Академический Документы

Профессиональный Документы

Культура Документы

Straightening

Загружено:

Simbu Arasan0 оценок0% нашли этот документ полезным (0 голосов)

125 просмотров10 страницFlame straightening is used to correct deformations from welding. When welding, shrinkage in the weld and surrounding material causes deformation. Flame straightening works by rapidly heating localized areas of plate with an oxy-acetylene flame to around 1000°C, increasing the plasticity of the steel. As the heated parts are constrained by the cooler surrounding material, excessively long parts will shorten during cooling. Multi-flame blowpipes are suitable for large areas while single-flame blowpipes can be used for thinner sheets. Straightening requires studying the deformations and applying intermittent heating bands above stiffeners to correct bending in small sections at a time.

Исходное описание:

STRAIGHTINING

Авторское право

© © All Rights Reserved

Доступные форматы

DOC, PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документFlame straightening is used to correct deformations from welding. When welding, shrinkage in the weld and surrounding material causes deformation. Flame straightening works by rapidly heating localized areas of plate with an oxy-acetylene flame to around 1000°C, increasing the plasticity of the steel. As the heated parts are constrained by the cooler surrounding material, excessively long parts will shorten during cooling. Multi-flame blowpipes are suitable for large areas while single-flame blowpipes can be used for thinner sheets. Straightening requires studying the deformations and applying intermittent heating bands above stiffeners to correct bending in small sections at a time.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате DOC, PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

125 просмотров10 страницStraightening

Загружено:

Simbu ArasanFlame straightening is used to correct deformations from welding. When welding, shrinkage in the weld and surrounding material causes deformation. Flame straightening works by rapidly heating localized areas of plate with an oxy-acetylene flame to around 1000°C, increasing the plasticity of the steel. As the heated parts are constrained by the cooler surrounding material, excessively long parts will shorten during cooling. Multi-flame blowpipes are suitable for large areas while single-flame blowpipes can be used for thinner sheets. Straightening requires studying the deformations and applying intermittent heating bands above stiffeners to correct bending in small sections at a time.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате DOC, PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 10

Lincoln Electric (UK) Ltd.

Harris Calorific Division

MARKET BRIEF

Flame straightening Technical information

Flame straightening is used for correcting deformations which occur in welded constructions. Shrinage

in the weld itself and the surrounding material due to cooling occurs in all welding. Shrinage causes

deformation and !ucling in the surrounding "late# even at some distance from the welds. Deformation

can also stem from thermal stresses created !$ rolling or thermal cutting. %he e&tent of the deformation is

largel$ de"endent on how welding is e&ecuted. Distortions are es"eciall$ visi!le on "ainted or lac'uered

surfaces. (t is usuall$ im"ossi!le to stretch areas that have shrun due to welding. )ne solution is to

attem"t to shrin the over*e&tended areas# a +o! for which flame straightening has "roved to !e suita!le.

Flame straightening is "articularl$ convenient since no e'ui"ment other than a !low"i"e is normall$

re'uired. %he o"erator however# must !e well aware of how the wor"iece will react to heating and how

shrinage forces can !est !e utilised for straightening. (n contrast to mechanical straightening# the results

of flame straightening are not evident until the structure has cooled.

Principle

%he "rinci"le of flame straightening is !ased on using the hottest flame "ossi!le (,refera!l$

)&$-.cet$lene) for ra"id heating of a limited "ortion of "late to a tem"erature of a""ro&. /00 degrees

Centigrade# at which "oint the "lasticit$ of the steel has !een su!stantiall$ increased. Since the

surrounding material remains cold# the heated "arts will !e restrained during the heating and u"set so that

the e&cessivel$ long "arts will shorten during cooling. %he "late ma$ also !e restrained !$ e&ternal

means such as clam"s or loads.

%his e&am"le illustrates the "rinci"le of flame straightening.

