Академический Документы

Профессиональный Документы

Культура Документы

Sap Centric Eam 20060224

Загружено:

Oscar Andres Agudelo Medina0 оценок0% нашли этот документ полезным (0 голосов)

161 просмотров39 страницUse SAP PM to capture quality equipment reliability data Tony Ciliberti, PE Dan MacPherson Canadian Nexen Petroleum Yemen Presentation - technical concepts - Tony - process changes and SAP configuration - Key take-aways. Fundamentals of ISO 14224 - How to capture ISO 14224 with SAP PM - BP for SAP PM technical objects and technical object structures.

Исходное описание:

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документUse SAP PM to capture quality equipment reliability data Tony Ciliberti, PE Dan MacPherson Canadian Nexen Petroleum Yemen Presentation - technical concepts - Tony - process changes and SAP configuration - Key take-aways. Fundamentals of ISO 14224 - How to capture ISO 14224 with SAP PM - BP for SAP PM technical objects and technical object structures.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

161 просмотров39 страницSap Centric Eam 20060224

Загружено:

Oscar Andres Agudelo MedinaUse SAP PM to capture quality equipment reliability data Tony Ciliberti, PE Dan MacPherson Canadian Nexen Petroleum Yemen Presentation - technical concepts - Tony - process changes and SAP configuration - Key take-aways. Fundamentals of ISO 14224 - How to capture ISO 14224 with SAP PM - BP for SAP PM technical objects and technical object structures.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 39

2006 Eventure Events. All rights reserved.

Use SAP PM to Capture

Quality

Equipment Reliability Data

Tony Ciliberti, PE

Dan MacPherson

Canadian Nexen Petroleum Yemen

Presentation

Technical concepts Tony

Process changes and SAP configuration - Dan

Key learning topics/take-aways

Fundamentals of ISO 14224

How to capture ISO 14224 with SAP PM

BP for SAP PM technical objects and technical object structures

ISO standards referenced

ISO 14224, Petroleum and natural gas industries Collection

and exchange of reliability and maintenance data for equipment

ISO 15926, Industrial automation systems and integration

Integration of life-cycle data for process plants including oil and

gas production facilities.

Agenda and ISO References

Nexen and SAP

Nexen, Inc

Global oil and gas company with 3000+ employees

and annual revenues of US$2.9 billion

SAP

First go-live in January 2002 (version 4.6C)

Global implementation with shared system

configuration and design

PM system has

Common order and notification types

Unique technical object structures and classifications

Reasons for change

Incomplete and disparate equipment characteristic,

reliability, and cost data

Data mining required for maintenance analyses

Key changes

1.Standardize technical object structures

2.Capture detailed equipment characteristic and

reliability data with taxonomy

3.Modify work processes to facilitate complete,

efficient, and accurate data capture

Changes at Nexen

Change 1: Standardize Technical Object

Structures

Define rules for technical

object configuration and

classification.

Functional area location (FAL)

versus functional equipment

location (FEL)

Functional physical object vs.

materialized physical object

FEL vs. primary equipment

vs. sub-equipment

Explicitly define ISO 14224

equipment unit boundaries

with technical objects

SAP Functional Location Hierarchy

Purpose/Objectives

Represent an enterprises

locations and functions

completely, logically, and

consistently

Catalog technical objects

Flexible structure to

accommodate both

simple and complex

facilities

Facilitate data capture per

ISO 14224 and data

exchange per ISO 15926

FAL Class P1

YEM-CPF-CPP-CP1

Power Plant 1

FAL - Class P2

YEM-CPF-CPP-CP1-YPG

CP1 Power Generation Packages

FAL Class P3

YEM-CPF-CPP-CP1-YPG-DG1

Wartsila 1 Power Generation Package

FAL- Class P2

YEM-CPF-CPP-CP1-ANC

Power Plant 1 Ancillary Equipment

FAL- Class EC

YEM-CPF-CPP-CP1-ANC-HEX

CP1 Ancillary Equipment Exchangers

FEL- Class EU

YEM-CPF-CPP-CP1-ANC-HEX-001

CP1 Swamp Cooler 1

P&ID Tag Y-91131

FEL Class EU

YEM-CPF-CPP-CP1-YPG-DG1-001

Wartsila 1 Reciprocating Engine

P&ID Tag RE-91101

FAL Class EC

YEM-CPF-CPP-CP1-YPG-DG1-PMP

Wartsila 1 Pumps

FAL Class EA

YEM-CPF-CPP-CP1-YPG-DG1-PMP-LUB

Wartsila 1 Lube Oil Pumps

FEL Class EU

YEM-CPF-CPP-CP1-YPG-DG1-PMP-LUB-001

Wartsila 1 Prelube Oil Pump

P&ID Tag P-91151

SAP Functional Location Structure:

