuşat YücelОценок пока нет

- Size Effect On Punching Shear Behavior of Slab-Column Assembly Made From Engineering Cementitious Composite Materials With Polyvinyl Alcohol FibersДокумент9 страницSize Effect On Punching Shear Behavior of Slab-Column Assembly Made From Engineering Cementitious Composite Materials With Polyvinyl Alcohol FibersfaridОценок пока нет

- SANDWICH BEAM FLEXURE BEHAVIOUR REPORT E3.4Документ15 страницSANDWICH BEAM FLEXURE BEHAVIOUR REPORT E3.4Wang Yi DanОценок пока нет

- Lifting Eyes Ara Paper 8mayДокумент14 страницLifting Eyes Ara Paper 8mayiuliandurdureanuОценок пока нет

- Behaviour of CFRP-Strengthened Slender Square RC ColumnsДокумент11 страницBehaviour of CFRP-Strengthened Slender Square RC Columnsy768673Оценок пока нет

- Mechanical Behavior of Polypropylene-Based Honeycomb-Core Composite Sandwich StructuresДокумент11 страницMechanical Behavior of Polypropylene-Based Honeycomb-Core Composite Sandwich Structuresburak köseerОценок пока нет

- Engineering Journal Behaviour of R.C Beam and Glass Fiber Reinforced Polymer Composite Beam For Shear StrengthДокумент9 страницEngineering Journal Behaviour of R.C Beam and Glass Fiber Reinforced Polymer Composite Beam For Shear StrengthEngineering JournalОценок пока нет

- Regain in Strength of Reinforced Concrete Columns-Akash ChauhanДокумент6 страницRegain in Strength of Reinforced Concrete Columns-Akash ChauhanAkash ChauhanОценок пока нет

- Effects of Unconfined Concrete Strength On FRP Confinement of ConcreteДокумент8 страницEffects of Unconfined Concrete Strength On FRP Confinement of Concretecaojin259Оценок пока нет

- Use of Split-Disk Tests For The Process Parameters-Kaynak2005Документ8 страницUse of Split-Disk Tests For The Process Parameters-Kaynak2005houcinejОценок пока нет

- Retrofitting of Reinforced Concrete Beams Using Advanced Composite OverlaysДокумент12 страницRetrofitting of Reinforced Concrete Beams Using Advanced Composite OverlaysSudha JОценок пока нет

- 14.Stress-Strain Relationship in Axial Compression For EPS ConcreteДокумент7 страниц14.Stress-Strain Relationship in Axial Compression For EPS ConcreteManuel GutarraОценок пока нет

- Jurnal FiberglassДокумент10 страницJurnal FiberglassChristian Jovie YudhanantaОценок пока нет

- Accepted ManuscriptДокумент29 страницAccepted ManuscriptMartín KunuschОценок пока нет

- Reinforced High-Strength Concrete Beams in FlexureДокумент11 страницReinforced High-Strength Concrete Beams in FlexureAndrei IancuОценок пока нет

- Journal Experoemntala and Analaydis OdДокумент3 страницыJournal Experoemntala and Analaydis OdSaravananОценок пока нет

- Strengthening of Reinforced Concrete Columns Using FRP-Akash Krupeshkumar ChauhanДокумент6 страницStrengthening of Reinforced Concrete Columns Using FRP-Akash Krupeshkumar ChauhanAkash ChauhanОценок пока нет

- Dry Self-Lubricating Composites: Shin Jen Shiao and Te Zei WangДокумент7 страницDry Self-Lubricating Composites: Shin Jen Shiao and Te Zei WangAhda Dapong Rizqy MaulanaОценок пока нет

- Material Mass (KG/M) Portland Cement Water Fly Ash (Unclassified) 19 MM Stone (Granite) 13 MM Stone (Granite) Crusher Sand (Granite) Filler SandДокумент24 страницыMaterial Mass (KG/M) Portland Cement Water Fly Ash (Unclassified) 19 MM Stone (Granite) 13 MM Stone (Granite) Crusher Sand (Granite) Filler Sanddisha847Оценок пока нет

- Proiect ConstructiiДокумент7 страницProiect ConstructiiAsofii CosminaОценок пока нет

- Experimental Studies On Effect of Stiffener Configuration On Compressive Strength of Stiffened PanelsДокумент10 страницExperimental Studies On Effect of Stiffener Configuration On Compressive Strength of Stiffened PanelsTJPRC PublicationsОценок пока нет

