Академический Документы

Профессиональный Документы

Культура Документы

Wps - 09 Mt-Imecol Asme304 Gtaw Sheet-Tubesheet Rev 0

Загружено:

Oscar Iván Duque Díaz0 оценок0% нашли этот документ полезным (0 голосов)

358 просмотров5 страницОригинальное название

Wps - 09 Mt-imecol Asme304 Gtaw Sheet-tubesheet Rev 0

Авторское право

© © All Rights Reserved

Доступные форматы

XLS, PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате XLS, PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

358 просмотров5 страницWps - 09 Mt-Imecol Asme304 Gtaw Sheet-Tubesheet Rev 0

Загружено:

Oscar Iván Duque DíazАвторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате XLS, PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 5

CODIGO:

WELDING PROCEDURE SPECIFICATIONS (WPS)

PAGINA:

1 DE 2

COMPANY NAME: By:

WPS No.: WPS-09 IMECOL GTAW SHEET-TUBESHEET INOX 304 Date:

Supporting PQR No.: PQR-09 IMECOL GTAW SHEET-TUBESHEET INOX 304 Date:

Revision No.: 0

Welding Process (es):

Types: Manual X Automatic Semi-automatic

Joint Design:

Backing: N.A Yes No

Backing Material (Type):

Metal Nonfusing Metal

Nonmetallic Other

P-No.: Group No.: To P-No.: Group No.:

OR

Specification type and grade:

To specification type and grade:

OR

Chem. Analysis and Mech. Prop.:

To Chem. Analysis and Mech. Prop.:

Thickness Range:

Base Metal: Groove: Fillet:

Pipe Dia.Range. Tests Diam. Range Qualif.

Other:

Spec. No. (SFA):

AWS No. (Class):

F-No.:

A-No.:

Size of Filler Metal:

Weld Metal:

Thickness Range:

Groove:

Fillet:

Electrode-Flux (Class):

Flux Trade Name:

Consumable Insert:

Other:

* Each base metal-filler metal combination should be recorded individually

For: Imecol SA.

Organization Pacific Engineering & Consulting Company SAS

Date By

Ing. Jeyson Julian Ramirez Gomez.

Pacific Engineering & Consulting Company Imecol SA.

Mayo 22 de 2012

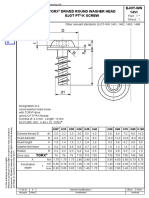

Sketches, Production Drawngs, Weld Symbols or Written Description

should show the general arrangement of the parts to be welded.

GTAW

JOINTS (QW-402)

Julio 4 de 2012

BASE METALS (QW-403)

Pared de Tubo(1. 5 mm+/-10%)

Where applicable, the root spacing and the details of weld groove may

be specified.

8 1 1 8

N.A

GROOVE (SEE DETAILS) Details

N.A

(Refer to both backing and retainers)

(At the option of the Mfgr., sketches may be attached to illustrate joint

desin, weld layer and bead sequence, e.g., for notch toughness

procedures, for multiple process procedure, etc.)

FILLER METALS (QW-404)

Platina ASTM A240/ASME SA 240 (TP 304)

Tuberia ASTM A312/ASME SA 312 (TP 304)

N.A.

N.A.

4" 2" a 4"

A5.9

ER309L

6

8

1/16"

N.A

N.A

Hasta 1/16"

NA

N.A

NA

NINGUNA

Pacific Engineering & Consulting Company

JOINTS (QW-402)

BASE METALS (QW-403)

Details

FILLER METALS (QW-404)

CODIGO:

WELDING PROCEDURE SPECIFICATIONS (WPS)

PAGINA:

2 DE 2

WPS No.: WPS-09 IMECOL GTAW SHEET-TUBESHEET INOX 304 REV. 0

Position(s) of Groove: Temperature Range:

Welding Progression: Up X Down Time Range:

Position(s) of fillet: 5F

Preheat Temp. Min.:

Interpass Temp. Max.:

Preheat Maintenance: Shielding

(Continuos or special heating where applicable should be recorded) Trailing

Backing

Current AC or DC: Polarity:

Amps (Range):

Volts (Range):

Tungsten Electrode Size and Type:

Mode of Metal Transfer for GMAW:

Electrode Wire Feed Speed Range:

String or Weave Bead:

Orifice or Gas Cup Size:

Initial and Interpass Cleaning (Brushing, Grinding, etc.):

