Академический Документы

Профессиональный Документы

Культура Документы

Pages From TBDP-A-M-SP-0008 - Rev 0 SPEC FOR CENTRIFUGAL PUMP PDF

Загружено:

Samuel Johnson0 оценок0% нашли этот документ полезным (0 голосов)

321 просмотров12 страницPROJECT NAME : PROVISION of DETAILED DESIGN SERVICES FOR THAI BINH DEVELOPMENT PROJECT, BLOCKS 102 and 106, OFFSHORE VIETNAM DOCUMENT TITLE : DATASHEET FOR POTABLE and SERVICE WATER PUMP P-5105 DOCUMENT NO. : TBDP-A-M-DS-0002 REV CODE ISSUE DATE DOC STATUS CONTRACTOR COMP

Исходное описание:

Оригинальное название

Pages from TBDP-A-M-SP-0008_Rev 0 SPEC FOR CENTRIFUGAL PUMP.pdf

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документPROJECT NAME : PROVISION of DETAILED DESIGN SERVICES FOR THAI BINH DEVELOPMENT PROJECT, BLOCKS 102 and 106, OFFSHORE VIETNAM DOCUMENT TITLE : DATASHEET FOR POTABLE and SERVICE WATER PUMP P-5105 DOCUMENT NO. : TBDP-A-M-DS-0002 REV CODE ISSUE DATE DOC STATUS CONTRACTOR COMP

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

321 просмотров12 страницPages From TBDP-A-M-SP-0008 - Rev 0 SPEC FOR CENTRIFUGAL PUMP PDF

Загружено:

Samuel JohnsonPROJECT NAME : PROVISION of DETAILED DESIGN SERVICES FOR THAI BINH DEVELOPMENT PROJECT, BLOCKS 102 and 106, OFFSHORE VIETNAM DOCUMENT TITLE : DATASHEET FOR POTABLE and SERVICE WATER PUMP P-5105 DOCUMENT NO. : TBDP-A-M-DS-0002 REV CODE ISSUE DATE DOC STATUS CONTRACTOR COMP

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 12

PROJ ECT NAME : PROVISION OF DETAILED DESIGN SERVICES

FOR THAI BINH DEVELOPMENT PROJECT,

BLOCKS 102 & 106, OFFSHORE VIETNAM

DOCUMENT TITLE : DATASHEET FOR POTABLE & SERVICE WATER PUMP

P-5105

DOCUMENT NO. : TBDP-A-M-DS-0002

CONTRACT NO. : PCV/TBDP- A/2011/702

CTR NO. : D-ME-300

REV CODE

ISSUE

DATE

DOC STATUS

CONTRACTOR

COMPANY

ACCEPTANCE

AUTHOR CHECKER APPROVER

NAME NAME NAME NAME DATE

A 27-01-14 IFR VT Long M Ross

Andrew

Hoang

0 03-03-14 AFC VT Long M Ross

Andrew

Hoang

Document Class: B - Confidential (Should only be shared with staff or contractors who have a need-to-know)

Client Name: PETRONAS Carigali Overseas Sdn Bhd (PCOSB)

Datasheet No.: TBDP-A-M-DS-0002

Revision No. : 0

Specification No: TBDP-A-M-SP-0008 P&ID No.: 11-TBDP-A-B-1204-1/1

Project: Page No. : 1 of 11

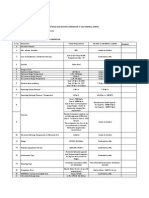

Equipment Name: Potable & Service Water Pump

Equipment Tag. No.: P-5105

Location: Thai Binh Drilling Wellhead Platform, i.e. TBDP-A, Offshore Vietnam Number Required: One

1 Applicable To: Proposal Purchase As Built

2 Number Required One (1x100%) Pump Size VTA Type Horizontal Centrifugal No. Stages VTA

3 Desgin Code API 610 and PTS 31.29.02.30 (Dec. 2010)

4 Manufacturer VTA Model VTA Serial No. VTA

5

6 No.

7 Pump 1

8 Motor 2

9 Gear 3

10 Turbine 4

11 Applicable overlay standard(s): N/A

12 Notes: Information below to be completed: By Purchaser By Manufacturer By Manufacturer Or Purchaser

13

14

15 Flow, Normal (m

3

/h) Rated (m

3

/h) Liquid Type Or Name Potable Water

16 Other Hazardous Flammable Corrosive

17 Suction Pressure Max./Rated (KPaa)

18 Discharge Pressure required at discharge flange (KPaa) Pumping Temp (C)

19 Differential Pressure (KPaa) Vapour Press. (KPaa)

20 Diff. Head at rated flow (m.liq) NPSHA at rated flow (m.liq) Relative Density (SG)

21 Process Variations N/A Viscosity (cP)

22 Starting Conditions N/A Specific Heat, Cp (kJ /kgC)

23 Service: Continuous (Note 3) Intermittent Chloride Concentration N/A (mg/kg)

24 Parallel Operation Req'd H

2

S Concentration N/A (mol fraction) Wet

25 Starting method Local Manual Corrosive / Erosive agent N/A

26

27 Location: Casing Throttle Bushing

28 Indoor Heated Outdoor Unheated Impeller Throat Bushing

29 Electrical Area Classification Cover Bearing Housing

30 Zone 2 Group Class Shaft Bearing Housing Adapter

PROVISION OF DETAILED DESIGN SERVICES FOR

THAI BINH DEVELOPMENT PROJECT, BLOCKS 102 & 106, OFFSHORE

VIETNAM

12.6 32.0

SS 316

SS 316

VTA

SS 316

SS 316

SS 316

IIA T3

N/A

450

1.56

0.999

3.0

318

(Min.)

Attached Attached ItemNo. ItemNo.

DATA SHEETS

MATERIALS

PUMPED LIQUID OPERATING CONDITIONS

SITE DATA

Date By

(Nor.) (Max.)

PUMP DATASHEET

ItemNo. Attached

P-5105 (Note 4)

PM-5105

36

6.5

1.016 1.007

VTA

0.7042

2.135

VTA

132

14

0.8904 1.166

25

3.11

31 Winterization Req'd Tropicalization Req'd. Shaft Sleeve Bearing Housing End Seals

32 Site Data Baseplate Coupling Guard Non-Sparking, VTA

33 Altitude mabove mean sea level Barometer (Bara) Casing Gasket Mechanical Seal Gland

Casing Fasteners VTA Mechanical Seal Gland Fasteners

34 Impeller Gasket Others

35 Range Of Ambient Temps: Min./Max. / 36 (C)

36 Relative Humidity Min./Average/Max. (%) Proposal Curve No. VTA Pump speed r/min

37 Unusual conditions: Dust Fumes Impeller Dia. Rated VTA Max. VTA Min. VTA (mm)

38 Other Offshore Marine Salt Laden Environment Impeller Type VTA

39 Rated Power VTA (kW) Efficiency at rated capacity VTA (%)

40 Power absorbed at 120% BEP VTA (kW)

41 MinimumContinuous Flow:

42 Thermal VTA (m

3

/h) Stable VTA (m

3

/h)

43 Induction Motor SteamTurbine Gear Preferred Oper. Region VTA To VTA (m

3

/h)

44 Other Allowable Oper. Region VTA To VTA (m

3

/h)

45 Max. Head @ Rated Impeller (m)

46 Max. Power @ Rated Impeller (kW)

47 Manufacturer VTA NPSHR At Rated Flow (mH

2

0,max)

48 VTA (kW) VTA (r/min) NPSHR fromrated capacity to 120% rated capacity (mH

2

0 max)

49 Frame Enclosure IP 56 Max. Suction Specific Speed/Actual

50 Horizontal Vertical Service Factor Max. Sound Press. Level Acceptable (dBA)

51 Volts/Phase/Hertz 400 / 3 / 50 Est. Max. Sound Press. Level (dBA)

52 Type Est. Max. Sound Power Level (dBA)

53 MinimumStarting Voltage

54 Insulation Class F Temp. Rise Class B Electricity

55 Full Load Amps VTA Drivers

56 Locked Rotor Amps Heating

57 Starting Method Direct On Line SystemVoltage Dip 80% Other

58 Lube Steam

59 Bearings (Type/Number): Drivers

60 Radial VTA / VTA Heating

61 Thrust VTA / VTA Cooling water: Source N/A

62 Vertical Thrust Capacity Supply Temp. N/A (C) Max. Return Temp. (

o

C)

63 Up (N) Down (N) Norm. Press. N/A (MPag) Design Press. (Mpag)

64 Min. Ret. Press. N/A (MPag) Max. Allow. D.P. (Mpa)

65 Chloride Concentration: N/A

VTA VTA

VTA

SS 316

SS 316

19.5

65 / 85 / 94

DRIVER TYPE

1.013

VTA

SS

PERFORMANCE

UTILITY CONDITIONS

N/A

N/A

11,000 US Unit / VTA

85 @1m from pump surface

N/A

N/A

MOTOR DRIVER (Refer to pages 8-11 of 11)

400

1.0

N/A

N/A N/A

Hertz

N/A

3

N/A

50

Min. Temp.