- Mk4suДокумент18 страницMk4suAyman ZakariaОценок пока нет

- Damage Initiation Mechanism in Rubber Sheet Composites During The Static LoadingДокумент8 страницDamage Initiation Mechanism in Rubber Sheet Composites During The Static LoadingMa RcoОценок пока нет

- Effect of Strain Rate and Density On Dynamic Behaviour of Syntactic FoamДокумент14 страницEffect of Strain Rate and Density On Dynamic Behaviour of Syntactic Foambenyamin1982100% (1)

- IosipescuДокумент8 страницIosipescuUnoalquadratoОценок пока нет

- Study of Tensile Strength and Hardness Property For EpoxyДокумент10 страницStudy of Tensile Strength and Hardness Property For EpoxychethanapraoОценок пока нет

- Partial Replacement of Coarse Aggregates by ExpandedДокумент4 страницыPartial Replacement of Coarse Aggregates by ExpandedInternational Journal of Research in Engineering and TechnologyОценок пока нет

- Short Fiber Reinforced Composite The Effect of Fiber Length and Volume FractionДокумент10 страницShort Fiber Reinforced Composite The Effect of Fiber Length and Volume FractionMiranti AuliaОценок пока нет

- 2018 - FRC - Influence of Test Methodology On The Applicability of Test Results of Fibre Reinforced Concrete For DesignДокумент10 страниц2018 - FRC - Influence of Test Methodology On The Applicability of Test Results of Fibre Reinforced Concrete For DesignJuhász KPОценок пока нет

- Fracture Toughness of Geopolymeric Concretes Reinforced With Basalt FibersДокумент6 страницFracture Toughness of Geopolymeric Concretes Reinforced With Basalt FibersSanjeeva YedavalliОценок пока нет

- Failure Mechanism of Fibre Reinforced Concrete Under Splitting Test Using Digital Image CorrelationДокумент14 страницFailure Mechanism of Fibre Reinforced Concrete Under Splitting Test Using Digital Image CorrelationkashifОценок пока нет

- Tension Tension Axial Fatigue of E-Glass Fiber-Reinforced Polymeric Composites Fatigue Life DiagramДокумент8 страницTension Tension Axial Fatigue of E-Glass Fiber-Reinforced Polymeric Composites Fatigue Life Diagramalemteka97Оценок пока нет

- Materials: Is Fracture Toughness of PUR Foams A Material Property? A Statistical ApproachДокумент13 страницMaterials: Is Fracture Toughness of PUR Foams A Material Property? A Statistical ApproachAlsayed DiabОценок пока нет

- 2001 - Creep Crack Growth in A SGF RF PP CompositeДокумент5 страниц2001 - Creep Crack Growth in A SGF RF PP CompositeSubramani PichandiОценок пока нет

- Materials: Is Fracture Toughness of PUR Foams A Material Property? A Statistical ApproachДокумент13 страницMaterials: Is Fracture Toughness of PUR Foams A Material Property? A Statistical ApproachAlsayed DiabОценок пока нет

- The Rehabilitation of The Deficient RC Exterior Beam-Column Joints Using Cement Based CompositesДокумент8 страницThe Rehabilitation of The Deficient RC Exterior Beam-Column Joints Using Cement Based CompositesVinod RevankarОценок пока нет

- Transverse Loading of Monofilament Reinforced Rnicrocornposites: A Novel Fragmentation Technique For Measuring The Fibre Compressive StrengthДокумент6 страницTransverse Loading of Monofilament Reinforced Rnicrocornposites: A Novel Fragmentation Technique For Measuring The Fibre Compressive StrengthRosane MouraОценок пока нет

- 2018 - WTC - Design Aspect of Fibre Reinforced Shotcrete Linings Based On Experimental Test ResultsДокумент8 страниц2018 - WTC - Design Aspect of Fibre Reinforced Shotcrete Linings Based On Experimental Test ResultsJuhász KPОценок пока нет

- Repair of Earthquake-Damaged RC Columns With FRP Wraps: Aci Structural Journal Technical PaperДокумент9 страницRepair of Earthquake-Damaged RC Columns With FRP Wraps: Aci Structural Journal Technical PaperD Raul CfОценок пока нет

- Failure and Fracture of Short Flass Fibre Reinforced Nylon Composites MooreДокумент8 страницFailure and Fracture of Short Flass Fibre Reinforced Nylon Composites MooreGerardo XZОценок пока нет

