Академический Документы

Профессиональный Документы

Культура Документы

Valerie Waldon

Загружено:

ycwbycwb0 оценок0% нашли этот документ полезным (0 голосов)

69 просмотров20 страницValimet is a manufacturer of spherical Metal Powders (aluminum and Aluminum alloys, others) by gas atomization. Valimet's Cold Spray Powders are used in rocket propellant thermal sprays, EM shielding, photovoltaics, refractories for Steel Industry. What is the best PSD for cold spray applications?

Исходное описание:

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документValimet is a manufacturer of spherical Metal Powders (aluminum and Aluminum alloys, others) by gas atomization. Valimet's Cold Spray Powders are used in rocket propellant thermal sprays, EM shielding, photovoltaics, refractories for Steel Industry. What is the best PSD for cold spray applications?

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

69 просмотров20 страницValerie Waldon

Загружено:

ycwbycwbValimet is a manufacturer of spherical Metal Powders (aluminum and Aluminum alloys, others) by gas atomization. Valimet's Cold Spray Powders are used in rocket propellant thermal sprays, EM shielding, photovoltaics, refractories for Steel Industry. What is the best PSD for cold spray applications?

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 20

Cold Spray Action Team

Worcester Polytechnic Institute

May 17-18, 2011

Presented by Valerie Waldon

Sales Manager, Valimet, Inc.

Introduction to Valimet

Defining Aluminum Base Cold Spray Powders

Valimets Experience in Supplying Cold Spray

P d Powders

Valimets Production Technology

Understanding Relationship between Understanding Relationship between

Atomization/Size Specification/Yield/

Sizing/Alloy Type/Cost Sizing/Alloy Type/Cost

Conclusions

Manufacturer of Spherical Metal Powders (Aluminum

and Aluminum Alloys, others) by Gas Atomization

O i S k C lif i i i 1960 Operating at Stockton, California, site since 1960s

Major Applications for Powders:

Rocket Propellant

Thermal Sprays

Packed Bed Diffusion Coatings

Heat Management for Micro-Processors

EM Shielding

Automotive Pigments

Photovoltaics Photovoltaics

Refractories for Steel Industry

Aluminum Metal Matrix Composites

Size Specifications

Morphology

What PSD

Specifications can Specifications can

be used for Cold

Spray?

What is the best

PSD for Cold Spray

Applications?

Valimet H-15 Aluminum

Applications?

Physical Physical Characteristics of Characteristics of Valimet Valimet yy

Spherical Spherical Aluminum Aluminum Powders Powders

Specification

H-2 H-3 H-5 H-10 H-12 H-15 H-30 H-50 H-60 H-95

Microtrac Analysis:

90 % 7.5 10.5 15.0 26.0 30.0 40.0 58.0 92.0 112.0 160.0

50 % 3.5 4.5 8.0 12.0 15.0 20.0 31.0 59.0 71.0 108.0

10 % 1 8 2 0 4 0 6 0 6 5 9 0 15 0 38 0 44 0 73 0

Typical Particle Size Distributions of Typical Particle Size Distributions of

10 % 1.8 2.0 4.0 6.0 6.5 9.0 15.0 38.0 44.0 73.0

yp yp

Standard Valimet Powders Standard Valimet Powders

Powder Type Particle Size/Specification

CP Aluminum (99.8%) H-10, H-12, H-15,

H 20 H 30 H-20, H-30

High Purity Aluminum

(99.95%)

-20 um, 9-40 um

Aluminum Silicon S 8 S 10 S 15 S 20 Aluminum Silicon

(AA 4047)

S-8, S-10, S-15, S-20

Alloy 6061 -270 mesh, -325 mesh,

270mesh/+15 um 270mesh/+15 um,

-44/10 microns, -30 um

Alloy 7075, 7090, 7005 -325 mesh, -200 mesh

Alloy 5083 5356 325 mesh Alloy 5083, 5356 -325 mesh

Alloy 356, 390 -325 mesh, -200 mesh

Alloy Al/Zn/XXX -325 mesh

Valimet produces powder by inert gas atomization, which

produces powder with a spherical shape produces powder with a spherical shape

SEM image of Spherical Powder

Inert atomization nozzle

Spinning Cup/Disk

Results in Coarser Particle Size

Ultrasonic Atomization

Not practiced by Valimet

Valimets atomization process creates a

distribution of particle sizes

Changes in process can move the center of

the distribution, but not the width

Results in a low yield of useable product

Results in a higher yield of useable product

Cold Spray powder sizing cannot be achieved by

traditional screens

Centrifugal classification leads to further losses

Starting Particle Size Distribution

Step 1: Remove Oversize Material

Step 2: Remove Undersize Material

Markets exist for Aluminum Powder and Al/Si Markets exist for Aluminum Powder and Al/Si