Phase

SS 316

ISSUE DATE

03-03-14

27-01-14 IFR

DOC. STATUS

AFC

Max. Press. Max. Temp. Min. Press.

Voltage

N/A N/A

N/A

VT Long

N/A

Andrew Hoang

N/A

REV

14

A VT Long

0

COMPANY ACCEPTANCE ACCEPTANCE DATE

AUTHOR

M Ross

M Ross

CHECKER APPROVER

Andrew Hoang

ISSUE DATE DOC. STATUS REV

CONTRACTOR

COMPANY ACCEPTANCE ACCEPTANCE DATE

Client Name: PETRONAS Carigali Overseas Sdn Bhd (PCOSB)

Datasheet No.: TBDP-A-M-DS-0002

Revision No. : 0

Specification No: TBDP-A-M-SP-0008 P&ID No.: 11-TBDP-A-B-1204-1/1

Proj ect: Page No. : 2 of 11

Equipment Name: Potable & Service Water Pump

Equipment Tag. No.: P-5105

Location: Thai Binh Drilling Wellhead Platform, i.e. TBDP-A, Offshore Vietnam Number Required: One

1

2

3 Rotation: (viewed From Coupling End) CW CCW Manufacturer's Standard (Note 11) Other (see below)

4 Pump Type: Specification No. PTS 30.48.00.31

5 OH2 OH3 OH6 Other Pump:

6 Casing Mounting: Primer

7 Centerline In-line Other Finish coat

8 Casing Split: Axial Radial Base Plate:

9 Casing Type: Primer

10 Single Volute Multiple Volute Diffuser Finish Coat

11 Case Pressure Rating: Details Of Lifting Devices

12 OH6 Pump Suction Region Designed For MAWP Shipment:

13 Max. Allowable Working Pressure (MAWP) (kPag) Domestic Export Export Boxing Required

14 @ (C) Outdoor Storage: 6 Months

15 Hydrotest Pressure 1.5 x MAWP (kPag)

16 Nozzle Connections: Horizontal Storage Vertical Storage

17 Type Of Shipping Preparation

18 Suction

19 Discharge Heating J acket Req'd.

20 Cooling Req'd.

21 Pressure Casing Aux. Connections: (Note 5,16) Cooling Water (c.w.) Piping Plan

22 No. C.W. Piping:

23 Drain Pipe Tubing Fittings

24 Vent C w Piping Materials:

150#

VTA

VTA VTA

150# RF

Type

VTA

Size (DN)

HEATING AND COOLING (N/A)

SURFACE PREPARATION AND PAINTING CONSTRUCTION

VTA

Flange Position

RF End

PUMP DATASHEET

VTA

Size

VTA

Top VTA

VTA

PROVISION OF DETAILED DESIGN SERVICES FOR

THAI BINH DEVELOPMENT PROJECT, BLOCKS 102 & 106, OFFSHORE

VIETNAM

ASME Class

VTA 24 Vent C.w. Piping Materials:

25 Warm-up S. Steel C. Steel Galvanized

26 Cooling Water Requirements:

27 Machined And Studded Connections Bearing Housing (m

3

/h)

28 Cylindrical Threads Required Heat Exchanger (m

3

/h)

29 Rotor: Total Cooling Water (m

3

/h)

30 Component Balance To ISO 1940 G1.0 Heat Medium: Steam Other

31 Couplings: Heating Piping: Tubing Pipe

32 Manufacturer Model

33 Rating (kW per 100 r/min) Bearing (type/Number)

34 Spacer Length (mm) Service factor Radial VTA / VTA

35 Coupling Balanced To ISO 1940-1 G6.3 Thrust VTA / VTA

36 Coupling With Proprietary Clamping Device Lubrication

37 Coupling Per ISO 14691 Grease Oil

38 Coupling Per ISO 10441 Purge Oil Mist Pure Oil Mist

39 Coupling Per API 671 ASME B15.1 Constant Level Oiler Preference

40 Non-spark Coupling Guard Oil Viscosity ISO Grade

41 Coupling Guard Standard Per

42 Baseplates: Accelerometer

43 API Baseplate Number Provision For Mounting Only

44 Non-grout Construction Flat Surface Req'd

45 Anchor bolts supplied by VENDOR Temp. Gauges (with Thermowells)

46 Anti-vibration Equipment Pressure Gauge Type

47 Other: No vent holes. Remarks:

48 With features to prevent liquid accumulation.

49 VTA Pump VTA (Kg)

50 Baseplate VTA (Kg)

51 Driver VTA (Kg)

52 Total VTA (Kg)

VTA VTA

1.5

VT Long

VT Long

VTA

MASSES

INSTRUMENTATION

VTA

VTA BEARINGS AND LUBRICATION

Andrew Hoang

CHECKER

M Ross

APPROVER

Andrew Hoang

COMPANY ACCPETANCE

AFC 0 03-03-14

ACEPTANCE DATE REV DOC STATUS

AUTHOR

CONTRACTOR

ISSUE DATE

A 27-01-14 IFR

N/A N/A N/A

M Ross

VTA

Client Name:

PETRONAS Carigali Overseas Sdn Bhd (PCOSB)

Datasheet No.: TBDP-A-M-DS-0002

Revision No. : 0

Specification No: TBDP-A-M-SP-0008 P&ID No.: 11-TBDP-A-B-1204-1/1

Project: Page No. : 3 of 11

Equipment Name: Potable & Service Water Pump

Equipment Tag. No.: P-5105

Location: Thai Binh Drilling Wellhead Platform, i.e. TBDP-A, Offshore Vietnam Number Required: One

1

2

3 Supplied By Pump Manufacturer Purchaser Barrier Flush Plan

4 Mounted By Pump Manufacturer Purchaser Barrier Flush Liquid

5 Seal Classification Code VTA Temperature Min. / Max. / C

6 Manufacturer Specific Gravity

7 Model Specific Heat kJ /kg C

8 Manufacturer Code Vapor Pressure (kPa abs) @ C

9 Seal Type Cartridge Component Pressure Required Min. / Max. / kPa

10 Seal Design Single Dual Dry gas MAWP of Secondary Seal System kPa

11 Pressurised Unpressurised Temperature Required Min. / Max. / C

12 Seal Chamber Taper Bore Cylindrical Bore Secondary Seal Flush Piping Tubing Pipe

13 Seal Chamber Size Oversized Standard Material 316SS Carbon Steel

14 Sleeve Material SS 316 Other

15 Pumping Ring Required Piping / Tubing Size mm

16 Throat Bushing Required Materials SS 316 Piping Assembly

17 Remarks Threaded Unions Flanged

18 Tube Type FittingSocket Welded

19 Remarks

20

21

22 Taps Required Quench Flush Drain Primary Seal Gauge Switches

23 Other Flow

24 Throttle Bushing Materials SS 316 Temperature

PUMP DATASHEET

MECHANICAL SEAL (Note 10) BARRIER / BUFFER FLUSH SYSTEM (N/A)