Hierarchical Asset Catalog

Functional Location Template (XXX-XXX-XXX-XXX-XXX-XXX-XXX-XXX-XXX)

M/O

1

Class

2

Node Example

3

Node Type

M BU Business Unit Entity YEM Business and process area FAL

M FC Facility CPF

O P1 Plant Level 1 CPP

O P2 Plant Level 2 CP1

O P3 Plant Level 3 YPG

O P4 Plant Level 4 DG1

O EC Equipment Class PMP ISO 14224

O ET Equipment Type

Equipment characteristic

O EA Equipment Application

Process characteristic

M EU Equipment Unit 001 ISO 14224 FEL

1.M/O Mandatory/Optional for equipment installation (nine levels maximum)

2.Additional plant levels are permissible

3.Abbreviations should be standardized

Functional versus Materialized Object

FEL SAP Primary Equipment

FAL Class P4

YEM-CPF-CPP-CP1-YPG-DG1

Wartsila 1 Power Generation Package

FEL Class EU

YEM-CPF-CPP-CP1-YPG-DG1-001

Wartsila 1 Reciprocating Engine

P&ID Tag RE-91101

FAL Class EC

YEM-CPF-CPP-CP1-YPG-DG1-PMP

Wartsila 1 Pumps

FAL Class EA

YEM-CPF-CPP-CP1-YPG-DG1-PMP-LUB

Wartsila 1 Lube Oil Pumps

FEL Class EU

YEM-CPF-CPP-CP1-YPG-DG1-PMP-LUB-001

Wartsila 1 Prelube Oil Pump

P&ID Tag P-91151

Materialized Physical Object

Pump Serial No. 1234

<Specification of Capabilities>

Functional Physical Object

<Specifications of Functional

Requirements>

FAL vs. FEL vs. Primary Equipment

FAL is a

grouping level

FEL is an equipment

installation location

and equivalent to a

functional physical

object

Class identifies

hierarchy node

Capabilities of

materialized

physical object

must meet or

exceed functional

requirements at its

installation point

Cardinality is 1:1

ISO 14224 Equipment Hierarchy

Comb. Engine i

Comb. Engine 1

Comb. Engine 3

Comb. Engine n

Comb. Engine 2

FPO/FEL

MPO/SAP

primary EQ

SAP sub-equipment

and catalog codes

Some maintainable items

are ISO equipment class

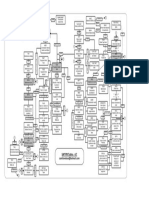

Decision Logic for FEL, Primary

Equipment, and Sub-equipment Objects

End

When the

parent equipment unit

is removed, is the item

removed as part of the

parent?

Is the item

a subunit or maintainable

item of an ISO 14224

equipment class

boundary?

Yes

Create equipment record

for the package and a

corresponding FEL.

Install package as primary

equipment in the FEL

Is discrete tracking of

location on parent

equipment required?

Create equipment record for

the item and a corresponding

FEL. Install item as primary

equipment in the FEL

No

Yes

Yes

No

Is the item an

equipment class as

defined by ISO 14224 or

equivalent company

standard?

Is the item a

component of a larger

package where the complete

package is routinely or

logically removed as a

materialized physical

object?

No

No

No

Create equipment

record for item

and install as sub-

equipment.

Start

Yes

Yes

ISO 14224 Equipment Class Boundary

Definition

Boundary used for data

analysis

Establishes consistency

in definition of

equipment units

Shows what is inside

the box.

Includes subunits and

maintainable items

SAP technical objects

within the boundary

need to be identified

Use Installed Base

Combustion

Engine

SAP Installed Base: Equipment Unit

Boundary Definitions

SAP Installed Base: Equipment Subunit

Boundary Definitions

SAP Technical Object Record

Boundary Display

Change 2: Capture Detailed Equipment

and Reliability Data with Taxonomy

Purpose/Objectives

Structure for capturing equipment data

Characteristic data

Support data flow from engineering and procurement to

maintenance technical objects (ISO 15926)

Reliability data

Classification of equipment for data analysis

purposes

Verification of equipment capabilities versus

functional requirements

ISO 14224 Equipment Classification:

Combustion Engines

PE

Class: PE_CE_DE_MP

ISO 14224 Equipment Characteristics:

Combustion Engine

SAP Classes and Characteristics:

Configuration of ISO 14224

More specific

characteristics

appear first

Green check

marks identify

inherited

characteristics

SAP Classification Assignment to

Technical Objects

Characteristics

inherited from

Class PE_CE.