- Friction and Wear of Polymer CompositesОт EverandFriction and Wear of Polymer CompositesРейтинг: 5 из 5 звезд5/5 (2)

- Support Settlement ExampleДокумент2 страницыSupport Settlement ExampleB.r. AnirudhОценок пока нет

- 2.6 Environment and Social ScienceДокумент4 страницы2.6 Environment and Social ScienceB.r. AnirudhОценок пока нет

- Example Indeterminate BeamДокумент4 страницыExample Indeterminate BeamB.r. AnirudhОценок пока нет

- MCQ On Planning and ManagementДокумент2 страницыMCQ On Planning and ManagementB.r. AnirudhОценок пока нет

- NetworksДокумент2 страницыNetworksB.r. AnirudhОценок пока нет

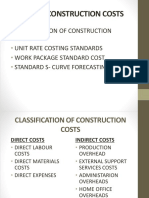

- Construction CostsДокумент4 страницыConstruction CostsB.r. AnirudhОценок пока нет

- Parametric Variations For Different ConditionsДокумент5 страницParametric Variations For Different ConditionsB.r. AnirudhОценок пока нет

- Problems in Fluid MechanicsДокумент1 страницаProblems in Fluid MechanicsB.r. AnirudhОценок пока нет

- AptitudeДокумент4 страницыAptitudeB.r. AnirudhОценок пока нет

- ABC Analysis Excel New2Документ6 страницABC Analysis Excel New2Rohit ShindeОценок пока нет

- 08 IndeterminacyДокумент10 страниц08 IndeterminacyTIBEBUОценок пока нет

- Time PeriodДокумент1 страницаTime Periodatoz2033Оценок пока нет

- FD IДокумент4 страницыFD IB.r. AnirudhОценок пока нет

- FD IДокумент4 страницыFD IB.r. AnirudhОценок пока нет

- 05ST08F Vibration Control of StructuresДокумент18 страниц05ST08F Vibration Control of StructuresB.r. AnirudhОценок пока нет

- Optimal Design of Shallow FoundationДокумент14 страницOptimal Design of Shallow FoundationB.r. AnirudhОценок пока нет

- Design and Analysis of RC Frame Buildings Subjected To EarthquakesДокумент10 страницDesign and Analysis of RC Frame Buildings Subjected To EarthquakesB.r. AnirudhОценок пока нет

- Effect of Prior Damage On The Post-Earthquake FireДокумент12 страницEffect of Prior Damage On The Post-Earthquake FireB.r. AnirudhОценок пока нет

- Vibration Analysis of Cracked BeamДокумент7 страницVibration Analysis of Cracked BeamB.r. AnirudhОценок пока нет

- Damage Detection Using PsoДокумент9 страницDamage Detection Using PsoB.r. AnirudhОценок пока нет

- Introduction To Civil EngineeringДокумент14 страницIntroduction To Civil EngineeringManish Shashikant DharekОценок пока нет

- Reliability Based Risk Assesment of Coastal StructuresДокумент18 страницReliability Based Risk Assesment of Coastal StructuresB.r. AnirudhОценок пока нет

- Robust Geotechnical DesignДокумент11 страницRobust Geotechnical DesignB.r. AnirudhОценок пока нет

- Dynamic Analysis of Kaswati Earth DamДокумент5 страницDynamic Analysis of Kaswati Earth DamB.r. AnirudhОценок пока нет

- Influence of Type of Superpalsticizers OnДокумент8 страницInfluence of Type of Superpalsticizers OnB.r. AnirudhОценок пока нет

- Static and Dynamic Analysis of Composite Laminated PlateДокумент5 страницStatic and Dynamic Analysis of Composite Laminated PlateB.r. AnirudhОценок пока нет

- Genetic Algorithm For Linear and NonlinearДокумент5 страницGenetic Algorithm For Linear and NonlinearB.r. AnirudhОценок пока нет

- Analytical Model of Reinforced Cement ConcreteДокумент13 страницAnalytical Model of Reinforced Cement ConcreteB.r. AnirudhОценок пока нет

- Femu of Ss Skewed PSC GirderДокумент12 страницFemu of Ss Skewed PSC GirderB.r. AnirudhОценок пока нет

- Thermal Decomposition of Aluminum Chloride HexahydrateДокумент8 страницThermal Decomposition of Aluminum Chloride HexahydrateМаксим Хило0% (1)