SEAL SYSTEM INSTRUMENTATION (N/A)

PROVISION OF DETAILED DESIGN SERVICES FOR

THAI BINH DEVELOPMENT PROJECT, BLOCKS 102 & 106, OFFSHORE

VIETNAM

SEAL GLAND

g p

25

26 Pressure

27 Primary Flushing Plan No. Plan 11 Secondary Seal

28 External Flush Liquid Flow

29 Supply Temperature Min/Max / C Pressure

30 Specific Gravity Level

31 Specific Heat kJ /kg C Remarks

32 Vapor Pressure (kPa abs) @ C

33 Flow Rate Required Min/Max m

3

/h

34 Pressure Required Min/Max kPa

35 Temperature Required Min/Max C

36 Primary Seal Flush Piping

37 Tubing Pipe Other

38 Material 316SS Carbon Steel

39 Other

40 Piping / Tubing Size mm

41 Piping Assembly

42 Threaded Unions Flanged

43 Tube Type Fittings Socket Welded

44 Remarks

45

46

47

48

49

50

51

52

53

0 03-03-14 AFC VT Long Andrew Hoang

DOC STATUS

AUTHOR

Andrew Hoang IFR VT Long M Ross

M Ross

REV ISSUE DATE

A

COMPANY ACCPETANCE

27-01-14

NOTES

ACEPTANCE DATE

CONTRACTOR

SEAL FLUSHING

CHECKER APPROVER

Client Name:

PETRONAS Carigali Overseas Sdn Bhd (PCOSB)

Datasheet No.: TBDP-A-M-DS-0002

Revision No. : 0

Specification No: TBDP-A-M-SP-0008 P&ID No.: 11-TBDP-A-B-1204-1/1

Project: Page No. : 4 of 11

Equipment Name: Potable & Service Water Pump

Equipment Tag. No.: P-5105

Location: Thai Binh Drilling Wellhead Platform, i.e. TBDP-A, Offshore Vietnam Number Required: One

1

2

3 Commissioning and Start-up Test Non-witness Witness Observe

4 Installation and Pre-commissioning (by Purchaser)

5 Price List Of 2 Years Normal Operation Spares (Note 24) (Note 25, 26)

6 Hydrostatic

7 Coordination Meeting Required Performance

8 Maximum Discharge Pressure To Include Retest On Seal Leakage

9 Max Relative Density NPSHR (Note 7)

10 Max Dia. Impellers And/or No. Of Stages True Peak Velocity Data

11 Operation To Trip Speed Complete Unit Test (Note 8)

12 OH3 Bearing HS6 Lifter Sound Level Test

13 Connection Design Approval Cleanliness Prior To

14 Torsional and Lateral Analysis Required Final Assembly

15 Torsional and Lateral Analysis Report Nozzle Load Test

16 Progress Reports Check For Co-planar

17 Outline Of Procedures For Optional Tests Mounting Pad Surfaces

18 Additional Data Requiring 10 Years Retention Mechanical Run Until Oil

19 Temp. Stable

20 Manifold Piping To Single Connection 4 h Mechanical Run After

21 Vent Drain Cooling Water Oil Temp. Stable

22 Mount Seal Reservoir Off Baseplate 8 h Mech. Run Test

23 Flanges Req'd In Place Of Socket Weld Unions True Peak Velocity Data

24 Installation List In Proposal BRG HSG Resonance Test

25 Connection Bolting Auxiliary Equipment Test

26 PTFE Coating ASTMA 153 Galvanized Disassemblyafter Test

OTHER PURCHASER REQUIREMENTS

SPARE PARTS

PROVISION OF DETAILED DESIGN SERVICES FOR

THAI BINH DEVELOPMENT PROJECT, BLOCKS 102 & 106, OFFSHORE

VIETNAM

QA INSPECTION AND TESTING (CONT.)

PIPING AND APPURTENANCES (NOTE 5, 9, 16)

PUMP DATASHEET

26 PTFE Coating ASTM A 153 Galvanized Disassembly after Test

27 Painted SS Vibration Test

28 Final/Site Acceptance Testing

29 Shop Inspection Impact Testing

30 Performance Curve Approval Per EN 13445

31 Test With Substitute Seal Per ASME Sec VIII Div. 1

32 Material Certification Required Vendor Keeps Repair And HT Records

33 Casing Impeller Shaft Vendor Submit Test Procedures

34 Other Vendor Submit Test Data Within 24h

35 Casting Repair Procedure Approval Req'd Include Plotted Vibration Spectra

36 Inspection Required For Connection Welds Submit Completed Inspection Check List

37 Mag. Particle Liquid Penetrant Record Final Assembly Running Clearance

38 Radiographic Ultrasonic

39 Inspection Required For Castings

40 Mag. Particle Liquid Penetrant

41 Radiographic Ultrasonic

42 Hardness Test Required:

43 Additional Subsurface Examination

44 For

45 Method

46

47

48

49

50

51

52

53

54

55

56

REV

AUTHOR

IFR VT Long

ACEPTANCE DATE

M Ross Andrew Hoang

M Ross

COMPANY ACCPETANCE

APPROVER

A

0

27-01-14

Andrew Hoang

NOTES

QA, INSPECTION AND TESTING (NOTE 22)

DOC STATUS ISSUE DATE

CHECKER

VT Long 03-03-14 AFC

REV ACEPTANCE DATE COMPANY ACCPETANCE DOC STATUS ISSUE DATE

CONTRACTOR

Client Name:

PETRONAS Carigali Overseas Sdn Bhd (PCOSB)

Datasheet No.: TBDP-A-M-DS-0002

Revision No. : 0

Specification No: TBDP-A-M-SP-0008 P&ID No.: 11-TBDP-A-B-1204-1/1

Project: Page No. : 5 of 11

Equipment Name: Potable & Service Water Pump

Equipment Tag. No.: P-5105

Location: Thai Binh Drilling Wellhead Platform, i.e. TBDP-A, Offshore Vietnam Number Required: One

1

2 1.

3 2. This data sheet shall be read and conformed conjunction with "Specification for Centrifugal Pumps", Doc. No.: TBDP-A-M-SP-0008

4 3. Pump and motor are intended for intermittent operation but shall be designed for continuous operation.

5 4. Pump shall comply with API 610 & PTS 31.29.02.30-Centrifugal pumps (amendment/supplements to ISO 13709-Dec.2010)

6 5. Pump shall be self venting type.

7 6. VENDOR to provide NPSH calculation with the bid proposal.

8 7. VENDOR shall ensure a design margin difference of 1m between NPSHA and NPSHR throughout the range from minimum continuous flow

9 up to rated flow. NPSHR test shall be performed in the following cases:

10 +If the difference between NPSHA and NPSHR is less than 1 m throughout the range from minimum continuous flow up to rated flow..

11 +For pumps with a suction specific speed above 11,000 US Unit.

12 +If the NPSHA at 120% of rated flow exceeds the NPSHR by less than 0.3m .

13 8. Complete unit test shall be carried out together with the pump motor.

14 9. Design and external protection requirement for bolting shall be as per PTS 39.01.10.12 (Dec 2010) Table 11.

15 10. VENDOR shall provide seal manufacturer's recommendation for the seal type/flush plan suitable for the specified service/duty.

16 VENDOR shall furnish completely filled seal datasheet as per API 682, with bid proposal.

17 11. Surface preparation and painting shall be as per Manufacturer's offshore standard (to be submitted with bid proposal for PURCHASER's review,

18 and approval), however colour scheme shall be as per PTS 30.48.00.31 (Sep 2012) & Supplementary to PTS 30.48.00.31-P (Oct. 2001, Rev.1)

19 12. Flange facing shall be smooth finish with a roughness between 125-250 micro inch.