Method of Back Gouging:

Oscillation:

Contact Tube to Work Distance:

Multiple or single pass (per side):

Multiple or single Electrode:

Travel Speed (Range):

Peening:

Other:

Elaborated By: Aproved By:

Ing. Jeyson Julian Ramirez Gomez. ING. German Barrera

CERTIFIED WELDING INSPECTOR - AWS DIRECTOR DE MANUFACTURA

Date Julio 4 de 2012

60 - 80 7,5 - 9,5 2,5 - 4,5

Ohter (e.g., remarks, comments. Hot wire

addition, tecnique, torch angle, etc.) Class Dia. Type Polar. Amp. Range

1 GTAW ER309L 1/16" DC-

Weld Layer(s) Process

Filler Metal Current

Volt Range

Travel Speed

Range (Inch/Min)

UN SOLO ELECTRODO (SIMPLE)

2,5 - 4,5 PULG/MIN

No

GRATA Y/O CEPILLO INOXIDABLE

NA

Recto hasta 1/8"

6mm - 8 mm

SENCILLO

(Spray arc, short circuiting arc, etc.)

NA

TECHNIQUE (QW-410)

OSCILADO y RECTO

No. 4

60 - 80

7,5 - 9,5

(Amps and Volts range should be recorded for each electrode size, position, and thickness, etc. This information may

be listed in a tabular form similar to that shown below.)

EWCe-2% de 3/32"

(Pure Tungsten, 2% Thoriated, etc.)

N.A

NA NA NA

ELECTRICAL CHARACTERISTICS (QW-409)

DC ELECT. NEGATIVO

NA SG-A Ar100% 28 CFH

NA NA NA

PREHEAT (QW-406) GAS (QW-408)

NA Porcent Composition

NA Gas(es) (Mixture) Flow Rate

POSITIONS (QW-405) POSTWELD HEAT TREATMENT (QW-407)

N.A N.A

N.A

QW-483 FORMAT FOR PROCEDURE QUALIFICATION RECORDS (PQR)

(See QW-200.2, Section IX, ASME Boiler and Pressure Vessel Code)

Record Actual Conditions Used to Weld Test Coupon

Company Name IMECOL SA.

Procedure Qualification Record N. PQR-09 IMECOL GTAW SHEET-TUBESHEET INOX 304

WPS N. WPS-09 IMECOL GTAW SHEET-TUBESHEET INOX 304 Date J ulio 4 de 2012

Welding Process (es) GTAW

Types (Manual, Automatic, Semi-Auto.) MANUAL

JOINTS (QW-402)

Groove Design of Test Coupon

(For combination qualificaions, the deposited weld metal thickness shall be recorded for each filler metal or process used.)

BASE METALS (QW-403) POSTWELD HEAT TREATMENT (QW-407)

Material Spec. ASTM A240/ASME A312 Temperature N.A.

Type or Grade TP 304/TP 304 Time N.A.

P.N. 8 to P-N 8 Other N.A.

Thickness of Test Coupon Sheet (1") Tube (1,5mm)

Diameter of Test Coupon 4"

Other N.A.

GAS (QW-408)

Percent Composition

Gas(es) (Mixture) Flow Rate

Shielding GS-A Ar100% 28 CFH

Trailing N.A N.A

FILLER METALS (QW-404) Backing N.A N.A

SFA Specification 5.9

AWS Classification ER309L ELECTRICAL CHARACTERISTICS (QW-409)

Filler Metal F-N. 6 Current DIRECTA

Weld Metal Analysis A-N. 8 Polarity DIRECTA

Size of Filler Metal 1/16" Amps. 60 - 80 Volts 7,5 - 9,5

Other N.A. Tungsten Electrode Size 3/32"

Weld Metal Thickness N.A Other

POSITION (QW-405) TECHNIQUE (QW-410)

Position of Groove Fillet (5F) Travel Speed 2,5 - 4,5 pulg/min

Weld Progression (Ulphill, Downhill) String or Weave Bead String and Weave

Other N.A. Oscillation 3 mm

Multipass or Single Pass (per side) SINGLE

Single or Multiple Electrodes SINGLE

PREHEAT (QW-406) Other N.A

Preheat Temp. N.A

Interpass Temp. N.A

Other N.A

UP

PQR-09 IMECOL GTAW SHEET-TUBESHEET INOX 304

Ultimate Ultimate Type of

area Unit Stress Failure &

cm2

psi Location

Guided-Bend Tests (QW-160)

Type and Figure N Result

Toughness Tests (QW-170)

Specimen Notch Specimen Test Impac Values

N Location Size Temp. Ft. Lbs. % Shear Mils Drop Weight Breack (Y/N)

N.A.