- Straub Flex 1L Coupling Data SheetДокумент1 страницаStraub Flex 1L Coupling Data SheetTrEnD SeT vicky rioОценок пока нет

- Chp.7 EnergyConversionДокумент80 страницChp.7 EnergyConversionVisuОценок пока нет

- 09 Silver 4 - M1 EdexcelДокумент13 страниц09 Silver 4 - M1 Edexcelsh.bonita.editsОценок пока нет

- 3 Loads Distribution MДокумент45 страниц3 Loads Distribution MRagheb IbrahimОценок пока нет

- Text Books: Book No. Title Author (S) Edition: ST ND THДокумент25 страницText Books: Book No. Title Author (S) Edition: ST ND THM HASIN ISHMAM JEETОценок пока нет

- Vibration Testing of Small Satellites: Part 2: Test Configuration, Fixtures, and InstrumentationДокумент12 страницVibration Testing of Small Satellites: Part 2: Test Configuration, Fixtures, and InstrumentationYoussef wagdyОценок пока нет

- Pratik Pawar Physics ProjectДокумент8 страницPratik Pawar Physics ProjectaagneysuchitaОценок пока нет

- Specific Liquid: AmmoniaДокумент29 страницSpecific Liquid: AmmoniaAljen Joseph SuzaraОценок пока нет

- Faculdade Estadual de Engenharia Química de Lorena - FAENQUILДокумент56 страницFaculdade Estadual de Engenharia Química de Lorena - FAENQUILLuis Gustavo PachecoОценок пока нет

- University BADJI MOKHTAR ANNABAДокумент6 страницUniversity BADJI MOKHTAR ANNABAmeghlaouirami5Оценок пока нет

- FactSheets EN PDFДокумент12 страницFactSheets EN PDFJom VillОценок пока нет

- AHU Vs FCU Comparison PDFДокумент5 страницAHU Vs FCU Comparison PDFamirin_kingОценок пока нет

- 20 11 10 Impedance PerovskitesДокумент57 страниц20 11 10 Impedance PerovskitesJuan BisquertОценок пока нет

- Unit 2 UV-Visible SpectrometryДокумент32 страницыUnit 2 UV-Visible SpectrometryKrishnanand NagarajanОценок пока нет

- Unit 6-Metals & Non-MetalsДокумент8 страницUnit 6-Metals & Non-MetalsRahul KumarОценок пока нет

- 2023 July Nov ME TA RevДокумент4 страницы2023 July Nov ME TA RevMd IsmayeelОценок пока нет

- Steel Drill Collars: Quality Control and Ultrasonic Inspection Precision BoringДокумент19 страницSteel Drill Collars: Quality Control and Ultrasonic Inspection Precision BoringAshba13Оценок пока нет

- Phys 410Документ3 страницыPhys 410Joram MuiruriОценок пока нет

- Fiberglass Vs Synthetic Air Filtration MediaДокумент13 страницFiberglass Vs Synthetic Air Filtration MediaSridhar VA100% (1)

- Monsoon in India Upsc Notes 58Документ3 страницыMonsoon in India Upsc Notes 58nikitasharma1431234Оценок пока нет

- Materials Science Manual Chapter 4Документ21 страницаMaterials Science Manual Chapter 4aoguОценок пока нет

- Experiment 6 Performance of Centrifugal Compressor: A. ObjectiveДокумент6 страницExperiment 6 Performance of Centrifugal Compressor: A. ObjectiveSurjit DuttaОценок пока нет

- Fatigue of RiserДокумент55 страницFatigue of RiserDao DungОценок пока нет

- LIDAR For IpipelineДокумент8 страницLIDAR For Ipipelinewiwiz2000Оценок пока нет

- 2D Resistivity Method To Investigate An Archaeological Structure in Jeniang, KedahДокумент8 страниц2D Resistivity Method To Investigate An Archaeological Structure in Jeniang, KedahHidaya MztzОценок пока нет

- James Deane Resume 2022Документ3 страницыJames Deane Resume 2022api-623113366Оценок пока нет

- Steel Plate Shear Wall Design Michel BruneauДокумент25 страницSteel Plate Shear Wall Design Michel BruneauAMAN FREDY100% (1)

- High Shrink Sleeves: Product DescriptionДокумент2 страницыHigh Shrink Sleeves: Product DescriptionCristobal Leal ArandaОценок пока нет

- Angle of Shearing ResistanceДокумент3 страницыAngle of Shearing Resistancezarakkhan masoodОценок пока нет