More specific

characteristics

appear first.

Characteristics

inherited from

Class PE. As

PE is the top

level class, all

equipment will

have these

Characteristics

ISO 14224 Failure and Maintenance

Notations

Catalog Codes

Problem report

Failure modes

Method of detection

Repair report

Failure descriptors

What failed

Subunit/maintainable item

assemblies/components

Failures causes

Maintenance activities to repair

SAP Notification Problem Report

Failure Modes

Methods of Detection

SAP Notification Repair Report

What Failed and How

Failure Descriptions

Assembly/MM Specification

First out, position,

number of defects, etc.

Subunits/Maintainable

Items

SAP Notification Repair Report

Failure Cause for Maintainable Item

Failure Causes

SAP Notification Repair Report

Maintenance Activities

Maintenance

Activities to Repair

SAP Notification Equipment Unit

Affected and How

System availability

is used to classify

failure severity

System affected is

the parent equipment

unit

Capturing Multiple Equipment Class Data

Within One Equipment Unit Failure

For subunits/maintainable items that are ISO equipment class:

Capture class-specific failure data with additional notifications)

The affected equipment specified for sub-equipment is the

parent equipment unit

ISO 14224 Equipment Class

Interpretation

Standard Interpretation

of ISO 14224

Equipment to

include/exclude

Clarifications of Class

Boundary

Components to

include/exclude

Repairs to

include/exclude

KPI definitions

Example from Meridium

Make SAP the single source of information

Modify work notification process to ensure that all

jobs are captured

Customize SAP to support/enable new

functionality

Change 3: Modify Work Processes for

Complete and Accurate Data Capture

Work Notification Process

Emergency Workflow Existing

Current Issues

Incomplete and

improper allocation of

costs and reliability

data

N1 notifications not

issued or issued after

work completion

Improper notification

sequence (N4 done

before N1)

Masila Field

(Ops Manager)

Production

(Prod. Mgr.)

Field

(Field Supt)

Plant

Tawila

Heijah

Camaal

Maintenance

(Maint. Mgr.)

Mechanical

Planning

I&E

R

a

d

io

C

a

lls R

a

d

io

c

a

lls

R

a

d

i

o

c

a

l

l

s

Radio calls

R

adio calls Radio calls

Radio calls

Notifications (sometimes)

Work Notification Process

Emergency Workflow After Changes

Benefits Realization

Proper allocation of

costs and reliability

data to technical

objects

All jobs captured with

discrete and detailed

work orders

Notification sequence

done properly

Masila Field

(Ops Manager)

Production

(Prod. Mgr.)

Field

(Field Supt)

Plant

Tawila

Heijah

Camaal

Maintenance

(Maint. Mgr.)

Mechanical

Planning

I&E

R

a

d

io

C

a

lls

R

a

d

io

c

a

lls

R

a

d

io

c

a

lls

R

a

d

i

o

c

a

l

l

s

R

a

d

io

c

a

lls

R

a

d

io

c

a

lls

R

a

d

io

c

a

lls

W

o

r

k

O

r

d

e

r

s

W

o

r

k

O

r

d

e

r

s

P

l

a

n

n

i

n

g

T

e

a

m

P

l

a

n

n

i

n

g

T

e

a

m

M

a

i

n

t

e

n

a

n

c

e

T

e

a

m

M

a

i

n

t

e

n

a

n

c

e

T

e

a

m

S

y

s

t

e

m

S

y

s

t

e

m

Order and Notification Processing

Scheduled

Events

(PMs)

Non

Scheduled

Events

Monitor Work

Queue

Review , assess,

prioritize, update and

action as required

Manage backlog

Process maintenance

order/ notification and

prepare work

package

Perform work and

record results

Update work

order and

notification

Work completed,

equipment

maintained and

results recorded

Unique order

and notification

types

Transaction

variant

Partner

functions

Capacity

Planning

New Tabs in N1 type

notification

Problem Report Details

Groups Required

Items, Failure and Causes

Maintenance Activities

System Affected

New User Status Profile

To categorize how the

problem was discovered

Notification Changes

SAP Notification Partner Functionality

IDs of personnel groups that

routinely use or maintain

equipment default from

technical objects.