20 13 Motor shall comply with Specification for LV Motors, Doc. No.: TBDP-A-E-SP-0105

21 14. Rated power (BkW) considered as the basis for sizing of motor and shall include positive tolerance (i.e margin 25%) over rated BkW

22 for driver sizing.

23 15. Motor rating selected shall be suitable for open discharge valve start -up of pump.

24 16. VENDOR shall provide the drain connection complete with isolation valve and blind flange.

25 17. Motor shall be rated at 400V, 3 Phase, 50 Hz, to be connected with 400V AC, 3 ph, 50Hz systemand shall be suitable for continuous operation.

PROVISION OF DETAILED DESIGN SERVICES FOR

THAI BINH DEVELOPMENT PROJECT, BLOCKS 102 & 106,

OFFSHORE VIETNAM

PUMP DATASHEET

VTA=VENDOR to advice and confirm, N/A =Not Applicable

25 17. Motor shall be rated at 400V, 3 Phase, 50 Hz, to be connected with 400V AC, 3 ph, 50Hz system and shall be suitable for continuous operation.

26 18. Cable gland connection size for electrical and instrumentation for pump package to off-limit electrical and instrument interfaces shall be M20.

27 VENDOR to confirm if different.

28 19. Y type permanent strainer screen shall to be supplied by PURCHASER at pump suction line. VENDOR to advise if diffirent mesh is required and

29 advise the maximum allowable particle size to enter pump.

30 20. Name plates shall be SS 316L and come with bracket (if any).

31 21. VENDOR shall provide special tools required for erection, installation, removal, operation and maintenance.

32 22. Material shall be furnished in accordance with BS EN ISO 10474 and the type indicated in PTS 31.29.02.30 Table I-1.

33 Inspection and testing requirements shall be in accordance with PTS 31.29.02.30.

34 23. Pump base plate shall be provided with two (2) earthing boss with grounding lugs, as per PTS standard drawing S68.004-H.

35 24. VENDOR cannot carry out the specified activity inspection, and/or test without PURCHASERs review and approval and/or attendance/witnessing.

36 VENDOR must notify PURCHASER by fax of the specified activities at least 14 working days in advance. The VENDOR cannot deviate from this rule

37 unless written approval has been given by COMPANY.

38 25. VENDOR must notify the PURCHASER of the specified activity at least 14 working days in advance. PURCHASERs witnessing is mandatory.

39 If PURCHASER do not elect to be present, written approval will be given by PURCHASER to VENDOR. VENDOR may proceed with his own

40 inspection/testing, provided controls and test records are made available to PURCHASER for review and shall be in the presence and witnessing of TPI

41 Agency, if also specified.

42 26. VENDOR shall submit to PURCHASER for comments the documents required prior to the performance of the specified activity, transmit or make

43 available for the review of PURCHASER the results of the controls and tests conducted, as applicable.

44

45

46

47

48

49

50

51

52

53

54

A

REV

CONTRACTOR

27-01-14 IFR VT Long M Ross Andrew Hoang

ISSUE DATE DOC STATUS

AUTHOR CHECKER APPROVER

Andrew Hoang VT Long M Ross 0 03-03-14 AFC

COMPANY ACCEPTANCEACEPPTANCE DATE

Client Name: PETRONAS Carigali Overseas Sdn Bhd (PCOSB)

Datasheet No.: TBDP-A-M-DS-0002

Revision No. : 0

Specification No: TBDP-A-M-SP-0008 P&ID No.: 11-TBDP-A-B-1204-1/1

Project: Page No. : 6 of 11

Equipment Name: Potable & Service Water Pump

Equipment Tag. No.: P-5105

Location: Thai Binh Drilling Wellhead Platform, i.e. TBDP-A, Offshore Vietnam Number Required: One

1

2 1. GENERAL

3 This requisition cover the noise limits of equipment, given below. For definitions, method of measuring etc, reference is made to EEMUA

4 specification no. 140 : Noise procedure specification.

5 2. NOISE LIMITS TO BE MET BY THE EQUIPMENT

6 The noise generated by the equipment shall not exceed the more stringent of the noise limits given in the table below for any of the conditions

7 of operation for which the equipment may normally be expected to be used.

8 Lp is the maximum (A-weighted) sound pressure level, dB re 20 uPa at any location at 1 m from the equipment surface.

9 Lw is the maximum (A-weighted) sound power level. dB re 1 pW.

10 If the equipment generates noise with tonal or impulsive components the limits shall be taken 5 dB(A) more stringent.

11 Noise levels will be verified according to the following standards: ISO 3740 series, ISO 11200 series or ISO 9614.

12 3. INFORMATION TO BE SUBMITTED WITH THE TENDER

13 This noise data sheet shall be returned with the tender and with guaranteed noise data filled in.

14 Vendor shall state which silencing measures were taken to meet the noise requirements.

15 Where applicable the completed silencer and / or acoustic enclosure data requisition sheet shall also be returned. (See PTS 31.10.00.96)

16

17 Equipment

18 Items / Locations

19

20

21 Lp

22 Lw

23 Lp

24 Lw

25 Lp

PROVISION OF DETAILED DESIGN SERVICES FOR

THAI BINH DEVELOPMENT PROJECT, BLOCKS 102 & 106,

OFFSHORE VIETNAM

b

Noise

limit

Noise levels guaranteed by supplier in dB(A)

(upper tolerance +0 dB)

NOISE LIMITATION DATASHEET

Remarks

Total 500

Silencing measures

1

Hz kHz kHz kHz kHz

Potable & Service Water Pump

P-5105

Hz Hz Hz

63 125 250

a

85

4 8 2

dB(A)

1

26 Lw

27 Lp

28 Lw

29 Lp

30 Lw

31 Lp

32 Lw

33 Lp

34 Lw

35 Lp

36 Lw

37 Lp

38 Lw

39 Lp

40 Lw

41

42 The Purchaser shall indicate:

43 - In column "b", the noise limit

44 - In column "a", using the appropriate number, which of the following applies to the required noise levels:

45 1) without acoustic provisions

46 2) with acoustic provisions

47 3) special low-noise design

48 4) Vendor best estimate, not necessarily guaranteed

49 5) Surge control valve noise levels at full recycle flow

50 6) ..

51

52

53

54

55

APPROVER

A

0 03-03-14

27-01-14 IFR VT Long M Ross

AUTHOR CHECKER

AFC VT Long M Ross

Andrew Hoang

Andrew Hoang

APPROVER

REV ISSUE DATE DOC STATUS

AUTHOR CHECKER

ACEEPTANCE DATE COMPANY ACCEPTANCE

CONTRACTOR

Client Name: PETRONAS Carigali Overseas Sdn Bhd (PCOSB)

Datasheet No.: TBDP-A-M-DS-0002

Revision No. : 0

Specification No: TBDP-A-M-SP-0008 P&ID No.: 11-TBDP-A-B-1204-1/1

Proj ect: Page No. : 7 of 11

Equipment Name: Potable & Service Water Pump

Equipment Tag. No.: P-5105

Location: Thai Binh Drilling Wellhead Platform, i.e. TBDP-A, Offshore Vietnam Number Required: One

1

2

3

4 Heaviest component to be handled during maintenance:- Tender est. *

5 Design est. *

6 Design update *

7 Description * mass * kg As supplied *

8

9 NOTES:

10 * VENDOR to complete for proposal .

11 1) One sheet shall be completed for each separately installed skid or item.

12 2) As supplied equipment shall be weighted by vendor and witnessed by Purchaser or nominee.

13 3) Vendor shall provide current calibration certificate of weighing equipment. Calibration methods shall be to BS 1610.

14 4) Vendor shall submit design update for significant changes in mass.

15

16 Dry * kg Operating * kg Test * kg

17

18

19 Other Description * * kg

20 temporary

21 masses

22

23

24 Certified final mass Date Name Company

MASS/CENTRE OF MASS DATASHEET

PROVISION OF DETAILED DESIGN SERVICES FOR

THAI BINH DEVELOPMENT PROJECT, BLOCKS 102 & 106,

OFFSHORE VIETNAM

INFORMATION STATUS

(Tick as necessary)

MASS DATA (KG)

25 Purchaser inspector

26 Vendor

27

28

29 NOTES:

30 1/ Equipment orientation on each skid or item to be indicated.

