Академический Документы

Профессиональный Документы

Культура Документы

1 Lead

Загружено:

Sharif M Mizanur Rahman0 оценок0% нашли этот документ полезным (0 голосов)

11 просмотров5 страницabc

Оригинальное название

1 lead

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документabc

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

11 просмотров5 страниц1 Lead

Загружено:

Sharif M Mizanur Rahmanabc

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 5

Removal of Lead and Cadmium from Aqueous

Waste Streams Using Granular Activated Carbon

(GAC) Columns

Brian E. Reed and Selvam Arunachalam

Department of Civil and Environmental Engineering,

West Virginia University, Morgantown, WV 26506

and

Bob Thomas

Norit Americas Inc., 1050 Crown Pointe Parkway, Atlanta, GA 30338

The use of granular activated carbon ( GAC) columns to treat metal-bearing

wastewaters was investigated. Synthetic wastewaters containing Pb and Cd ( I0 or

50 mg/ L) , acetic acid (0.001 N ) or EDTA (1:O.I or 1:1 Me:EDTA molar ratios)

were studied. For metal-only and metal-acetic acid experiments, significant

quantities (as high as 325 bed volumes ( BV) ) of wastewater were treated prior

to breakthrough (Ce=0.03 Co). X/ M values were as high as about 30 mg Pb/g

carbon. For EDTA experiments, C, was always>0.03 C,. The amount of metal

not removed corresponded to the amount that was complexed by EDTA. Column

pH is the critical parameter influencing column performance. The increase in

effluent metal concentration corresponded with the decrease in column pH. GA C

columns were successfully regenerated using a 1 L ( = 8 B V) 0. I N HNO, rinse

followed by a I L 0.1 N NaOH rinse. Column performance was not adversely

affected by regeneration. When the regeneration step was used on virgin carbon,

a dramatic improvement in column performance was observed and was attributed

to the increase in carbon surface pH ( pH= II) and the deposition of OH- in the

pore liquid. Possible removal mechanism are precipitation on the carbon surface

and in the pore liquid, and adsorption.

INTRODUCTION

The presence of heavy metals in the environment is of major

concern because of their toxicity and threat to human life and

the environment. I n 1983, an estimated 7.9 billion gallons of

heavy metal-bearing wastewaters were generated in the U.S.

[I]. Lead, cadmium, and mercury are examples of heavy metals

that have been classified as priority pollutants by the U.S.

Environmental Protection Agency. Anthropogenic sources of

heavy metals include wastes from the electroplating and metal

finishing industries, metallurgical industry, tannery opera-

tions, chemical manufacturing, mine drainage, battery man-

ufacturing, leachates from landfills, and contaminated

groundwater from hazardous waste sites.

For wastes with high metal concentrations, precipitation

processes (e.g., hydroxide, sulfide) are the most economical.

However, many metal-bearing wastes contain substances, such

as complexing agents, that decrease the effectiveness of pre-

cipitation processes leading to relatively high metal concen-

trations in the effluent. In addition, the current regulatory

trend is for heavy metal discharge limits approaching those of

drinking water standards. Thus, additional treatment proc-

esses, downline from the precipitation process, may berequired

to polish the effluent prior to discharge. These tertiary

processes may also be the primary metal removal process for

waste streams having low concentrations of metals. Examples

of such processes are ion exchange, reverse osmosis, and ad-

sorption. Ion exchange and reverse osmosis, while effective in

producing an effluent low in metals, have high operation and

maintenance costs and are subject to fouling. Adsorption by

activated carbon is an established treatment method for organic

contaminants. Although the ability of activated carbons to

remove heavy metals has been established by numerous re-

searchers [2-6], they have not been used in an actual treatment

setting for inorganic adsorbates. The majority of these studies

were conducted in the batch mode. If activated carbon is to

be considered as a viable method for heavy metal removal,

additional information on its efficiency in the column mode

must be gathered.

The goal of this research was to demonstrate the efficacy

of using granular activated carbon (GAC) columns to treat

heavy-metal bearing waste streams. Lead and cadmium were

60 February, 1994

Environmental Progress (Vol. 13, No. 1)

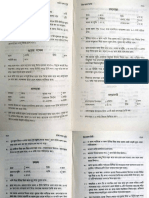

Table 1 Characteristics of Hydrodarco 4000

Surface Area (N2 BET Method), m2/g

Slurry pH

Ash Content, %

Molasses Number

Iodine Number

Mean Pore Radius, angstroms

Total Pore Volume, mL/g

Apparent Density, g/mL

Particle Density Wetted, g/mL

Mean Particle Diameter, mm

Effective Size

Uniformity Coefficient

Particle Size Distribution, U.S. Sieves

+12

12x 16

16 x 20

20 x 30

30 x 40

40 x 50

- 50

625

5.2

23

812

647

29

1.04

0.37

1.4

1.09

0.74

1.44

Percent

5.86

19.12

34.87

38.75

1.05

0.13

0.23

chosen as the study heavy metals because of their presence on

the USEPA priority pollutant list. Darco HD4000 (American

Norit Company, Inc.) was selected as the study activated car-

bon because the authors have investigated this carbon in earlier

work. Specific objectives of the research were to: 1) conduct

GAC column studies using synthetic waste streams containing

lead and cadmium, organic compounds (EDTA and acetic

acid), and different influent pH values, and 2) study the effect

of regeneration on GAC column performance.