Additional groups can be

added as applicable

Transaction Variants Notification Create

Transaction Variants Queues / List

Edits

Standard List Edits /

Queues

Standard variants

per group (selection

and display)

Summary of SAP System Changes

Configuration changes

Catalog profiles and content

Notification screen templates

Functional location structure

indicator

User status profile

Classification

Class hierarchy

Enhancements

Notification content

EXIT_SAPMIWO0_020

Equipment record content

EXIT_SAPMIEQ0_001

Transaction simplification

Transaction variant

GUI xt

On-screen notification close-out

process

Spares ordering

Queuing by discipline

Partner functionality

Customized work lists based on

partner ID

Reporting to support new

functionality

BIW web applications / queries

PM content to BW

Data and Technical Administration

Centralized data repository with common

technical and costing design

Master data is the foundation of sound end to end

business processes

Centralized support for technical design

ISO 14224 interpretations and performance measures

Part of the change management and governance

process

Local business ownership of data and results

2006 Eventure Events. All rights reserved.

Tony Ciliberti, PE

Canadian Nexen Petroleum Yemen

vciliberti@gmail.com

tony_ciliberti@nexeninc.com

574-323-6237 (conference contact number)

Dan MacPherson

Canadian Nexen Petroleum Yemen

dan.macpherson@telus.net

dan_macpherson@nexeninc.com

Вам также может понравиться

- PM OverviewДокумент143 страницыPM OverviewRam KumarОценок пока нет

- BP FLocДокумент0 страницBP FLocvvr1Оценок пока нет

- Linear Asset Management - v1Документ33 страницыLinear Asset Management - v1SonderОценок пока нет

- A Holistic Approach To Asset Management in The NetherlandsДокумент10 страницA Holistic Approach To Asset Management in The NetherlandsSushmit SharmaОценок пока нет

- International Social Network Maintenance AssessmentДокумент12 страницInternational Social Network Maintenance Assessmentruayo100% (1)

- Key Performance Indicators For Stores and MRO - Reliabilityweb - A Culture of ReliabilityДокумент7 страницKey Performance Indicators For Stores and MRO - Reliabilityweb - A Culture of ReliabilitytohemaОценок пока нет

- SAP PM Tables and Related FieldsДокумент8 страницSAP PM Tables and Related FieldsSunil PeddiОценок пока нет

- PLM-Enterprise Asset PMДокумент23 страницыPLM-Enterprise Asset PMRohan HazratiОценок пока нет

- Sap PM TablesДокумент1 страницаSap PM TablesleeОценок пока нет

- IAM - IAM Diploma Break DownДокумент5 страницIAM - IAM Diploma Break Downcanjobs2020Оценок пока нет

- 04 Function Location Create, Change, Display - IL01 IL02 IL03Документ33 страницы04 Function Location Create, Change, Display - IL01 IL02 IL03PragneshОценок пока нет

- 2018 05 04 - Session 3.2 Practical Applic ISO 14224 - ISOTC67 WG4 Seminar May 2018Документ29 страниц2018 05 04 - Session 3.2 Practical Applic ISO 14224 - ISOTC67 WG4 Seminar May 2018John Jairo Simanca CastilloОценок пока нет

- Schedule counter-based PM plan (40Документ71 страницаSchedule counter-based PM plan (40carchilisОценок пока нет

- Managing Linear AssetsДокумент9 страницManaging Linear AssetsSuryanarayana TataОценок пока нет

- Class header data and characteristics documentДокумент1 страницаClass header data and characteristics documentsachinWebDОценок пока нет

- Proactive Maintenance (4HI) - Process DiagramsДокумент1 страницаProactive Maintenance (4HI) - Process DiagramsNaveen Reddy KasarlaОценок пока нет

- 1 Asset Hierarchy PDFДокумент2 страницы1 Asset Hierarchy PDFSaravanan RasayaОценок пока нет

- 10-003 RFP For CMMS SystemДокумент17 страниц10-003 RFP For CMMS SystemBaleissaОценок пока нет

- Functional LocationДокумент18 страницFunctional LocationSrinivasa ReddyОценок пока нет

- Best Practices For SAP-PM History DocumentationДокумент8 страницBest Practices For SAP-PM History DocumentationLaammeem Noon100% (1)

- Sap PM Work Clearance Management (WCM) : Kaushal Kumar K Eim Solutions PVT LTD 7/26/2019Документ2 страницыSap PM Work Clearance Management (WCM) : Kaushal Kumar K Eim Solutions PVT LTD 7/26/2019kumarОценок пока нет

