Академический Документы

Профессиональный Документы

Культура Документы

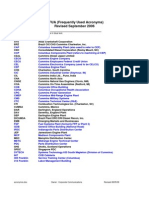

TQM 2&16 Mark With Answer

Загружено:

Jaga Deesh100%(1)100% нашли этот документ полезным (1 голос)

419 просмотров25 страницTQM 2&16 Mark with answer

Оригинальное название

TQM 2&16 Mark with answer

Авторское право

© © All Rights Reserved

Доступные форматы

DOCX, PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документTQM 2&16 Mark with answer

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате DOCX, PDF, TXT или читайте онлайн в Scribd

100%(1)100% нашли этот документ полезным (1 голос)

419 просмотров25 страницTQM 2&16 Mark With Answer

Загружено:

Jaga DeeshTQM 2&16 Mark with answer

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате DOCX, PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 25

GE2022 TOTAL QUALITY MANAGEMENT YEAR/ SEM: IV / 7

Recognised by AICTE, New Delhi. Affiliated to Anna University, Chennai

DEPARTMENT OF COMPUTER SCIENCE AND ENGINEERING

PREFACE OF THE COURSE FILE

Name of the Staff Members : Mr. Jagadeesh K.

Department of Staff : Computer Science and Engineering

Department of Student : Computer Science and Engineering

Year / Semester : IV/07

Subject Code : GE2022

Name of the Subject : TOTAL QUALITY MANAGEMENT

SYLLABUS

GE2022 TOTAL QUALITY MANAGEMENT L T P C / 3 0 0 3

UNIT I INTRODUCTION 9

Introduction - Need for quality - Evolution of quality - Definition of quality - Dimensions of manufacturing and service

quality - Basic concepts of TQM - Definition of TQM TQM Framework - Contributions of Deming, Juran and Crosby

Barriers to TQM.

UNIT II TQM PRINCIPLES 9

Leadership Strategic quality planning, Quality statements - Customer focus Customer orientation, Customer

satisfaction, Customer complaints, Customer retention - Employee involvement Motivation, Empowerment, Team and

Teamwork, Recognition and Reward, Performance appraisal - Continuous process improvement PDSA cycle, 5s,

Kaizen - Supplier partnership Partnering, Supplier selection, Supplier Rating.

UNIT III TQM TOOLS & TECHNIQUES I 9

The seven traditional tools of quality New management tools Six-sigma: Concepts, methodology, applications to

manufacturing, service sector including IT Bench marking Reason to bench mark, Bench marking process FMEA

Stages, Types.

UNIT IV TQM TOOLS & TECHNIQUES II 9

Quality circles Quality Function Deployment (QFD) Taguchi quality loss function TPM Concepts, improvement

needs Cost of Quality Performance measures.

UNIT V QUALITY SYSTEMS 9

Need for ISO 9000- ISO 9000-2000 Quality System Elements, Documentation, and Quality auditing- QS 9000 ISO

14000 Concepts, Requirements and Benefits Case studies of TQM implementation in manufacturing and service

sectors including IT.

TEXT BOOK: TOTAL: 45 PERIODS

1. Dale H.Besterfiled, et at., Total Quality Management, Pearson Education Asia, 3

rd

Edition, Indian Reprint (2006).

REFERENCES:

1. James R. Evans and William M. Lindsay, The Management and Control of Quality, 6th Edition, South-Western

(Thomson Learning), 2005.

2. Oakland, J.S., TQM Text with Cases, Butterworth Heinemann Ltd., Oxford, 3

rd

Edition, 2003.

3. Suganthi,L and Anand Samuel, Total Quality Management, Prentice Hall (India) Pvt. Ltd.,2006.

4. Janakiraman, B and Gopal, R.K, Total Quality Management Text and Cases, Prentice Hall (India) Pvt. Ltd., 2006.

GE2022 TOTAL QUALITY MANAGEMENT YEAR/ SEM: IV / 7

2 Marks with Answer

UNIT I

PART - A

1. Define quality.

Quality is defined as the degree to which a set of inherent characteristics fulfills requirements .Degree means that

quality that can be used with adjectives such as poor, good and excellent. Inherent is defined as existing in something

especially as a permanent characteristic. Characteristic can be quantitative or qualitative. Requirements is a need or

expectation that is stated, generally implied by the organization, its customers, and other interested parties. Quality fulfills

or exceeds our expectations. It is quantified as

Q = P/E

Q Quality

P Performance

E Expectations.

It is also defined as the degree of excellence a product or service provides.

According to Deming It is the predictable degree of uniformity, at low cost and suited to the market. According to

Joseph Juran Quality is fitness for use. According to Philip B. Crosby Quality is conformance to requirements.

2. What are the dimensions of Quality?

The dimensions of Quality are:

1. Performance Primary product characteristics such as the brightness of the picture.

2. Features Secondary characteristics, added features, such as remote control.

3. Conformance Meeting specifications or industry standards.

4. Reliability Consistency of performance over time, average time for the unit to fail.

5. Durability Useful life includes repair.

6. Service Resolution of problems and complaints, ease of repair.

7. Response Human to human interface, such as the courtesy of the dealer.

8. Aesthetics Sensory characteristics such as exterior finish.

9. Reputation Past performance and other intangibles, such as being ranked first.

3. Define Quality planning.

It is defined as the process of planning to design and obtain a better quality product or service and to attain new

break through goals.

4. What are the steps in Quality planning?

According to Juran the steps included in Quality planning are:

1. Establish quality goals.

2. Identify customers.

3. Discover customer needs.

4. Develop product features.

5. Develop process features.

6. Establish process controls, transfer to operations.

5. Define Quality cost.

Quality cost is defined as those costs associated with the non achievement of product or service quality as defined

by the requirements established by the organization and its contracts with customers and society. Simply stated quality

cost is the cost of poor products or services. Quality cost is equated with the cost of attaining quality, it is also equated

with the extra cost incurred due to poor quality.

6. What are the types of quality cost?

Various types of costs associated with Quality are

1. Prevention cost

2. Appraisal cost

GE2022 TOTAL QUALITY MANAGEMENT YEAR/ SEM: IV / 7

3. Internal Failure cost and

4. External Failure cost

7. What is total quality cost?

Total Quality cost is the summation of all Quality cost

Total Quality cost = [Prevention cost +Appraisal cost +Internal failure cost +External failure cost]

8. Define activity based costing.

Activity based costing can be defined as a cost calculated based on the activities involved in the manufacturing

process

9. What is trend analysis?

Trend analysis of quality cost shows the changes in cost over time period or change in cost that may occur in

future. Time to time comparison of changes in quality cost over time period can be analyzed using trend analysis method.

10. Define Pareto analysis?

Pareto chart was developed by an Italian economist namely Vilfrado pareto. The pareto chart is a specialized

version of a histogram that rank the categories in the chart from most frequent to least frequent. This chart is used to

display the pareto principle in action, arranging data so that a few vital factors are causing most of the quality problems.

This chart is used to analyze the defects that occur frequently.It is based on the 80-20 rule according to which 80% of the

problems are caused by 20% of the components and 20% of the problems are caused by 80% of the components.

11. Define TQM?

TQM is a management philosophy which seeks to integrate all organizational functions (marketing, finance,

design, engineering, and production, customer service ) to focus on meeting customer needs and organizational

objectives. It views organizations as a collection of processes. It maintains that organizations must strive to continuously

improve these processes by incorporating the knowledge and experiences of workers.

The Simple Objective of TQM

Do the right things, right the first time, every time.

Some Basic Tenets of TQM

1. The customer determines quality.

2. Improving quality requires the establishment of effective quality metrics. We must speak with data not just

opinions.

3. People working within systems create quality.

4. Quality is a moving target. It requires a commitment toward sustained continuous improvement.

5. Prevention not detection is the key to producing high quality. We must design quality into products and reduce

variability.