METHODOLOGY

Lead and cadmium concentrations of 10 and 50 mg/L, were

used for each of three synthetic wastewaters investigated. The

characteristics of the column influents were as foIlows: 1) lead

or cadmium only at pHs of 4 (Pb only) and 5.4, 2)10-3 M

acetic acid at pH =4.7, and 3) EDTA at Me:EDTA molar

ratios of 1:O.l and 1:1, pH =5.4. Wastewaters 2 and 3 were

used to simulate wastes containing weak organic acids and

strong complexing agents, respectively. Lead and cadmium

were analyzed by flame atomic absorption spectrophotometry

using a Perkin-Elmer 2380 atomic absorption spectropho-

tometer. Samples were stored in polyethylene bottles and ac-

idified using concentrated HN03 immediately following sam-

pling. The pH was measured using a Fisher Scientific Accumet

mini pH meter (Model 640 A). All stock solutions were for-

mulated using reagent grade chemicals. Experiments were con-

ducted at an ionic strength of 0.01 (added as NaNO,) and a

temperature of about 22C. Hydrodarco 4000, the study ac-

tivated carbon, was supplied by Norit Americas Inc. Selected

characteristics of Hydrodarco 4000 are presented in Table 1.

Approximately 50 g (dry) of the carbon was weighed, sieved

through a U.S. No. 50 sieve, and washed with distilled water

to remove fines. The carbon was placed in 15 inch long, 1 .I25

inch inner diameter acrylic columns such that the formation

of air voids was minimized. Rounded stones and glass wool

were used as the column support media. The length of the

adsorptive bed was approximately 7.5 inches and the bed vol-

ume was 0.12 L. A hydraulic flow rate of 40 mL/min (6.24

cm3/cm2, 1.5 gal/ft*.min) was maintained using a Cole-Parmer

peristaltic pump with Masterflex speed controller. Columns

were operated in the up flow mode. Effluent samples were

InfIuent pH: 5.47

Dar co HD4000: 50 g

0. 8 -

0

0

U

2

0.4

0. 2

v Run 2

0 Run 3

A Run 4

0.0

0 100 200 300 400

Be d Volumea

1 2 , I I I I I

-

0 100 zoo 900 400

Be d Volumea

FIGURE 1. Breakthrough and effluent pH curves for 10

mglL Pb and pH =5.4.

collected either every 30 or 60 minutes, measured for pH, and

acidified. During the course of the column cycle (opera-

tion +regeneration) the volume and metal concentration of the

influent, effluent (including samples), and regenerants were

measured and used in mass balance calculations. Mass balance

results were used to calculate surface concentrations (X/M),

mass of metal removed, and desorption efficiencies. Following

each column run, carbon was regenerated using a procedure

consisting of 0.1 N HN03 and 0.1 N NaOH rinses.

Approximately 1 liter of 0.1 N HNO, was pumped through

the column at a flow rate of 10 mL/min. Samples of the acid

rinse were taken periodically and measured for pH and metal

content. This procedure was repeated using 1 liter of 0.1 N

NaOH. The 0.1 N NaOH remaining in the column after the

base rinse was allowed to contact the carbon for approximately

five days. The five day contact time was chosen strictly on

logistics (i.e., it was the minimum amount of time before the

new column run could begin). Following regeneration, the

column cycle was repeated. Depending on the experiment, the

column cycle was repeated either three or four times. Metal

removal dramatically increased following the first regeneration

step. Thus, in later experiments, the regeneration procedure

was used as a carbon pretreatment step for virgin carbon (i.e.,

before the first column run). Desorption efficiency was de-

termined using mass balance calculations.

RESULTS AND DISCUSSION

For ease of presentation, results from each of the synthetic

wastewaters are presented separately.

Environmental Progress (Vol. 13, No. 1)

February, 1994 61

1.0

0.8

50 mg/L Cadmium

Influent pH: 5.4

0.6 Carbon: 50 g

EBV: 0. 12 L

0 Run 1

v Run 2

o Run 3

0 50 100 150 200 250 300 350 400 450

Bed Volumes

0 50 100 150 200 250 300 350 400 450

Bed Volumes

FIGURE 2. Breakthrough and effluent pH curves for 5

mglL Cd and pH =5.4.

Metal-Only

Normalized effluent lead concentration (C,/C,) versus num-

ber of bed volumes (BV) treated for 10 mg/L, pH =5.47 are

presented in Figure 1. These curves will be referred to as break-

through curves for the remainder of this article. Breakthrough

was defined at C, =0.03 C,. Breakthrough occurred at about

50 BV for Run 1. Lead removal increased by approximately

600 percent following the 0.1 N HN03 - 0.1 NaOH N regen-

eration step. Based on the lead-only results, the regeneration

procedure was used as a pretreatment step for virgin carbon

for the remainder of the column experiments. Also presented

in Figure 1 is the effluent pH versus BV treated. Effluent pH

for Run 1 decreased from about 7 at the beginning of column

operation to 5.4 at the end. Initial effluent pH for Runs 2

through 4 were greater than 11 and decreased to about 8 at

breakthrough. Breakthrough and effluent pH curves for 50

mg/L Cd, pH =5.4 are presented in Figure 2. While the shape

of the breakthrough and pH curves are similar, much less

cadmium was removed compared to lead. In Table 2, a sum-

mary of column performance for the metal-only column studies

is presented.