Fillet-Weld Test (QW-180)

Result - Satisfactory: yes X No Penetration into Parent Metal: Yes X No

Macro - Results Satisfactorio.

Other Tests

type of Test Liquidos Penetrantes Informe: 2012 PECC-11-LP-Imecol Rev 0.

Deposit Analysis

Other

Welder's Name Gustavo Ruiz Rosero Clock N CC. 16.727.421 Stamp N GR

Tests conducted by: J eyson J . Ramirez G. Laboratory Test N 2012 PECC-10-MacroAtaque-Imecol Rev 0.

We certify that the statements in this record are correrd are correct and that the test welds were prepared, welded, and test in

accordance with the requirements of Section IX of the ASME Code.

Manufacturer IMECOL S.A

Date J ulio 4 de 2012 By Ing. J eyson J . Ramirez G.

(Detail of record of test are illustrative only and may be modified to conform to the type and number of tests required by the Code.)

N.A. N.A. N.A. N.A. N.A. N.A. N.A.

Specimen % Elong en 5cm

N Kg-f

Total Load

QW-483 (Back)

Tensile Test (QW-150)

PQR N :

Вам также может понравиться

- MRPL Mangalore CDU VDU Heaters Welding Procedure SpecificationДокумент5 страницMRPL Mangalore CDU VDU Heaters Welding Procedure SpecificationDeepak100% (1)

- Cswip 3.0 ReportingДокумент32 страницыCswip 3.0 ReportingAvijit DebnathОценок пока нет

- P 11 CNDT JP41 Ut-Aws D1.1 Rev 07Документ22 страницыP 11 CNDT JP41 Ut-Aws D1.1 Rev 07Vimal MenonОценок пока нет

- Wps 1010 IfrДокумент28 страницWps 1010 IfrSyed Mahmud Habibur RahmanОценок пока нет

- All Position Stainless Steel Welding ProcedureДокумент6 страницAll Position Stainless Steel Welding ProcedureJaime PatrónОценок пока нет

- Electrode Brad Qualification Procedure As Per ASME Section II Part C Along With NPCIL ProcedureДокумент2 страницыElectrode Brad Qualification Procedure As Per ASME Section II Part C Along With NPCIL ProcedurePrashant Puri100% (1)

- Aws d1.1 WPS, PQR & WQTДокумент4 страницыAws d1.1 WPS, PQR & WQTWeld Bro SandeepОценок пока нет

- LBW WOPQ REV. 2010a Interactive FormДокумент1 страницаLBW WOPQ REV. 2010a Interactive Formcosmicbunny100% (1)

- PQR TipsДокумент2 страницыPQR TipsWaqas WaqasОценок пока нет

- 1 Paut ReportДокумент1 страница1 Paut ReportAhmedОценок пока нет

- Welded Tube Joint SpecДокумент8 страницWelded Tube Joint SpecAvinash ShuklaОценок пока нет

- Atf Wpqr-Blank v1Документ1 страницаAtf Wpqr-Blank v1lth770310Оценок пока нет

- Sample PWHT ProcedureДокумент9 страницSample PWHT ProcedurefizanlaminОценок пока нет

- WPS & PQR (E Co Cr-E)Документ3 страницыWPS & PQR (E Co Cr-E)HossamSAshourОценок пока нет

- WPS PQR Procedure PDFДокумент31 страницаWPS PQR Procedure PDFsudeesh kumarОценок пока нет

- WPS 316 L PDFДокумент4 страницыWPS 316 L PDFIrinaОценок пока нет

- Stainless steel welding procedure qualification recordДокумент1 страницаStainless steel welding procedure qualification recordchandraОценок пока нет

- Gta+sma PQRДокумент3 страницыGta+sma PQRRahul MoottolikandyОценок пока нет

- WPS-PQR (Er309l Mo)Документ4 страницыWPS-PQR (Er309l Mo)Hamza Nouman0% (1)

- Radiographic Inspection Report SheetДокумент1 страницаRadiographic Inspection Report SheetMike BoyesОценок пока нет