6. Top Management must provide leadership and support for all quality initiatives.

12. What are the Points in Demings Philosophy?

1. Create constancy of purpose for improvement of products and service.

2. Adopt a new philosophy: we are in a new economic age.

3. Cease dependence upon inspection as a way to achieve quality.

4. End the practice of awarding business based on price tag.

5. Constantly improve the process of planning, production, and service- this system includes people.

6. Institute training on the job.

7. Institute improved supervision (leadership)

8. Drive out fear.

9. Break down barriers between departments.

10. Eliminate slogans/targets asking for increased productivity without providing methods

11. Eliminate numerical quotas.

12. Remove barriers that stand between workers and their pride of workmanship.

13. Institute programs for education and retraining.

14. Put all emphasis in the company to work to accomplish the transformation.

GE2022 TOTAL QUALITY MANAGEMENT YEAR/ SEM: IV / 7

13. Define Vision Statement?

A vision is a guiding image of success formed in terms of a contribution to society. If a strategic plan is the

"blueprint" for an organization's work, then the vision is the "artist's rendering" of the achievement of that plan. It is a

description in words that conjures up a similar picture for each member of the group of the destination of the group's work

together.

A vision statement outlines what a company wants to be. It focuses on tomorrow; it is inspirational; it provides

clear decision-making criteria; and it is timeless.

14. Define Mission Statement?

A mission statement outlines what the company is now. It focuses on today; it identifies the customer(s); it

identifies the critical process(es); and it states the level of performance. It has been said that a vision is something to be

pursued, while a mission is something to be accomplished.

15. Define Quality Policy?

The overall intentions and direction of an organization regarding quality, as formally expressed by top

management.

1. Recognize that top management and all organizational units are fully committed to quality. Quality is

everyones responsibility and our future is dependent upon maintaining a position of quality leadership, focused

on Customer Satisfaction.

2. Define quality as the elimination of variation through an increase in process capability and reduction in cycle

time.

3. Adopt the defect prevention approach to quality rather than defect detection.

4. Establish a cooperative environment for teamwork and mutual problem solving among all employees.

5. Make incremental, sustained improvements in quality and productivity through ongoing training and

application in statistical techniques.

6. Involve suppliers and customers in process and unit cost optimization.

16. What are the barriers to TQM?

The main barriers to TQM are as follows:

i. Lack of understanding of the TQM concept

ii. Absence of visible support from senior & top management

iii. Fear of change

iv. Poor internal communication

v. Heavy work loads

vi. Nature of organization

vii. Lack of adequate education & training

viii. Limited resources

ix. Irregularity of the meetings

x. Delay in implementation of the recommendation

xi. Difficulties in evaluation

17. What is quality council?

A quality council is a group of top level managers established to build quality into the culture. It develops the

quality strategy and guide and support their implementations. The quality council is composed of senior managers of the

functional areas eg: design, marketing, finance, production and quality and a coordinator or consultant and a union

representative

18. What are the six basic concepts of TQM?

The six basic concepts of T.Q.M are

a. A committed and involved management

b. Focus an customer

c. Effective involvement and utilization of the entire work force

d. Continuous improvement

e. Treating supplier as partners &

f. Performance measure

GE2022 TOTAL QUALITY MANAGEMENT YEAR/ SEM: IV / 7

19. What are the benefits of TQM?

Improved product quality

Improved productivity

Reduced quality costs

Increased profitability

20. Define quality audit.

It is a systematic and independent examination to determine whether quality activities and related results comply

with planned arrangements.

UNIT - II

1. What is quality planning and strategic planning?

Quality planning is the pre-determined activities in order to achieve conformation to the requirements

Strategic planning is known as long term planning. Goals are needed for long term planning. Objectives are

needed for short term planning. The basic steps of strategic planning are.

1. Customer needs, 2. Customer positioning, 3. Predict the future, 4.Gap Analysis, 5. Closing the gaps

6.Alignment of strategic planning, 7. Implementation.

2. What is the role of senior management?

The major role of senior management is as follows:

1. MBWA (mgmt by wandering around)

2. Strategy of problem solving and decision making

3. Strong information base

4. Recognition and reward system

5. Spending most of the time on quality

6. Communication

7. Identity and encourage potential employee

8. Accept the responsibility

9. To play a role mode

10. Remove road block

3. Differentiate customer satisfaction and retention.

Satisfaction, Customers are important asset to the organization; satisfied customers will buy more, Retention, buy

more frequently, and pay their bill promptly

4. Define Employee involvement.

Employee involvement is one approach to improve quality and productivity. It is not a replacement for

management nor is it the final word in quality improvement, it aims at better meeting of organizational goals at all levels.

5. What is meant by empowerment?

Empowerment is an environment in which people have the ability, the confidence, and the commitment to take

the responsibility and ownership to improve the process and initiate the necessary steps to satisfy customer requirements

within well defined boundaries in order to achieve organizational values and goals.

6. List the Types of teams.

Process improvement teams

Cross-functional teams

Natural work teams

Self-directed/ self managed teams

7. Define 5s concept.

It simplifies your work environment, reduces waste and non-value activity while improving quality efficiency and

safety.

8. How will you measure the supplier rating?

It depends on the characteristics used to measure the performance of a particular process

i. Quantity

ii. Cost

GE2022 TOTAL QUALITY MANAGEMENT YEAR/ SEM: IV / 7

iii. Time

iv. Accuracy

v. Function

9. How will you retain the customer?

Customer retention represents the activities that produces the necessary customer satisfaction which in turn

creates the customer loyalty.

10. Advantages of continuous process.

Reduce resources Reduce errors Meet or exceed expectations of downstream customers Make the process safer

11. What is meant by performance appraisal?

The purpose of performance appraisal is to let the employees know how they are doing & provide a basis for

promotion & salary increase, counseling and other purposes relating the employees future. Employees should be aware of

the process of appraisal. The parameters of evaluation should be known to the employees. The appraisal should point out

the employees strength & weakness.

12. How the quality of costs are estimated in a firm.

The companies estimate quality costs for the following reasons : a) To quantifying the size of the quality problem

in the language of money improves communication between middle managers and upper managers. b) To identify major

opportunities for cost reduction. c) To identify the opportunities for reducing customer dissatisfaction and associated

threats to product salability.

13. How many types of customers?

There are two types of customers.

Internal customers - each of them receives a product or service and in exchange, providers a product or service.

External customers - one who uses the product or service, the one who purchase the product, or the who

influences the sale of the product.

14. Name three key elements to a partnering relationship

Three key elements to a partnering relationship

i. Long-term commitment ii. Trust iii. Shared vision

15. What are the types of sourcing?

Three types of sourcing

a) Sole sourcing b) Multiple sourcing c) Single sourcing

16. List the two conditions for the selection and evaluation of suppliers

The two conditions for the selection and evaluation of suppliers

The supplier understands and appreciates the management philosophy of the organization.

The supplier has a stable management system.

17. How to motivate work force and what meant by motivation?

Know thyself Know your employees

Establish a positive attitude Share the goals Monitor progress

Develop interesting work Communicate Celebrate success

Motivation is the creation of the desire to do something. Knowledge of motivation helps to understand the

utilization of employee involvement to achieve process improvement.

18. What are the different levels in motivation?

Abraham Maslow stated the motivation could be explained in terms of needs and that there are five levels: Level

1- survival

Level 2 security

Level 3 social

Level 4 esteem

Level 5 self actualization

19. What are the benefits of employee involvement?

1. Employees make better decision using their expert knowledge of the process.

2. Employees are more likely to implement & support decisions they had a part in making.

GE2022 TOTAL QUALITY MANAGEMENT YEAR/ SEM: IV / 7

3. Employees are better able to spot & pinpoint areas for improvement

4. Employees are better able to take immediate corrective action.

5. Employee involvement reduces labor / management friction by encouraging more effective communication &

co-operation.

6. Employee involvement increases the morale by creating a feeling of belonging to the organization.

7. Employees are better able to accept change because they control the work environment.

8. Employees have an increased commitment to unit goals because they are involved.

21. How should be the frontline employees of an organization?

The customers should not be dealt by the front line employees who do not possess adequate experience in

handling the customers. The organization should try to:

1. Hire the best

2. Develop the best employees as the best ones.

3. Motivate the professionals to stay and excel.

The frontline employees should possess a good personality .The organization should also understand that if its

employees are not happy, they will not treat the customers properly. The tendency of the customer is that he gets

frustrated even on small things. He gets infuriated if he is not given the due attention. It can not be denied that the front

line employees are able to gather a lot of information on customers

22. Narrate the steps to achieve employee satisfaction.

Know thyself

Know your employees

Establish a positive attitude

Share the goals

Monitor progress

Develop interesting work like job rotation , job enlargement and job enrichment.