Powder outside of Cold Spray Requirements

No current market for most other off-size

Al i All d Aluminum Alloy powders

Size Specification and Yield greatly impact price

Price of Cold Spray Powder must reflect all Price of Cold Spray Powder must reflect all

manufacturing costs (Raw Material, Atomization,

Sizing, etc.)

Type of Powder

Aluminum-Aluminum Silicon Other Alloys (6061 etc )

Type of Powder

Aluminum-Aluminum Silicon

Common Production

Other Alloys (6061, etc.)

Special Production

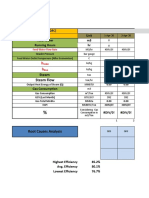

Size Specification Results in

20% Yield of Cold Spray

P d

100% Cost of Aluminum

metal per pound

500% of Alloy Ingot Cost per

pound

Powder

Atomization costs distributed

to other products

All atomizing and sizing

costs assigned to Cold Spray

Powder

Sizing costs distributed to

other products

Possible disposal costs with

off-size Cold Spray powder

Size Specification Results in

60% Yield of Cold Spray

100% Cost of Aluminum

metal per pound

167% of Alloy Ingot Cost per

pound 60% Yield of Cold Spray

Powder

metal per pound pound

Atomization costs distributed

to other products

All atomizing and sizing

costs assigned to Cold Spray

Powder Powder

Sizing costs may be

distributed to other products

Possible disposal costs with

off-size Cold Spray powder

Cold Spray Powders can be produced by gas

atomization and proper sizing

The narrower the size specification the lower the The narrower the size specification, the lower the

yield of powder in specification and higher the

cost/price

To realize viable cost it is important to use the To realize viable cost, it is important to use the

broadest size range compatible with Cold Spray

operations

Alloy Cold Spray Powder has additional technical/cost Alloy Cold Spray Powder has additional technical/cost

problems (no market for off-size powder)

Impact of yield (size specification) greater for Alloy

Cold Spray Powders Cold Spray Powders

Alternative production technology may produce

higher yield, but less cost effective

Вам также может понравиться

- Iron Powder ManufacturerДокумент24 страницыIron Powder ManufacturerniloblueОценок пока нет

- Modelling a Focke-Wulf Fw 190A-8/R8: In 1/32 scaleОт EverandModelling a Focke-Wulf Fw 190A-8/R8: In 1/32 scaleРейтинг: 5 из 5 звезд5/5 (1)

- Aluminum Powder Metallurgy ProcessingДокумент161 страницаAluminum Powder Metallurgy ProcessingMustafa Levent SipahiОценок пока нет

- Aluminium CompaniesДокумент4 страницыAluminium CompaniesHumayun KhanОценок пока нет

- Peoples Steel Mills LTDДокумент19 страницPeoples Steel Mills LTDalmasОценок пока нет

- Steel ExclusionsДокумент16 страницSteel Exclusionsanitah1234Оценок пока нет

- Agarvanshi Aluminium LTDДокумент60 страницAgarvanshi Aluminium LTDSaurabh KumarОценок пока нет

- Essential Rubber Formulary: Formulas for PractitionersОт EverandEssential Rubber Formulary: Formulas for PractitionersРейтинг: 3 из 5 звезд3/5 (1)

- CF8M ValvesДокумент4 страницыCF8M ValvesPranav PrashantОценок пока нет

- Products: Ventilation Air Conditioning Refrigeration HeatingДокумент16 страницProducts: Ventilation Air Conditioning Refrigeration HeatingzainulmarengОценок пока нет

- Attieh Brochure (Small FS)Документ20 страницAttieh Brochure (Small FS)Ismail Sabri50% (2)