- Contact Us: Guides in PDF: (Member Access) Welding Procedure Specification (WPS)Документ4 страницыContact Us: Guides in PDF: (Member Access) Welding Procedure Specification (WPS)Maulik PatelОценок пока нет

- WPSДокумент1 страницаWPSNidhinkorothОценок пока нет

- Welder and Welding Operator Performance Qualification RecordДокумент1 страницаWelder and Welding Operator Performance Qualification RecordAsif HameedОценок пока нет

- WPS GTAW Stainless SteelДокумент7 страницWPS GTAW Stainless SteelVarun MalhotraОценок пока нет

- Wps Butt AWSДокумент4 страницыWps Butt AWSMohd Ashraf75% (4)

- Blocks For Ultrasonic TestingДокумент3 страницыBlocks For Ultrasonic TestingMahade Hasan DipuОценок пока нет

- Procedure For Liquid Penetrant ExaminationДокумент66 страницProcedure For Liquid Penetrant ExaminationSanooj Siddikh100% (1)

- WPQ Sample PrintoutДокумент1 страницаWPQ Sample PrintoutKannan VelОценок пока нет

- WELDER QUALIFICATION REPORTДокумент2 страницыWELDER QUALIFICATION REPORTAkash Singh TomarОценок пока нет

- WPS Format For AWS D1.1 - WPS - SMAWДокумент1 страницаWPS Format For AWS D1.1 - WPS - SMAWThe Welding Inspections CommunityОценок пока нет

- PQRДокумент3 страницыPQRnazirulhakimОценок пока нет

- D17.1 D17.1M 2017 Sample PQTR FormДокумент1 страницаD17.1 D17.1M 2017 Sample PQTR FormPabloLamelaОценок пока нет

- LANL Engineering Standards Manual PWHT ProcedureДокумент6 страницLANL Engineering Standards Manual PWHT ProcedurevictorbirlanОценок пока нет

- MSS SP 54 Radiographic Examination MethodДокумент9 страницMSS SP 54 Radiographic Examination MethodSunil Kumar100% (1)

- WPS - EngineerДокумент20 страницWPS - Engineerhunghoanglong100% (1)

- RT Procedure 10.09.16Документ9 страницRT Procedure 10.09.16mukeshsingh6Оценок пока нет

- Dissimilar Base Metal ThicknessДокумент5 страницDissimilar Base Metal ThicknessFERNANDO MIRANDA100% (2)

- Aws 001Документ1 страницаAws 001akshay sarfareОценок пока нет

- ET NDT Sample Test Report FormatДокумент1 страницаET NDT Sample Test Report Formatanas dwiОценок пока нет

- Report - Form - MT - PT - RT - Ut - Cal - 2015Документ9 страницReport - Form - MT - PT - RT - Ut - Cal - 2015YuwantoniAlОценок пока нет

- Smaw Wps FinalДокумент3 страницыSmaw Wps FinalsheikmoinОценок пока нет

- ASME IX QW (Welding General Requirements)Документ12 страницASME IX QW (Welding General Requirements)Ariq Fauzan100% (1)

- PQR & WPQ Standard Testing Parameter WorksheetДокумент4 страницыPQR & WPQ Standard Testing Parameter WorksheetcosmicbunnyОценок пока нет

- Fit Up Welding Visual Inspection ReportДокумент2 страницыFit Up Welding Visual Inspection Reportmohd as shahiddin jafriОценок пока нет

- Sample API 1104 WpsДокумент3 страницыSample API 1104 WpsMuhammadShabbir0% (1)

- Report 1 Paut Sts 409Документ12 страницReport 1 Paut Sts 409DEBJYOTI SENGUPTA100% (2)

- Welding Procedure Specification: Page 1 of 1Документ2 страницыWelding Procedure Specification: Page 1 of 1Anderson Perez Martinez100% (1)

- ASME U & R STAMPS GUIDEДокумент12 страницASME U & R STAMPS GUIDEShaheen Andre ChikkuОценок пока нет

- Visible Penetrant Examination Using The Water-Washable ProcessДокумент6 страницVisible Penetrant Examination Using The Water-Washable ProcessERNESTO ENRIQUE FERNANDEZ BAPTISTAОценок пока нет

- Aws D1.6 - SS316 WPSДокумент1 страницаAws D1.6 - SS316 WPSBoby Thomas0% (1)