(f we first e&amine an unrestricted steel !ar which is uniforml$ heated (Fig.1)# we find that it will e&"and

in all directions. 2hen the flame is removed the wor"iece will cool and contract to its original

dimensions. (f the !ar is restrained during heating (Fig.3)# longitudinal e&"ansion is "revented. %his will

lead to a !uild*u" of com"ression stresses which increase as the tem"erature increases. Finall$ the

com"ressive $ield strength limit is reached and the material is "lasticall$ u"set. %his u"*set is e&"edited

!$ the fact that the u"set limit decreases as the tem"erature increases. During the cooling the wor"iece

will !e shortened due to the u"setting.

,age 1 of 10 4% 5une 3000

Unrestrained

Fig.1

4estrained

Fig.2

Heat Source Heat Source

Equipment

%he !est straightening effect is o!tained !$ a num!er of local heatings. %his has led to the use of multi*

flame "late straightening !low"i"es with three flames. %his t$"e of !low"i"e greatl$ facilitates flame

straightening# "ermits the !est "ossi!le control of the straightening "rocess# is the most economical and

"roduces the smoothest surface. 6ulti*flame !low"i"es are es"eciall$ suita!le for straightening large

areas of "late such as decs and dec structures on shi"s. For straightening !eams and sheet metal less

than 7 mm thic# a single*flame !low"i"e is most suita!le. Single*flame !low"i"es of var$ing si8es can

!e connected to the same t$"e of shan as the multi*flame !low"i"e. %he three*flame !low"i"e is

suita!le for straightening "lates from 7 9 13 mm. %he o"erator should also have a straight edge of

a""ro&imatel$ 1.: meters to determine the a""earance and si8e of deformations.

Execution

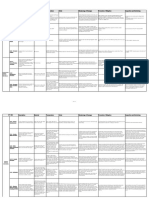

Different constructions with different t$"es of deformation demand different straightening methods. (t is

therefore im"ossi!le to "rovide a general descri"tion of the flame straightening "rocess. Such factors as

residual stresses due to rolling# thermal cutting and welding greatl$ affect the results of straightening.

%olerance re'uirements can also var$ from case to case. . few e&am"les of how flame straightening can

!e e&ecuted will !e given here. %he straightening involves a dec section and the wall of a dechouse#

!oth with a "late thicness of a""ro&. ; mm. <oth of these constructions are flame straightened in the

same manner e&ce"t that the dec can usuall$ onl$ !e reached from one side. <egin !$ straightening the

"late directl$ a!ove the stiffeners. Straighten the side of the "late which is too long# i.e. the conve& side.

,age 3 of 10 4% 5une 3000

=o88le

7 mm

,late

%he !low"i"e should !e held so that the ti"

of the inner cone of the flame is a""ro&. 7

mm from the "late surface.

Fig.3

6ove the !low"i"e directl$ over the stiffeners

(Fig.3) so that the intermittent heat !ands !ecome

dar red in colour (tem"erature a""ro&. /00 deg

Centigrade). .lwa$s locate one of the flames directl$

a!ove the stiffener while the remaining flames are

dis"laced according to t$"e of deformations in the

surrounding "late. %he following e&am"les illustrate

the location of the !low"i"es. 2here the "late has

!een s$mmetricall$ deformed on !oth sides of the

stiffener (Fig.4) either u"wards (>) or downwards (*).

%he <low"i"e is then located s$mmetricall$ with one

flame on either side of the stiffener# des"ite the fact

that this is the concave side of the stiffener.

%his "late is as$mmetricall$ deformed (Fig.5) it is deformed u"wards on one side of the stiffener and

downwards on the other. %he !low"i"e should !e a""lied eccentricall$. )ne of the outer flames is located

directl$ a!ove the stiffener while the remaining flames are over the side of the stiffener where the "late is

deformed u"wards.

,age ? of 10 4% 5une 3000

Fig.4 Blopipes * *

! !

Fig.5 > *

Fig."

%he heat !ands should !e a""ro&. 100 mm long on a

7 * / mm thic "late and a""ro&. 3:0 9 ?:0 mm long

on an ; 9 13 mm thic "late. %he distance !etween

heat !ands should !e a""ro&. 100 mm.

Deformations which are as distinct as those shown in the two e&am"les (Fig@s. 7 A :) are rare. (t is

therefore essential that the deformations in the vicinit$ of the stiffener# i.e. the area directl$ affected !$

the flames# !e carefull$ studied.