31 2/ C of M Coordinates to be clearly shown on G.A. drawings.

32

33

34

35

36

37 OVERALL SIZES

38 DIMENSION 'L' *

39 DIMENSION 'W' *

40 DIMENSION 'H' *

41

42

43

44

45

46

47 CENTRE OF MASS

48 Dimension Dry Operating

49 'X' * *

50 'Y' * *

51 'Z' * *

52

53

A 27-01-14 IFR VT Long

COMPANY ACCEPTANCEACCEPTANCE DATE

CONTRACTOR

REV ISSUE DATE DOC STATUS

AUTHOR CHECKER APPROVER

0 03-03-14 AFC VT Long M Ross Andrew Hoang

M Ross Andrew Hoang

DIMENSIONAL DATA (mm)

'

W

'

Y

'

C of M

'L'

'X'

Plan

C of M

Elevation

'

H

'

'

Z

'

'

W

'

Y

'

'L'

'X'

Plan

Elevation

'

H

'

'

Z

'

Client Name: PETRONAS Carigali Overseas Sdn Bhd (PCOSB)

Datasheet No.: TBDP-A-M-DS-0002

Revision No. : 0

Specification No: TBDP-A-M-SP-0008 P&ID No.: 11-TBDP-A-B-1204-1/1

Proj ect: Page No. : 8 of 11

Equipment Name: Potable & Service Water Pump

Equipment Tag. No.: P-5105

Location: Thai Binh Drilling Wellhead Platform, i.e. TBDP-A, Offshore Vietnam Number Required: One

1

2 1.0 STANDARDS (Note 4) 6.0 CONSTRUCTION

3 NEMA UL 6748 IEEE ANSI Enclosure Drip-proof Ex'd' Ex'e' X Ex'n'A

4 BS X IEC X TEFC WP2 WP1 X IP 56

5 X OTHERS PTS 33.66.05.31 (Feb.2010)

6 * Shaft X Horizontal Vertical Hollow

7 2.0 CERTIFYING SCHEME W/Coupling W/Gear Train X Solid

8 X IECEx UL FM

9 Motor Type X Squirrel Cage Wound Rotor

10 3.0 AREA CLASSIFICATION Others

11 NEC Class Div. Group

12 X IEC Zone Group Temp Class T3 Fan X Anti Static X Non-ferrous

13 SAFE Bi-directional X Uni-directional

14

15 4 ENVIRONMENTAL CONDITION Finish Factory Standard For Offshore

16 X Offshore Onshore X Salt-laden X Others MID GREEN COLOR

17 Indoor X Outdoor X Tropical

18 Frame Material X Cast Iron Aluminium Alloy

19 Design Amb. Temp. 36 C Max .Temp C Min. Temp C

20 Relative Humidity % Max Terminal Boxes X Rotatable In 90 Deg. Increments

21 Altitude: Below 10m MSL X IP 56

22 X Above 10m MSL X Ex'e'

23

24 5.0 RATING & PERFORMANCE 7.0 ACCESSORIES

25 Supply Voltage Volts Phase Hz X Nameplate (316 Stainless Steel)

26 Motor Rating VTA HP 1.1 (VTA) kW RPM Space Heater ( Power Supply V Ph Hz )

27 System Short Circuit Rating kA Separate Space Heater Terminal Box (if any)

28 Stator Thermistor (PTC Type) Qty Per Phase

PROVISION OF DETAILED DESIGN SERVICES FOR

THAI BINH DEVELOPMENT PROJECT, BLOCKS 102 & 106, OFFSHORE

VIETNAM

94

400 3

2 IIA

36 14

50

1450(VTA)

LOW VOLTAGE MOTOR DATASHEET

50 1 230

28 Stator Thermistor (PTC Type) Qty Per Phase

29 Insulation Class: Thermistor Relay Volt PH

30 B X F H Others Rtd Selector Switch-indicator And Alarm Contact

31 Operating Temp Class/Rise: Bearing RTDs (type PT100 Ohm) Qty Per Bearing

32 X B F H Others Stator RTDs (type PT 100 Ohm) Qty Per Phase

33 Separate RTDs Terminal Box

34 Duty Cycle X Continuous Intermittent Differential CTs

35 Surge Protection

36 Duty Type S1 (to IEC 60034-1) Vibration Detector

37 X Terminal Block

38 Starting Method Full Voltage (normal) X 10 M Tail At Discharge Head

39 Reduced Volt.

40 X 80 % Of Full Voltage Capability

41 Others Remote Control Unit (RCU)

42 Required Off/On Switch

43 Max Starting Current: 7 x Full Load Current (to PTS: 33.66.05.31) Not Required Start Push-Button

44 Stop Push-Button

45 Method Of Cooling: IC 4A1A1 / IC 5A1A1 (to IEC 60034-6)

46

47 Performance To: IEC 60034

48

49

50 Main Power Cable CU/XLPE/SWB/PVC 3C x 2.5mm

2

+E M20

51

52 Space Heater N/A N/A N/A

53

54 Rtds/thermistor

55

NOTES:

1) Space Heaters Are Required For Motors Rated 3.7 Kw And Larger.

2) * VENDOR To advise.

3) Motor shall also comply with requirements as per Specs for LV motor Doc. No.

Gland Size Cable Type Cable Size

0 03-03-14 AFC VT Long M Ross Andrew Hoang

A 27-01-14 IFR VT Long M Ross Andrew Hoang

REV ISSUE DATE DOC STATUS

AUTHOR CHECKER APPROVER

COMPANY ACCEPTANCE ACCEPTANCE DATE

CONTRACTOR

Client Name: PETRONAS Carigali Overseas Sdn Bhd (PCOSB)

Datasheet No.: TBDP-A-M-DS-0002

Revision No. : 0

Specification No: TBDP-A-M-SP-0008 P&ID No.: 11-TBDP-A-B-1204-1/1

Project: Page No. : 9 of 11

Equipment Name: Potable & Service Water Pump

Equipment Tag. No.: P-5105

Location: Thai Binh Drilling Wellhead Platform, i.e. TBDP-A, Offshore Vietnam Number Required: One

1

2 8.0 TESTING & INSPECTION

3 8.1 TEST TO THE FOLLOWING CODES & STANDARDS

4 X IEC/BS ANSI/NEMA/UL

5 8.2 ROUTINE TESTS

6 X Manufacturer's Type Tests ( See Notes)

7 X No-load Losses, Current And Speed Measurement

8 X High Potential Test

9 Witness By PCOSB

10 Third Party Inspection

11 X Testing Authority Certificates For Type Tests

12 X Witnessing Not Required

13 8.3 BASIC TEST

14 X Winding Resistance Measurement (cold & Hot)

15 X Locked Rotor Current/torque

16 X Winding Temperature Rise

17 X Bearing Temperature Rise

18 Slip, Power Factor/efficiency Test

19 X Vibration Measurement

20 X Noise Measurement

21 Witness By PCOSB

22 Third Party Inspection

23 Testing Authority Certificates

24 Witnessing Not Required

25 8.4 PERFORMANCE/SPECIAL TESTS

26 Momentary Overload (Current/Torque)

27 Overspeed

PROVISION OF DETAILED DESIGN SERVICES FOR

THAI BINH DEVELOPMENT PROJECT, BLOCKS 102 & 106,

OFFSHORE VIETNAM

LOW VOLTAGE MOTOR DATASHEET

27 Overspeed

28 Speed Vs Torque/Current/P.F

29 Witness By PCOSB

30 Third Party Inspection

31 Testing Authority Certificates

32 Witnessing Not Required

33 NOTES:

34 Type Tests Should Include Most Or All Of The Following;

35 1 Winding Resistance Cold

36 2 Full Load Heat Run

37 3 Winding Resistance Hot

38 4 Calculated Winding Temperature Rise

39 5 Calculated Winding Temperature at 20

o

C

40 6 Bearing Temperature Rise

41 7 Slip At No, 1/2, 3/4 And Full Load

42 8 Efficiency At 1/2, 3/4 And Full Load

43 9 Motor Current Unbalance At Full Load

44 10 Locked Rotor Current

45 11 Locked Rotor Torque

46 12 No Load Current

47 13 No Load Losses

48 14 Vibration At No Load And Full Load

49 15 Noise At No Load And Full Load

50 16 Insulation Resistance

51 17 Torque-speed Curve

52 18 Noise Level Test

NOTES:

4) Motor Brand Shall Be ABB, LOHER, BROOK HANSEN or PCOSB Approved Equivalent.