- M 2 SAW D1.1 2015 Form PDFДокумент1 страницаM 2 SAW D1.1 2015 Form PDFyounessОценок пока нет

- STD 1104 - Welding of Pipelines and Related FacilitiesДокумент38 страницSTD 1104 - Welding of Pipelines and Related FacilitiesGishnu SunilОценок пока нет

- PQR 01 PDFДокумент2 страницыPQR 01 PDFVijay BhaleraoОценок пока нет

- WPQ WELDER PERFORMANCE QUALIFICATIONДокумент2 страницыWPQ WELDER PERFORMANCE QUALIFICATIONalokbdasОценок пока нет

- Aws d1.5 PQRДокумент2 страницыAws d1.5 PQRjacquesmayolОценок пока нет

- Joint Efficiency TutorialДокумент47 страницJoint Efficiency TutorialJignesh ShahОценок пока нет

- Impact of Non-Destructive Testing: Proceedings of the 28th Annual British Conference on Non-Destructive Testing, Sheffield, UK, 18-21 September 1989От EverandImpact of Non-Destructive Testing: Proceedings of the 28th Annual British Conference on Non-Destructive Testing, Sheffield, UK, 18-21 September 1989C. BrookОценок пока нет

- PQR FormatДокумент2 страницыPQR Formatravi0009880% (5)

- Procedure Qualification Records (PQR) : in Accordance With ASME SECTION IX For Power PippingДокумент6 страницProcedure Qualification Records (PQR) : in Accordance With ASME SECTION IX For Power PippingNovita Dwi IsnaeniОценок пока нет

- GuidelinesДокумент15 страницGuidelinesOscar Iván Duque DíazОценок пока нет

- Guidelines PDFДокумент11 страницGuidelines PDFOscar Iván Duque DíazОценок пока нет

- Hora Lunes Martes Miercoles Jueves Viernes SabadoДокумент1 страницаHora Lunes Martes Miercoles Jueves Viernes SabadoOscar Iván Duque DíazОценок пока нет

- Inst CTRLДокумент2 страницыInst CTRLRCОценок пока нет

- Rosoft 3d Pipe Usermanualenu 6.64Документ11 страницRosoft 3d Pipe Usermanualenu 6.64Oscar Iván Duque DíazОценок пока нет

- Bibliographic References for Metallurgy DocumentДокумент10 страницBibliographic References for Metallurgy DocumentOscar Iván Duque DíazОценок пока нет

- Arl Oscar Ivan DuqueДокумент1 страницаArl Oscar Ivan DuqueOscar Iván Duque DíazОценок пока нет

- Cwi QuestionsДокумент6 страницCwi QuestionsGokul Thangam75% (4)

- Copia EPS Oscar Duque PDFДокумент1 страницаCopia EPS Oscar Duque PDFOscar Iván Duque DíazОценок пока нет

- TesisДокумент2 страницыTesisOscar Iván Duque DíazОценок пока нет

- IndiceДокумент2 страницыIndiceOscar Iván Duque DíazОценок пока нет

- Index of /ebooks/books/openДокумент5 страницIndex of /ebooks/books/openOscar Iván Duque Díaz0% (1)

- Symbols Meaning:: We P Wo WW WF Nu SP Cap S/PLДокумент2 страницыSymbols Meaning:: We P Wo WW WF Nu SP Cap S/PLOscar Iván Duque DíazОценок пока нет

- 00039Документ8 страниц00039Joe BlagОценок пока нет

- Essential Physics 1 - F. FirkДокумент209 страницEssential Physics 1 - F. FirkJhoan EpvОценок пока нет

- TesisДокумент2 страницыTesisOscar Iván Duque DíazОценок пока нет

- Price List1Документ5 страницPrice List1Oscar Iván Duque DíazОценок пока нет

- Welding Procedure Specification (WPS)Документ0 страницWelding Procedure Specification (WPS)Oscar Iván Duque DíazОценок пока нет

- Links LibrosДокумент29 страницLinks LibrosOscar Iván Duque Díaz100% (1)

- FCAW Hidrogen PDFДокумент4 страницыFCAW Hidrogen PDFglimgloОценок пока нет

- Guide Line For Equipment ReabilityДокумент162 страницыGuide Line For Equipment ReabilityRogerio Marques VasquesОценок пока нет