It is hypothesized that lead was removed in greater quan-

tities, compared to cadmium, because of its solution chemistry.

Lead begins to form hydroxide species at pH =5 and forms

Pb(OH)* (s) at about pH =5.5 to 6 while, cadmium begins to

form hydroxide species at pH=8 and forms Cd(OH), (s) at

pH= 8.5 to 9. The lower the pH at which metal hydroxide

species form, the better the removal. Thus, it was expected

that lead would be better removed compared to cadmium.

Table 2 Summary of Column Performance for Metal-

Onlv ExDeriments

Influent BV Treated

10 mg/L Pb - pH =4

Run 1 40

Run 2 250

Run 3 240

Run 4 235

10 mg/L Pb - pH =5.4

Run 1 50

Run 2 325

Run 3 315

Run 4 300

Run 1 20

Run 2 110

Run 3 110

Run 4 110

Run 1 25

Run 2 125

Run 3 120

Run 4 120

10 mg/L Cd - pH =5.4

Run 1 80

Run 2 80

Run 3 80

Run 1 40

Run 2 40

Run 3 40

50 mg/L Pb - pH =4

50 mg/L Pb - pH =5.4

50 mg/L Cd - pH =5.4

Me Removed, X/M, mg

mg Me/g carbon

48 0.97

306 6.11

272 5.43

249 5.00

23 0.46

35 1 7.01

359 7.18

368 7.36

282 5.64

1280 25.6

1320 26.4

1370 27.4

341 6.81

1340 26.8

1440 28.7

1550 31.0

88 1.76

91 1.83

101 2.00

290 5.76

240 4.76

230 4.63

GAC columns were successfully regenerated using a rela-

tively simple procedure consisting of 1 liter (= 8 BV) rinses of

0.1 N HN03 and NaOH. Column performance was not ad-

versely affected by the regeneration procedure. The dramatic

improvement in column performance after the first regener-

ation is attributed to an increase in OH available for surface

and pore liquid precipitation as well as an increase in the

number of surface sites available for adsorption. The regen-

eration procedure as a pretreatment step for virgin carbon is

recommended.

Lead-Acetic Acid

Acetic acid was used to simulate a moderately acidic waste-

water such as a landfill leachate. Breakthrough and effluent

pH curves for 0.001 M acetic acid and 10 mg/L Pb and Cd

are presented in Figures 3 and 4, respectively. A summary of

column performance for acetic acid experiments is presented

in Table 3.

Approximately 120 BV of 10 mg/L Pb and 70 BV of 50

mg/L Pb were treated at breakthrough for each of the three

column runs. The presence of acetic acid caused a deterioration

of the column performance compared to the lead-only exper-

iments. Because of differences in influent pH, it is not possible

to directly compare the two systems. However, if results for

the lead-only system are interpolated to pH =4.7, the presence

of acetic acid decreased the BV treated by about two-thirds

for 10 mg/L and one-third for 50 mg/L. As in the lead-only

column studies, the deterioration in column performance co-

incided with the rapid drop in column pH. The increase in

waste acidity accelerated this phenomenon and caused break-

through to occur earlier than in the lead-only experiments. At

10 mg/L Pb, the run number did not appear to effect column

performance. For 50 mg/L Pb, the BV treated, mass of lead

62 February, 1994 Environmental Progress (Vol. 13, No. 1)

2.2

, I I I I

0. 6

0.4

0.2

2.0

1.0

1.6

1.4

Q 1.2

u 1.0

0. 8

0.6

0.4

0.2

0.0

U

2

-

-

-

Influent pH: 4. 7

0.001 M CH,COOH

Darco HD4 0 0 0 : 50 g

BV: 0.12 L

0 100 200 so0 400

Bed Volumes

g 10

4

*

2 6

A

0 100 200 a00 400

Bed Volumer

FIGURE 3. Breakthrough and effluent pH curves for 10

mglL Pb, 0.001 M acetic acid, and pH =4.7.

removed, and lead surface concentration decreased slightly

after Run 1 but, were constant for Runs 2 and 3. Exhaustion

of the columns (defined as the point where the breakthrough

curve first intersects the CJC, =1 line) occurred between 150

and 175 BV for 10 mg/L and between 100 and 120 BV for 50

mg/L Pb. At exhaustion, effluent and influent pH were equal

The presence of acetic acid did not appear to significantly

affect cadmium removal compared to the cadmium-only sys-

(pH =4.7).

Y v B

10 mg/L Cadmium

Influent pH: 4.7

0.001 M CH,COOH

Carbon: 50 g

BV: 0.12 L

v Run 2

0 Run 3

0 50 100 150 200 250 300 350 400 450

Bed Volumes

FIGURE 4. Breakthrough and effluent pH curves for 10

mglL Cd, 0.001 M acetic acid, and pH =4.7.

tems. It is unclear why the increase acidity (via acetic acid) did

not decrease removal. Possibly, the solution chemistry of cad-

mium played a role. In the future, additional research will be

conducted to shed light on this phenomenon.

For both lead and cadmium, desorption occurred as the

column pH decreased. For metals present in cationic form,

Table 3 Summary of Column Performance for Metal-Acetic Acid Experiments

Influent BV Treated' Me Removed', mg X/M', mg Me/g carbon

10 mg/L Pb - pH =4.7

Run 1 120; 155

Run 2 100; 145

Run 3 120; 170

Run 1 75; 120

Run 2 70; 110

Run 3 70; 110

10 mg/L Cd- pH=4. 7

Run 1 80; 120

Run 2 75; 110

Run 3 70; 120

Run 1 40; 95

Run 2 40; 90

Run 3 40; 115

50 mg/L Pb - pH =4.7

50 mg/L Cd - pH =4.7

' First number at breakthrough; second number at exhaustion.