(n this case (Fig.#) the !low"i"e is located ecentricall$# since the "late is flat in the middle# the "late

there will rise and then revert !ac to its original sha"e. .s in the "revious case# the flames are "ositioned

over the high sections.

%he stiffeners are distinctl$ visa!le in this case (Fig.$) since the "late has !een deformed downwards on

!oth sides of the stiffeners. )nl$ one flame located directl$ over the stiffeners should !e used in this

case.

(n this case the "late in the middle is not deformed. (n an$ case# the o"erator should a""l$ the !low"i"e

eccentricall$ while carefull$ o!serving how the "late reacts to the heating. (f the "late droo"s down# the

!low"i"e must !e returned to the normal "osition with the centre flame directl$ over the stiffener.

,age 7 of 10 4% 5une 3000

Fig.# ! !% & !%

Fig.$

Fig.'

* > * >0 * > *

2hen flame straightening near the stiffeners the o"erator should tae care to ensure that as large an area

as "ossi!le is treated in order to "revent the individual heating "asses from adversel$ affecting each

other.

%he following illustration (Fig.1%) "resents an e&am"le of a correct heating se'uence.

First the "late a!ove ever$ other stiffener is straightened (1#3 A ?). %hen the "late a!ove stiffeners 7# : A

/ are straightened# !ut with the heat !ands somewhat dis"laced.

(f e&treme deformation still remains after the first straightening "ass (1 9 3)# further straightening ma$ !e

necessar$. %hese "asses are mared with the num!ers ? 9 / (Fig.11).

,age : of 10 4% 5une 3000

& !0 ! & & ! !

1 7 3 : ? /

* >0 > * * > >

Fig.1%

(n cram"ed areas# the !low"i"e can !e dis"laced !$ half the distance !etween flames (see "ass ? A 7

fig.12) as heating the same area twice is not recomended. During the second straightening ensure that

there is s"ace !etween the heat !ands otherwise the stiffener ma$ !end. %he a""earance of the "late after

the initial straightening with the !low"i"e eccentricall$ located must !e studied carefull$.

,age / of 10 4% 5une 3000

Fig.11

1 ? : / 7 3

Fig.12 ? 7

1 3

1 A 3

? A 7

4e"eated heating is not alwa$s advisa!le in ever$ case. <ucles with large !um"s# for e&am"le# are

difficult to straighten.

Fig.13 shows a !ucle which is suita!le for renewed heating. %his !ucle has the smooth contour which

is necessar$ for a second straightening "ass to !e "ossi!le.

(traightening )uc*les

.fter the area around the !eams is straightened# the remaining !ucles in the intermediate "late surfaces

must !e heated. Conve& !ucles on the dec must !e straightened first. %o o!tain the smoothest "ossi!le

finish on the com"leted wor# the small !ucles must !e treated !efore the larger ones.

,age B of 10 4% 5une 3000

.fter the 1

st

straightening "ass

3nd

1st

.fter the 3

nd

straightening "ass

Fig.13

Fig.14

%he e&am"le in Fig.14 illustrates this method.

Firstl$ 3 or ? s"ots are heated (=o.1 in fig.17).

.fter these have cooled their e&tended areas are

then heated (=o.3 in fig.17). (t is im"ortant that

heating is not resumed until the first s"ots have

com"letel$ cooled down.

1

3

Fig.15

? ?

(f the deformation is not corrected !$ heating the middle of the "late# new heating !ands (=o.? Fig.1:)

must !e a""lied to the sides.

Continued heating is now carried out de"ending on the t$"e of !ucle "resent in the "late# according to

either Fig.1/ or Fig.1B !elow.

,age ; of 10 4% 5une 3000

Fig.1"

!

7 7

(f the !ucles are uniforml$ distri!uted over the entire "late# heat !ands are a""lied in accordance with

Fig.1". (f the !ucles occur mostl$ in the middle# the new heat !ands shall !e a""lied within the

"revious heat !ands as in Fig.1#. 6an$ of the "reviousl$ concave !ucles will disa""ear as the conve&

!ucles are straightened. %hose !ucles still remaining on the wall are now straightened from the inside

in the same manner as descri!ed a!ove.