- Step 2. Assess Performance Failure Modes PDFДокумент39 страницStep 2. Assess Performance Failure Modes PDFjglowitz100% (1)

- Compatible Units/Operational Level CostingДокумент53 страницыCompatible Units/Operational Level CostingVassilis IliadisОценок пока нет

- Idle Mind of A SAP PM ConsultantДокумент78 страницIdle Mind of A SAP PM ConsultantRam KumarОценок пока нет

- SAP PM Level 1 MaterialДокумент79 страницSAP PM Level 1 MaterialNaveen Reddy KasarlaОценок пока нет

- Blueprint Session 1 PM Structure WorkshopДокумент13 страницBlueprint Session 1 PM Structure WorkshopDhiraj PatilОценок пока нет

- Key Performance Indicator (KPI) Planning: IBM Maximo Asset Management Best PracticesДокумент20 страницKey Performance Indicator (KPI) Planning: IBM Maximo Asset Management Best PracticesJacky MoraudОценок пока нет

- Master DataДокумент109 страницMaster Datagraemesquires85100% (1)

- SAP Plant Maintenance OverviewДокумент62 страницыSAP Plant Maintenance OverviewRam Kumar100% (1)

- ISO 14224 Maintenance Standard PDFДокумент69 страницISO 14224 Maintenance Standard PDFSuyono Tok100% (3)

- Benchmarking Guide for Higher Music Education InstitutionsДокумент36 страницBenchmarking Guide for Higher Music Education Institutionserast_dudeОценок пока нет

- Sap PM 1658718318Документ107 страницSap PM 1658718318learn funОценок пока нет

- Priti Chandna Resume PM PDFДокумент5 страницPriti Chandna Resume PM PDFSonia Sachdeva Chandna100% (1)

- Asset Criticality Ranking PDFДокумент6 страницAsset Criticality Ranking PDFsarifinОценок пока нет

- PLM 300course1of2 190207121942 PDFДокумент80 страницPLM 300course1of2 190207121942 PDFSuriya KandhanОценок пока нет

- Overview of Plant Maintenance Processes in SAPДокумент3 страницыOverview of Plant Maintenance Processes in SAPadi8066Оценок пока нет

- There Are 10 Business Processes in SAP PMДокумент4 страницыThere Are 10 Business Processes in SAP PMprocriesОценок пока нет

- SAP Plant Maintenance - NotesДокумент6 страницSAP Plant Maintenance - Notesprsiva2420034066Оценок пока нет

- PM T CodesДокумент9 страницPM T CodesRehan KhanОценок пока нет

- Corrective Maintenance Process DiagramДокумент2 страницыCorrective Maintenance Process DiagramAsfar100% (1)

- BlueprintSession4 PMWorkCompletionProcessДокумент21 страницаBlueprintSession4 PMWorkCompletionProcessDhiraj PatilОценок пока нет

- Utilities Function List SAP PM English UsefulДокумент668 страницUtilities Function List SAP PM English UsefulnileshpimpaleОценок пока нет

- Failure Codes For Power PlantsДокумент80 страницFailure Codes For Power PlantsMohammed Aslam100% (3)

- Top 40 SAP Plant Maintenance TcodesДокумент2 страницыTop 40 SAP Plant Maintenance TcodespalhotaОценок пока нет

- PM PreventiveMaintenance Manual For TrainingДокумент25 страницPM PreventiveMaintenance Manual For TrainingsachinWebDОценок пока нет

- RCM Maximo Oil Gas 06 FinalДокумент23 страницыRCM Maximo Oil Gas 06 FinalNovan ErstyawanОценок пока нет

- Spare Parts Management with SAP - Key StrategiesДокумент47 страницSpare Parts Management with SAP - Key Strategiesamerican7404Оценок пока нет

- Maintenance Execution & Shutdowns Best PracticeДокумент39 страницMaintenance Execution & Shutdowns Best PracticeSUNIL TVОценок пока нет

- Back To Basics MROДокумент5 страницBack To Basics MROrstein666Оценок пока нет

- CMMS computerized maintenance management system The Ultimate Step-By-Step GuideОт EverandCMMS computerized maintenance management system The Ultimate Step-By-Step GuideОценок пока нет

- Reliability Centered Maintenance Rcm A Complete Guide - 2020 EditionОт EverandReliability Centered Maintenance Rcm A Complete Guide - 2020 EditionОценок пока нет