127; 162

129; 153

149; 179

483; 626

421; 522

416; 523

87; 110

80; 100

78; 106

225; 350

175; 320

240; 375

2.55; 3.23

2.57; 3.06

2.97; 3.58

9.66; 12.5

8.42; 10.4

8.32; 10.5

1.73; 2.20

1.59; 2.00

1.56; 2.13

4.50; 7.00

3.50; 6.43

4.77; 7.53

Environmental Progress (Vol. 13, No. 1) February, 1994 63

10 mg/L Lead

Influent pH: 5.47

Pb:EDTA 1:O.l

Darco HD4000: 50 g

BV: 0. 12 L

0

V

\

V

0.2 1

v Run 2

0 Run 3

0. 0 I I

I I I I

0 100 200 so0 400

Bed Volumes

i

4

0 100 200 300 400

Bed Volumes

FIGURE 5. Breakthrough and effluent pH curves for 10

mglL Pb, Pb:EDTA ratio of l:O.l, and pH =4.7.

adsorption decreases with a decrease in pH. Thus, as the col-

umn pH decreased towards the influent pH (pH =4.7), metal

desorbed from the carbon. Cadmium desorbs at a higher pH

compared with lead because Cd2' is formed at a higher pH

(as was discussed earlier, Me2+is less adsorbable than

Me(OH)+) and, Cd(OH);! (s) dissolves at a higher pH compared

to Pb(OH);! (s). It is apparent that solution chemistry plays a

key role in metal removal by activated carbon.

Lead-EDTA

Breakthrough and effluent pH curves for 10 mg/L Pb at a

Pb:EDTA molar ratio of 1:O.l are presented in Figure 5 . For

all runs, C, was greater than 0.03C0 at the beginning of the

column run. Thus, based on the definition of breakthrough,

zero BV were treated. According to thermodynamic calcula-

tions, 10 percent of the lead forms complexes with EDTA at

this pb:EDTA molar ratio. For the entire column run about

10 percent of the lead was not removed. Thus, it is hypothesized

that the Pb-EDTA complex was not adsorbed by the carbon.

Similar results were observed for the Pb:EDTA molar ratio

of 1 : 1 and Cd:EDTA molar ratios of 1 :O. 1 and 1 : 1.

CONCLUSIONS

Significant quantities of metal-bearing wastewaters were

treated using GAC columns. Column pH and influent char-

acteristics appear to be the critical parameters influencing GAC

column performance. The sudden increase in the column ef-

fluent lead concentration corresponded noticeably with a de-

crease in the effluent pH. Acetic acid at 0.001 M decreased

column performance compared with the lead-only experiments

but large amounts of lead were still removed from solution.

It is hypothesized that acetic acid reacted with the carbon

associated OH- (on the surface and in the pore liquid), which

produced a more rapid decrease in column pH and a subsequent

decrease in lead removal. The presence of EDTA adversely

affected column performance most likely because of solution

complexation. Wastewaters containing strong complexing

agents will either have to undergo pretreatment prior to en-

tering the GAC column or an activated carbon that adsorbs

the organic-metal complexes will have to be identified.

GAC columns were successfully regenerated using a rela-

tively simple procedure consisting of 1 liter (= 8 BV) rinses of

0.1 N HNO, and NaOH. Column performance was not ad-

versely affected by the regeneration procedure. When the re-

generation step was used on virgin carbon, a dramatic

improvement in column performance was observed. This was

attributed to an increase in OH- available for surface and pore

liquid precipitation as well as an increase in the number of

surface sites available for adsorption. The use of the regen-

eration procedure as a pretreatment step for virgin carbon is

recommended. Given the encouraging performance of the GAC

columns in treating several lead wastewaters and the relative

ease of column regeneration, the use of GAC columns to treat

metal-bearing waste streams should be considered.

LITERATURE CITED

1. Grosse, D. W., JournalAir Polhtion ControlAssociation,

36, p. 683, (1986).

2. Reed, B. E., and Matsumoto, M. R., Journal of Envi-

ronmental Engineering Division, ASCE, 119(2), p. 332,

(1993).

3. Reed, B. E., and Nonavinakere, S. K., Separation Science

and Technology, 27(14), p. 1985, (1992).

4. Corapcioglu, M. O., and Huang, C. P., Water Research,

9(9), p. 1031, (1987).

5 . Netzer, A., and Hughes, D. E., Water Research, 18(8),

p. 927, (1984).

6. Huang, C. P., and Ostovic, F. B., Journal of Environ-

mentalEngineering Division, ASCE, 104(5), p. 863, (1978).