Communicate effectively

Celebrate the success.

23. What is meant by Quality circle?

Quality Circle are the group of people from one work unit who voluntarily meet together on a regular basis to

identify, analyze and solve problems relating to quality and other problems in other areas. They choose their own

problems, discuss among themselves and try to arrive at a viable solution for implementation. These quality circles are

quite successful in Japan, though success of equal magnitude has not been able to be achieved in other countries.

24. What is Continuous improvement?

Continuous process improvement is the heart of TQM Process. It consists of measuring key quality parameters

and take active steps to improve them. TQM demands structured improvement programs in all these areas of business

administration, customer services, product quality and so on. The main aim of continuous process improvement is to

improve the levels of customer satisfaction and reducing the cost of attaining this. The Organization should strive to

achieve perfection and quality by continuously improving the production process and business.

25. What is 5 S Practice?

5-S (JAPANESE 5-S PRACTICE) is the key for Total Quality Environment. The 5-S Practice is a technique used

to establish and maintain quality environment in an organization.

The 5-S Stands for five Japanese words.

1. Seire (Organize)

2. Seiton (Put things in order)

3. Seiso (Clean up)

4. Seiketsu (Standarardise)

5. Shitsuke (Discipline)

GE2022 TOTAL QUALITY MANAGEMENT YEAR/ SEM: IV / 7

26. What is Seire?

SEIRE is a Japanese word which means Organize.

It is about separating the things which are necessary for the Job from those that are unnecessary and keeping the

number of necessary things as low as possible and at a convenient location. Differentiation should be made between

necessary and unnecessary things.

27. What is Seiton?

SEITON is a Japanese word which means to put things in order.

Things must be kept in order so that they are ready for use when needed. An American Mechanical Engineer

recalls that he used to spend so many hours for searching tools and parts, when he worked in U.S.A. Only after he joined

in a Japanese company, he saw how easily workers were able to find what they needed and he realized the value of Seiton

It is all about neatness. Neatness is a study of efficiency. It is a question of how quickly one can get the things needed and

how quickly one can put them away. Things should be put back where they belong.

28. What is Seiso?

SEISO is a Japanese word, which means Clean up.

Keep the workplace clean. Everyone in the organization from the managing director to the sweeper should

undertake this Job.

29. What is Seiketsu?

SEIKETSU is a Japanese word which means Standarardise.

Seiketsu means continually and repeatedly maintaining neatness and cleanliness in the organization. It claims both

personal cleanliness and the cleanliness of the environment. The emphasis is on visual management, transparency in

storage (put appropriate labels) and standardization.

30. What is Shitsuke?

Shitsuke is a Japanese word which means Discipline.

Discipline means instilling the ability of doing things the way they are supposed to be done. Discipline is a

process of repetition and practice. The emphasis in self-discipline is on creating a work force with good habits.

31. What is the logic behind 5-S Practice?

The logic behind the 5-S Practice is that organization, neatness, cleanliness, standardization and discipline at the

work place are the basic requirements for producing high quality products and services, with high productivity and no

wastage.

32. What is PDSA or Shewart Cycle?

The PDSA Cycle was first developed by Walter Shewart and then it was modified by Deming as PDCA Cycle..

PDSA stands for PLAN, DO, STUDY and ACT. Its a model used for testing ideas that may create an improvement.

It can be used to test ideas for improvement quickly and easily based on existing ideas, research, feedback, theory

audit etc or practical ideas that have been proven to work elsewhere.

It is a very effective improvement technique and it uses simple measurements to monitor the effect of changes

overtime.

It encourages starting with small changes, which can build in to larger improvements through successive quick

cycles of changes. The PDSA Cycle has been used for decades as an effective tool for continuous improvement. This

method is well established and validated and is particularly suited for small and dynamic organizations.

33. What do you mean by KAIZEN?

Kaizen is a Japanese word, which means small but continuous improvement. It means ongoing improvement

involving everyone including managers and workers.

In the Kaizen philosophy, improvement in all areas of business such as cost, meeting delivery schedules,

employee safety and skill development, supplier relations, new product development or productivity all enhances the

quality of the firm. Thus, any activity directed towards improvements falls under Kaizen Umbrella.

GE2022 TOTAL QUALITY MANAGEMENT YEAR/ SEM: IV / 7

Activities such as establishing traditional quality control systems , installing robotics and advanced technology,

instituting employee suggestion systems, maintaining equipment and implementing JIT Production systems all leads to

improvement (or) all can be reduced to one word namely KAIZEN.

34. What are the types of Quality problems ?

There are about five types of Quality problems. These problems can be classified in to

1. Compliance problem These problems arise because the existing system is not performing properly.

2. Unstructured problem - These problems arise because the existing system is not performing properly.

3. Efficiency problem - These problems arise because the existing system is not performing properly.

4. Process design problem These problem arises because of poor process design.

5. Product design problem These problem arises because of poor product design.

35. Define Capability Index

Capability Index is the ratio of tolerance to the capability. There are two measures.

One indicates the ability of process to meet the specifications.

Another indicates the centering of the process on the target.

36. Define Partnering

Partnering is a relationship between two or more parties based upon trust, dedication to common goals and

objectives and understanding of each participants expectations and values.

37. What are the benefits of Partnering?

The benefits of partnering are

Improved Quality

Increased efficiency

Lower cost

Increased opportunity for Innovation

Continuous improvement in products and services.

38. What are the approaches to be followed for continuous process improvement?

The following are the different approaches towards continuous process improvement.

Juran trilogy Juran approach on quality improvement is from cost oriented perspective.

Shewarts Plan Do Study Act (PDSA) Cycle

This approach is basically applying scientific methods for continuous improvement and quality.

5S for workplace organization to improve quality.

KAIZEN The Japanese approach to Quality improvement.

UNIT -III

1. What are the seven quality tools?

Cause-and-effect diagram ; Check sheet ; Control chart ; Histogram ; Pareto chart ; Scatter diagram; Stratification

2. What are Measures of Central Tendency? What are Measures of Dispersion?

Measures of central tendency are measures of the location of the middle or the center of a distribution. The definition of

"middle" or "center" is purposely left somewhat vague so that the term "central tendency" can refer to a wide variety of

measures. The mean is the most commonly used measure of central tendency.

3. Define Process Capability?

Process capability study is a statistical tool or technique, to assess the variation in the ability of the process during

the conversion of feed material.

It is defined as the quality performance capability of the process with given process factors and under normal, in

control condition. Based on the results of any process that are continuously measured, standard deviation is calculated by

taking the square root of its variance to calculate the indices of process capability namely CP and Cpk.

The need for process capability is to

i. Predict the extent to which the process will be able to hold tolerance or customer requirements.

ii. Choose, from among competing process, the most one for meeting the customer requirements.

iii. Redesign and implement a new process that eliminates the source of variability now at work.

GE2022 TOTAL QUALITY MANAGEMENT YEAR/ SEM: IV / 7

4. Define Mean, Median, and Mode with example?

The mean is the sum of all the scores divided by the number of scores. The formula in summation notation is: =

X/N where is the population mean and N is the number of scores.

Median: When there is an odd number of numbers, the median is simply the middle number. For example, the

median of 2, 4, and 7 is 4. When there is an even number of numbers, the median is the mean of the two middle numbers.

Thus, the median of the numbers 2, 4, 7, 12 is (4+7)/2 = 5.5.

Mode is the most frequently occurring score in a distribution and is used as a measure of central tendency. The

advantage of the mode as a measure of central tendency is that its meaning is obvious.

5. What are Key concepts of Six sigma?

Critical to quality: Attributes most important to the customer

Defect: Failing to deliver what the customer wants

Process capability: What your process can deliver

Variation: What the customer sees and feels

Design for six- sigma (DFSS): Designing to meet customer needs and process capability

6. What is Themes of Six sigma?

Themes of six sigma are as follows :

Genuine focus on the customer

Data and fact driven management

Process is where the action is

Proactive management

Boundary less collaboration

7. What are Six Sigma Methodologies?

Six Sigma methodologies are classified as two types which are improvement oriented namely DMAIC and DFSS.