- BR 44393 Aas Ice Fios Aas br44393 enДокумент5 страницBR 44393 Aas Ice Fios Aas br44393 enMartin RiveraОценок пока нет

- BLK 8 Lot 15 Unit 8 North Forbes Subdivision, Catbangen, City of San Fernando, La Union 09178768779Документ4 страницыBLK 8 Lot 15 Unit 8 North Forbes Subdivision, Catbangen, City of San Fernando, La Union 09178768779heroshito2013Оценок пока нет

- Java Tutorial - BalajiДокумент11 страницJava Tutorial - BalajiBalaji Kumar100% (1)

- How To Derive An IT Audit UniverseДокумент4 страницыHow To Derive An IT Audit UniversekolocokroОценок пока нет

- Unlimited Adventures - Reference CardДокумент4 страницыUnlimited Adventures - Reference CardJorge Martínez RomeraОценок пока нет

- Digital Concepts 6.1 Megapixel Camera-87480Документ48 страницDigital Concepts 6.1 Megapixel Camera-87480Tom PritchardОценок пока нет

- Leica M525 OH4 Brochure enДокумент20 страницLeica M525 OH4 Brochure enNimsi AstiviaОценок пока нет

- DBMS Practical File DBMS Practical FileДокумент39 страницDBMS Practical File DBMS Practical FileNisarga NaikОценок пока нет

- Revo540c Manual PDFДокумент126 страницRevo540c Manual PDFJose Antonio Siñani VilteОценок пока нет

- Everyday Errors in Checkers Play-BackgammonДокумент203 страницыEveryday Errors in Checkers Play-BackgammonApostolopoulos Spyros100% (1)

- Pascals TriangleДокумент6 страницPascals TriangleGeethangalin VaanavinothanОценок пока нет

- VB6 Bank Management System with MS Access DatabaseДокумент29 страницVB6 Bank Management System with MS Access Databaserakshitha sОценок пока нет

- 8085 Microprocessor Lab ManualДокумент43 страницы8085 Microprocessor Lab ManualMukulSinghОценок пока нет

- Statistics with R — A practical guide for beginnersДокумент101 страницаStatistics with R — A practical guide for beginnersPedro PereiraОценок пока нет

- How To Install Pfsense On A Checkpoint FirewallДокумент11 страницHow To Install Pfsense On A Checkpoint FirewallRDPearceОценок пока нет

- Tips & Ticks Vol IДокумент30 страницTips & Ticks Vol Ifurnspace100% (2)

- Check Linux Server Configuration and Troubleshoot IssuesДокумент5 страницCheck Linux Server Configuration and Troubleshoot Issuessopan sonar100% (1)

- Rsit Win ServerДокумент68 страницRsit Win ServerJorge ArévaloОценок пока нет

- STS WiFi (MAR2011v2)Документ27 страницSTS WiFi (MAR2011v2)Hoang NguyenОценок пока нет

- Activity 6 GALUPOДокумент7 страницActivity 6 GALUPOSophia Manila SillaОценок пока нет

- WhirlpoolДокумент2 страницыWhirlpoolJeffrey DavisОценок пока нет

- Useful CommandsДокумент61 страницаUseful CommandsPradeep KoyiladaОценок пока нет

- VPC SI System ArchitectureДокумент12 страницVPC SI System ArchitectureK OuertaniОценок пока нет

- C Terror - en Algunos Caso de Verde VerdeДокумент9 страницC Terror - en Algunos Caso de Verde VerdePedro Osorio G.Оценок пока нет

- Anil Mahadik: UploadДокумент16 страницAnil Mahadik: UploadAnil MahadikОценок пока нет

- RPSC AEN (M) 2018 | SOCIAL ASPECTS OF ENGINEERING - Important Central and State Government SchemesДокумент58 страницRPSC AEN (M) 2018 | SOCIAL ASPECTS OF ENGINEERING - Important Central and State Government SchemesVikas VermaОценок пока нет

- 6se7090 0xx84 0fb0 Siemens ManualДокумент1 страница6se7090 0xx84 0fb0 Siemens ManualjosipdianaОценок пока нет

- FIRST User Guide Login HelpДокумент10 страницFIRST User Guide Login HelpMaryamAmiriОценок пока нет

- Quickbooks Update Error 15227Документ4 страницыQuickbooks Update Error 15227andrewmoore01Оценок пока нет

- GDДокумент21 страницаGDSunilОценок пока нет