- Reduced Iron Powders Atomized Iron and Steel PowdersДокумент24 страницыReduced Iron Powders Atomized Iron and Steel PowdersTien-HitechDangОценок пока нет

- 6005 Aluminum Sheet SuppliersДокумент15 страниц6005 Aluminum Sheet Supplierssanghvi overseas incОценок пока нет

- Pg.34 Soon Lian Aluminium Alloy ProductsДокумент88 страницPg.34 Soon Lian Aluminium Alloy ProductsKelvin XuОценок пока нет

- 1484 V0qusf PL Impexmetal Katalog en 09-WwwДокумент32 страницы1484 V0qusf PL Impexmetal Katalog en 09-Wwwmuamer1Оценок пока нет

- Yamaha CF EngДокумент8 страницYamaha CF EngNguyen Trong TanОценок пока нет

- Public Media PDF PDF BALLДокумент64 страницыPublic Media PDF PDF BALLCarlos LópezОценок пока нет

- OneSteel Valve Product CatalogueДокумент40 страницOneSteel Valve Product CatalogueEr Pupone de Naza100% (1)

- QPS Brochure G CompressedДокумент20 страницQPS Brochure G CompressedsaidshooОценок пока нет

- 625 Alloy PowderДокумент3 страницы625 Alloy PowderSuperalloys GaoОценок пока нет

- Slabbrochure Baosteel PDFДокумент36 страницSlabbrochure Baosteel PDFKetnipha SukwannawitОценок пока нет

- QCS001 OutputДокумент661 страницаQCS001 OutputPrabha KaranОценок пока нет

- Bluescope Sheet Coil Product Guide Nov 20101Документ54 страницыBluescope Sheet Coil Product Guide Nov 20101vijay_paliwal9903Оценок пока нет

- Aluminium Casting For Container Corner FittingsДокумент3 страницыAluminium Casting For Container Corner FittingsUsman DoltanaОценок пока нет

- Sumitomo Products For The Oil and Gas IndustriesДокумент36 страницSumitomo Products For The Oil and Gas IndustriesRahulprabhakaran Vannostran100% (1)

- 3coated SteelДокумент20 страниц3coated Steelalifakash1605Оценок пока нет

- Nextgen Steel Alloys 160527100216 PDFДокумент25 страницNextgen Steel Alloys 160527100216 PDFVysakh VasudevanОценок пока нет

- General Information Theory - LindabДокумент27 страницGeneral Information Theory - LindabaudithanОценок пока нет

- PROFILEДокумент2 страницыPROFILEnarpat kumarОценок пока нет

- Brochure PSMДокумент19 страницBrochure PSMsirajuddin khowajaОценок пока нет

- Fischer Price List 2014 v1 (Email)Документ96 страницFischer Price List 2014 v1 (Email)ElfiraTaufidaОценок пока нет

- Usha Martin Alloys&Steel Division JSRДокумент3 страницыUsha Martin Alloys&Steel Division JSRpiyushboseОценок пока нет

- Minimization of Defect in Aluminium Alloy Wheel Casting Using 7 QC ToolsДокумент4 страницыMinimization of Defect in Aluminium Alloy Wheel Casting Using 7 QC ToolsijaertОценок пока нет

- Shanghai Metal CorporationДокумент5 страницShanghai Metal CorporationLivingstone CaesarОценок пока нет

- Crown-Fusion Brochure Flanged Floaters 2 CompressedДокумент14 страницCrown-Fusion Brochure Flanged Floaters 2 Compressedclaudio godinezОценок пока нет

- Crown-Fusion Brochure Flanged Floaters 2Документ14 страницCrown-Fusion Brochure Flanged Floaters 2claudio godinezОценок пока нет

- Alloy and MicrostructureДокумент4 страницыAlloy and MicrostructureNico Agung NugrahaОценок пока нет

- Alumec PDFДокумент7 страницAlumec PDFetamil87Оценок пока нет

- Steel Rebar Industry ProfileДокумент34 страницыSteel Rebar Industry Profileocean blueОценок пока нет

- Trimet Wire Catalog 2016Документ67 страницTrimet Wire Catalog 2016Akaruii BowoОценок пока нет

- AluminumДокумент7 страницAluminumjagadish.kvОценок пока нет

- Steelstrong: Always Strong in Valve WorldДокумент32 страницыSteelstrong: Always Strong in Valve WorldBharat Bhushan SharmaОценок пока нет