Fig.1#

!0 ! 0

7

? ?

7

1

3 3

>

1

Fig.1$

(f there are an$ sections where the u""er "art is

conve&l$ distorted and the lower "art is

concavel$ distorted# straighten in the following

se'uence. Firstl$ the conve&l$ distorted section

is straightened from the outside (=o@s. 1 A 3

Fig.1$). %he lower "art is then heated from the

inside (=o@s. ? A 7 Fig.1'). )!serve that the

heating !ands on !oth the outside and the inside

form a common "attern and that heating is

e&ecuted from the conve& side of the "late.

2hether the final heating (=o.: Fig.2%) in the

transitional area !etween the (>) to (*) is to !e

done from the outside or the inside must !e

determined in each individual case. Heating

shall !e carried out from the conve& side of the

"late# which in this case means from the outside.

(n this case the !low"i"e should !e moved

u"wards. (f heat has to !e a""lied from the

inside the !low"i"e is moved in the other

direction (alwa$s towards the conve&l$ distorted

section).

(n most cases the flame*straightened section will now !e within tolerance and straightening is concluded.

However there ma$ !e some s"ecial cases such as short !ucles which re'uire further treatment as

!elow.

(hort )uc*les

Short "rominent !ucles can "rove difficult to straighten !ut if treated in the following manner the

!ucles can !e e&tended# there!$ lowering their rigidit$.

%he flame is a""lied in the middle of the !ucles and directed forward. %his "reheats the material over a

large area and the "late will then rise toward the flame (Fig.31). .fter the !ucle has !een e&tended in

one direction# the !low"i"e is directed at the middle and the !ucle is e&tended in the other direction. %he

!ucle then loses its rigidit$ and !ecomes easier to straighten.

,age C of 10 4% 5une 3000

7 7

? ?

Fig.1'

: :

Fig.2%

Direction

of travel

Starting "oint

Fig.21

Starting "oint

Direction

of travel

Fig.22

Flame straightening of pre&fa)ricate+ parts

,re*fa!ricated "arts to !e flame straightened must !e firml$ fi&ed to "revent movement. (t is therefore

im"ossi!le to straighten o"en "late surfaces efectivel$. (t is 'uite common for shi"$ards to construct

dechouses as se"arate units from the shi" and then "lace them on the dec with all straightening

com"leted. %his construction method is onl$ "ossi!le if the !ottom "lates that are to !e welded to the

dec are sufficientl$ stiffened during straightening.

Flame straightening cannot !egin until all welding is com"leted. %he dec "lates in the dechouse should

!e straightened first and then the underl$ing walls (Fig.23).

,age 10 of 10 4% 5une 3000

5

" "

3

4 4

1

2 2

Fig.23

Вам также может понравиться

- Preheat PDFДокумент11 страницPreheat PDFromanosky11Оценок пока нет

- Flame Straightening S355Документ9 страницFlame Straightening S355Anonymous oI04sS100% (1)

- Mechanical Testing 01B: Part 2 Charpy Impact TestingДокумент25 страницMechanical Testing 01B: Part 2 Charpy Impact Testingsamurai7_77100% (1)

- Astm e 2218 - 02Документ15 страницAstm e 2218 - 02Jaime Rafael Patron PrioloОценок пока нет

- Submerged Arc Welding: Training & EducationДокумент17 страницSubmerged Arc Welding: Training & Educationtanveer ahmedОценок пока нет

- A Study On Transverse Weld Cracks PDFДокумент8 страницA Study On Transverse Weld Cracks PDFRifani ImamОценок пока нет

- Module 3 Construction and DesignДокумент5 страницModule 3 Construction and DesignDhimas Surya Negara100% (1)

- Temper Embrittlement - J and X FactorДокумент2 страницыTemper Embrittlement - J and X Factorgovimano100% (2)

- CMT Welding Research PaperДокумент23 страницыCMT Welding Research PaperUpendra93Оценок пока нет

- AWS C7.3-2016 - Process Specification For Electron Beam WeldingДокумент36 страницAWS C7.3-2016 - Process Specification For Electron Beam Weldingarnoldbatista55100% (1)