- Cement Mill Shell LinerДокумент7 страницCement Mill Shell LinerMahaveer SinghОценок пока нет

- Aircraft Structure Design PrinciplesДокумент28 страницAircraft Structure Design PrinciplesVenugopal Krishna0% (1)

- CITOject F Ejection Material AdvantagesДокумент4 страницыCITOject F Ejection Material AdvantagesAbdul WasayОценок пока нет

- Methods TO CUT STEEL PLATEДокумент4 страницыMethods TO CUT STEEL PLATEmaheshbandhamОценок пока нет

- Welding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test CertificateДокумент3 страницыWelding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test Certificateramesh rajaОценок пока нет

- TVET 1 Worksheet 8 Rivera, JomareДокумент7 страницTVET 1 Worksheet 8 Rivera, JomareJomare RiveraОценок пока нет

- HMC InternДокумент40 страницHMC InternMuhammad UsmanОценок пока нет

- Etds 6900 20x - v21Документ2 страницыEtds 6900 20x - v21Nirupam KediaОценок пока нет

- Part Book PC130F-7 Hidraulic PDFДокумент11 страницPart Book PC130F-7 Hidraulic PDFChimanОценок пока нет

- Drills 7 TappersДокумент10 страницDrills 7 TappersBe HappyОценок пока нет

- Loctite 7075 TdsДокумент1 страницаLoctite 7075 TdsSurajPachhadeОценок пока нет

- Eu 01-6-0600Документ4 страницыEu 01-6-0600Faiz FSОценок пока нет

- Precision Pliers and Cutters GuideДокумент40 страницPrecision Pliers and Cutters Guidepavel10082020Оценок пока нет

- AWS - PHB-1-1994 The Everyday Pocket Handbook For Arc Welding Steel PDFДокумент36 страницAWS - PHB-1-1994 The Everyday Pocket Handbook For Arc Welding Steel PDFahmedabdelaziz851647Оценок пока нет

- Tools & Work Holding Devices in CNC MachinesДокумент17 страницTools & Work Holding Devices in CNC MachinesAhtisham AmjadОценок пока нет

- Tooling by Design - Hole Extrusions Part 1Документ2 страницыTooling by Design - Hole Extrusions Part 1BalaОценок пока нет

- Mini DOJO ConceptДокумент24 страницыMini DOJO ConceptMukesh Sharma Akshu100% (3)

- WPS SampleДокумент2 страницыWPS Sampleeetua100% (1)

- Woodworking For Beginners Step-By-Step Gu - Tom FosterДокумент105 страницWoodworking For Beginners Step-By-Step Gu - Tom FosterLalu budi SetiawanОценок пока нет

- White and Colour WashingДокумент2 страницыWhite and Colour WashingAnonymous Qm0zbNkОценок пока нет

- K To 12 Basic Education Curriculum (Final)Документ9 страницK To 12 Basic Education Curriculum (Final)Lyn VallesОценок пока нет

- Vinnapas RE 5044 NДокумент2 страницыVinnapas RE 5044 NShambhatia100% (1)

- Actual Welding Records For Procedure Qualification Test As Per Asme Section IxДокумент2 страницыActual Welding Records For Procedure Qualification Test As Per Asme Section IxR.BALASUBRAMANIОценок пока нет

- CNC ReportДокумент39 страницCNC Reportrasaiya69% (13)

- Ejot WN-1451Документ1 страницаEjot WN-1451Diogo DoiОценок пока нет

- Cores, Chaplets and Chills: AdditivesДокумент10 страницCores, Chaplets and Chills: AdditivesGandi GahanОценок пока нет

- Ball Valve With Flanged Connections, Short Pattern, Welded FlangeДокумент1 страницаBall Valve With Flanged Connections, Short Pattern, Welded FlangecvfОценок пока нет

- 269 Sep 20 OkДокумент84 страницы269 Sep 20 Okgabriela100% (1)

- Weld Between Cf8A Stainless Steel Casting and Ni-Cr-Mo-V Forged Steel, With Ni-Cr-Fe Alloy Buttering. Practical CaseДокумент5 страницWeld Between Cf8A Stainless Steel Casting and Ni-Cr-Mo-V Forged Steel, With Ni-Cr-Fe Alloy Buttering. Practical CaseJose ManuelОценок пока нет

- Welding SymbolsДокумент28 страницWelding SymbolsPandu Pratama YudhaОценок пока нет