64 February, 1994 Environmental Progress (Vol. 13, No. 1)

Вам также может понравиться

- Chemical Treatment Options For Tannery Wastewater: Shaikh Obaidullah Al MahmoodДокумент6 страницChemical Treatment Options For Tannery Wastewater: Shaikh Obaidullah Al MahmoodShaikh Obaidullah Al MahmoodОценок пока нет

- Effect of Alkali Treatment On Heavy Metals Adsorption Capacity of Sewage SludgeДокумент7 страницEffect of Alkali Treatment On Heavy Metals Adsorption Capacity of Sewage SludgeMuhanned AljeboryОценок пока нет

- Iron Foulingcase2 - 2009729103712Документ10 страницIron Foulingcase2 - 2009729103712dassagraОценок пока нет

- Bioremediation of Lead and Cadmium by Tea Waste: Sreedevi.P, Parameswari C.SДокумент5 страницBioremediation of Lead and Cadmium by Tea Waste: Sreedevi.P, Parameswari C.SIOSRjournalОценок пока нет

- The Parable of The PipelineДокумент4 страницыThe Parable of The PipelineRudraОценок пока нет

- Speciation of heavy metals in sewage sludge co-compostedДокумент7 страницSpeciation of heavy metals in sewage sludge co-compostedCristian CarrascoОценок пока нет

- Heavy Metal RemovalДокумент4 страницыHeavy Metal RemovalBhinitha ChandrasagaranОценок пока нет

- Adsorp Cu Sekam PadiДокумент7 страницAdsorp Cu Sekam PadiDinda JuwitaОценок пока нет

- Determination Foods eДокумент7 страницDetermination Foods eRoberta MatosОценок пока нет

- Research Article: Effect of Oxidizing Decontamination Process On Corrosion Property of 304L Stainless SteelДокумент7 страницResearch Article: Effect of Oxidizing Decontamination Process On Corrosion Property of 304L Stainless Steelmihaela_filip_8Оценок пока нет

- Bekta 2004Документ12 страницBekta 2004Dwi suparwatiОценок пока нет

- 12.study On The Removal of PB (II) Ions From Aqueous Solution Using Chemically Modified Corn Cob. (Siti Raihan Zakaria) PP 74-81Документ8 страниц12.study On The Removal of PB (II) Ions From Aqueous Solution Using Chemically Modified Corn Cob. (Siti Raihan Zakaria) PP 74-81upenapahangОценок пока нет

- Heavy Metal Analysis of Wastewater Using AASДокумент14 страницHeavy Metal Analysis of Wastewater Using AASMuhamad Alif AdamОценок пока нет

- Heavy Metal Separation Using Modified Amberlite ResinДокумент31 страницаHeavy Metal Separation Using Modified Amberlite ResinVestineoОценок пока нет

- Ultrasound-Assisted Solubilization of Trace and Minor Metals From Plant Tissue Using Ethylenediaminetetraacetic Acid in Alkaline MediumДокумент6 страницUltrasound-Assisted Solubilization of Trace and Minor Metals From Plant Tissue Using Ethylenediaminetetraacetic Acid in Alkaline MediumImad AghilaОценок пока нет

- Navratil 2003 PDFДокумент4 страницыNavratil 2003 PDFwameath0% (1)

- Surface Modification of A Granular Activated Carbon by CitriДокумент9 страницSurface Modification of A Granular Activated Carbon by CitriAnonymous ggzcpPM4Оценок пока нет

- Bagasse Fly Ash Removes Copper & CadmiumДокумент25 страницBagasse Fly Ash Removes Copper & CadmiumSatyamGuptaОценок пока нет

- Method CarbonДокумент12 страницMethod CarbonPépé TechopathamОценок пока нет

- Study of Mechanisms of Manganese Removal From Leachates: G. Bazdanis, D. Zaharaki and K. KomnitsasДокумент6 страницStudy of Mechanisms of Manganese Removal From Leachates: G. Bazdanis, D. Zaharaki and K. KomnitsasIoannis KapageridisОценок пока нет

- Study On Decolorization of Methylene Blue by H2O2 Catalyzed With IronДокумент6 страницStudy On Decolorization of Methylene Blue by H2O2 Catalyzed With IrondumitriuОценок пока нет

- Hydrometallurgical recovery of metals from flue dustДокумент6 страницHydrometallurgical recovery of metals from flue dustGeorgi SavovОценок пока нет

- Electrochemical treatment of landfill leachateДокумент4 страницыElectrochemical treatment of landfill leachateAsif Fareed QaisraniОценок пока нет

- Sulfate Removal From Coal Mine Water in Western Pennsylvania: Regulatory Requirements, Design, and Performance 1Документ22 страницыSulfate Removal From Coal Mine Water in Western Pennsylvania: Regulatory Requirements, Design, and Performance 1Nova Novrita TokyoОценок пока нет

- Bruno, CaselliДокумент6 страницBruno, CaselliYury Andrea MartinezОценок пока нет

- Aq Solutions ClinoptiloliteДокумент14 страницAq Solutions ClinoptiloliteJoe ForbesОценок пока нет

- Removal of Copper (II) From Wastewater Using Modified Carbon Nanotubes of CooperДокумент14 страницRemoval of Copper (II) From Wastewater Using Modified Carbon Nanotubes of CooperAyad DariОценок пока нет

- Adsorption of Nickel in Water by Brown Algae: Laminaria Japonica and Undaria PinnatifidaДокумент3 страницыAdsorption of Nickel in Water by Brown Algae: Laminaria Japonica and Undaria PinnatifidaRakesh SHОценок пока нет

- Removal of Lead (II) and Copper (II) From Aqueous Solution Using Pomegranate Peel As A New AdsorbentДокумент3 страницыRemoval of Lead (II) and Copper (II) From Aqueous Solution Using Pomegranate Peel As A New AdsorbentDea AlvichaОценок пока нет