- Competitive Solutions For Joining TechnologyДокумент19 страницCompetitive Solutions For Joining Technologyjy12bhuОценок пока нет

- Welding Defect - MACRO PDFДокумент5 страницWelding Defect - MACRO PDFvijay rajputОценок пока нет

- Sample Procedure Qualification Record (PQR) : (Smaw, Gmaw, Gtaw, Fcaw, Ofw, Paw)Документ2 страницыSample Procedure Qualification Record (PQR) : (Smaw, Gmaw, Gtaw, Fcaw, Ofw, Paw)Thanakit Srisaeng0% (1)

- Microstructure Examination of SteelДокумент8 страницMicrostructure Examination of SteelYun Jian100% (1)

- Heat Treatment of SteelsДокумент162 страницыHeat Treatment of SteelsINSTECH ConsultingОценок пока нет

- Pickling Heat Tint For SSДокумент2 страницыPickling Heat Tint For SSTuan DangОценок пока нет

- " Policy": Quality Manual SpecifiesДокумент3 страницы" Policy": Quality Manual SpecifiesHakanОценок пока нет

- Projection WeldДокумент20 страницProjection WeldCebrac ItatibaОценок пока нет

- Effect of Different Metalurgical Phases On The Welding Residual Stresses of Base MetalДокумент71 страницаEffect of Different Metalurgical Phases On The Welding Residual Stresses of Base Metalsalmanzafar_37304938Оценок пока нет

- Weld AbilityДокумент34 страницыWeld AbilityGauthamSarangОценок пока нет

- Cswip - Section 02-Terms and Definition PDFДокумент19 страницCswip - Section 02-Terms and Definition PDFNsidibe Michael EtimОценок пока нет

- WeldingДокумент21 страницаWeldingprabhatkumar_6657012Оценок пока нет

- Adhesion Cross-Cut Test ExampleДокумент2 страницыAdhesion Cross-Cut Test ExampleRaduОценок пока нет

- MEI - Aluminium MIG WeldДокумент56 страницMEI - Aluminium MIG WeldSaravana Kumar100% (1)

- Carefully Evaluate Code RequirementsДокумент3 страницыCarefully Evaluate Code Requirementsmayav1Оценок пока нет

- Set-Up Tack Welding Procedure For Drum Long & Cirseam Butt Welds Control No. Revision No.: 0 Date: Page: 1 of 1Документ1 страницаSet-Up Tack Welding Procedure For Drum Long & Cirseam Butt Welds Control No. Revision No.: 0 Date: Page: 1 of 1sbmmlaОценок пока нет

- BOC IPRM S08-ConsumablesДокумент187 страницBOC IPRM S08-ConsumablesEduard Lupus Lobo100% (1)

- Welding Recommendation TS890Документ2 страницыWelding Recommendation TS890max_powerОценок пока нет

- Taking Your Weld's TemperatureДокумент6 страницTaking Your Weld's Temperatureweldingheattreatment100% (1)

- Ri - 2Документ139 страницRi - 2Benjamin BrownОценок пока нет

- Wtia Iiw Iwe V3 - 0 PDFДокумент2 страницыWtia Iiw Iwe V3 - 0 PDFRizwan NazirОценок пока нет

- 2018 Handling and Storage Recommendations - EN - Rev1!02!2018Документ4 страницы2018 Handling and Storage Recommendations - EN - Rev1!02!2018David Hortas CasasОценок пока нет

- Welding Defect - ISO6520Документ3 страницыWelding Defect - ISO6520manojballaОценок пока нет

- Welding 11-14%Cr IIW Document - Part 1Документ20 страницWelding 11-14%Cr IIW Document - Part 1Manuel CarreñoОценок пока нет

- Fundamentals of Flame Straightening - tcm410 113398Документ32 страницыFundamentals of Flame Straightening - tcm410 113398RobertBostanОценок пока нет

- ISO - TR - 15608 - Welding Guide Line PDFДокумент10 страницISO - TR - 15608 - Welding Guide Line PDFDacher DanielОценок пока нет