- Shurjoint 2011 CatalogДокумент163 страницыShurjoint 2011 CatalogabdulzameerОценок пока нет

- V410065 en US FactSheet Main 01Документ1 страницаV410065 en US FactSheet Main 01Janeth MendozaОценок пока нет

- Grilles and Diffusers CatalogueДокумент15 страницGrilles and Diffusers CataloguestarykОценок пока нет

- Piston ManufacturingДокумент41 страницаPiston ManufacturingDima AlinОценок пока нет

- Catalogue - SteelДокумент23 страницыCatalogue - SteelBinh Hung OngОценок пока нет

- Cosmos Alminium-Technical SpecificationsДокумент2 страницыCosmos Alminium-Technical SpecificationsmindsopenОценок пока нет

- AluminumДокумент5 страницAluminumBlueOneGaussОценок пока нет

- Shurjoint Geral 2015 English v3 ImpДокумент218 страницShurjoint Geral 2015 English v3 ImpBárbara VoltarelliОценок пока нет

- Crucibles Catalogue 01Документ12 страницCrucibles Catalogue 01nfcastingsОценок пока нет

- 2010 Alumec Brochure English New CoverДокумент8 страниц2010 Alumec Brochure English New CoverMohammed KhatibОценок пока нет

- Fabrication and ApplicationДокумент8 страницFabrication and Application000Оценок пока нет

- PTM Three and Three CatalogueДокумент31 страницаPTM Three and Three CatalogueSalvatore ShwОценок пока нет

- Recent Findings and Developments in Chromium Plated Gun TubesДокумент29 страницRecent Findings and Developments in Chromium Plated Gun TubesycwbycwbОценок пока нет

- Additive Material Repairs: The Changing Nature of SustainmentДокумент28 страницAdditive Material Repairs: The Changing Nature of SustainmentycwbycwbОценок пока нет

- A Systems Engineering Modeling and Simulation Approach For Rotorcraft Drive System OptimizationДокумент12 страницA Systems Engineering Modeling and Simulation Approach For Rotorcraft Drive System OptimizationycwbycwbОценок пока нет

- 3di Workshop Presentations Public ReleaseДокумент177 страниц3di Workshop Presentations Public ReleaseycwbycwbОценок пока нет

- Erosion of A Chromium-Plated Tank Gun Barrel PDFДокумент16 страницErosion of A Chromium-Plated Tank Gun Barrel PDFycwbycwbОценок пока нет

- Additive Manufacturing For Defense and Government (CTC)Документ36 страницAdditive Manufacturing For Defense and Government (CTC)ycwbycwbОценок пока нет

- Advanced Oilfield Metals - Better Outcomes PDFДокумент19 страницAdvanced Oilfield Metals - Better Outcomes PDFycwbycwbОценок пока нет

- Study of Materials Test Methods For Wear Resistance in Oil and Mining IndustryДокумент2 страницыStudy of Materials Test Methods For Wear Resistance in Oil and Mining IndustryycwbycwbОценок пока нет

- Use of Electroplated Chromium in Gun BarrelsДокумент41 страницаUse of Electroplated Chromium in Gun BarrelsycwbycwbОценок пока нет

- State-Of-The-Art Survey On Hot Corrosion in Marine Gas Turbine EnginesДокумент11 страницState-Of-The-Art Survey On Hot Corrosion in Marine Gas Turbine EnginesycwbycwbОценок пока нет

- Study of Materials Test Methods For Wear Resistance in Oil and Mining Industry PDFДокумент11 страницStudy of Materials Test Methods For Wear Resistance in Oil and Mining Industry PDFycwbycwbОценок пока нет

- Rev.I 112014 HTK Ultra Strip 100 EnglДокумент1 страницаRev.I 112014 HTK Ultra Strip 100 EnglycwbycwbОценок пока нет

- Erosion of A Chromium-Plated Tank Gun BarrelДокумент16 страницErosion of A Chromium-Plated Tank Gun BarrelycwbycwbОценок пока нет

- Degradation of HVOF, Fe3Al Coatings in Simulated Coal AshДокумент20 страницDegradation of HVOF, Fe3Al Coatings in Simulated Coal AshycwbycwbОценок пока нет