- Competition and Complexation of Heavy Metal Ions and Humic Acid On Zeolitic MCM-22 and Activated CarbonДокумент8 страницCompetition and Complexation of Heavy Metal Ions and Humic Acid On Zeolitic MCM-22 and Activated CarbonMurat AkdoğanОценок пока нет

- Physico-Chemical Method For Ammonia Removal From Synthetic Wastewater Using Limestone and GAC in Batch and Column StudiesДокумент7 страницPhysico-Chemical Method For Ammonia Removal From Synthetic Wastewater Using Limestone and GAC in Batch and Column StudiesArash AbbasiОценок пока нет

- Removal of Heavy Metals by Cement Kiln Dust: M. H. El-Awady, T. M. SamiДокумент2 страницыRemoval of Heavy Metals by Cement Kiln Dust: M. H. El-Awady, T. M. SamiMargabrielОценок пока нет

- Analytical &: Phosphorous Removal From Wastewater Effluent Using Electro-Coagulation by Aluminum and Iron PlatesДокумент13 страницAnalytical &: Phosphorous Removal From Wastewater Effluent Using Electro-Coagulation by Aluminum and Iron PlatesHamed8665Оценок пока нет

- Pengolahan Limbah Campuran Logam Fe, Cu, Ni Dan Amonia Menggunakan Metode Flotasi-Filtrasi Dengan Zeolit Alam LampungДокумент5 страницPengolahan Limbah Campuran Logam Fe, Cu, Ni Dan Amonia Menggunakan Metode Flotasi-Filtrasi Dengan Zeolit Alam LampungNurhayatun NafsiyahОценок пока нет

- Kinetics and Equilibrium Adsorption Study of Lead (II) Onto Activated Carbon Prepared From Coconut ShellДокумент7 страницKinetics and Equilibrium Adsorption Study of Lead (II) Onto Activated Carbon Prepared From Coconut ShellsureshbabuchallariОценок пока нет

- Characterization of Hydroxybenzoic Acid Chelating Resins: Equilibrium, Kinetics, and Isotherm Profiles For CD (II) and PB (II)Документ32 страницыCharacterization of Hydroxybenzoic Acid Chelating Resins: Equilibrium, Kinetics, and Isotherm Profiles For CD (II) and PB (II)TailorriteshОценок пока нет

- Escobar 2006Документ8 страницEscobar 2006Risanto WibowoОценок пока нет

- Ziegler KJ 2003bДокумент6 страницZiegler KJ 2003bRiyasath ReihanОценок пока нет

- Optimization of Brine Leaching of Metals From Hydrometallurgical ResidueДокумент6 страницOptimization of Brine Leaching of Metals From Hydrometallurgical ResidueEkawatiОценок пока нет

- Determination of CD and PB in Seawater by Graphite Furnace Atomic Absorption Spectrometry With The Use of Hydrofluoric Acid As A Chemical ModifierДокумент12 страницDetermination of CD and PB in Seawater by Graphite Furnace Atomic Absorption Spectrometry With The Use of Hydrofluoric Acid As A Chemical ModifierIvan SotoОценок пока нет

- Catalytic Ammonia Decomposition Over Ru Carbon CatalystsДокумент7 страницCatalytic Ammonia Decomposition Over Ru Carbon CatalystsLuong NguyenОценок пока нет

- 2019 XANTHATED COAL AS A LEAD CATION EXCHANGER Tche QuimДокумент12 страниц2019 XANTHATED COAL AS A LEAD CATION EXCHANGER Tche QuimRoberto FernandezОценок пока нет

- Adsorption of Crystal Violet Dye onto ZeolitesДокумент13 страницAdsorption of Crystal Violet Dye onto ZeolitessamsudinhafidОценок пока нет

- 075e PDFДокумент8 страниц075e PDFJaberОценок пока нет

- Gold recovery from hydrochloric solutions using ion exchange resinДокумент10 страницGold recovery from hydrochloric solutions using ion exchange resinEliomar Moura Jr.Оценок пока нет

- Metales Pesados 1999-03-03Документ7 страницMetales Pesados 1999-03-03William EliezerОценок пока нет

- Referensi FotofentonДокумент5 страницReferensi FotofentonNurillahi Febria LeswanaОценок пока нет

- Recovery of Silver From The Nitrate Leaching SolutionДокумент5 страницRecovery of Silver From The Nitrate Leaching SolutionPablo Arrien OportoОценок пока нет

- Uptake of trivalent chromium from aqueous solutions using protonated dry alginate beadsДокумент8 страницUptake of trivalent chromium from aqueous solutions using protonated dry alginate beadsSebastian Andres Zapata AhumadaОценок пока нет

- Adsorption of Silver Onto Activated Carbon From Acidic Media: Nitrate and Sulfate MediaДокумент8 страницAdsorption of Silver Onto Activated Carbon From Acidic Media: Nitrate and Sulfate MediaAtchaya அட்சயாОценок пока нет

- Synthesis and Characterization of Polysaccharide Cation Exchange ResinДокумент6 страницSynthesis and Characterization of Polysaccharide Cation Exchange ResinSameera PatelОценок пока нет

- Extraction of Lithium by HFДокумент24 страницыExtraction of Lithium by HFTalexandra PatienceОценок пока нет