5) All Motors Shall Be Of Low Noise Type.

7) The Space Heaters Shall Be Automatically Switched On When Motor Is Tripped Or Stopped.

8) Rain Canopy Shall Be Provided For Motors With Vertical Shaft.

COMPANY ACCEPTANCE ACCEPTANCE DATE

VT Long M Ross

REV ISSUE DATE DOC STATUS

AUTHOR CHECKER APPROVER

Andrew Hoang IFR VT Long

Andrew Hoang

REMARKS

M Ross

AFC 0 03-03-14

A 27-01-14

COMPANY ACCEPTANCE

CONTRACTOR

ACCEPTANCE DATE REV ISSUE DATE DOC STATUS

Client Name: PETRONAS Carigali Overseas Sdn Bhd (PCOSB)

Datasheet No.: TBDP-A-M-DS-0002

Revision No. : 0

Specification No: TBDP-A-M-SP-0008 P&ID No.: 11-TBDP-A-B-1204-1/1

Proj ect: Page No. : 10 of 11

Equipment Name: Potable & Service Water Pump

Equipment Tag. No.: P-5105

Location: Thai Binh Drilling Wellhead Platform, i.e. TBDP-A, Offshore Vietnam Number Required: One

1

2

3

Manufacturer

4

Nameplate Rating kW

5

Speed RPM

6

Poles

7

Frame Size

8

Model No.

9

Nominal Current A

10

Locked Rotor Current A

11

Starting Inrush Current A

12

Power Factor

13

Full Load Torque

14

Starting Torque

15

Max Torque

16

Acceleration Time Equip And Motor Sec

17

Max Stall Time Sec

18

Motor Inertia N-M

2

19

No Of Consecutive Starts Hot Cold

20

Total No Start Per Hour Hot Cold

21

Rotation Facing Coupling End (CW/CCW)

22

Bearing Type

23

Lubrication

24

Total Shaft End Float mm

25

Method Of Cooling ( IC Code )

26

Mounting Arrangement ( Im Code )

DATA TO BE FURNISHED BY VENDOR

PROVISION OF DETAILED DESIGN SERVICES FOR

THAI BINH DEVELOPMENT PROJECT, BLOCKS 102 & 106,

OFFSHORE VIETNAM

LOW VOLTAGE MOTOR DATASHEET

g g ( )

27

RTD Relay Setting : Bearing

28

Stator

29

Field Test Data Min Megger Reading OHMS

30

Max Potential AC DC

31

Enclosure Protection (IP/NEMA)

32

Space Heater Rating W

33

Rotor Weight kg

34

Stator Weight kg

35

Motor Net Weight kg

36

Dimension (LX W X H) : (L) X (W) X (H) mm

37

38

39

Current(AMPS)

40

Efficiency

41

Power Factor

42

Torque(Nm)

43

Slip (%)

44

Min Permissible Starting Voltage V

45

Safe Locked Rotor Time: (HOT) Sec. (COLD) Sec

46

Multi-speed Motor Type

47

No Of Windings

48

49

OTHER SPECIAL FEATURES:

50

51 NOTE:

52

The Above Information May Be Provided By The Manufacturer by Way of this Standard Data Sheets

53

Provided All Relevant Information Is Provided.

54

REMARKS

A

03-03-14 VT Long 0 AFC

27 01 14 IFR VT L MR A d H

M Ross Andrew Hoang

Full Load Start 1/2 Load 3/4 Load

REV ISSUE DATE DOC STATUS

AUTHOR CHECKER APPROVER

A

COMPANY ACCEPTANCE ACCEPTANCE DATE

CONTRACTOR

27-01-14 IFR VT Long M Ross Andrew Hoang

Client Name: PETRONAS Carigali Overseas Sdn Bhd (PCOSB)

Datasheet No.: TBDP-A-M-DS-0002

Revision No. : 0

Specification No: TBDP-A-M-SP-0008 P&ID No.:11-TBDP-A-B-1204-1/1

Project: Page No. : 11 of 11

Equipment Name: Potable & Service Water Pump

Equipment Tag. No.: P-5105

Location: Thai Binh Drilling Wellhead Platform, i.e. TBDP-A, Offshore Vietnam Number Required: One

1

2 9 SPECIFIC REQUIREMENT

3 GENERAL

4 - When motors are furnished with the driven equipment as a package, the torque characteristics and speed shall be the responsibility of the driven equipment

5 VENDOR. Motor design shall be based on IEC.

6 - The cable entry size for terminal boxes shall be suitable for PURCHASER's cable termination. The cable entry size shall be approved by PURCHASER.

7 - Motors and all individual items forming part of motors shall have an expected service life of 20 years. This includes heaters, wirings, terminals etc. but with

8 the exception of the rolling element bearings.

9 - Motor screens or louvres shall be corrosion resistant.

10 - Motors shall be provided with lifting eyes or other types of facilities to lift the motors.

11

12 WINDINGS

13 - Stator windings shall be made of high quality enamelled copper wire with class F insulation which shall be resistant to high humidity, saline atmosphere,

14 chemical fumes, oil and grease.

15 - The windings especially the end windings shall be adequately braced to prevent movement and cracking of the insulation at the slot exists during all

16 conditions of service.

17 - The connections inside the motor shall not be mechanically overstressed during starting.

18 - Winding insulation shall be based on full vacuum pressure impregnation (VPI) method.

19

20 BEARINGS

21 - Bearings shall have a rated L10 lifetime in excess of 40,000 hours under the worst case operating conditions. The lifetime shall be calculated in accordance

22 with ISO R 281-1. When the motor shaft is subjected to external forces a relaxation to 32,000 hours lifetime is permitted.

23 - Motors with rated output upto 22 kW may be equipped with pre-lubricated non-rechargeable bearings. The rated L10 lifetime of these bearings shall be in

24 excess of 16,000 hours.

25

26 TERMINAL BOXES AND MOTOR TERMINALS

PROVISION OF DETAILED DESIGN SERVICES FOR

THAI BINH DEVELOPMENT PROJECT, BLOCKS 102 & 106, OFFSHORE

VIETNAM

LOW VOLTAGE MOTOR DATASHEET

26 TERMINAL BOXES AND MOTOR TERMINALS

27 - The main terminal box shall permit easy mounting and removal of the cable without breaking or stressing the cable.

28 - Terminals and cable termination boxes shall provide sufficient space for segregating the cores and maintaining the minimum insulation clearances and

29 creepage distances.

30 - Cable terminals, terminal leads, and associated fittings for motors controlled by conventional circuit breakers shall be able to withstand a maximum through

31 fault level.

32 - The main cable terminals inside the cable box shall have the following characteristics :

33 a) be non-loosening to prevent slackening of connection due to vibration.

34 b) guaranteed sufficient contact pressure without damaging the cable conductor.

35 c) guaranteed good contact, independent of temperature changes and other conditions mentioned in the specification.

36 - An earthing clamp or bolt of adequate dimensions shall be provided inside the terminal box for connection of the cable earthing.

37 - An earth stud terminal with nuts and washers and diameter not less than that of a line terminal shall be provided on the exterior of the motor frame for the

38 connection of an earthing cable.