DMAIC is Define Measure Analysis Improvement and Control. We use this methodology, when we have some

existing system.

DFSS is Design for Six Sigma. We use this system when the entire system is to be installed from the beginning.

8. Define six sigma problem solving method?

Define improvement opportunity with an emphasis on increasing customer satisfaction.

Measure determine process capability(cp/cpk) & dpmo(defect per million opportunities).

Analyze identify the vital few process input variable that affect key product output variable(finding the knobs)

Improve make changes to process setting, redesign process etc to reduce the number of defect of key output

variables.

Control implement process control plan, install real time process monitoring tools, standardize processes to

maintain levels.

9. What are the New Seven Management tools?

Affinity diagram ; Interrelationship digraph ; Tree diagram ; Prioritization matrix ; Matrix diagram ;

Process decision program ; Activity network diagram.

10. What is meant by FMEA?

FMEA is a systematic tool for identifying:

Effects or consequences of a potential product or process failure.

Methods to eliminate or reduce the chance of a failure occurring.

11. What are the different sampling techniques?

Simple random sampling

Cluster sampling

Stratified random sampling

Systematic sampling

GE2022 TOTAL QUALITY MANAGEMENT YEAR/ SEM: IV / 7

12. Define failure rate.

It is the probability of failure per unit of time of items in operation, sometimes estimated as a ration of the number

of failures to be accumulated operating time for the items.

13. Define benchmarking.

A benchmark is a point of reference against which other things are compared or measured.

Benchmarking is a systematic, scientific method adopted by the organization to measure its performance against

the best industry practice

14. Give the types of benchmarking.

Strategic benchmarking

Performance benchmarking

Process benchmarking

Functional benchmarking

Internal benchmarking

External benchmarking

International benchmarking

9. List the reasons to benchmark?

The essence of benchmarking is the process of borrowing ideas and adapting them to gain competitive advantage.

It is also needed to facilitate comparison with the best

It helps continuous quality improvement

10. List the steps in Benchmarking process

Planning

Analysis

Integration

Action

Maturity

11. List down the pillars of TQM.

Strategic quality planning

People and team work

Quality in daily work

Continuous improvement

12. List four stages of FMEA.

Specifying possibilities

Quantifying risk

Correcting high risk causes

Re-evaluation of risk

13. List Six Sigma implementation Levels.

Business level

Operation level

Process level

14. Give the key roles of Six Sigma .

Executive leadership

Champions

Master Black Belt

Black Belt

Green Belt

15. Benefits of Six sigma.

Improved customer satisfaction

Generates sustained success

GE2022 TOTAL QUALITY MANAGEMENT YEAR/ SEM: IV / 7

Increased productivity

Reduction in total defects

Less wastage of materials

Upto 50% process cost reduction

UNIT - IV

1. What is meant by QFD?

Quality Function Deployment is a planning tool used to fulfill customer expectations. It is a disciplined approach

to product design, engineering, and production and provides in-depth evaluation of a product

2. What are the benefits of QFD?

Customer driven

Reduces implementation time

Promote team work

Provides documentation

3. Define the quality circle.

A quality circle is a volunteer group composed of workers usually under the leadership of their supervisor, who

are trained to identify, analyze and solve work-related problems and present their solutions to management in order to

improve the performance of the organization, and motivate and enrich the work of employees

4. List the structure of quality circle

Members

Leaders

Facilitators or coordinators

Management

5. List the operations of Quality circle.

Training initial or refresher

Problem identification

Problem analysis

Preparation and recommendation for problem solution

Management presentations

Quality circle administration

6. Benefit of quality circle

Team work

Positive attitude

Personality advancement

Positive working environment

Increased productivity

7. Write about House of quality.

The primary planning tool in QFD is the House of Quality. House of Quality is a set of matrix used to translate

the voice of the customers into technical design requirement that meet specific target values and characteristics of the final

product. Because of its structure, it is referred to as the House of Quality.

8. What are the six steps to build House of Quality?

Listing customer requirement

Developing relationship matrix: between WHATs and HOWs

Competitive Assessments

Developing Prioritized customer requirement

Developing prioritized technical characteristics

9. What are the parts of house of quality?

Customer requirements

GE2022 TOTAL QUALITY MANAGEMENT YEAR/ SEM: IV / 7

Prioritized customer requirements

Technical descriptors

Prioritized technical descriptors

Relationship between requirements and descriptors

Interrelationship between technical descriptors

10. What is meant by Taguchi Quality loss function?

The costs of quality would vary with the products deviation on either side of the mean. The squared-error loss

function has been in use but Taguchi modified the function to represent total losses.

11. Give three characteristics used to define the quality loss function.

Nominalthe-Best Characteristic

Smaller-the-Better Characteristic

Larger-the-Better Characteristic

12. Use of Taguchi quality loss function.

To improve the quality

To get the market retention

13. What is TPM?

Total Productive Maintenance (TPM) is a maintenance program which involves a newly defined concept for

maintaining plants and equipment. The goal of the TPM program is to markedly increase production while, at the same

time, increasing employee morale and job satisfaction

14. What is meant by Smaller-the- Better?

Smaller-the-Better characteristic, the ideal target value is defined as zero. An example of this characteristic is

minimization of heat losses in a heat exchanger. Minimizing this characteristic as much as possible would produce a more

desirable product

15. Define nominal upper and lower boundaries

For a nominal characteristic, there is a defined target value for the product which has to be achieved. There is a

specified upper and lower limit, with the target specification being the middle point. Quality is in this case is defined in

terms of deviation from the target value. An example of this characteristic is the thickness of a windshield in a car.

16. What is TPM?

Total Productive Maintenance (TPM) is a maintenance program which involves a newly defined concept for

maintaining plants and equipment. The goal of the TPM program is to markedly increase production while, at the same

time, increasing employee morale and job satisfaction

17. What is meant by predictive maintenance and preventive maintenance?

Predictive maintenance is the process of using data and statistical tool to determine when a piece of equipment

will fail.

Preventive maintenance is the process of periodically performing activities such as lubrication on the equipment

to keep it running.

18. Name different loss measurements in TPM?

Down time losses Planned Unplanned

Reduced Speed Losses

Poor Quality Losses

19. Name is meant by Availability?

Down time losses are measured by equipment availability (A) using the equation,

Availability A=(T/P)*100

Where T= Operation time (P-D)

P=Planned operation time

D= Down time

GE2022 TOTAL QUALITY MANAGEMENT YEAR/ SEM: IV / 7

20. Define Quality cost.

Quality cost is defined as those costs associated with the non achievement of product or service quality as defined

by the requirements established by the organization and its contracts with customers and society. Simply stated quality

cost is the cost of poor products or services. Quality cost is equated with the cost of attaining quality; it is also equated

with the extra cost incurred due to poor quality.

21. What are the types of quality cost?

Various types of costs associated with Quality are

Prevention cost

Appraisal cost

Internal Failure cost and

External Failure cost

22. What is total quality cost?

Total Quality cost is the summation of all Quality cost

Total Quality cost = [Prevention cost +Appraisal cost +Internal failure cost +External failure cost]

23. Write some effects of failure.

Noise

Vibration

Erratic operation

poor performance

Lack of stability.

24. What is meant by performance efficiency?

Reduced speed losses are measured by tracking performance efficiency using the equation,

Performance efficiency E=(C*N/T)*100

Where C=Cycle time

N= Number of units produced.

25. What are the goals of TPM?

The overall goals of total productive maintenance, which is an extension of TQM are

Maintaining and improving equipment capacity

Maintaining equipment for life

Using support from all areas of the operation

Encouraging input from all employees

Using teams for continuous improvement

UNIT V

1. What are the general requirements of quality management system? (Dec, 2011)

The organization shall establish, document, implement and maintain a quality management system and

continually improve its effectiveness in accordance with the requirements of this international standard.