- 14 CodДокумент4 страницы14 Codtfgrn7srtqОценок пока нет

- 10 1007-BF02706737Документ6 страниц10 1007-BF02706737alinoriОценок пока нет

- ALUM - SULFATE - JSCT - v15-20Документ7 страницALUM - SULFATE - JSCT - v15-20Noureddine MerahОценок пока нет

- Aireacion y Hierro PDFДокумент5 страницAireacion y Hierro PDFAlvaro DelgadoОценок пока нет

- Characterization of Mesoporous Activated Carbons Prepared by Pyrolysisnext Term of Sewage Sludge With PyrolusiteДокумент5 страницCharacterization of Mesoporous Activated Carbons Prepared by Pyrolysisnext Term of Sewage Sludge With PyrolusiteyemresimsekОценок пока нет

- Adsorption Characteristics of Spent Co As An Alternative Adsorbent For Cadmium in SolutionДокумент12 страницAdsorption Characteristics of Spent Co As An Alternative Adsorbent For Cadmium in Solutionhaneen radОценок пока нет

- Ion Exchange Resins and Adsorbents in Chemical Processing: Second EditionОт EverandIon Exchange Resins and Adsorbents in Chemical Processing: Second EditionРейтинг: 5 из 5 звезд5/5 (1)

- Reactive Transport Modeling: Applications in Subsurface Energy and Environmental ProblemsОт EverandReactive Transport Modeling: Applications in Subsurface Energy and Environmental ProblemsYitian XiaoОценок пока нет

- 03 Practical ApplicationДокумент1 страница03 Practical ApplicationSharif M Mizanur RahmanОценок пока нет

- Chicken Grill RecipeДокумент1 страницаChicken Grill RecipeSharif M Mizanur RahmanОценок пока нет

- Diabetic Cooking RecipesДокумент43 страницыDiabetic Cooking Recipesmoro4500Оценок пока нет

- Meraj and ScienceДокумент93 страницыMeraj and ScienceSharif M Mizanur RahmanОценок пока нет

- Black Holes: Warped Spacetime and Gravitational WavesДокумент10 страницBlack Holes: Warped Spacetime and Gravitational WavesSharif M Mizanur RahmanОценок пока нет

- Lectures 1-9 History and Philosophy of Science and TechnologyДокумент59 страницLectures 1-9 History and Philosophy of Science and TechnologyZaky IbenОценок пока нет

- History of Science Fullversion PDFДокумент70 страницHistory of Science Fullversion PDFSharif M Mizanur RahmanОценок пока нет

- Respiration HandoutДокумент9 страницRespiration HandoutSharif M Mizanur RahmanОценок пока нет

- Ethanolfromcornstarch PDFДокумент44 страницыEthanolfromcornstarch PDFDerrick Scott FullerОценок пока нет

- FISHYFRIEEДокумент1 страницаFISHYFRIEESharif M Mizanur RahmanОценок пока нет

- Kyokushin Karate Complete GuideДокумент129 страницKyokushin Karate Complete Guidemalarem67% (3)

- FISHYДокумент1 страницаFISHYSharif M Mizanur RahmanОценок пока нет

- Kyokushin TerminologieДокумент13 страницKyokushin TerminologieSharif M Mizanur RahmanОценок пока нет

- Tanning KnowlegeДокумент5 страницTanning KnowlegeAnwar SuliantoОценок пока нет

- s40550 016 0045 3Документ9 страницs40550 016 0045 3Kate MaryОценок пока нет

- Fakruddin Recipe BiryaniДокумент1 страницаFakruddin Recipe BiryaniSharif M Mizanur RahmanОценок пока нет

- Ranna Khaddo O Pusti by Siddika Kabir Part 3 (p310-p429)Документ60 страницRanna Khaddo O Pusti by Siddika Kabir Part 3 (p310-p429)Sharif M Mizanur RahmanОценок пока нет

- Diabetic Cooking RecipesДокумент43 страницыDiabetic Cooking Recipesmoro4500Оценок пока нет

- Development of An ASPEN PLUSДокумент36 страницDevelopment of An ASPEN PLUSkiny81Оценок пока нет

- CARFAX Vehicle History Report For This 2007 TOYOTA COROLLAДокумент6 страницCARFAX Vehicle History Report For This 2007 TOYOTA COROLLASharif M Mizanur RahmanОценок пока нет

- Energy Guide Refrig - 2265225Документ2 страницыEnergy Guide Refrig - 2265225Sharif M Mizanur RahmanОценок пока нет

- Recipe For HealthДокумент1 страницаRecipe For HealthSharif M Mizanur RahmanОценок пока нет

- Recipetehari PDFДокумент153 страницыRecipetehari PDFSharif M Mizanur RahmanОценок пока нет

- PRON 25 WordsДокумент1 страницаPRON 25 WordsSharif M Mizanur RahmanОценок пока нет

- Ge Strategies For Protein PurificationДокумент167 страницGe Strategies For Protein PurificationSharif M Mizanur RahmanОценок пока нет

- Ranna Khaddo O Pusti by Siddika Kabir Part 2 (p190-p309)Документ60 страницRanna Khaddo O Pusti by Siddika Kabir Part 2 (p190-p309)Sharif M Mizanur RahmanОценок пока нет

- U.S. Meat Goat Operations: Veterinary ServicesДокумент4 страницыU.S. Meat Goat Operations: Veterinary ServicesSharif M Mizanur RahmanОценок пока нет