39 VENDOR DATA REQUIREMENTS

40 The VENDOR shall supply as a minimum the following data for the purpose of evaluation, approval and records by PURCHASER :-

41 - a) All physical drawings showing all dimensions, location of terminals boxes and size, connection diagrams, methods of terminations, couplings, keyways etc.

42 b) A complete set of installation, operating and maintenance data.

43 c) A list of recommended spares (separately priced).

44 MOTOR NAMEPLATE

45 Each motor shall be equipped with a stainless steel nameplate permanently attached to the motor. Information shall be impressed onto the nameplate and

46 shall include the following :-

47 a) Manufacturer's name i) Locked rotor current

48 b) Motor serial number j) Full load speed

49 c) Bearing manufacturer's name and part numbers k) Enclosure (Index of Protection e.g. IP56)

50 d) Kilowatt rating l) Type of explosion protection (e.g. Ex'n' IIA T3)

51 e) Voltage m) Frame number

52 f) Frequency n) Insulation class and temperature rise.

53 g) Phase o) Space heater wattage and voltage (if applicable)

54

h) Full load current

55

56

03-03-14 AFC M Ross

REV ISSUE DATE DOC STATUS

AUTHOR CHECKER APPROVER

M Ross Andrew Hoang VT Long

ACCEPTANCE DATE COMPANY ACCEPTANCE

0

A 27-01-14 IFR

Andrew Hoang VT Long

REV ISSUE DATE DOC STATUS

CONTRACTOR

Вам также может понравиться

- HRD Hot Water Pump P001Документ6 страницHRD Hot Water Pump P001nguyenquoc1988Оценок пока нет

- Data Sheet: LPG Filling Pump P-001/002/003/004/005/006Документ5 страницData Sheet: LPG Filling Pump P-001/002/003/004/005/006Denstar Ricardo Silalahi100% (1)

- 2009 02 M HD 319 0Документ5 страниц2009 02 M HD 319 0ZoebairОценок пока нет

- BLOCK B - O MON PIPELINE GAS HEATER DATAДокумент9 страницBLOCK B - O MON PIPELINE GAS HEATER DATALuong AnhОценок пока нет

- TBDP A M DS 0007 2Документ7 страницTBDP A M DS 0007 2Bùi Văn HợpОценок пока нет

- Data Sheet: Hydraulic Power UnitДокумент3 страницыData Sheet: Hydraulic Power UnitEDUARDOОценок пока нет

- Pump Data SheetДокумент6 страницPump Data SheetmihailspiridonОценок пока нет

- Rev A. Magnetic Level Gauge With Level Transmitter Datasheet PDFДокумент15 страницRev A. Magnetic Level Gauge With Level Transmitter Datasheet PDFNguyễnQuíTrọngОценок пока нет

- APNEA-J-DSH-0002 Rev. 1Документ3 страницыAPNEA-J-DSH-0002 Rev. 1Michelle MartinezОценок пока нет

- Reciprocating CompressorДокумент6 страницReciprocating CompressorEDUARDOОценок пока нет

- 145B9973 - Off Base Piping List of Lines PDFДокумент4 страницы145B9973 - Off Base Piping List of Lines PDFHumayun NawazОценок пока нет

- SVSW 004110 G16 0001 Rev.a Datasheet For PumpДокумент6 страницSVSW 004110 G16 0001 Rev.a Datasheet For Pumpnguyenquoc1988Оценок пока нет

- Fire Water Make Up PumpДокумент7 страницFire Water Make Up PumpAlvin SmithОценок пока нет

- W13018-YT01-GDF-457110 Rev 5-APVДокумент8 страницW13018-YT01-GDF-457110 Rev 5-APVJosé santanaОценок пока нет

- Control Valve Data SheetДокумент22 страницыControl Valve Data Sheetnileshana100% (1)

- Data Sheet For Power TransformerДокумент3 страницыData Sheet For Power TransformerNakkolopОценок пока нет

- DAT Centrifugal PumpДокумент5 страницDAT Centrifugal PumpEDUARDOОценок пока нет

- Control Valve Specification and Sizing DetailsДокумент34 страницыControl Valve Specification and Sizing DetailsRahulTewari67% (3)

- Datasheet-A Rev No. Sr. No. Description SpecificationДокумент3 страницыDatasheet-A Rev No. Sr. No. Description Specificationinstruman007Оценок пока нет

- Adsorption Pump Data Sheet for 800 TPY Odorant Production UnitДокумент7 страницAdsorption Pump Data Sheet for 800 TPY Odorant Production UnitalikajbafОценок пока нет

- Water Cooled Chiller Package Data SheetДокумент9 страницWater Cooled Chiller Package Data SheetMohan VarkeyОценок пока нет

- Reaction Tank Design For WWTPДокумент9 страницReaction Tank Design For WWTPDavid LambertОценок пока нет

- Data Sheet For Instrument Air Package: Contract No.: CSA-12S-041SDДокумент8 страницData Sheet For Instrument Air Package: Contract No.: CSA-12S-041SDMrbudakbaekОценок пока нет

- Bb.g-Vsp-Pve-Ed-20-Me-Das-001 - 0Документ24 страницыBb.g-Vsp-Pve-Ed-20-Me-Das-001 - 0Luong AnhОценок пока нет

- Data Sheet Fuel Gas Filter Rev 0Документ22 страницыData Sheet Fuel Gas Filter Rev 0Bowo Edhi WibowoОценок пока нет

- Min1244a12 - Tag 130-Pu-029Документ7 страницMin1244a12 - Tag 130-Pu-029Monty MathewsОценок пока нет

- STV SW Project Level Gauge DatasheetДокумент4 страницыSTV SW Project Level Gauge Datasheetnguyenquoc1988Оценок пока нет

- LNTДокумент25 страницLNTAnshik JainОценок пока нет

- HSD-A-TS-M-DS-0010 - Rev-A01 Mechanical Datasheet For Closed Drain Vessel Immersion HeaterДокумент2 страницыHSD-A-TS-M-DS-0010 - Rev-A01 Mechanical Datasheet For Closed Drain Vessel Immersion HeaterThanh Phuc Nguyen100% (1)

- API STD 676-2009 - Hoja de RequisiciónДокумент28 страницAPI STD 676-2009 - Hoja de RequisiciónRicardo CastroОценок пока нет

- Typical Flare PackageДокумент5 страницTypical Flare PackageRahmat RiskiОценок пока нет

- Submittal Data: End Suction Stainless Steel PumpsДокумент3 страницыSubmittal Data: End Suction Stainless Steel PumpsGustavo Farelo SuarezОценок пока нет

- 00-GRC-EDA-100038-33 (Technical Submittal For Instruments) Rev02Документ11 страниц00-GRC-EDA-100038-33 (Technical Submittal For Instruments) Rev02Alaa RamadanОценок пока нет

- Safety Relief Valve DatasheetДокумент1 страницаSafety Relief Valve Datasheetalmandhari330% (1)

- DEWA Transformer Site Test Report DetailsДокумент28 страницDEWA Transformer Site Test Report DetailsZaheer Ahamed100% (2)

- VPC (Flowserve)Документ5 страницVPC (Flowserve)Wissam JarmakОценок пока нет

- Compile All Rev3Документ181 страницаCompile All Rev3AndiWSutomoОценок пока нет

- Technical Comparison Format - Process Gas Reciprocating CompressorДокумент11 страницTechnical Comparison Format - Process Gas Reciprocating CompressorAlvin Smith100% (1)

- Attachment-6 TBE ANSI Pump BCUДокумент31 страницаAttachment-6 TBE ANSI Pump BCURanu Januar100% (1)

- Technical Bid Evaluation Heat ExchangerДокумент211 страницTechnical Bid Evaluation Heat ExchangerpragatheeskОценок пока нет

- HT Motor DatasheetДокумент62 страницыHT Motor DatasheetShantanu Dutta100% (2)

- ZAU 256 MS 2105 00003 0001 A01 Datasheet For Produced Water Storage Vessel (V 8421)Документ6 страницZAU 256 MS 2105 00003 0001 A01 Datasheet For Produced Water Storage Vessel (V 8421)Vijayaraj KumarОценок пока нет