- Honeywell CLEEN Projects Briefing 2011Документ33 страницыHoneywell CLEEN Projects Briefing 2011ycwbycwbОценок пока нет

- Microstructure and Mechanical Properties of 18ni-300 Maraging Steel Fabricated by Selective Laser MeltingДокумент7 страницMicrostructure and Mechanical Properties of 18ni-300 Maraging Steel Fabricated by Selective Laser MeltingycwbycwbОценок пока нет

- Warm Spray Technology For Ti, Ti6Al4V and WC-CoДокумент46 страницWarm Spray Technology For Ti, Ti6Al4V and WC-CoycwbycwbОценок пока нет

- AMC Advanced Mould Coatings 2017Документ4 страницыAMC Advanced Mould Coatings 2017ycwbycwbОценок пока нет

- Yttria-Stabilized Zirconia Thermal Barrier Coatings - A ReviewДокумент10 страницYttria-Stabilized Zirconia Thermal Barrier Coatings - A ReviewycwbycwbОценок пока нет

- Laser Surface Modification of HVOF Coatings For Improvement of Corrosion and Wear PerformanceДокумент293 страницыLaser Surface Modification of HVOF Coatings For Improvement of Corrosion and Wear PerformanceycwbycwbОценок пока нет

- Advanced Low Conductivity Thermal Barrier Coatings PDFДокумент39 страницAdvanced Low Conductivity Thermal Barrier Coatings PDFycwbycwbОценок пока нет

- Abrasive Resistant Coatings-A ReviewДокумент24 страницыAbrasive Resistant Coatings-A ReviewsumohiОценок пока нет

- Additive Manufacturing - Next Generation OEM & Sustainment SolutionsДокумент15 страницAdditive Manufacturing - Next Generation OEM & Sustainment SolutionsycwbycwbОценок пока нет

- CMAS Corrosion and Thermal Cycle of Al-Modified PS-PVD Environmental Barrier CoatingДокумент19 страницCMAS Corrosion and Thermal Cycle of Al-Modified PS-PVD Environmental Barrier CoatingycwbycwbОценок пока нет

- HVOF Thermal Spray TiC-TiB2 Coatings For AUSC Boiler-Turbine Components For Enhanced Corrosion Protection PDFДокумент24 страницыHVOF Thermal Spray TiC-TiB2 Coatings For AUSC Boiler-Turbine Components For Enhanced Corrosion Protection PDFycwbycwbОценок пока нет

- Gas Turbine Coatings Eddy Current Quantitative and Qualitative EvaluationДокумент10 страницGas Turbine Coatings Eddy Current Quantitative and Qualitative EvaluationycwbycwbОценок пока нет

- Durability of Gadolinium Zirconate-YSZ Double-Layered Thermal Barrier Coatings Under Different Thermal Cyclic Test Conditions PDFДокумент14 страницDurability of Gadolinium Zirconate-YSZ Double-Layered Thermal Barrier Coatings Under Different Thermal Cyclic Test Conditions PDFycwbycwbОценок пока нет

- Applications of High Frequency Eddy Current Technology For Material Characterization of Thin CoatingsДокумент7 страницApplications of High Frequency Eddy Current Technology For Material Characterization of Thin CoatingsycwbycwbОценок пока нет

- Material Characterization of Thin Coatings Using High Frequency Eddy Current TechnologyДокумент6 страницMaterial Characterization of Thin Coatings Using High Frequency Eddy Current TechnologyycwbycwbОценок пока нет

- EP2511396 Guided Non-Line of Sight CoatingДокумент13 страницEP2511396 Guided Non-Line of Sight CoatingycwbycwbОценок пока нет

- Practice Calculations 2012Документ58 страницPractice Calculations 2012Lia Romain67% (6)

- Prospectus Syllabus: Post Graduate Diploma Course in Food Analysis and Quality AssuranceДокумент19 страницProspectus Syllabus: Post Graduate Diploma Course in Food Analysis and Quality Assurancepriyanka thapliyal100% (1)

- Mep MainДокумент57 страницMep Mainravi_92Оценок пока нет

- Consolidation Theories of Soils: By: Alemayehu Teferra (Prof., Dr.-Ing.)Документ33 страницыConsolidation Theories of Soils: By: Alemayehu Teferra (Prof., Dr.-Ing.)ASAMENEWОценок пока нет