The organization shall:

Determine the processes needed for the quality management system and their application throughout the

organization

Determine the sequence and interaction of these processes,

Determine criteria and methods needed to ensure that both the operation and control of these processes are

effective,

Ensure the availability of resources and information necessary to support the operation and monitoring of these

processes,

Monitor, measure (where applicable), and analyse these processes, and

Implement actions necessary to achieve planned results and continual improvement of these processes.

GE2022 TOTAL QUALITY MANAGEMENT YEAR/ SEM: IV / 7

2. Draw the documentation pyramid. (Dec, 2011)

3. What are ISO 9000 quality standards?

ISO 9000 are a set of quality standards aimed at promoting the growth of international trade by facilitating

harmonious interactions between suppliers and customers located in diverse locations globally. It is a quality management

system [QMS] to ensure quality of products and services.

4. Define Quality Management Systems?

Quality management systems are the organizational structures, responsibilities, processes, procedures, and

resources used for implementing quality.

5. Give any five elements of ISO 9000.

Management responsibility,

Quality system,

Contract review,

Design control,

Document control,

Purchasing,

Purchaser supplied product,

Product identification and traceability,

Process control,

Inspection & testing

6. What are the different types of documents found in ISO 9000?

Quality Policy Manual (What? Why?)

Quality System Procedures (Who? When? Where?)

Work Instructions (How?)

Records, formats, forms (Evidence)

7. What are the eight quality principles underlying ISO 9000: 2000?

Customer focus,

Leadership,

Involvement of people,

Process approach,

System approach to management,

Continuous improvement,

Decisions based on facts, and

Mutually beneficial supplier relationships.

GE2022 TOTAL QUALITY MANAGEMENT YEAR/ SEM: IV / 7

8. Define quality system audit.

Quality system audits is a systematic, independent examination to determine whether quality activities and results

comply with planned arrangements, whether these arrangements are implemented effectively, and whether these are

suitable to achieve objectives.

9. What are the different types of audit?

First party audit (internal), Second party audit (by customer), and Third party audit (by independent agency).

Another classification: System audit, Process audit, Product audit, Adequacy audit, and Compliance audit.

10. What are the different stages in conducting quality audit?

Audit planning schedules, personnel, notifications, checklist.

Performance opening meetings, audit process, noting of non-conformities.

Reporting Observations, suggestions for corrective action

Follow-up implementation of corrective action.

11. What are the quality function needs served by the computer?

Data collection,

Data analysis and reporting,

Statistical analysis,

Process control,

Test and inspection

System design

12. What are the documentation requirements of quality management systems?

The quality management system documentation shall include

Documented statements of a quality policy and quality objectives,

A quality manual

Documented procedures and records required by this International Standard, and

Documents, including records, determined by the organization to be necessary to ensure the effective planning,

operation and control of its processes.

13. What is quality manual?

The organization shall establish and maintain a quality manual that includes

The scope of the quality management system, including details of and justification for any exclusions

The documented procedures established for the quality management system, or reference to them, and

A description of the interaction between the processes of the quality management system.

14. Explain the managements responsibility for iso.

Top management shall provide evidence of its commitment to the development and implementation of the

Quality management system and continually improving its effectiveness by

Communicating to the organization the importance of meeting customer as well as statutory and regulatory

requirements,

Establishing the quality policy,

Ensuring that quality objectives are established,

Conducting management reviews, and

Ensuring the availability of resources.

15. What is the need for ISO standards?

ISO 9000 is needed to unify the quality terms and definitions used by industrialized nations and use terms to

demonstrate a suppliers capability of controlling its processes.

16. What is third party audit? (Dec, 2010)

The third party certification audit is carried out much in the same way as first party and second party quality

system assessments and audits. However, the big difference is that an independent accredited auditing body carries out the

assessment and audit, as opposed to carrying it out by the organization themselves. Also note that the organization going

for third party audits are responsible for the payment of the third party audit process.

GE2022 TOTAL QUALITY MANAGEMENT YEAR/ SEM: IV / 7

17. Give the objectives of internal audit.

Determine the actual performance conforms to the documented qualitysystems.

Initiate corrective action activities in response to deficiencies.

Follow up on noncompliance items of previous audits.

Provide continued improvement in the system through feedback to management.

18. What is Environment Management Systems Standards?

An EMS meeting the requirements of ISO 14001:2004 is a management tool enabling an organization of any size

or type to:

Identify and control the environmental impact of its activities, products or services, and to

Improve its environmental performance continually, and to

Implement a systematic approach to setting environmental objectives and targets, to achieving these and to

demonstrating that they have been achieved.

19. What are the benefits of ISO 14001?

Facilitate trade and remove trade barriers

Improve environmental performance of planet earth

Build consensus that there is a need for environment management and a common terminology for EMS.

20. What are the requirements of ISO 14001?

General requirements

Environmental policy

Planning

Implementation and operation

Checking and corrective action

Management review

21. What are the four elements for the planning of ISO 1400?

Environmental aspects

Legal and other requirement

Objectives and targets

Environmental management programs

22. What is ISO 9000:2000?

The ISO 9000 series of standards is set of formal standards framed by technical committee ISO/TC 176 on quality

assurance and stimulated by the international organization for standardization for product and service.

ISO 9000 series consists of ISO 9000, 9001, 9004.

9000 Quality Management System fundamental and vocabulary

9001 Quality Management System Requirement

9004 - Quality Management System guidelines for performance

16 MARKS WITH KEY

UNIT I INTRODUCTION

1. Explain the Dimensions of product or Manufacturing quality. (NOV/DEC 2011)

Dimensions of quality

Quality has different dimensions. These dimensions are somewhat independent and therefore, a product can be excellent

in one dimension and average or poor in another.

Dimensions of product quality with explanation:

1. Performance 2. Features 3. Usability 4. Conformance

5. Reliability 6. Durability 7. Maintainability/Serviceability 8. Efficiency

9. Aesthetics 10. Reputation 11. Safety

2. Explain the Dimensions of service quality. (NOV/DEC 2011)

Dimensions of service quality:

1. Time 2. Timeliness 3. Completeness 4. Consistency 5. Accessibility/Convenience

6. Accuracy 7. Responsiveness 8. Courtesy 9. Competency/Expertise

GE2022 TOTAL QUALITY MANAGEMENT YEAR/ SEM: IV / 7

3. Explain the evolution of TQM.

Historical Review Of TQM Explanation

4. Write basic concepts of TQM? (NOV/DEC 2011)

Basic concepts/Principles of TQM Explanation

5. Explain the contributions of Deming to TQM. (NOV/DEC 2011)

Demings 14 points for Management Explanation

6. Explain the contributions of Juran to TQM.

Biographical

Contributions of Juran Explanation:

7. Explain the contributions of Crossby to TQM.

Biographical

Contributions of Crossby Explanation

8. Explain the TQM framework.

Basic concepts/principles of TQM:

Cause-and-effect cycle of TQM:

Stages in the evolution of quality:

Benefits of quality systems:

9. State and explain the barriers to TQM implementation in an organization. (NOV/DEC 2011)

How TQM in Implemented in Organization

List the barriers and explain

UNIT-II TQM PRINCIPLES

1. Explain the different types of Teams. (Dec 2011)

Definition

Characteristics of successful teams

Stages of team development

Barriers to team progress & Types

2. Explain all the elements in 5S principle and also the implantation procedure of 5S in a manufacturing

company. (Dec 2011)

Principle & Objectives of 5S

Factors in implementing 5s

Benefits in implementing 5s

List Types and explanation of 5S

3. Write about the system of recognition a reward followed in an organization. (Dec 2011)

Recognition

Reward

Intrinsic vs Extrinsic rewards

Steve smiths twenty different ways to recognize the employee

4. Explain leadership

Characteristics of quality leaders

Leadership roles

Role of senior management

5) Explain strategic planning

Definition

Strategic planning cycle with Diagram

6) Explain Quality statements

Vision statement:

Mission statement

Quality policy statement

7) Write short notes on: i) customer perception of quality and ii) Customer complaints (Dec 2010)

Customer Perception of Quality

Customer Complaints

o Customer feedback or customer complaint is required

o Tools used for collecting customer complaints

o Steps to solve customer complaints

GE2022 TOTAL QUALITY MANAGEMENT YEAR/ SEM: IV / 7

8) List the five levels in Maslows Hierarchy of needs and describe in detail each level.