- On OFF ValveДокумент30 страницOn OFF ValveAjay TiwariОценок пока нет

- Atlas - Tech Data SheetsДокумент20 страницAtlas - Tech Data SheetsJAY PARIKHОценок пока нет

- Data Sheet For Mixer M34Документ5 страницData Sheet For Mixer M34bingminОценок пока нет

- Tank Calculation Kasikan Gs Rev BДокумент20 страницTank Calculation Kasikan Gs Rev BTrian Desta Rizal80% (5)

- Qw-482 - Welding Procedure Specification: (Ref. Specification: Asme Section Ix)Документ48 страницQw-482 - Welding Procedure Specification: (Ref. Specification: Asme Section Ix)kamalakarsastry13530% (1)

- HD Api610Документ5 страницHD Api610Venkat RanganОценок пока нет

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1От EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Рейтинг: 3.5 из 5 звезд3.5/5 (3)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsОт EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsРейтинг: 4.5 из 5 звезд4.5/5 (10)

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsОт EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsОценок пока нет

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsОт EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsОценок пока нет

- All-in-One Manual of Industrial Piping Practice and MaintenanceОт EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceРейтинг: 5 из 5 звезд5/5 (1)

- Fluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceОт EverandFluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceОценок пока нет

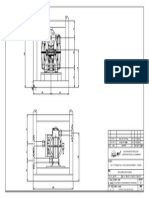

- GA DrawingДокумент8 страницGA DrawingSamuel JohnsonОценок пока нет

- Pressure Safety ValveДокумент2 страницыPressure Safety ValveSamuel JohnsonОценок пока нет

- Southern Petroleum Construction J.S Company: Equipment Arrangement DrawingsДокумент1 страницаSouthern Petroleum Construction J.S Company: Equipment Arrangement DrawingsSamuel JohnsonОценок пока нет

- 2014-4966-1M-1008 Rev D Hot Water Circulation Pump DatasheetДокумент10 страниц2014-4966-1M-1008 Rev D Hot Water Circulation Pump DatasheetSamuel JohnsonОценок пока нет

- RAL and BS British Standard Paint Colour ChartДокумент9 страницRAL and BS British Standard Paint Colour Chartashish8Оценок пока нет

- Pressure Safety ValveДокумент2 страницыPressure Safety ValveSamuel JohnsonОценок пока нет

- Oil and GasДокумент6 страницOil and GasSamuel JohnsonОценок пока нет

- 2014-4966-1M-1008 Rev D Hot Water Circulation Pump DatasheetДокумент10 страниц2014-4966-1M-1008 Rev D Hot Water Circulation Pump DatasheetSamuel JohnsonОценок пока нет

- ASCO Filter RegulatorДокумент4 страницыASCO Filter RegulatorSamuel JohnsonОценок пока нет

- Formula For: Word Formula: Letter Formula:: Pump Outlet FlowДокумент2 страницыFormula For: Word Formula: Letter Formula:: Pump Outlet FlowSamuel JohnsonОценок пока нет

- Pressure Safety ValveДокумент2 страницыPressure Safety ValveSamuel JohnsonОценок пока нет

- Hello WorldДокумент1 страницаHello WorldSamuel JohnsonОценок пока нет

- Flowrate & Pipe Size PDFДокумент10 страницFlowrate & Pipe Size PDFSamuel JohnsonОценок пока нет

- Type of Valve: 1, Gate ValveДокумент3 страницыType of Valve: 1, Gate ValveSamuel JohnsonОценок пока нет

- Radioactive Source License Schedule PDFДокумент1 страницаRadioactive Source License Schedule PDFSamuel JohnsonОценок пока нет

- Speed Torque Characteristics of 3 Phase Induction MotorДокумент4 страницыSpeed Torque Characteristics of 3 Phase Induction MotorAdi AdnanОценок пока нет

- Finite Element Analysis of Switched Reluctance Motor With Exterior RotorДокумент4 страницыFinite Element Analysis of Switched Reluctance Motor With Exterior RotorerpublicationОценок пока нет

- Is 15539 2004 PDFДокумент11 страницIs 15539 2004 PDFagniva dattaОценок пока нет

- Literature Review of Speed Control of Induction MotorДокумент4 страницыLiterature Review of Speed Control of Induction MotoraflsmperkОценок пока нет

- DC Machines1.1 1Документ19 страницDC Machines1.1 1Janaka Chathuranga AbeywardenaОценок пока нет

- STM8-128-MCKIT Motor Control Starter Kit-CD00236528Документ22 страницыSTM8-128-MCKIT Motor Control Starter Kit-CD00236528Dan EsentherОценок пока нет

- Single Phase Induction MotorДокумент24 страницыSingle Phase Induction MotorKh Muhammad MashoodОценок пока нет

- Hokei MINATO Magnetic MotorДокумент31 страницаHokei MINATO Magnetic Motormorsee100% (4)

- Karakteristik Generator DC Shunt PDFДокумент79 страницKarakteristik Generator DC Shunt PDFMichael BastosОценок пока нет

- Whitepaper Slot Fill WindingsДокумент7 страницWhitepaper Slot Fill WindingsSnowdenKonanОценок пока нет

- Energy Conversion Chapter 9 Questions and ProblemsДокумент2 страницыEnergy Conversion Chapter 9 Questions and ProblemsLuelsonCordovaDeclaradorОценок пока нет

- Models PDFДокумент736 страницModels PDFUriel Fernando Sandoval100% (2)

- p343 en PM j86 PDFДокумент64 страницыp343 en PM j86 PDFNhat TranОценок пока нет

- Eddy Current MotorДокумент3 страницыEddy Current Motorbijlwanr50% (2)

- An1130 Brushless DC Motor Control - Good!Документ28 страницAn1130 Brushless DC Motor Control - Good!R2osОценок пока нет

- C400D6 enДокумент2 страницыC400D6 enandresОценок пока нет

- Doubly Fed Electric MachineДокумент19 страницDoubly Fed Electric MachineChristopher PerkinsОценок пока нет

- Thermal Overload SizingДокумент2 страницыThermal Overload SizingBeloved Gelou100% (1)

- Micom P220 and P225: Motor Protection RelaysДокумент8 страницMicom P220 and P225: Motor Protection RelaysAbdulbaset SlamaОценок пока нет

- Nidec CPLS MotorsДокумент68 страницNidec CPLS MotorsTraian SerbanОценок пока нет

- Syntec Servo Products Specification Manual - V2.5.2Документ122 страницыSyntec Servo Products Specification Manual - V2.5.2Trí Chốt100% (1)

- Rotary Valves AclДокумент47 страницRotary Valves AclAlexialee83100% (4)

- Ac Generators: Compiled and Presented by Doren NedrickДокумент20 страницAc Generators: Compiled and Presented by Doren Nedrickadamwaiz100% (1)

- Electrical Machines and ElectronicsДокумент2 страницыElectrical Machines and ElectronicsDax Shukla50% (2)

- No Load and Block Rotor Tests for 3-Phase Induction MotorДокумент11 страницNo Load and Block Rotor Tests for 3-Phase Induction MotorKsr Akhil100% (1)

- Soft Start of An Induction Motor Using DspaceДокумент46 страницSoft Start of An Induction Motor Using DspacedanОценок пока нет

- Electrical and Electronics Engineering Question Paper 2012Документ10 страницElectrical and Electronics Engineering Question Paper 2012Thakur Sameer ShettyОценок пока нет

- Lec 3Документ18 страницLec 3Kashif SubhanОценок пока нет

- 00 SR Simulation of Motor and Control Based On MATLABДокумент98 страниц00 SR Simulation of Motor and Control Based On MATLABEduardo BittencourtОценок пока нет

- Installation Operation Maintenance Manual (Harvest Series)Документ36 страницInstallation Operation Maintenance Manual (Harvest Series)berkahharianОценок пока нет