- 00 Cover WE Rev2Документ5 страниц00 Cover WE Rev2ariyonodndiОценок пока нет

- Impact of Non-Destructive Testing: Proceedings of the 28th Annual British Conference on Non-Destructive Testing, Sheffield, UK, 18-21 September 1989От EverandImpact of Non-Destructive Testing: Proceedings of the 28th Annual British Conference on Non-Destructive Testing, Sheffield, UK, 18-21 September 1989C. BrookОценок пока нет

- Gas Metal Arc Welding - PulseДокумент68 страницGas Metal Arc Welding - Pulsegreatsteel100% (1)

- GMAW of Creep Resistant SteelsДокумент5 страницGMAW of Creep Resistant SteelsJustin Morse100% (1)

- Aws Form E-9 Stud Welding Procedure Specification (WPS) or Procedure Qualification Record (PQR) or Welder Qualification Record (WQR) 000 PDFДокумент1 страницаAws Form E-9 Stud Welding Procedure Specification (WPS) or Procedure Qualification Record (PQR) or Welder Qualification Record (WQR) 000 PDFrajОценок пока нет

- Welding Engineering - FALL2021-22 - Module 1Документ44 страницыWelding Engineering - FALL2021-22 - Module 1dhaya nidhiОценок пока нет

- Types of CrackingДокумент26 страницTypes of CrackingAnonymous c3eiDyWОценок пока нет

- Adiabatic Shear Localization: Frontiers and AdvancesОт EverandAdiabatic Shear Localization: Frontiers and AdvancesBradley DoddОценок пока нет

- How To MIG Weld AluminumДокумент8 страницHow To MIG Weld AluminumHandri YantoОценок пока нет

- Welders Visual Inspection Handbook-2013 WEB PDFДокумент77 страницWelders Visual Inspection Handbook-2013 WEB PDFquiron2014Оценок пока нет

- CSWIP Welder Training: SymbolsДокумент52 страницыCSWIP Welder Training: SymbolsBUDAPESОценок пока нет

- CIGWELDДокумент244 страницыCIGWELDrodastrid5653100% (1)

- Liquid Penetrant (Lev1el-I-level - II''Документ100 страницLiquid Penetrant (Lev1el-I-level - II''Chandresh100% (1)

- Welding Process and ConsumableДокумент64 страницыWelding Process and Consumablenizar_ikmps100% (1)

- Advanced Gas Metal Arc Welding ProcДокумент20 страницAdvanced Gas Metal Arc Welding ProcjavadmohammadiОценок пока нет

- Shallow Crack Fracture Mechanics Toughness Tests and Applications: First International ConferenceОт EverandShallow Crack Fracture Mechanics Toughness Tests and Applications: First International ConferenceОценок пока нет

- Welding Repair Procedure: PCH Steel Engineering & Construction Sdn. BHDДокумент8 страницWelding Repair Procedure: PCH Steel Engineering & Construction Sdn. BHDmohd as shahiddin jafriОценок пока нет

- Pulse Mig WeldingДокумент7 страницPulse Mig WeldingajayОценок пока нет

- DIN en ISO 6947-1997 Welds-Working Positions Definitions of Angles of Slope and RotationДокумент12 страницDIN en ISO 6947-1997 Welds-Working Positions Definitions of Angles of Slope and RotationHector Flores GarciaОценок пока нет

- UT Outline Training LV IIIДокумент4 страницыUT Outline Training LV IIITrung Tinh HoОценок пока нет

- The Iron Puddler My life in the rolling mills and what came of itОт EverandThe Iron Puddler My life in the rolling mills and what came of itОценок пока нет

- Information Symposium Measurement and Control Techniques in Rolling: Luxembourg, 2 and 3 September 1981От EverandInformation Symposium Measurement and Control Techniques in Rolling: Luxembourg, 2 and 3 September 1981Оценок пока нет

- TWI Welding Training 4Документ36 страницTWI Welding Training 4Simbu Arasan100% (1)

- Mitsui Engineering & Shipbuilding Asia Pte. LTD.: Name: DateДокумент4 страницыMitsui Engineering & Shipbuilding Asia Pte. LTD.: Name: DateSimbu ArasanОценок пока нет