Maslows Hierarchy of Needs:

Level 1

Level 2

Level 3

Level 4

Level 5

9) What are the characteristics of empowered employee? And also discuss the benefits of empowered environment.

List Characteristics of empowered employees and explain

10) Explain customer satisfaction model.

The customers are

Types of customers

Customer supply chain

With necessary diagram

11) Explain in detail the concept of Employee involvement.

ASPECTS OF EMPLOYEE INVOLVEMENT

1. Employee motivation, 2.Employee Empowerment, 3.Teams and Team work, 4.Recognition and Reward

Schemes, 5. Performance Appraisal

The various levels of employee involvement

Level Action Primary outcome

1. Information sharing Managers decide, then inform employees Conformance

2. Dialogue Managers get employee input, then decide Acceptance

3. Special problem

solving

Managers assign a one-time problem to selected

employees

Contribution

4. Intra-group problem

solving

Intact groups meet weekly to solve local

problems

Commitment

5. Inter-group problem

solving

Cross-functional groups meet to solve mutual

problems

Cooperation

6.Focused problem

solving

Intact groups extend daily involvement in a

specific issue

Concentration

7.Limited self-direction Team functions with minimum supervision Accountability

8. Total self-direction Executives facilitate self-management Ownership

12) Write short note on: Supplier partnership, Partnering, supplier selection, supplier rating.

Supplier partnership, Partnering

o Principles of customer / supplier relation

o Supplier partnering

o Benefits of supplier partnering

o Japanese review of partnering

supplier selection

o Supplier sourcing

o Basis of supplier selection

o Stage in supplier selection & evaluation

supplier rating

o Objectives of supplier rating

o Example supplier scorecard

o Three basic factors for successful supplier rating system

13) Explain about Performance appraisal. (NOV/DEC 2011)

Performance appraisal.

Appraisal formats

Appraisal process

BENEFITS OF PERFORMANCE APPRAISAL

14) What are the steps involved in continuous improvement process. (Dec 2011)

Definition

Input / output process model

GE2022 TOTAL QUALITY MANAGEMENT YEAR/ SEM: IV / 7

Basic ways to improve process

Juran trilogy

Juran trilogy diagram

Quality planning

Quality improvement

Steps in Continuous Improvement Strategy:

15) Explain about PDSA CYCLE

PDSA cycle diagram and explanation

Benefits of PDSA cycle

UNIT III TQM TOOLS & TECHNIQUES I

1. Explain the seven traditional tools of quality.

Pareto chart:

Flowchart:

Cause-and-Effect Diagrams

o Constructing the Cause-and-Effect Diagram:

Check Sheets

o Purpose

o Data Collection

Histograms

o Purpose

o Histograms

o Constructing a Histogram

o Conclusion

Scatter Diagrams

o Purpose

o Scatter Diagrams

o Interpreting the Results:

o Conclusion:

Control Charts

o Purpose

o Control charts

2. Explain the New management tools (NOV/DEC 2013)

Affinity diagram

Interrelations diagram

Tree diagram

Matrix diagram

Matrix data analysis

Arrow diagram

Process decision program chart (PDPC)

3. What is six sigma? Explain briefly the concept of Six Sigma. (NOV/DEC 2011)

Definition

Why do we need six sigma?

Six Sigma concepts:

Six Sigma as a Metric

Six Sigma as a Methodology

DMAIC

4. Explain about Benchmarking (NOV/DEC 2011)

Benchmarking

Advantages of benchmarking

The Benchmarking process

Types of Benchmarking

Implementation in manufacturing

GE2022 TOTAL QUALITY MANAGEMENT YEAR/ SEM: IV / 7

5. Explain the FAILURE MODE AND EFFECT ANALYSIS (FMEA).

Definition

Objectives of FEMA:

Types of FEMA:

o System FEMA

o Design FEMA

o Process FEMA

o Service FEMA

o Equipment FEMA

o Maintenance FEMA

Concept FEMA

Benefits of FEMA:

6. Explain about STAGES OF FEMA.

The FEMA methodology has four stages

Stage1: specifying possibilities

o Functions

o Possible failure modes

o Root causes

o Effects

o Detection/prevention

Stage 2: quantifying Risk

o probability of cause

o severity of effect

o effectiveness of control to prevent cause

o Risk priority number

Stage3: correcting High risk causes

o prioritizing work

o detailing action

o assigning action responsibility

o check points on completion

Stage4: re-evaluation of risk

o Recalculation of risk priority number

The design of FEMA document:

The process of FEMA and documentation

UNIT-IV TQM TOOLS & TECHNIQUES II

1. Explain about TAGUCHIS QUALITY LOSS FUNCTION. (MAY/JUNE 2009), (NOV/DEC 2011)

Genichi Taguchi's Quality Loss Function

Quality through Robust Design Methodology

Loss Function

2. Discuss Objectives of Quality Function Deployment and Highlight the benefits of QFD. (Apr /May 2010)

QFD definition and explanation

Objectives of QFD Benefits of QFD

3. Briefly explain the steps involved in QFD (NOV/DEC 2010)

Quality Function Development Process:

Phase 1: product planning

Phase 2: part development

Phase 3: process planning

Phase 4: production planning

4. Explain each section of the basic structures of house of quality. (APR/MAY 2010)

House of quality:

Basic structure of house of quality:

Develop a relationship matrix between WHATS AND HOWS

Constructing the house of quality:

GE2022 TOTAL QUALITY MANAGEMENT YEAR/ SEM: IV / 7

5. Give detailed notes about quality circle.

Definition Quality circle

Working with quality circle

Essential requirement for the success of quality circle

Objectives of quality circle process

Major benefits of quality circle

6. Explain the seven step plan to establish the TPM in an organization in detail. (NOV/DEC 2011)

UNIT-V QUALITY SYSTEMS

1. Explain the elements of ISO 9000 standards.

2. Discuss about implementation of ISO 9000

3. Explain documentation in quality standard.

4. Explain Quality Audits in detail. (Dec, 2011)

5. Explain ISO 14000 environmental standards.

6. Explain the benefits of ISO 9000.

7. Explain the benefits of EMS. (Dec, 2011)

UNIVERSITY QUESTION PAPER

November / December 2012

PART A (10 x 2 = 20)

1. List out the six basic concept of total quality management.

2. What are four absolutes of quality observed by Crosby?

3. State the importance of customer retention.

4. What is kaizen?

5. What are the benefits of bench marking?

6. Describe the evolution of six in Motorolo Company.

7. Draw the general structure of house of quality.

8. What is taguchi quality loss function?

9. List out the global benefits of adopting ISO 9000 quality System.

10. Differentiate between ISO 9000 and QS 9000.

PART B (5 x 16 = 80)

11. a. i. Elaborate the Demings philosophy over the quality and productivity improvement. (10)

(ii) Describe the barriers in the implementation of TQM. (6)

OR

b. Consider anyone service organization of your choice and explain the various dimension of quality of service.

(16)

12. a. i. explains the PDCA improvement cycle in detail. (10)

ii. Brief on employee empowerment. (6)

OR

b. What is a team? and explain the functions and characteristics of a successful team. (16)

13. a. Discuss the new seven tools in detail with their typical application. (16)

OR

b. Discuss the reason of benchmarking and state the advantage and limitations. (16)

14. a. i. What are the goals of TPM and explain the six losses in TOM? (10)

ii. Explain the components of quality costs. (6)

OR

b. Write short note on

i. QFD (8)

ii. Quality circle (4)

ii. Typical performance measures of TQM (4)

15. a. i. Discuss the elements of ISO 9000:2000 quality system. (10)

ii. What are the gams realized by a company with the TQM implementation. (6)

OR

b. What methodology would you suggest to implement TQM in an automobile manufacturing company?