- Isoa Hea OMPASS - 2016 - 2017 PDFДокумент13 страницIsoa Hea OMPASS - 2016 - 2017 PDFSharif M Mizanur RahmanОценок пока нет

- Ranna Khaddo O Pusti by Siddika Kabir Part 1 (p50-p189)Документ73 страницыRanna Khaddo O Pusti by Siddika Kabir Part 1 (p50-p189)Sharif M Mizanur RahmanОценок пока нет

- Ranna Khaddo O Pusti by Siddika Kabir Part 4 (p430-p524)Документ48 страницRanna Khaddo O Pusti by Siddika Kabir Part 4 (p430-p524)Sharif M Mizanur Rahman0% (1)

- Lab Manual 11 Infrared SpectrosДокумент5 страницLab Manual 11 Infrared SpectrosLuca Selva CampobassoОценок пока нет

- Adventist University of The Philippines College of Dentistry Day 2 Set 6 Anesthesiology and PharmacologyДокумент58 страницAdventist University of The Philippines College of Dentistry Day 2 Set 6 Anesthesiology and PharmacologyRC DomeОценок пока нет

- Maintenance of A Coal Fired Power PlantДокумент11 страницMaintenance of A Coal Fired Power PlantRuel Agon Jr.100% (1)

- Synthesis of Cesium Octacyanomolybdate (V) - and Cesium Cyanotungstate (V) Dihydrate: A More Successful Method OctaДокумент3 страницыSynthesis of Cesium Octacyanomolybdate (V) - and Cesium Cyanotungstate (V) Dihydrate: A More Successful Method OctaDabasish DekaОценок пока нет

- Studies On Degradation of Synthetic Polymer Nylon 6 by FungusДокумент8 страницStudies On Degradation of Synthetic Polymer Nylon 6 by FungusTiten PinastiОценок пока нет

- 2023 Liu JCleanerProdДокумент14 страниц2023 Liu JCleanerProdNgô Ích SơnОценок пока нет

- Who Took Jerell'S Ipod? - An Organic: Compound MysteryДокумент8 страницWho Took Jerell'S Ipod? - An Organic: Compound Mysteryakm1187Оценок пока нет

- Philips NMR and MRIДокумент98 страницPhilips NMR and MRItsram90Оценок пока нет

- Importance of biochemistry for nursing studentsДокумент2 страницыImportance of biochemistry for nursing studentsKathrina CraveОценок пока нет

- BS 4660Документ17 страницBS 4660danferreiro8318Оценок пока нет

- Set 2 MSДокумент7 страницSet 2 MSsanjith4arisОценок пока нет

- D 5117 - 96 - Rduxmtctukve PDFДокумент4 страницыD 5117 - 96 - Rduxmtctukve PDFchabibОценок пока нет

- Biology For QLD An Aust Perp 3E Units1!2!9780190310219 Sample Chapter 3 Low Res SecureДокумент38 страницBiology For QLD An Aust Perp 3E Units1!2!9780190310219 Sample Chapter 3 Low Res SecureRocil Clyde LumbayОценок пока нет

- Jess 106Документ16 страницJess 106Tej Krishan SinghОценок пока нет

- EP0070932B1Документ5 страницEP0070932B1bayuОценок пока нет

- TestДокумент94 страницыTestmutiaraОценок пока нет

- Identification and Quantification of Secondary Metabolites .. - PDFДокумент16 страницIdentification and Quantification of Secondary Metabolites .. - PDFAmandaОценок пока нет

- Physical Properties of SolutionДокумент3 страницыPhysical Properties of SolutionRhye Tabaday LopezОценок пока нет

- Effect of Preparation Method of Ni Catalyst Using Bentonite As The Support MaterialДокумент8 страницEffect of Preparation Method of Ni Catalyst Using Bentonite As The Support MaterialNastitiОценок пока нет

- Turbocharger Service InstructionsДокумент4 страницыTurbocharger Service Instructionskarol1177Оценок пока нет

- Patterns of Electron Flow Through Light Reaction EventsДокумент25 страницPatterns of Electron Flow Through Light Reaction EventsMar'JОценок пока нет

- Basic Inorganic ChemistryДокумент20 страницBasic Inorganic ChemistryOMED gardiОценок пока нет

- Progress in Polyethylene Terephthalate RecyclingДокумент24 страницыProgress in Polyethylene Terephthalate RecyclingyuppeОценок пока нет

- Cyanide-Free Gold Ore Dressing Agent PDFДокумент13 страницCyanide-Free Gold Ore Dressing Agent PDFAldemar Arciniegas100% (1)

- Neutralization Titrations in A Aqueous SolutionsДокумент4 страницыNeutralization Titrations in A Aqueous SolutionsUgur ASİT100% (2)

- Air Pollution Control Technology Fact Sheet: EPA-452/F-03-017Документ0 страницAir Pollution Control Technology Fact Sheet: EPA-452/F-03-017widhisaputrawijayaОценок пока нет

- Research Paper March 10 2019Документ12 страницResearch Paper March 10 2019vincent jancarlo ricarteОценок пока нет

- Int Esws at Y9 Workbook Answers TTPPДокумент37 страницInt Esws at Y9 Workbook Answers TTPPChrystal GraceОценок пока нет

- Hardtop Ultra Comp AДокумент13 страницHardtop Ultra Comp Anuryati jahariОценок пока нет

- EndocrineДокумент3 страницыEndocrinePotato HeadОценок пока нет