- 571 SummaryДокумент3 страницы571 SummarySimbu Arasan100% (1)

- OPES2024 Brochure V7Документ12 страницOPES2024 Brochure V7Simbu ArasanОценок пока нет

- My Desk: Time Is GoldДокумент22 страницыMy Desk: Time Is GoldSimbu ArasanОценок пока нет

- 004 - Standard Procedure For Surface Preparation and PaintingДокумент9 страниц004 - Standard Procedure For Surface Preparation and PaintingSimbu ArasanОценок пока нет

- 001 - Standard Procedure For Hydrostatic Pressure Test of PipingДокумент8 страниц001 - Standard Procedure For Hydrostatic Pressure Test of PipingSimbu Arasan0% (1)

- BHEL Earthing SystemДокумент8 страницBHEL Earthing SystemSimbu ArasanОценок пока нет

- Electrode Backing RegisterДокумент4 страницыElectrode Backing RegisterSimbu Arasan100% (1)

- TATA PROJECTS LIMITED, SBU-Utility Services: Material Requisition Cum Issue Voucher (MRIV)Документ4 страницыTATA PROJECTS LIMITED, SBU-Utility Services: Material Requisition Cum Issue Voucher (MRIV)Simbu ArasanОценок пока нет

- Nano Membrane Status SheetДокумент3 страницыNano Membrane Status SheetSimbu ArasanОценок пока нет

- 003 - Standard Procedure For Coating and WrappingДокумент6 страниц003 - Standard Procedure For Coating and WrappingSimbu ArasanОценок пока нет

- UF NF Dispatch Master Data 04-11-15Документ47 страницUF NF Dispatch Master Data 04-11-15Simbu ArasanОценок пока нет

- Structural Tank Instructions 11967-AДокумент22 страницыStructural Tank Instructions 11967-Aiftikhar_khalid_1Оценок пока нет

- 006 CBCRDT Tata ProjectsДокумент3 страницы006 CBCRDT Tata ProjectsSimbu ArasanОценок пока нет

- WPPDC-QMD-001-Material Control and Werehousing ProcedureДокумент5 страницWPPDC-QMD-001-Material Control and Werehousing ProcedureSimbu ArasanОценок пока нет

- TPL-US-QMD-002 - Surface Preparation and Painting ProcedureДокумент4 страницыTPL-US-QMD-002 - Surface Preparation and Painting ProcedureSimbu ArasanОценок пока нет

- SWRO-Mobile Plant Requirements: S.No Item Previous Qty Changed / Required QtyДокумент2 страницыSWRO-Mobile Plant Requirements: S.No Item Previous Qty Changed / Required QtySimbu ArasanОценок пока нет

- DO's & Dont'sДокумент5 страницDO's & Dont'sSimbu ArasanОценок пока нет

- Standard BOQ-UF 1000LPH-Single MembraneДокумент9 страницStandard BOQ-UF 1000LPH-Single MembraneSimbu ArasanОценок пока нет

- Standerd 1000LPH BOM-SS PipeДокумент10 страницStanderd 1000LPH BOM-SS PipeSimbu ArasanОценок пока нет

- Uf 500 LPHДокумент6 страницUf 500 LPHSimbu ArasanОценок пока нет

- CR QapДокумент2 страницыCR QapSimbu ArasanОценок пока нет

- Types of Damages On Flexible Pavement For Malaysian Federal RoadДокумент12 страницTypes of Damages On Flexible Pavement For Malaysian Federal Roadfarahazura100% (1)

- Cmat 11Документ4 страницыCmat 11Emmanuel Cafirma RiveraОценок пока нет

- NEC 2011 Hazardous Artilcle 510Документ1 страницаNEC 2011 Hazardous Artilcle 510grand_ammarОценок пока нет

- Table 6 1 AWS D1 1 D1 1M 2010 PDFДокумент1 страницаTable 6 1 AWS D1 1 D1 1M 2010 PDFFu AdОценок пока нет

- Design For Manufacturability For CNC MachiningДокумент4 страницыDesign For Manufacturability For CNC Machiningviorelu99Оценок пока нет