(16)

GE2022 TOTAL QUALITY MANAGEMENT YEAR/ SEM: IV / 7

GE2022 TOTAL QUALITY MANAGEMENT YEAR/ SEM: IV / 7

GE2022 TOTAL QUALITY MANAGEMENT YEAR/ SEM: IV / 7

MAY / JUNE 2012

PART A (10 x 2 = 20)

1. What are the various factors which constitutes the framework of TQM?

2. Define the tools required to implement kaizen in a manufacturing system.

3. How are customer needs and requirement documented

4. What are the benefits of 5s?

5. What are all thedenefits of TPM?

6. What are all the problems involved in benchmarking a direct completion?

7. What does DMAIC convey in 6sigma?

8. What is meant by house of quality?

9. Define the term quality loss function

10. List out the main elements of ISO 14000.

PART B (5 x 16 = 80)

11.a. Discuss jurans principle of quality improvements. (16)

OR

b. Explain demings 14 philosophy for quality improvement (16)

12.a.i. Give an example of win win strategy and win loss strategy in day to day life

ii. Design a customer satisfaction questionnaire to evaluate the level of customer satisfaction in the following industries

1. A mobile service provider

2. A sports shoe manufacturer

OR

b.i. Discuss how quality council is structured in

1. University academic department

2. Manufacturing facility

ii. Distinguish between external and internal customers

13. a. i. Perform a FMEA to anticipate various problems faced and methods to eliminate the proves of getting up from bed

in morning and going to school.

ii. Describe how simultaneous or concurrent design is better over sequential design in quarantying quality ti the end users

OR

b. i. With an example illustrate how benchmarking can help a system to improve both efficiency and effectiveness of a

system.

ii. With example explain the concept of six sigma

14. a. Device a QFD methodology for design and development of cups used in vending machine for dispersing hot and

cold beverages

OR

b. i. Discuss the benefits of QFD (8)

ii. For an out of round condition (smaller the better) of a steel shaft, the true indicator readings for eight shafts are 0.05,

0.04, 0.04, 0.03, 0.04, 0.02, 0.04 and 0.03 mm (8)

1. If average loss at 0.03 is Rs 15, what is the loss function

2. What is the loss at 0.05

3. What is the average quality cost.

15. a. i. Discuss the need of standardized procedure for quality assurance, explain the requirement of ISO

documentation (10)

ii. Explain the term quality cost. (6)

OR

b. i. Differentiate between external and internal audits on quality (6)

ii. Differentiate between ISO 9000 and QS 14000. List the benefits that a firm would enjoy by implementing this series of

quality documentation procedures (10)

Вам также может понравиться

- 2008 Treasure Chest of Six Sigma - Tools and Best Practs PDFДокумент1 015 страниц2008 Treasure Chest of Six Sigma - Tools and Best Practs PDFGilmarBos100% (1)

- Process Improvement Acronym DecoderДокумент2 страницыProcess Improvement Acronym Decoderpremsagar_bОценок пока нет

- 1 Introduction To Statistical Quality Control, 6 Edition by Douglas C. MontgomeryДокумент66 страниц1 Introduction To Statistical Quality Control, 6 Edition by Douglas C. MontgomeryAmiluddin AmilОценок пока нет

- SynthesisДокумент38 страницSynthesisDevina Gomez Toripil100% (1)

- Strategy Execution WorkshopДокумент3 страницыStrategy Execution WorkshopAnupam NairОценок пока нет

- Chapter 5 - QualityДокумент81 страницаChapter 5 - QualityThư Trần Nguyễn AnhОценок пока нет

- Chapter - 6 Quality Management and Control: Ataklty Adugna (Ass. Professor)Документ49 страницChapter - 6 Quality Management and Control: Ataklty Adugna (Ass. Professor)yared haftuОценок пока нет

- Online Education Portal Project: Uality Anagement LANДокумент10 страницOnline Education Portal Project: Uality Anagement LANHehe HoОценок пока нет

- Balanced Score CardДокумент19 страницBalanced Score CardAamirx64Оценок пока нет

- MBA S3 Syllabus - OprationsДокумент54 страницыMBA S3 Syllabus - Oprationsmrkidman2008Оценок пока нет

- Total Quality ManagementДокумент97 страницTotal Quality ManagementRodiemerОценок пока нет

- Project Quality ManagementДокумент53 страницыProject Quality ManagementEnsha AnwashОценок пока нет

- Philosophies of Quality Gurus 2019Документ64 страницыPhilosophies of Quality Gurus 2019Neesha NazОценок пока нет

- Quality Management - Course Outline - 91-92 PDFДокумент5 страницQuality Management - Course Outline - 91-92 PDFtohidi_mahboobeh_223Оценок пока нет

- GSOE9810 Exam NotesДокумент8 страницGSOE9810 Exam NotesSaika DhakaОценок пока нет

- What Is TQM?Документ43 страницыWhat Is TQM?nimra100% (1)

- ApplyingTRIZ at CompanyДокумент45 страницApplyingTRIZ at Companymancheung6429Оценок пока нет

- Total Quality Management: D. Ali Jibreen Presented By: Zein AlabbadiДокумент15 страницTotal Quality Management: D. Ali Jibreen Presented By: Zein AlabbadiaymanОценок пока нет

- Sixsigma UltimateДокумент271 страницаSixsigma UltimateCosmetic ClinicОценок пока нет

- Dmaic Six SigmaДокумент2 страницыDmaic Six SigmaSagarias Albus100% (2)

- P-Dmaic Roadmap r2 From SSIДокумент1 страницаP-Dmaic Roadmap r2 From SSIShiva KumarОценок пока нет

- TQM 2 and 16 Marks PDFДокумент127 страницTQM 2 and 16 Marks PDFanand_duraiswamyОценок пока нет

- Chapter 9Документ33 страницыChapter 9Denise BaterinaОценок пока нет

- OpMan-Chapter 6 - QualityДокумент57 страницOpMan-Chapter 6 - QualityTrina Mae RodriguezОценок пока нет

- Mbn603 Quality ManagementДокумент6 страницMbn603 Quality ManagementVignesh SankarОценок пока нет

- Production Operation ManagemenT (ALL 5 UNITS)Документ134 страницыProduction Operation ManagemenT (ALL 5 UNITS)Archi VarshneyОценок пока нет

- Value Creation Strategies: Quality Concepts and ToolsДокумент87 страницValue Creation Strategies: Quality Concepts and ToolsAjay PadhiОценок пока нет

- Lecture 1. TQM Evolution NewДокумент56 страницLecture 1. TQM Evolution NewAimee Berba100% (1)

- Strategic Quality PlanningДокумент68 страницStrategic Quality PlanningZiza Yusup100% (1)

- TQM Principles and ConceptДокумент19 страницTQM Principles and ConceptRenaliz GonzalesОценок пока нет

- Definition of Total Quality Management (TQM)Документ6 страницDefinition of Total Quality Management (TQM)Tamizha Tamizha100% (1)

- Productivity and Reliability-Based Maintenance Management, Second EditionОт EverandProductivity and Reliability-Based Maintenance Management, Second EditionОценок пока нет

- GE2022 TQM Question BankДокумент21 страницаGE2022 TQM Question BankVadivel AeroОценок пока нет

- Rajalakshmi Engineering College, Thandalam, Chennai - 602 105 Department of Mechanical EngineeringДокумент3 страницыRajalakshmi Engineering College, Thandalam, Chennai - 602 105 Department of Mechanical EngineeringvsanthanamОценок пока нет

- Lesson Plan ESДокумент5 страницLesson Plan ESsureshvkumarОценок пока нет

- Chapter TwoДокумент28 страницChapter TwoAlfiya DemozeОценок пока нет

- MBA IInd SEM POM Chapter 04 Quality ManagementДокумент62 страницыMBA IInd SEM POM Chapter 04 Quality ManagementPravie100% (5)

- Speaker: Dr. Nay Zin Latt Chairman: Business Group Hotel GroupДокумент32 страницыSpeaker: Dr. Nay Zin Latt Chairman: Business Group Hotel GroupThe Vimokkha Online JournalОценок пока нет

- Total Quality Management (TQM)Документ35 страницTotal Quality Management (TQM)cyndrellaОценок пока нет

- Total Quality Management: M. Ali HassanДокумент12 страницTotal Quality Management: M. Ali Hassanapi-27544491Оценок пока нет