- HVAC Cooling Load CalculationДокумент98 страницHVAC Cooling Load CalculationVishnupriya B.100% (3)

- Icml Mla IДокумент3 страницыIcml Mla IDeepak100% (1)

- (SSOP) : Sanitation Standard Operating ProcedureДокумент6 страниц(SSOP) : Sanitation Standard Operating ProcedureAsrel05100% (1)

- 3330703Документ2 страницы3330703Syed Aaqib Farhan AhmedОценок пока нет

- Omnirad 819 - EN PDS 2Документ3 страницыOmnirad 819 - EN PDS 2brausenpaulОценок пока нет

- Instrumentation & Process ControlДокумент51 страницаInstrumentation & Process ControlChiến Phan Công100% (1)

- Gas Arc Welding - GMAW and GTAW Gas Arc Welding - GMAW and GTAWДокумент3 страницыGas Arc Welding - GMAW and GTAW Gas Arc Welding - GMAW and GTAWJulioОценок пока нет

- Apiezon AP100 Grease MSDSДокумент5 страницApiezon AP100 Grease MSDSData Sheet SolutionsОценок пока нет

- Chem 1Документ1 страницаChem 1himanshupandit485Оценок пока нет

- DDFC Boiler Effeciency AnalysisДокумент21 страницаDDFC Boiler Effeciency AnalysisPublic DemandОценок пока нет

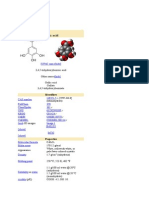

- Gallic AcidДокумент28 страницGallic AcidDolih GozaliОценок пока нет

- Effect of Temperature On Sliding Wear of AISI 316 L (N) Stainless Steel  " Analysis of Measured Wear and Surface Roughness of Wear TracksДокумент7 страницEffect of Temperature On Sliding Wear of AISI 316 L (N) Stainless Steel  " Analysis of Measured Wear and Surface Roughness of Wear TracksSamir BoseОценок пока нет

- Reducing Eliminating ESD Hazards During PYRO OperationsДокумент42 страницыReducing Eliminating ESD Hazards During PYRO OperationsAnonymous TI2bUTОценок пока нет

- DSR Unit 1Документ69 страницDSR Unit 1hujefaОценок пока нет

- Encapsulation State of Messenger RNA Inside Lipid NanoparticlesДокумент5 страницEncapsulation State of Messenger RNA Inside Lipid NanoparticlesPencari IlmuОценок пока нет

- Bunting Powered Bronze Bushings PDFДокумент56 страницBunting Powered Bronze Bushings PDFFitunopОценок пока нет

- MohitДокумент3 страницыMohitVivek kumar0% (1)

- Effect of Irrigation and Stainless Steel Drills On Dental Implant Bed Heat GenerationДокумент10 страницEffect of Irrigation and Stainless Steel Drills On Dental Implant Bed Heat GenerationIsabel XochihuaОценок пока нет

- Thermoelectric Cooling ModulesДокумент8 страницThermoelectric Cooling ModuleshabteabОценок пока нет

- Question & Answer - Module 1 NACEДокумент6 страницQuestion & Answer - Module 1 NACEraghuvarma0% (1)

- Oxygen Content Using A 14-Mev Neutron Activation and Direct-Counting TechniqueДокумент8 страницOxygen Content Using A 14-Mev Neutron Activation and Direct-Counting Techniqueruben carcamoОценок пока нет

- USP-NF Atorvastatin CalciumДокумент8 страницUSP-NF Atorvastatin CalciumPhạm Đức LộcОценок пока нет

- BS en Iso 23936-2-2011Документ78 страницBS en Iso 23936-2-2011Franklin Osorio Sanchez67% (3)

- Introduction To Sensors PDFДокумент211 страницIntroduction To Sensors PDFVũ Mạnh Cường100% (2)

- Chemical Engineering CommunicationsДокумент16 страницChemical Engineering CommunicationsMichelle Quilaqueo NovoaОценок пока нет

- Nippon Muki Catalogue (Seperator Type, J-Model)Документ20 страницNippon Muki Catalogue (Seperator Type, J-Model)Hou HonОценок пока нет