- Method Statement For PRE-ENGINEERED BUILDING ASSEMBLYДокумент39 страницMethod Statement For PRE-ENGINEERED BUILDING ASSEMBLYStephanie EmersonОценок пока нет

- Analysis of Fatigue Fracture of Tank Wagon Railway Axles: Cosmin LocoveiДокумент5 страницAnalysis of Fatigue Fracture of Tank Wagon Railway Axles: Cosmin LocoveiZoser KalengayiОценок пока нет

- Cost Estimation Manual For Low Rise Buildings: Bureau of ConstructionДокумент3 страницыCost Estimation Manual For Low Rise Buildings: Bureau of Constructionjhomel garcia100% (1)

- Boring Log: Testana Engineering, IncДокумент1 страницаBoring Log: Testana Engineering, IncetwinОценок пока нет

- Appendix E - Sizing of Water Piping SystemДокумент18 страницAppendix E - Sizing of Water Piping SystemnjbahmadОценок пока нет

- Category Business Name Phone CityДокумент24 страницыCategory Business Name Phone CityMadhav PatilОценок пока нет

- 01CBO Procurement Manual EnglishДокумент86 страниц01CBO Procurement Manual EnglishfeteneОценок пока нет

- ARAMCO DrawingДокумент1 страницаARAMCO DrawingLainhatanhОценок пока нет

- Fan Coil Unit 1) Box EnclosureДокумент2 страницыFan Coil Unit 1) Box EnclosureRUSHALI SRIVASTAVAОценок пока нет

- 100-510-45436 - H Hpt-06-Mb1-Eb1 O&m ManualДокумент15 страниц100-510-45436 - H Hpt-06-Mb1-Eb1 O&m ManualMiki 40Оценок пока нет

- Silres BS 3003: Silane EmulsionsДокумент3 страницыSilres BS 3003: Silane EmulsionsilterОценок пока нет

- Guideline For Quality Management of Concrete BДокумент62 страницыGuideline For Quality Management of Concrete BRam KrishnaОценок пока нет

- General Principles of Foundation Design: To Prepare A Plan of The Base of The StructureДокумент119 страницGeneral Principles of Foundation Design: To Prepare A Plan of The Base of The StructureTashi TamangОценок пока нет

- Control of Corrossion On Underwater PilesДокумент26 страницControl of Corrossion On Underwater PilesSafreena KhОценок пока нет

- List of Din Standardspdf PDFДокумент84 страницыList of Din Standardspdf PDFZoran DjuricicОценок пока нет

- 13012022031306157Документ4 страницы13012022031306157Shah FaisalОценок пока нет

- Civil2020 v3.2 Release NoteДокумент10 страницCivil2020 v3.2 Release NoteVarun VermaОценок пока нет

- Three Storey Commercial Building (Concrete) - 18-009 - PinagsamaДокумент21 страницаThree Storey Commercial Building (Concrete) - 18-009 - PinagsamaJohn Michael TalanОценок пока нет

- List of Material: Saudi Arabian Oil CompanyДокумент1 страницаList of Material: Saudi Arabian Oil CompanyAbu Anas M.SalaheldinОценок пока нет

- 2e-Aruana 40 Efi 2017Документ57 страниц2e-Aruana 40 Efi 2017costinbalca46Оценок пока нет

- Data Mesin Pendingin GMCP Kendari: NO Nama Part MesinДокумент10 страницData Mesin Pendingin GMCP Kendari: NO Nama Part Mesinrosiyady pusdika candra seОценок пока нет

- CURTIS 250 Through 350hp Parts BreakdownДокумент38 страницCURTIS 250 Through 350hp Parts BreakdownrobertОценок пока нет

- Seepage Flow Net FDMДокумент68 страницSeepage Flow Net FDMRenalyn AndradeОценок пока нет

- Duane Banks Stadium RenovationДокумент3 страницыDuane Banks Stadium RenovationGazetteonlineОценок пока нет

- Arbt - 1 - Syllabus - 2021Документ6 страницArbt - 1 - Syllabus - 2021Angel Mine AlcantaraОценок пока нет