- Chapter 2 SCMДокумент15 страницChapter 2 SCMShazli ArshadОценок пока нет

- GE8077 TQM UNIT V NotesДокумент14 страницGE8077 TQM UNIT V NotesdineshbabuОценок пока нет

- ISO-TS 16949 AwarenessДокумент117 страницISO-TS 16949 AwarenessRavikumar PatilОценок пока нет

- Crosby 14 StepsДокумент1 страницаCrosby 14 StepsDharshan KofiОценок пока нет

- Log in Sign Up Browse: Answers To The Questions in Question Paper From MBA in TQMДокумент6 страницLog in Sign Up Browse: Answers To The Questions in Question Paper From MBA in TQMthakur_neha20_903303Оценок пока нет

- Quality AwardsДокумент28 страницQuality Awardsrmanojbabu100% (1)

- System Process: CMMI, ISOДокумент23 страницыSystem Process: CMMI, ISObdiitОценок пока нет

- Midterm Exam: Deadline: December 04, 2021Документ13 страницMidterm Exam: Deadline: December 04, 2021Jannatul FerdaousОценок пока нет

- Quality Management Autumn 2005: Lectures ppt-1Документ44 страницыQuality Management Autumn 2005: Lectures ppt-1Jackson ..Оценок пока нет

- Juran'S Trilogy-Planning, Control, ImprovementДокумент18 страницJuran'S Trilogy-Planning, Control, ImprovementJoannah RiveraОценок пока нет

- A Comparison of ISO 9000-2000 Quality System Standards, QS9000, IsO:TS 16949 and Baldrige CriteriaДокумент10 страницA Comparison of ISO 9000-2000 Quality System Standards, QS9000, IsO:TS 16949 and Baldrige CriteriaAfifОценок пока нет

- Cbme 1 TQMДокумент62 страницыCbme 1 TQMEdrymae Tobias100% (1)

- Cause-And-Effect Diagram: Why Implement Cost of Quality (COQ) ?Документ3 страницыCause-And-Effect Diagram: Why Implement Cost of Quality (COQ) ?Doren Joy BatucanОценок пока нет

- PNACY483Документ97 страницPNACY483Ahmed SukkerОценок пока нет

- Job EnlargementДокумент1 страницаJob EnlargementTirusameer YarlagaddaОценок пока нет

- Lesson 26-27-28 Quality ManagementДокумент7 страницLesson 26-27-28 Quality ManagementChaqib SultanОценок пока нет

- Factors, Measures, and Problems of Quality Costs Program Implementation in The Manufacturing EnvironmentДокумент6 страницFactors, Measures, and Problems of Quality Costs Program Implementation in The Manufacturing EnvironmentFahad IzharОценок пока нет

- What Is QualityДокумент18 страницWhat Is QualityMehroz KhanОценок пока нет

- Choosing Brand Elements To Build Brand EquityДокумент14 страницChoosing Brand Elements To Build Brand Equitypawanshrestha1100% (1)

- Presentations Part 1Документ109 страницPresentations Part 1rahuldesai1189Оценок пока нет

- Group 1 - PCM 804 SSCMДокумент20 страницGroup 1 - PCM 804 SSCMPhilcas LiОценок пока нет

- Quality Management Gurus TheoriesДокумент6 страницQuality Management Gurus TheoriesSyafiqah RedzwanОценок пока нет

- The Management and Control of QualityДокумент44 страницыThe Management and Control of QualitylalaОценок пока нет

- Statistical Quality Control: Chapter ThirteenДокумент23 страницыStatistical Quality Control: Chapter ThirteendewimachfudОценок пока нет

- Crosby's Concept of Cost of QualityДокумент7 страницCrosby's Concept of Cost of QualityRana Muhammad Arif KhanОценок пока нет

- Quality Management System Process A Complete Guide - 2020 EditionОт EverandQuality Management System Process A Complete Guide - 2020 EditionОценок пока нет

- TQM Question Bank Final 1Документ36 страницTQM Question Bank Final 1menakadevieceОценок пока нет

- Unit 1&2Документ34 страницыUnit 1&2AbinayaОценок пока нет

- Criterion 7: Continuous ImprovementДокумент2 страницыCriterion 7: Continuous ImprovementJaga DeeshОценок пока нет

- Model Exam - 1 Cs6303 CA - 19.02.18 Answer KeyДокумент8 страницModel Exam - 1 Cs6303 CA - 19.02.18 Answer KeyJaga DeeshОценок пока нет

- Model Exam - 1 Cs6303 CA - 19.02.18 Answer KeyДокумент8 страницModel Exam - 1 Cs6303 CA - 19.02.18 Answer KeyJaga DeeshОценок пока нет

- Vijay ResumeДокумент2 страницыVijay ResumeJaga DeeshОценок пока нет

- Part - AДокумент1 страницаPart - AJaga DeeshОценок пока нет

- Cs2312 ObjectДокумент2 страницыCs2312 ObjectJaga DeeshОценок пока нет

- Six SigmaДокумент2 страницыSix Sigma123qwerty00Оценок пока нет

- KJISPaper SPI CMMIДокумент12 страницKJISPaper SPI CMMIYonatan AimerОценок пока нет

- Critical To Quality in Telemedicine - A Case StudyДокумент6 страницCritical To Quality in Telemedicine - A Case StudydrustagiОценок пока нет

- Chapter 7: Design For Quality and Product ExcellenceДокумент15 страницChapter 7: Design For Quality and Product Excellence132345usdfghj100% (1)

- GE Six SigmaДокумент6 страницGE Six Sigmaimran27pk100% (2)

- International Journal of Business and Management Invention (IJBMI)Документ5 страницInternational Journal of Business and Management Invention (IJBMI)inventionjournalsОценок пока нет

- Six SigmaДокумент9 страницSix SigmaAnjana AshokkumarОценок пока нет

- DFSS SciPyДокумент7 страницDFSS SciPyGoran ChristianssonОценок пока нет

- 1 Statistical Quality Control, 7th Edition by Douglas C. MontgomeryДокумент69 страниц1 Statistical Quality Control, 7th Edition by Douglas C. Montgomerynawaf alshaikhОценок пока нет

- Acronym NsДокумент8 страницAcronym Nsacere18Оценок пока нет

- Six SigmaДокумент18 страницSix SigmarajeeevaОценок пока нет

- Six Sigma Master Black Belt - ISI MBB 2223 02 Part-A: Descriptive Questions 5 Questions Each Carrying 10 MarksДокумент4 страницыSix Sigma Master Black Belt - ISI MBB 2223 02 Part-A: Descriptive Questions 5 Questions Each Carrying 10 MarksSanjoy sharmaОценок пока нет

- Six Sigma TutorialsДокумент24 страницыSix Sigma Tutorialssatyamech1_395565923Оценок пока нет

- 6 SigmaДокумент13 страниц6 SigmaThee BouyyОценок пока нет

- Philips Healthcare (Suzhou) Co., LTDДокумент4 страницыPhilips Healthcare (Suzhou) Co., LTDAli R.MОценок пока нет

- Design of 6 Sigma in MatlabДокумент18 страницDesign of 6 Sigma in MatlabrealpaladinОценок пока нет

- 13 - SCM - Jit - Lean - Adl - 2020-RecordedДокумент56 страниц13 - SCM - Jit - Lean - Adl - 2020-RecordedJoe RobsonОценок пока нет

- Improve An Engine Cooling Fan Using Design For Six Sigma Techniques PDFДокумент7 страницImprove An Engine Cooling Fan Using Design For Six Sigma Techniques PDFGUESSOUMAОценок пока нет

- 10 TFT-LCD - Contrast - Ratio - Improvement - by - Using - Design - For - Six - Sigma - DisciplinesДокумент12 страниц10 TFT-LCD - Contrast - Ratio - Improvement - by - Using - Design - For - Six - Sigma - DisciplinesOsvaldoRJRОценок пока нет

- GB 01 Pre-Define 0721Документ76 страницGB 01 Pre-Define 0721Suhel suhel khanОценок пока нет

- ETM5943 Assignment5 ImplPlanДокумент3 страницыETM5943 Assignment5 ImplPlankbobhateОценок пока нет